Home/Warm floors – Questions about floor repair, installation./Collectors for water floors. Selection of collectors/Servo drive for heated floors: Types and principle of its operation

A new type of heating system is a water heated floor. This heating model has proven itself well, both as an additional and as the main source of heat for the room. During its operation, many additional equipment are used that perform their functions. One of the important elements for adjusting and controlling temperature is a servo drive for heated floors.

What is a servo drive and how does it work?

A servo drive is a device that regulates and controls the temperature regime in the coolant. It consists of: a spring mechanism, a valve and a bellows filled with methylbenzene. The circulation of the water heating system is controlled in the following way:

- Having received a signal from the thermostat, the servomotor is connected to the network.

- Methylbenzene begins to heat up from the incoming energy.

- As the internal liquid heats up, the bellows increases in size.

- Having reached certain indicators, the cylinder begins to put pressure on the valve.

- The pressure causes the valve to change its position, thereby opening the flow of coolant.

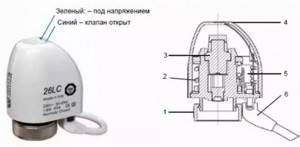

Diagram of the operating principle of a servo drive (click to enlarge)

Having received the desired room temperature, the thermostat sends a signal to the servomotor, and its principle of operation begins to repeat in the reverse order. In the absence of electricity, the liquid cools, the bellows narrows, the pressure decreases, and the valve returns to its original position.

Such a simple but effective operation of the servo drive is due to the connection between thermal energy and electricity.

It is worth noting that there are servos without methylbenzene. In such devices, the movement of the valve occurs due to the heating and cooling of thermoelements, such as a spring or plate.

Types and classification of the device

Currently, the consumer market provides several models for underfloor heating servos. Each has its own advantages and disadvantages. According to the classification of works, they are divided into three main types:

- Mechanical. This equipment is easy to use; all settings are performed manually by turning the wheel. The advantages of a mechanical servo drive include: high strength and affordable price. Negative qualities include the inability to establish an optimal microclimate.

- Electronic. This model is equipped with a display through which you can visually monitor the process of operation of the heating system and temperature conditions. The advantages of the product include the presence of functions that make it possible to set the desired microclimate for a certain time of day. Setting and adjustment is performed both manually and automatically. According to consumer reviews, the device has no negative qualities.

- Remote. A distinctive feature of this device is that all settings can be made via infrared channel or radio control. Thus, even being at a great distance from the house, the owner will be able to set the desired temperature before his arrival.

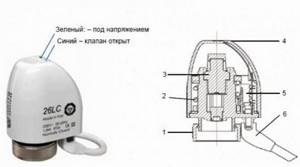

Indication of the valve position on the servomotor and its structure: 1- Nut; 2 - Spring; 3 - Bellows; 4 — Housing with LEDs; 5 - Auxiliary contact; 6 - Cable

It is also worth noting that, regardless of the classification of work, servo drives for a warm water floor manifold are also divided according to the design of the “normal” valve position:

- Normally open. This type is used if constant circulation of the coolant is desired. This is due to the fact that the valve of the equipment is initially in the open position, so even if it breaks down or in the absence of electricity, the water system will be able to supply the pipeline with hot water.

- Normally closed. This model differs from the first one in that the initial position of the valve is closed. Therefore, it is not rational to use it during regular power outages in the northern regions of the country.

- Universal. This is a new type of servo drive, which can change the initial position of the valve depending on the requirements of the heating model.

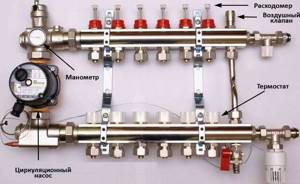

Installation of the Servo Drive on the Collector

Before you give your preference to one or another type of servomotor, you need to familiarize yourself with its characteristics of heating elements. This detail is due to the fact that the valve’s exposure time when heating and cooling the bellows is different. On average, when the bellows heats up, the valve begins to operate after 2 - 3 minutes, when cooled - 10 - 15 minutes.

Fundamental differences and recommendations for use in different types of servos

Servo drives for heated water floors come in 2 types:

- Normally open. Initially, the tap he controls will be open. If there is no power to the drive, the coolant circulates freely through the device;

- Normally closed. Accordingly, the tap will initially be closed. There is no power - the coolant does not pass through it.

There are servos where you can select a default position. They are called universal or switchable. When choosing a specific type, you need to know in which position the crane needs to be most of the time. If the coolant circulation is assumed to be constant, it is recommended to choose a normally open type of device.

If your region experiences prolonged frosts, you should only select a normally open type of servo drive. Since in the absence or failure of the power supply, as well as in the event of a breakdown of the drive, the circulation of the coolant will not be disrupted and the floor will be hot as long as hot water is supplied from the boiler.

Normally closed devices are used in regions with mild climates, where stopping the supply of coolant to the system will not have negative consequences. Among the models of both types there are servo drives with smooth adjustment. It is recommended to use them when the project requires quantitative dosing of the coolant supply.

Servomotor connection

Anyone can install servo drives for water heated floors. To perform installation, you do not need any knowledge or experience in this field. To do this, it will be enough to follow the attached instructions and follow a few basic rules:

- correspondence between the characteristics of the servo drive and the water heated floor;

- identical threaded fit between the commutator and the servomotor;

- good access to all parts of the servo drive.

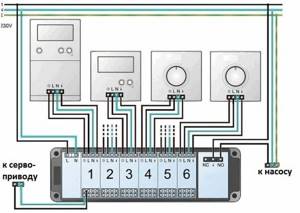

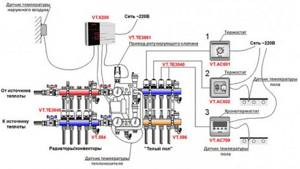

Scheme of a water heated floor with remote servos

Also, to install the device, you will not need additional tools or sealing materials. The servo drive can be positioned in any position, regardless of model and type. But before the first connection, it is important that the valve is in the open position.

If a beginner has doubts about the correct connection of the servomotor to the heating system, it is recommended to use a heated floor communicator. This device will help connect all elements to the terminals and perform the functions of a fuse.

Popular manufacturers of servo drives for water heated floors

You can purchase servomotors in different ways, such as: the Internet, building stores, or the market. They are produced by different manufacturers and have their own characteristics. According to consumer reviews, the best companies are considered.

"VALTEC"

This company employs highly qualified Russian and Italian employees to produce basic heating systems and their additional equipment. The best servos produced by them are:

- A. – These servos are of the “normally” open type. They are produced in mechanical models and have the following characteristics: connecting size - M 30 x 15; power – 2 W; conductor cross-section – 0.75 sq. mm.

- 0. – this device is produced “normally” closed with an on-screen display. . The actuator is designed with toluene, making it suitable for three-way valves.

- 0. – this device operates due to the liquid in the bellows. Available in “normally” open form. The work is done through the supplied adapter. Product power – 1.8 W, conductor cross-section – 0.75 sq. mm.

VALTEC

"Watts"

"Watts" is considered one of the leading companies in the production of additional thermoelements for heated floors. The distinctive feature of the company is the quality of its products at an affordable price. The following are considered effective series of servo drives from these manufacturers:

- 22C. — this equipment for temperature control is installed on a return coolant. They are produced in a “normally” open and closed form. The power of the product is 2.5 W.

- 22СХ. — these devices are produced in “normally” open and closed forms, electric models. The level of electricity consumption is 1.8 W, operating temperature is 100 – 110 °C.

- — servos of this series for the collector are available with an LED indicator. Thanks to it, you can track the process of equipment operation. When there is electricity, the color is green, and when there is no electricity, blue.

Watts

"Rehau"

Servomotors from this German company are considered the best additional equipment for heated floors. Recommended, innovative series are considered:

- UNI for 230.24 V. Using an adapter, servos of this series are attached to the commutator . Visual monitoring of system operation is carried out through a built-in indicator. Cable cross-section - 0.5 sq. mm.

- UNI 230, 24. This servo drive is produced with a built-in monitor, in a “normally” closed form. The product is attached to both the supply and return coolant.

Rehau

Having examined the types of servomotors and familiarized yourself with their operating principles, you can independently verify that their use increases the functionality of the water system. The devices are reliable, have full temperature control and are easy to use. Having performed the correct installation, servo drives for a heated water floor collector can last quite a long time, which will allow saving on the family budget in the desired microclimate.

AdminAuthor of the article

Did you like the article?

Share with your friends:

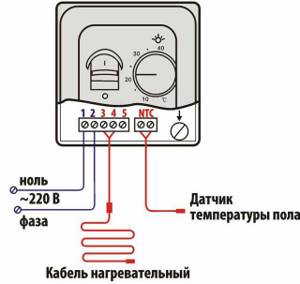

Water floor thermostat sensors

Before using the control device, you need to learn how to regulate the temperature of a heated floor and what elements the system consists of.

Thermostat sensors monitor temperature:

- heated floors;

- indoor air.

The fact is that when installing a thermostat, a number of conditions must be observed:

- there should be no sources of cold or warm air in the immediate vicinity of the device;

- sunlight cannot fall on it;

- absence of drafts;

- it must be placed so that the device can most reliably display the temperature in a given room, which means it must be installed at a height of 1 to 1.5 meters from the floor surface.

A remote floor temperature sensor is a small device attached to the end of a long cable. This device must be fixed to the floor at a distance of no less than 50 centimeters from the walls. It should be installed at an equal distance with respect to the nearest pipes containing the coolant. The opposite end of the cable is brought to the thermostat and connected to the required terminals (read: “Correct installation of the heated floor thermostat and operating conditions”).

Install the floor sensor before pouring the screed when laying the heating circuit. But since devices can break, to ensure the possibility of replacement, it is advisable to place them in a special corrugated sleeve. The end of the hose located in the screed should be insulated, otherwise cement mortar may get into it

The second end is placed in a groove on the wall and placed on the mounting box of the device. This sequence of installing water floor sensors is not an easy task, but if the device breaks down, it can be changed quickly and easily.

In the case where a floor heating system was used, the installation method is similar. In this case, the corrugated hose must be attached to the system and not be pinched.

Sometimes, provided that a corrugated hose is not used, depending on the height of the concrete screed and the type of floor surface (soft or hard), there is a need to use wires with different densities of the protective sheath. Manufacturers produce hard and soft products, as well as modifications of wires that are resistant to aggressive environments.