Forced movement of the heated coolant along the main line significantly increases the efficiency of the heating system. That is why the question of how to choose a circulation pump for a heating system is one of the most important when designing and installing a heating circuit.

Some heating circuit designs provide the ability to operate without forced movement of the coolant. Their main advantage is complete energy independence, but their performance is lower than that of systems with forced movement of heated coolant.

The article discusses the main operational characteristics of circulation pumps, their varieties, design features and principle of operation. In addition, a list of the most common supercharger malfunctions is provided, possible causes of their occurrence are indicated, and recommendations for troubleshooting are given.

Design and principle of operation of the circulation pump

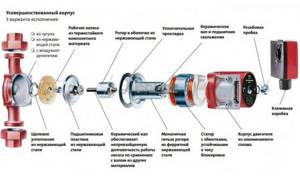

The device is one of the modifications of a hydraulic centrifugal machine and consists of the following main components:

- Metal or polymer body;

- A rotor that ensures rotation of the impeller;

- Pipes;

- Lip, disc and labyrinth seals;

- An electronic control unit that allows you to control the parameters of the electric motor and set the required mode.

The inlet and outlet pipes can have different locations, which allows you to select a circulation pump that optimally fits into the design of the designed circuit. Due to its small overall dimensions, the pump is often installed in the heat generator housing, which greatly simplifies the installation of the pipeline.

Operating principle of the circulation pump

The forced submission process can be divided into several stages:

- Suction of coolant liquid through the inlet pipe;

- The rotating turbine throws liquid towards the walls of the housing;

- Due to the centrifugal force, the working pressure of the coolant increases and it moves through the outlet pipe into the main pipeline.

As the working medium moves to the edge of the turbine, the vacuum in the inlet pipe increases, which ensures continuous fluid intake.

If the power of the device built into the heat generator is not enough to ensure effective circulation, the necessary parameters can be achieved by installing an additional circulation blower into the system.

Installation features

As a rule, circular electric pumps are installed in the main using a bypass - a parallel pipeline with a ball valve through which coolant is supplied when the pump branch is turned off. This design allows you to remove the circular valve for adjustment, repair or replacement without draining the coolant from the system.

Choosing the right circulation pump for heating is a responsible task, the solution of which is best left to specialists. The comfort and efficiency of the heating system (optimal efficiency of the device), as well as energy consumption, the savings of which, with the right solution, can reach 80%, depend on the selected unit.

If you wish, you can independently select a circulation pump for the heating system, make calculations using formulas; the highest accuracy of calculations is obtained when using computer programs. When working with programs, you need to understand how to enter data correctly - in many cases this requires special technical knowledge, which will take some time to obtain

Purpose and types of circulation pumps

The product is a compact centrifugal-type supercharger that provides forced movement of liquid along a closed circuit. The use of a circulation pump in the heating circuit can significantly increase the speed and uniformity of heating of the heated room. In addition, it should be noted that effective heating of a cottage or apartment with an area of more than 100 m2 without ensuring forced movement of the coolant through pipelines is practically impossible.

There are three types of circulation blowers:

1. Wet type units

due to their low efficiency (about 55%), they are used mainly in household highways. A feature of such systems is that all elements of the installation work in direct contact with the coolant. Lubrication of bearing units and cooling of rubbing surfaces is also carried out by the working medium.

Distinctive features of “wet” installations include:

- Placing the rotor in a sealed stainless steel glass;

- All components are in direct contact with the transported liquid;

- During transportation, constant heat removal and lubrication of rubbing surfaces are carried out.

The operation of “wet” models is characterized by low noise levels and stable output pressure; in addition, virtually no maintenance is required until any element wears out or fails.

The entry of air into the housing of a “wet” type device can cause increased wear of rotating parts, overheating of bearing units and premature failure of the entire installation.

2. Dry pumps

type are characterized by high efficiency up to (80%), which makes it possible to use them for forced movement of liquid in circuits with a significant length of pipelines. Their main difference is the complete sealing of the impeller chamber, which completely eliminates contact of the coolant with bearings and other elements.

The main advantage of units with a “dry” rotor is the ability to operate when air enters the impeller chamber, in other words, such blowers remain operational when aired.

Another advantage of such models compared to “wet” type units is better cooling of the components, since they do not come into contact with the heated coolant.

In addition, all bearing units and elements are reliably protected from the effects of abrasive suspension. Only the impeller and the inner walls of the housing are exposed to harmful effects. This arrangement makes it possible to use “dry” circulation blowers in a heating system with an open circuit, where the likelihood of contamination of the coolant is much higher than in closed circuits.

The disadvantages of this arrangement include:

- Increased noise level;

- Lack of constant lubrication of rubbing surfaces;

- Complex seal design, which reduces the reliability of the product.

The indicated disadvantages of “dry” blowers are not of fundamental importance, since the noise of the device is practically unimportant in industrial buildings, and timely maintenance avoids coolant leakage.

3. Superchargers with variable speed impeller rotation

allow you to vary the angular speed of the turbine, thereby providing:

- Optimal parameters of the heat generator;

- Maintaining the set temperature value in all radiators;

- Reducing the temperature of the coolant while maintaining the temperature in the room, by accelerating the transportation of the coolant.

In specialty stores you can find one-, two-, three-, and four-speed superchargers. The speed is changed using different switching schemes. There are blowers with infinitely variable speed control of the impeller, but their cost is outside the budget segment.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system increases significantly. In this case, thin pipes can be used, which, in turn, helps reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is released into the atmosphere is reduced, and the daily consumption of electrical energy is no more than 250 W.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will certainly pay off later when used due to energy savings and durability. The device will not require repair for a long time.

Vilo pumps have many positive properties.

The most important of them are the following:

- After water evaporates, there is no heat loss.

- The operation of the system can be controlled automatically. The device has a liquid crystal screen, a built-in thermostat and other elements that allow control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent failure due to sudden surges in voltage in the electrical network.

- The motor operates silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, room area and pressure height. The last parameter is the most important.

You can see how to distinguish an original pump from a fake in the following video:

Circulation pumps for heating systems: technical characteristics

The vast majority of existing schemes include one or another modification of the circulation blower. The main technical characteristics by which the required device is selected are:

Unit performance

. The amount of coolant pumped per unit time depends on the pump performance. The value of this parameter depends on the length of the pipelines, the number of turns, the presence of vertical sections, etc.;

Pressure characteristics

show the maximum height to which this device can raise the entire coolant column;

Operating voltage

. Various models can be connected to both single-phase and three-phase networks;

Rated pump power

. If it is possible to operate in several modes, the product data sheet indicates power and current indicators for each speed mode. Most existing devices are designed for 55 - 75 W.

Permissible medium temperature

. When choosing equipment, it is advisable to choose a model that can withstand a coolant temperature of 110 0C;

Device mounting dimensions

include the thread diameter of the inlet and outlet pipes (for home use this is most often 1 or 1.25 inches) and installation dimensions (for the most common models it can be 130 or 180 mm);

Electrical equipment protection level

(engine). Household systems are equipped with circulation pumps with protection class IP44. The designation indicates that the entry of abrasive particles larger than 1 mm into the housing cavity is completely excluded, and the electrical equipment is reliably protected from splashes and condensation;

The maximum liquid pressure in the outlet pipe; for household modifications, this value rarely exceeds 10 bar.

Brand Importance

Modern manufacturers of devices for circulating coolant in a heating system offer almost identical characteristics of their products. The differences mainly relate to reliability and trouble-free operation. That is why many experts advise to overpay a little and give preference to a well-known brand.

For your information. Today, the most reliable companies are the aforementioned Grundfos, Willo, Speroni, Wester and Elso-Therm.

In addition, there are a large number of Chinese options (counterfeits), the quality of which, to put it mildly, leaves much to be desired. Of course, in this case you can save a lot, but even the seller of the product can hardly guarantee that the labeling corresponds to the actual characteristics of the circulation pump.

To avoid problems with poor-quality pump operation, which is caused by cheap equipment, errors in calculations or incorrect installation, it is better to immediately entrust the organization of the home heating system to specialists.

The smallest circulation pump for heating

Compact units designed for an operating voltage of 12V are widely used due to the following advantages:

- Minimum power consumption;

- Soft start;

- Electronic control of turbine speed;

- Long service life;

- Versatility and ease of installation;

- No vibrations during operation;

- Built-in overheating protection.

The use of such devices can significantly reduce electricity costs without loss of efficiency.

Areas of application

The Wilo brand produces pumps designed for different purposes and therefore having different characteristics.

With the help of such a pump, you can water the beds directly from a well, borehole or the nearest body of water.

The scope of their application is wide and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in wells for water extraction.

- Such pumps are also suitable for pumping out groundwater when creating basements and cellars.

- They are also used on construction sites when working with contaminated water.

- Owners of private suburban areas have found good use for them, in particular those who grow plants on their plots.

The Vilo pump can operate in the most difficult conditions, and it does not matter what the temperature of the water circulated through the pipes will be or what the pressure will be.

You can connect the device yourself without any problems. For this purpose, it is equipped with special spring terminals. It does not have a fan, so there is virtually no noise during operation.

How much does a circulation pump for heating systems cost?

The cost of the units is directly related to the operational parameters and reputation of the manufacturer. Below are the performance characteristics of circulation pumps and the cost of products of some well-known brands:

1. Grundfos circulation pump

| Model | Overall dimensions, mm | Head, m | Flow, m3/h | Rated power W | price, rub. |

| Grundfos UPS 25-40 | 100*100*180 | 3,5 | 2,8 | 25/35/45 | 5 160 |

| Grundfos UPS 32-40 | 100*100*180 | 3,5 | 2,8 | 25/35/45 | 5 530 |

| Grundfos UPS 25-60 | 100*100*180 | 5,5 | 4,0 | 50/55/60 | 6 190 |

| Grundfos UPS 32-60 | 100*100*180 | 5,8 | 4,2 | 50/55/60 | 6 630 |

2. Valtec VRS circulation pump

| Model | Overall dimensions, mm | Head, m | Flow, m3/h | Rated power, W | price, rub. |

| Valtec VRS 25/6 | 100*100*180 | 6,0 | 4,1 | 46/67/93 | 3 323 |

| Valtec VRS 25/4 | 100*100*180 | 4,5 | 3,4 | 38/53/75 | 3 455 |

| Valtec VRS 32/4 | 100*100*180 | 4,5 | 3,96 | 38/53/72 | 3 455 |

| Valtec VRS 25/4-130 | 100*100*130 | 4,5 | 3,0 | 38/53/75 | 3 455 |

| Valtec VRS 32/6 | 100*100*180 | 6,0 | 4,2 | 46/67/93 | 3 617 |

3. DAB VA circulation pump

| Model | Overall dimensions, mm | Head, m | Flow, m3/h | Rated power, W | price, rub. |

| DAB VA 25/130 | 100*100*130 | 2,71 | 3,0 | 31/38/43 W | 4 611 |

| DAB VA 25/180 | 100*100*180 | 2,71 | 3,0 | 31/38/43 W | 4 611 |

| DAB VA 35/180 | 100*100*180 | 4,3 | 3,0 | 35/50/56 W | 4 733 |

| DAB VA 35/130, 1/2 | 100*100*130 | 4,3 | 3,0 | 35/50/56 W | 4 733 |

| DAB VA 35/130 | 100*100*130 | 4,3 | 3,0 | 35/50/56 W | 4 733 |

Based on the above data, you can select the necessary pump model for a specific heating circuit, corresponding not only to the features of the system, but also to your financial capabilities.

Tips for choosing a device for a heated floor system in your home

How to choose a pump for underfloor heating? Today, the market mainly offers CO pumps with a standard flow rate of about 40 l/min (about 2.5 cubic meters/hour) and a pressure of up to six meters. The flow rate is directly proportional to the pressure value.

When purchasing, you should understand that the flow rate of 40 l/min indicated on the pump will not always correspond to the actual flow rate. Because the latter depends on what the throughput of the floor assembly or the system itself is. A large number of long circuits reduces consumption.

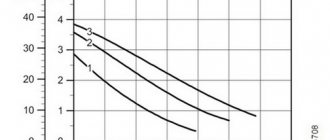

It’s easy to understand this using two graphs: theoretical (for all similar pumps) - No. 1, and real for the 2.5 cubic meter pump considered in the example. with a pressure of six meters - No. 2.

The higher the throughput capabilities of your system, the weaker the pressure on all connected circuits. Those. The more circuits are closed to one mixing unit, the greater the flow rate.

How to choose the right circulation pump for heating your home

It is possible to determine the required characteristics of the circulation pump with sufficient accuracy only after the final approval of the heating system design. The performance of the unit is selected based on the length of the pipelines, the number and location of radiators, the number of bends and turns, the presence of vertical sections and their length. Only with this information can you choose the right circulation pump for a specific heating circuit. In addition, when choosing a pump, the following should be considered:

1. The technical characteristics of the pump must correspond as much as possible to the design parameters;

2. You should not choose circulation blowers with obviously too high power, this can lead to unnecessary energy consumption and increased noise of the pump;

3. Preference should be given to devices that have the ability to adjust the turbine rotation speed, this will allow the parameters of the heating system to be adjusted as accurately as possible.

If the circulation pump is selected correctly, the operation of the heating system will be stable and efficient with minimal energy and electricity costs.

How to choose a hot water recirculation pump?

When purchasing equipment for hot water recirculation, you need to decide on its main parameters. These include:

- Productivity - this characteristic depends on the area of housing. On average, for a two-story private house or a three-room apartment, a unit that pumps 70–100 liters of coolant per minute is sufficient;

- Pressure is another important characteristic that indicates the maximum height of coolant supply. In the case of a two-story private house, you should choose a device that creates a pressure of 3–4 m;

- Energy consumption - this factor allows you to determine how much it will cost to operate a recirculation pump. It must be remembered that the more powerful and productive the unit, the more expensive its use will be;

- Availability of built-in protection - it is best to buy a pump equipped with a water flow relay. This element will protect the pump from running dry and, as a result, overheating of the unit’s motor.

Other important factors include the pump cooling system. If the unit is not equipped with ventilation, then its motor will constantly heat up and fail.

Read with this

- Calculation and selection of a circulation pump

- Installation of a circulation pump: tips for proper installation in a heating system with your own hands

- Characteristics of circulation pumps for heating wilo

- Bypass: what is it and how to install it?

- Do-it-yourself heating circulation pump repair: main faults and their elimination

- Do-it-yourself heat accumulator: making a heat accumulator for heating step by step

- Heating system for a private house in Leningrad and its diagram

- Calculation, selection and installation of a water pump for heated floors

- How to choose a UPS for a heating pump

- How to properly connect the Internet cable to an outlet. connection diagram for rj 45

Tips for connecting a circulation pump to a heating system

When starting to install a pump, you should remember a few simple but important rules:

- The optimal location for installing the pump is a section of the return line directly in front of the heat generator. With this arrangement, the device works with cooled coolant, which significantly extends its service life. In addition, the risk of boiler airing is significantly reduced.

- The supercharger should be installed in such a way that the drive shaft of the device is horizontal. Failure to comply with this rule can lead to a significant reduction in the power of the unit and premature failure due to overheating of bearing units and other rubbing surfaces.

- It is advisable to install a check valve directly behind the outlet pipe, which protects the unit from the counterflow of coolant.

Correct installation of the circulation pump will allow you to achieve not only its maximum performance, but also the efficient operation of the entire heating system.

Rules and features of choice

You should start choosing a specific circulation pump model only after the heating system has been designed and the total length of its closed circuit is known. In addition to the length of the heating system circuit, the choice of a circulation pump is also influenced by the number of radiators with which it will be equipped. Only after receiving all this data can it be determined with high accuracy what performance the circulation pump should have and what magnitude of coolant pressure in the system it should provide. It is very important to calculate the performance of a circulation pump for a heating system based on the lowest temperature outside, when the pumping device will operate at maximum load.

When choosing a circulation pump for a heating system based on the characteristics of such a device, you can rely on the following recommendations from experienced specialists.

- If, when choosing a circulation pump, several models suited you and you liked them at once, preference should be given to the one whose technical characteristics most closely correspond to the calculated values obtained when designing the heating system.

- It is undesirable to choose a circulation pump with too large a margin in terms of performance and the generated coolant pressure. Such a device, consuming only part of its power, will consume a significant amount of electricity and create excessive noise during operation.

- It is better to purchase circulation pump models whose operating modes can be adjusted. The use of such devices with a special switch on the body allows you to optimize the operation of the entire heating system as a whole.

Circulation pumps, if properly selected and installed, can make the operation of heating systems more efficient, as well as reduce the cost of heating rooms.

How to remove air from a circulation pump

Before starting the system, you need to flush the pipeline to remove solid particles that could cause the impeller to jam. When using a pump with a wet rotor, air must be vented. To do this, slightly loosen the shiny screw located in the center of the circulation unit. Reset the air until water appears from under the slightly open screw.

The procedure is repeated several times at intervals of 5-10 minutes. In this case, the unit must be in working condition (connected to the network). There is no need to stop it while the air is being released.

It is recommended to unscrew the screw completely before the start of the heating season. Before doing this, turn off the taps installed before and after the unit.

If difficulties arise with the maintenance of the heating system, you can use the services of specialists. But most often, measures to prepare the pump and pipeline for the winter season are carried out independently by the owners of the household.

How to calculate pump parameters

Before choosing a heating pump, it is necessary to perform some calculations to help determine the performance of the unit. To do this, it is recommended to use the formula:

Q = 0.86R/TF–TR, where:

- Q – performance indicator;

- R – thermal power;

- TF – inlet liquid temperature;

- TR – outlet liquid temperature.

Thermal power is determined from the table or by referring to SNiP 2.04.07-86 standards.

We calculate the heating circulation pump correctly.

According to SNiP standards, taking into account temperatures down to minus 30 degrees:

- in small houses up to 2 floors - 173-177 W/m2; – for small buildings whose number of storeys does not exceed two;

- in buildings with more than 3-4 storeys – 97-101 W/m

An alternative option for determining thermal power is to use the formula: V x T x K = kcal/h.

Explanation of values:

- V – volume of the room (to obtain data you need to multiply the width, length and height), unit of measurement – m3;

- T – temperature difference between the street air temperature and the desired indoor temperature, unit of measurement – °C;

- K – thermal dissipation coefficient (selected taking into account the thermal protection characteristics of the room).

| Coefficient | Room type |

| 0,6 – 0,9 | Excellent thermal insulation of all surfaces (ceiling, roof, walls, floor). |

| 1,0 – 1,9 | Average thermal insulation. The walls are made of double brickwork, there are a small number of windows, the roof is arranged taking into account the rules of the roofing pie. |

| 2,0 – 2,9 | The walls are made of single brick, the roof is not insulated, there are many windows. The degree of thermal insulation is below average. |

| 3,0 – 4,0 | The structure is made of wood or metal. There is no thermal insulation layer. |

As a result of calculating the thermal power using the above formula, the value in kcal/hour is obtained. In order to convert the indicator into the usual kW/hour, you should divide it by 860.