During operation of the heating system, the appearance of moisture in the chimney harms not only the chimney itself, but also the heating device. By reacting with combustion products, moisture turns into chemically aggressive substances that disrupt the operation of the heating system.

It is impossible to completely get rid of condensation, but you can minimize its amount and prevent undesirable consequences.

Reasons for the formation of moisture in the chimney

When burned, any fuel for a boiler, stove or fireplace releases water vapor, which cools in the chimney pipe and forms a deposit in the form of droplets on the walls. This happens due to the temperature difference at the outlet of the heating unit and in individual parts of the chimney.

Additionally, moisture can enter the smoke channel from the outside during rain. The chemical reaction of water with soot and resins leads to the formation of acids and alkalis.

Condensate flows down along the smooth walls, where it accumulates, preventing the removal of smoke and impairing draft. Rough surfaces retain and absorb moisture, subject to corrosion and premature destruction.

In addition, substances accumulated in the chimney can enter the room, causing an unpleasant odor and harming health.

Note! Condensation can form not only from the inside, but also from the outside of the chimney - at very different temperatures in the pipe and outside. The result may be destruction of the pipe itself, if it is made of moisture-absorbing materials, as well as the walls and roof at the points of contact with the chimney.

Repairing pipe leaks on the roof

Before answering the question of what and how to fix a leak on the roof near the pipe, you need to decide what material it is made of. It is very important. This is the starting point for repair work.

The chimney duct can be mounted from the following materials:

When eliminating a leak, you need to follow a certain sequence of actions, which can differ significantly for each chimney material. Therefore, the technology for eliminating such defects for each type of pipe should be considered in detail.

Fixing brick chimney leaks

If a pipe made of red brick is leaking on a roof, then to fix the problem you will need the following materials and tools:

- cement grade M 400 or M 500;

- sand, preferably river or sea, but quarry sand is also suitable;

- water;

- Master OK.

How to seal the gap between the pipe and the roof, having all of the above? You must adhere to the following sequence of actions:

- A cement mortar is made from the prepared materials by mixing 3-4 parts of sand and one part of cement;

- the detected leak site is thoroughly cleaned of dirt and remnants of destroyed bricks;

- The prepared mixture is applied using a trowel to the damaged areas.

It is better to repair a roof pipe in sunny, dry weather. This way the cement mortar will harden much faster.

Repairing metal chimney leaks

If a metal chimney is leaking, then to correct the current situation you will need:

- special clamps with a rubber gasket that can be secured to the pipe where the gap occurs. The diameter of the clamp should be approximately equal to the thickness of the pipe. Its width should be slightly larger than the size of the crack;

- in addition, small cracks can be eliminated using cold welding, instructions for use of which can be found on the packaging.

The specified materials for eliminating metal pipe leaks can only be used as a temporary measure. As soon as possible, the damaged section of the chimney must be replaced with a new one.

Repairing asbestos chimney leaks

If water flows through an asbestos pipe, then you can eliminate the leak by performing a number of the following actions:

- First of all, you need to stock up on cotton fabric and “Iron Lead” paint. You can buy such materials at any hardware store;

- then the chimney, namely the damaged area, should be cleaned of dirt and dust;

- the paint is applied in a thick layer;

- fabric is tightly wrapped over it;

- Then the paint and varnish material is reapplied.

For the most part, such repairs are also a temporary measure that allows you to postpone the replacement of the chimney pipe for a certain period. You should not delay replacing a damaged asbestos chimney.

Factors influencing condensation formation

The process of condensation formation in the chimney channel depends on several factors:

- The moisture content of the fuel used by the heating system. Even apparently dry firewood contains moisture, which turns into steam when burned. Peat, coal and other combustible materials have a certain percentage of moisture. Natural gas, when burned in a gas boiler, also releases a large amount of water vapor. There is no absolutely dry fuel, but poorly dried or damp material increases the condensation process.

- Traction level. The better the draft, the faster the steam is released and the less moisture settles on the walls of the pipe. It simply does not have time to mix with other combustion products. If the draft is poor, a vicious circle results: condensation accumulates in the chimney, causing clogging and further impairing the circulation of gases.

- The temperature of the air in the pipe and the gases leaving the heating device. The first time after kindling, smoke moves through the unheated channel, which also has a low temperature. It is at the start that the greatest condensation occurs. Therefore, systems that operate continuously, without regular shutdowns, are least susceptible to condensation.

- Temperature and humidity of the external environment. In the cold season, due to the difference in temperatures inside and outside the chimney, as well as increased air humidity, condensation forms more actively on the outer and end parts of the pipe.

- The material from which the chimney is made. Brick and asbestos cement prevent the flow of moisture droplets and absorb the resulting acids. Metal pipes can be susceptible to corrosion and rust. Chimneys made of ceramic blocks or stainless steel sections prevent chemically aggressive compounds from clinging to a smooth surface. The smoother the inner surface and the lower the moisture absorption capacity of the pipe material, the less condensate will form in it.

- Integrity of the chimney structure. If the tightness of the pipe is broken or damage appears on its inner surface, the draft deteriorates, the channel becomes clogged faster, and moisture from the outside can get inside. All this leads to increased steam condensation and deterioration of the chimney.

We recommend that you read: What you need to know to build a canopy from corrugated pipe with your own hands

Getting rid of leaks at the junction of the pipe and the roof

If water does not get inside the chimney, but simply oozes out when it rains, it means that the joint with the roof is not properly sealed. This problem can be resolved using one of the following methods:

- apply a rubber cuff;

- install a metal apron;

- apply bitumen tape.

Rubber cuff

This is a simple and inexpensive method, which will require a rubber cuff, sealant and self-tapping screws (not always). A hole of the required diameter is cut in the upper part of the product. The cuff is put on the pipe and lowered to the roof level. To ensure sufficient adhesion to the surface, a sealant is used. The optimal effect is achieved when the base is also connected to the roof with self-tapping screws, but this is not always possible. When it comes to slate or tiles, using such fasteners will not work. Using rubber cuffs you can only protect areas near round pipes. This option is not suitable for rectangular and square chimneys.

Metal apron

The most reliable means of combating leaks is a metal apron. Such a product can be purchased at a specialized store or made independently from a steel sheet. The first option is preferable, since there will be less fuss with calculations. Externally, the apron is a plate with a through cap. It is put on the pipe in the same way as a rubber cuff. The upper part is secured using a construction clamp. At this stage you should be as careful as possible so as not to damage the chimney itself. In this case, even the slightest gaps are not allowed.

The lower part is fixed with self-tapping screws. To enhance reliability, the structure can be supplemented with a rubber gasket, and all joints can be sealed with sealant. Installing a metal apron is a rather complicated process. In all other cases, eliminating the defect does not require any special skills from the performer. Options are possible here, so count on your strengths and do not hesitate to seek help from specialists.

Bitumen tape

It is much easier to deal with roof leaks by making an apron from inexpensive bitumen tape. In addition to this material, you will need scissors, a torch and a metal brush. Bitumen tape can be used for any type of surface and section of the chimney, which distinguishes it from the same rubber. You are guaranteed at least two to three “dry” years on the treated areas. Durability depends on the intensity of precipitation, temperature changes and other atmospheric phenomena.

Using scissors, the tape is cut into pieces of the desired size. The outer lower part of the pipe and the area around it are thoroughly cleaned with a metal brush. Remaining dirt and dust are removed with a damp cloth. Pieces of tape are carefully glued to the joints. It doesn't matter where the slot is located. The chimney must be sealed around the entire perimeter. Thus, we will get a full-fledged apron like a metal one. To ensure that the bitumen tape adheres to the surfaces as tightly as possible, it is heated with a gas burner. For reliability, you can additionally use a wooden board or block. If the roof material allows, such fixation will be very useful.

Chimney design requirements

Compliance with the requirements of the rules and regulations during the construction and operation of the smoke exhaust system will extend its service life, including by minimizing the formation of condensate:

- When the pipe is positioned vertically, horizontal sections no more than a meter long or inclined sections, but without sharp corners, are allowed.

- The internal surface of the chimney must be smooth, without protrusions, cracks or other irregularities.

- It is not allowed to reduce the diameter of the channel compared to the outlet pipe of the heating unit.

- The ability to clean the chimney is an important requirement when constructing a chimney.

- To ensure good draft and free removal of combustion products, the height of the pipe must take into account the height of the roof of the heated building.

Is it possible to calculate the probability of condensation occurring?

Yes, if it appears due to overheating of the walls due to too much steam emission. In this case, it is realistic to determine what the power of the operating equipment should be.

In general, the rate of heat release (per 10 m2 of room area) is 1 kW. If the ceilings in the room are no higher than 3 meters, the formula is as follows:

MK = S*UMK/10, where

MK is the design power of the boiler in kW; S – area of the room in which the heating unit operates; WMC is a specific indicator that depends on the climatic zone of residence and is equal to:

- 0.9 – for the south;

- 1.2 – for the middle band;

- 2 – for northern latitudes.

If a double-circuit boiler is used, the resulting MK figure must be multiplied by 0.25 (additional coefficient).

How to fix the problem?

Even if you fulfill all the requirements when constructing a chimney, condensation will not be completely avoided. In a finished design this is even more impossible. But the problem can be solved by getting rid of the condensate that has already formed, reducing its concentration and minimizing the destructive consequences:

- Use dry fuel only. During combustion, less moisture will be released, soot formation will be reduced, in addition, such fuel produces more heat at lower costs.

Important! This method will not help when using a gas boiler, since it is impossible to reduce the amount of water vapor released during the combustion of natural gas.

- If the chimney is made of hygroscopic material, lining is used. A stainless steel pipe is laid inside the shaft, which absorbs the effects of aggressive substances. The sleeve will solve another problem - it heats up faster than brick or asbestos cement, which means drops will not form at the very beginning of the chimney.

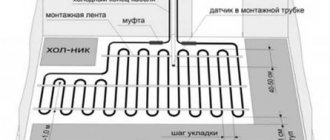

- Insulating parts of the pipe located outside the heated room will help reduce the temperature difference. The smoke will cool more slowly, most of it will have time to disappear along with the condensation steam. For this purpose, thin steel pipes are wrapped with heat-insulating materials or hidden in an additionally constructed brick shaft.

- To improve draft, you should clean the chimney and eliminate any damage to the integrity of the pipe. This will facilitate the removal of combustion products and protect the system.

- To prevent rain and debris from entering, the top of the chimney is equipped with a cone-shaped nozzle - a deflector. It does not let sediment inside and also improves traction.

- A condensate drain should be installed at the beginning of the chimney and at bends in the structure. Mount it in such a way that it is easy to empty when filling.

We recommend that you read: How to make a chimney from a steel pipe with your own hands?

Major renovation

If serious damage to the brickwork is detected, a major repair of the pipe is performed, including complete disassembly of the pipe. To work safely at height, the area must be prepared. The bricks are disassembled layer by layer, starting from the top row. The work uses a hammer or perforator. Disassembly is carried out to a row of intact material. The dismantled bricks are collected in a bucket and lowered down. For new masonry, refractory bricks and mortar of Portland cement, sand and lime are used. The pipe is laid out in one brick, strictly horizontally. The inner surface must be smooth, without obstructions for the passage of gases. The end of the pipe is a cement cap, which is most influenced by weather conditions.

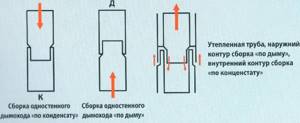

In cases where it is impossible to completely disassemble the chimney, a sleeve is inserted into its channel - a pipe of suitable diameter made of metal or ceramics. Its smooth surface increases traction, and less soot accumulates on the inner walls. Before installing the sleeve, check that there are no foreign objects or obstacles in the channel. The pipe is lowered entirely or in parts, to connect which the masonry will have to be dismantled. The space remaining between the pipe and the masonry is filled with non-flammable insulation. After installation, the hole is protected from precipitation by a metal roof. Installing a round sleeve promotes efficient removal of combustion products, increases the tightness of the pipe, and reduces heat loss. This option is acceptable only for straight channels that have the same size throughout their entire height.

The second effective way to create a reliable and sealed chimney is to treat the channel with special mixtures. They harden quickly and form a smooth surface that can withstand high temperatures. The Russian mixture “Masan” is developed on the basis of heat-resistant perlite, the Finnish “Mordax” is made from granite chips. Chimney lining has its advantages:

- formation of a monolithic surface without seams;

- speed of the application process;

- the cross-section of the chimney practically does not decrease, since the lining layer is very thin;

- the mixture has high adhesion;

- leakage of combustion products is eliminated.

Before starting work, the chimney is cleared of soot and moistened. The mixture is applied using a special metal brush attached to a winch. To get an even layer, the composition is applied 3 times, the next layer is applied after the previous one has dried. The size of the brush must correspond to the cross-section of the channel.

Preventive measures

Serious condensation problems can be avoided through preventive maintenance. A number of preventive measures that are taken in a timely manner will facilitate the maintenance of the heating system and extend the life of its safe and efficient operation:

- cleaning the chimney - the absence of blockages will ensure good draft and rapid removal of combustion products and water vapor (at least once a year);

- releasing the condensate drain from moisture as it fills;

- routine inspection and necessary repairs of the entire heating system.

All this work, if carried out regularly, will reduce the amount of condensate and avoid many other problems in the operation of the heating and smoke exhaust system.

Note! Prevention must be carried out before the start of the heating season, and it will not hurt after its completion.

Why is condensation dangerous?

There is only one problem - slow but inevitable damage to the system. All other consequences, whatever one may say, follow from this.

Accumulation of solid particles on the channel walls

- Acids formed have a negative effect on steel

- When flowing down, condensate can enter the firebox, thereby causing damage to the heating unit.

- Clogging of the channel due to the adhesion of solid particles to the walls. As a consequence, deterioration in draft, the occurrence of reverse draft, smoke in the room, and when it accumulates and dries out, ignition of soot in the pipe.

- Leaks through leaks. Moisture penetrates through the smallest gaps, causing destruction of the finish and contamination.

[\su_list] Condensation is harmful to any pipe, but is especially destructive to a brick one.

It's all about the surface of the material. The brick channel is rougher, there are recesses between the bricks, the texture of the mortar and its sagging. All this contributes to the easy and rapid accumulation of condensation. We will discuss the dangers of condensation for chimneys made of different materials in other articles.

Types of sealant for stainless steel chimneys

By sealing the cracks of stove or fireplace pipes, combustion products will not enter the room through them. Reliable insulation makes using a stove, fireplace or boiler as safe as possible.

Watch video - high-temperature products for stainless steel and other materials

Review of high-temperature sealants: which are not suitable for joining chimneys, and which are suitable

All sealing agents can be divided into several types:

- based on silicone or silicate;

- by composition: one-component or two-component;

- according to temperature characteristics: temperature-resistant sealants and heat-resistant.

As the name suggests, one-part sealants consist of a single component and do not require mixing of ingredients before sealing. This makes them easy to use and popular with home owners who appreciate the ease of use of the insulation product.

Two-component ones must be mixed before starting work, strictly observing the proportions specified in the instructions. In this case, the finished product should be used within several hours after mixing. This option is not suitable for sealing joints with your own hands; professional builders usually use two-component insulation.

In addition to chimney insulation, sealing compounds are also used to insulate the seams of a heating system structure based on an electric boiler when eliminating pipe leaks.