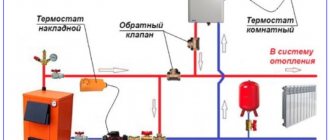

Everyone who uses water heating is well aware of the trouble of airing the system, and if with autonomy this issue is easier to solve, then for centralized systems it is much more difficult, but in any case, installing a Mayevsky tap on a cast iron radiator helps a lot.

In fact, this valve is used for various water batteries, such as sectional, tubular and panel ones, made of cast iron, steel, aluminum and bimetal - air space can accumulate in any of them, so its etching is sometimes the first necessity to ensure complete heating premises. But you will find out about everything in small details below, and you can also watch the video in this article.

Design and operating principle

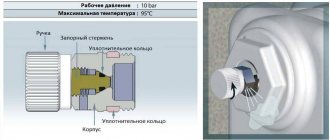

First of all, let's explain what a Mayevsky valve is - a service valve designed for manually bleeding air at certain points of the heating system. A modern example of a faucet, shown in the drawing, includes the following parts:

- brass body with nickel plated;

- locking screw with a conical tip;

- nylon cap with outlet;

- O-ring made of plastic or EPDM rubber.

The plate can be rotated and the outlet channel can be directed in the desired direction.

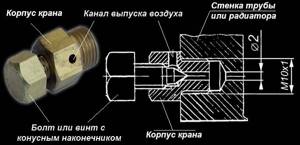

A calibrated hole with a diameter of 2 mm is drilled in the end of the body, and a connecting pipe thread is made on the outside. Inside the housing there is a chamber with a side exit into which a locking cone screw is screwed.

The tap operates on the principle of a needle valve - when the screw is tightened, the main hole is sealed with a cone-shaped tip. To ventilate the system, the screw is unscrewed, the cone opens the flow area, then the air along with water comes out through the side channel. The position of the outlet is adjusted by rotating the plastic cap.

Historical reference. The manual air separator was invented by the Russian engineer Ch. B. Mayevsky in the 30s of the last century. The invention served as a replacement for conventional water valves used to remove air pockets from centralized heating networks. The installation of new taps made it impossible for unauthorized withdrawal of hot water from the system.

What the old Soviet Mayevsky valve looks like is shown in the diagram. The official name of the plumbing element is needle-type radiator air valve STD 7073B.

Technical characteristics of Mayevsky air separators used in water heating systems of private and apartment buildings:

- maximum operating temperature – 120 °C;

- liquid medium - prepared water or non-freezing coolant (antifreeze);

- operating pressure – up to 10 Bar (1 MPa);

- connecting dimensions of pipe thread – ¼”, ½”, ¾”, metric – M10 pitch 1 mm;

- The service life of a product made of high-quality brass is at least 30 years.

Note. For more extreme operating conditions, there are models of taps designed for a pressure of 16 Bar (marking according to GOST - Ru16) and a liquid temperature of +150 degrees.

Valve balancing valve

The next type of taps for radiators are valve taps . The valve itself is used to provide such functions as:

For smooth operation of heating systems, it is recommended to use valve valves (balancing). They perform functions such as:

Valve taps consist of the following parts:

All parts are made using brass, which has high resistance to zinc leaching. It is because of this that the valve does not need all kinds of additional coatings.

Balancing valves are divided into the following groups:

Requirements for the operation of the balancing valve:

Typical dimensions of valve (balancing) valves

They are determined in the region of one inch. Diameters vary depending on model. Today, manufacturers in most cases mark cranes, indicating their exact dimensions and production characteristics. The markings indicate special symbols with which the indicators are deciphered (for example, D - diameter, P - working pressure).

Installation of valve taps on the battery

Scope of application and types of cranes

Mayevsky manual valves are used for the following purposes:

- First of all, removing air bubbles from heating radiators of all types - aluminum, steel and cast iron.

- Venting air from heated towel rails.

- Periodic de-airing of problem areas of the heating network - expansion joints turned upward, bypass loops (for example, above the front door), risers and other places where air accumulates.

Installation of air bleed valves is provided by all manufacturers of modern radiators. Heating devices are supplied from the factory with fittings (plugs) with a hole for the Mayevsky valve. The battery valve is selected according to the diameter of the external pipe thread - G¼”, ½”, ¾”.

Reference. The G¼” external thread of the air valve is identical to that of a standard pressure gauge.

If you need to organize air bleed in a problem area of the system, buy a Soviet-style valve with an external metric thread M10 x 1. The pipe wall is drilled with a Ø9 mm drill, the thread is cut with a tap, then a Mayevsky valve is screwed in and the joint is sealed with plumbing flax.

Another option is to cut a tee into the main line and install a slotted valve on the outlet pipe, as done in the photo below. The method will help with a cold (air-filled) heated towel rail that does not have a thread for an air vent.

Some models of heated towel rails have a slot for an air vent (photo on the left)

The operating principle of all Mayevsky valves is the same, but commercially available products may differ in design:

- The shut-off valve is made for a slotted screwdriver, a special key, or equipped with a handle. The old version of the product uses a hex head bolt.

- The needle (cone) that covers the hole can be metal or plastic.

- The corresponding “aged” valves shown in the photo are installed on designer cast-iron batteries.

Faucets with a handle are convenient to use - the air can be easily released without any tools. On the other hand, anyone can turn the valve, including small children, which should not be allowed. Hence the recommendation - buy and install traditional products with a slot or a tetrahedral key.

Retro-style valves for designer batteries (left) and a small 1/4-inch “air vent” for a ball valve (right)

Reference. Manufacturers equip some models of ball valves with Mayevsky air vents. Here the option with a handle is more appropriate, and the valve with a G¼” thread can be removed and replaced with a pressure gauge or a plug can be installed.

Do not confuse “Mayevskie” with automatic float-type air vents. The latter are similar in principle of operation - the passage hole is also closed with a needle, but air is removed without human intervention. There are 2 types of such devices - universal (used in boiler safety groups) and radiator ones.

Valves for automatic air release - radiator and universal

Which faucet is better?

This question will only be answered when specific conditions and characteristics that are a priority are identified. In the absence of any need for regulation or automation, simple structures (for example, common ball valves) are quite suitable. If the priority is the function of maintaining the optimal air temperature in the room without much effort (automatic adjustment), then it is preferable to choose a thermal head. The problem with the thermal head is that it cannot be used in systems with central heating. A more economical option is to use valve balancing valves.

Source

Installation of "Mayevsky" on a cast iron battery

Installation of drain valves on the liners of aluminum and steel radiators is quite simple and does not require a detailed description. The valve with the rubber ring is carefully tightened with a small force of the key, then the nylon cap is turned in the desired direction. A valve with a wide plastic ring and a hole in a metal body is immediately fixed in the required position - with the outlet fitting downwards.

Another thing is installing a valve in a cast iron radiator plug of type MS-140. Some craftsmen make a homemade faucet - drill the fitting, cut a thread and screw in a simple bolt. The option is extremely primitive and inconvenient - when the bolt is loosened and the air is released, an uncontrolled leak will form.

How to install Mayevsky correctly without unscrewing the stuck fitting:

- Buy an old-style faucet with an M10 x 1 landing thread and be sure to prepare the appropriate taps - numbers one and two. The so-called machine tap will not work - cast iron is too hard, the tool will simply break.

- Empty the heater and drill out the top plug first with a thin drill bit, e.g. Ø5 mm.

- Carefully break the hole with a Ø9 mm drill, then chamfer it to ensure the tool fits in securely.

- Cut the thread by alternately passing the hole with taps No. 1 and 2. Check how well the valve is screwed in.

- Having sealed the threads with flax, tighten and tighten the tap with medium force.

Advice. Drilling cast iron and cutting threads should not be done “dry”. Be sure to lubricate the tool with machine oil, otherwise the working edge will quickly become dull.

An easier way is to replace the standard liner with a new one, with a ready-made hole for the “air vent”. In this case, a modern valve with an external thread G½” (15 mm) is used. The main thing is to successfully unscrew the old battery plug. How to install “Mayevsky” on the MS-140 radiator, watch the video:

Conditions for installing air vents on radiators made of different metals

Mayevsky's air outlet valve is installed on radiators of any type - bimetallic and aluminum, cast iron and steel. Aluminum at high temperatures, aluminum reacts with the chemical components of the coolant, releasing hydrogen. Also, you cannot install aluminum and copper in a common system; these are antagonists; copper ions will gradually destroy light and ductile aluminum.

Gaseous media form air pockets even in those heating devices in which the metal does not react with the coolant. Installation of a release valve is a prerequisite for a closed circuit made of any metal, including nodal and rotary sections of the pipeline and heated towel rails.

Note! The Mayevsky tap for old-style cast iron radiators is not a prerequisite; it simply optimizes the operation of the entire heating system.

In the process of freeing the air pockets, there is a large loss of heat due to the release of coolant, even with a small hole diameter of about 15 mm. With a small diameter, it is impossible to select an appropriate air vent, so you can install ball valves that will not “break” during a water hammer.

As a rule, the tap has a small diameter

Installation

In heating systems of residential buildings, where pipes of small diameters are mainly used, taps are installed on radiators using threaded connections. The most convenient type of connection is recognized as colloquially called “American”. The fitting part is equipped with one or two union nuts, each of which covers the connecting shank and can rotate freely around it. The nut is screwed onto the pipe, pressing the tap against it, while the end of the pipe rests against the gasket installed inside the tap. Installation of fittings on an “American” connection is simpler than on a coupling connection, and the valve can be located quite close to the wall.

American crane.

In order to disassemble the connection, it is enough to unscrew the nut on one side. This allows, for example, to dismantle heating radiators for repairs or access to a section of the wall located behind them without disconnecting the entire riser. Replacing faucets on an American model, as well as installation, requires minimal effort. Most “American” ones have a hexagon shape; their installation on batteries is done using a regular wrench. But in some models the nut is equipped with two protrusions, for which a special key is provided. The first option is undoubtedly more convenient, since wrenches are used quite often in the household, and therefore are always at hand.

When installing the valve for the heating radiator for the first time, all threaded connections are assembled without sealing. In this way, they find out whether the parts fit together well and how freely they move. Knowing this, you can determine the amount of sealing material that will be needed for a given threaded connection. A lack of seal will lead to a leak, but its excess is even more undesirable: while tightening, the nut may burst, the only way out in this case is to replace the entire part.