Chimney draft is an aerodynamic phenomenon that is caused by the movement of air masses from a point with increased pressure to a point of low pressure. This indicator is very important, as it ensures the normal removal of combustion products from the heating device through the smoke exhaust duct. If the chimney structure malfunctions for one reason or another, backdraft occurs, which leads to smoke in residential premises.

The draft in the chimney must always be sufficient so that smoke does not enter the living space

Reasons for the formation of backdraft

Backdraft in a chimney is a phenomenon that occurs as a result of disruption of natural air circulation in the chimney communication. It is worth noting that if this phenomenon occurs, the normal operation of the chimney is disrupted, and it ceases to perform its main function - removing smoke outside the building.

Important! Normal indicators of natural draft in the chimney vary from 10 to 20 Pa. If there is a decrease in draft below 10 Pa, then in this case the removal of fuel combustion products outside the house is disrupted, and they can enter the living quarters.

Backdraft can occur due to various reasons. Consider these reasons:

- errors in calculating the height of the chimney duct (low design);

- errors in calculating the chimney cross-section;

- sudden change in weather (rain, fog, strong wind, etc.);

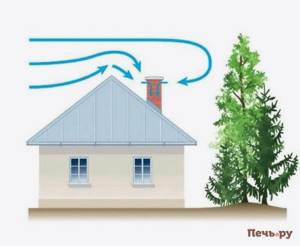

- narrow smoke circulation in the chimney structure. This phenomenon causes smoke to be trapped inside a residential building. Such turbulence occurs if the chimney pipe is installed incorrectly in relation to the roof ridge, namely below the ridge. With this arrangement of the pipe, due to the wind, the draft “overturns” ;

- a building located above the level of a specific house with a chimney, located in close proximity to it. In this case, as a rule, there is resistance to draft in the chimney communication;

- lack of air flow;

- problems with the internal ventilation system.

The low position of the chimney pipe leads to a violation of draft

Ways to reduce

If you have identified problems with traction, then, of course, they need to be eliminated as quickly as possible.

The choice of means to combat poor or reverse draft depends on the reasons that led to the abnormal operation of the chimney.

Pipe cleaning

One of the common methods of improving traction is cleaning the pipe. Fuel, burning in a stove, releases various substances that settle on the inner surface of the chimney. Soot sticks well to pipes if they are uneven or bent.

When carrying out work, do not forget about safety measures

How to clean a chimney so that there is good draft?

First of all, acting purely mechanically. The chimney channels can be made wider, getting rid of plaque, in the following ways:

- After preparing about one bucket of potatoes, peel and cut them. Potato peelings will also work. Throw a little into the firebox and wait. When burned, potatoes will release starch, which will become a means that can soften carbon deposits. Soft pieces of soot will fall off on their own, but firmly stuck ones will have to be removed mechanically.

- Firewood from aspen. Heat the stove with two or three logs. They will heat up the chimney pipes very much and help get rid of carbon deposits. But this method requires special care, since the likelihood of a fire will be very high (soot may ignite).

- Rock salt. This method is more suitable for prevention. Salt added at the time of combustion improves the condition of the chimney pipes.

- Pipe brush. A heavy weight is attached to a brush suspended on a steel rope and lowered into the chimney openings. By lowering and raising this structure, you can force soot formations to fly off the walls of the pipes and fall into the furnace. These fragments are then removed from the firebox.

The second group of anti-particulate measures is based on the use of chemicals. The most popular chemicals for cleaning chimneys are “Log-chimney sweep”, “Komichek”. Chemicals are added to the coals formed during the heating of a stove or fireplace according to the instructions and the heating continues. After all the fuel has burned out, it is advisable to leave the coals, since they continue to “work” in terms of cleaning the chimney (at least, that’s what the manufacturers advise).

When used correctly, chemicals will not cause harm to your home.

Do not believe the spiteful critics who talk about the obligatory combustion of soot when using the chemical method. This method does not pose any danger, since the beneficial effect occurs due to chemical reactions, and not due to the ultra-high combustion temperatures of the reagent.

Special mention should be made of the observance of safety measures when carrying out all work related to the chimney. Do not fix chimney problems in windy weather! Try to use safety devices when working at height!

We invite you to familiarize yourself with: Water-heated floors on wooden floors

If certain features of the chimney design are identified that negatively affect the draft force, adjustments should be made to eliminate them. These actions include:

- dismantling several separate pipes and installing a single chimney channel;

- adding roof pipes to the required height;

- insulation of chimney elements, etc.

In some cases, traction may improve if drafts are avoided in the house or bathhouse. You can help with draft problems by installing ventilation devices on windows.

If there is no desired effect after all the methods described above, you should adopt modern devices to improve draft in the chimney.

Installation of devices

To improve the operation of the chimney, it is best to use special devices that allow you to regulate and control the draft. Such devices can be bought in a store or made with your own hands.

Let's try to make the heating process safe and efficient with our own hands. The most common way to combat soot accumulation in pipes is with a brush and a sinker.

First, let's prepare everything you need:

- A hard bristle brush. The diameter of this device is selected taking into account the cross-section of the pipe (from fifty to three hundred millimeters).

- A thin metal cable (can be replaced with a very strong rope or rope).

- Weight for hanging from a brush.

This is what a device for cleaning a chimney pipe looks like

Do not start work if there is strong wind or too much humidity outside. Try to think through and use reliable insurance to protect yourself from unforeseen events.

The ruff is weighted using a sinker, attaching it to the bottom of the device. The brush itself is hung on a cable. All fastenings must be especially reliable, otherwise the structure will fall apart and you will have to perform additional actions - to “fish” them out of the pipe.

First, all inspection holes in the chimney are cleaned, and then they begin to clean the pipe itself. By making a few up and down motions, you can get rid of any soot that will fall from the chimney into the furnace. It is best to have someone else around the stove to signal efficiency and when to stop working.

Cleaning the pipe should be completed when the soot stops falling out.

You can also clean the pipe using improvised means, about which many videos have been made.

It involves using a special regulator. This device has a mechanism for regulating the pressure in the pipe and a special sensor that analyzes the current draft. It can create a pressure of 10-35 Pa. Works automatically. Such a regulator is the best solution, since it can both reduce and increase thrust. Thanks to it, there will be no backflow of smoke.

The blower is also very effective. It affects the supply of fresh air to the firebox. If you close it completely, then a minimum of air will enter the firebox and the draft will immediately decrease.

How to calculate the draft in a chimney pipe?

Calculation of chimney draft is an activity that is usually performed for industrial chimney structures. Such designs require rather complex thrust calculations. For private houses, this indicator is less important.

Ventilation communications and chimneys have one principle that underlies their functioning. This principle is the difference in pressure indicators outside and inside the building. In order to calculate the required natural draft indicator for a specific case, there is a fairly simple formula: the height of the chimney must be multiplied by the difference in the density of the external and internal air.

Let's consider the process of calculating draft in a chimney structure in more detail:

- When using heating equipment, natural draft allows you to get rid of fuel combustion products, removing them outside the structure. The difference in temperature indicators indicates the difference in air density outside and inside the building. It is worth noting that to calculate thrust it is not necessary to take into account such an indicator as dynamic pressure. This is not necessary due to the low speed of movement of air masses . The necessary data to obtain natural thrust in a particular case are necessarily substituted into the formula of Bernoulli’s law for gas.

- At the next stage, you need to calculate the total pressure loss and compare these indicators directly with the thrust. The thrust calculation can be considered ready in the case when the pressure indicators are identical to the thrust value. Such a chimney design will perfectly cope with the tasks assigned to it and will last a fairly long service life. However, if identity cannot be achieved, it is necessary to repeat the calculations again, changing the amount of pressure loss or the amount of thrust.

Calculation of draft is necessary when designing industrial chimneys, where the pipes are very tall

Helpful information! When installing ventilation communications, which also function due to natural draft, you can use the same calculations.

To increase thrust in calculations, there are two main ways. Let's look at them:

- lengthen the chimney;

- increase the temperature difference, which will accordingly affect the external and internal air density. It is worth noting that this method is not always possible.

In turn, pressure loss is reduced by the following methods:

- increasing the cross-sectional area of the smoke exhaust duct;

- reducing the length of the smoke path through the channel (shortening the chimney);

- in addition, pressure losses decrease in direct proportion to the decrease in the roughness coefficient of the internal walls of the chimney;

- reducing the length of horizontal sections that provide resistance to the removal of combustion products from the heating device.

Obvious incredible traction

Every day we encounter the curvature of space, we even use it for our own purposes, but still, we do not allow ourselves to admit it. Let’s verify the obvious with an example of an impossible (from a scientific point of view) natural craving.

- Introduction.

By clarifying the issues of correct perception of the world around me, I pursue a specific goal. Few people realize, but this is the path to power that you have never dreamed of. The path is real and the most direct, in comparison with rituals, conspiracies and prayers.

It happens that I am reproached for this. They say you can’t easily give people information that evil people can misuse. But I do not think so. It would be bad not to return to the people what rightfully belongs to them.

After all, a person is deprived of correct perception from childhood, and academic science plays an important role here. Therefore, the analysis of the questions described below is extremely useful for everyone.

I have been convinced many times that many people are born with enormous capabilities, but do not possess them. There is not enough will, not enough attention, but most importantly, they do not see the world as it is. Even if a person tries to use his power, he often acts on emptiness, on something that simply does not exist. But everything could have been different.

So let's finally reveal another worldwide deception.

- Sit behind the stove with a stupid speech.

Silly speech should be understood as a scientific explanation of the phenomenon of NATURAL CRAVING. Academicians believe that natural draft is created due to the difference in pressure inside and outside the pipe ( ΔP ). And the very first catch lies in the calculation formula, according to which we are asked to calculate all this with “mathematical accuracy”:

Where

delta P – pressure difference inside and outside the pipe;

C = 0.0342 (this is a fraudulent coefficient that attracts incorrect calculations to reality);

a – atmospheric pressure;

h – pipe height;

T 0 – absolute external temperature;

T i – absolute internal temperature;

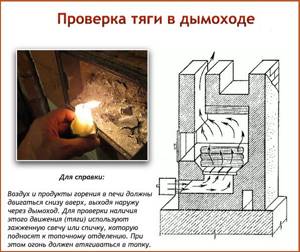

Thus, if nothing is burning in the oven (the temperature inside and outside is the same), then the expression in parentheses is equal to ZERO. Judging by the rules of school arithmetic, the difference in pressure inside and outside the pipe in this case is equal to ZERO (when multiplied by ZERO, the result is ZERO). That is, there should be no traction. But in life everything is not like that. There is always draft in the chimney, as well as in the gas water heater pipe and in the ventilation duct - both when the stove is heated and when it is cold. For the truly stubborn and distrustful, here is a poster:

That is, BEFORE lighting the fire, there should already be draft. For those who are still not sure that geysers and any stoves “can be turned on” only if there is natural draft, I recommend watching this short video

Not only does draft without a difference in external and internal temperature in the pipe exist, the lying academic lads even keep a special device for measuring it - called ANEMOMETER. If these arguments are not enough, then you can conduct a full-scale experiment according to the pictures.

On ventilation in your own apartment;

Or on your own stove in a cold state.

The above formula not only invites us to believe in the impossibility of natural draft without heating. Numerous scientific definitions, explanations and comments to it hide the main reason for this phenomenon. Because everywhere they say that the draft in the pipe is caused by the difference in pressure inside and outside.

This is a no brainer - the movement of air masses is always caused by pressure differences. The main thing remains behind the scenes - what causes the pressure difference itself? We are told that it is a difference in temperature.

But how can this be? After all, this algebraic expression should literally be read like this:

The magnitude of the pressure difference is directly proportional to the magnitude of the atmospheric pressure and the height of the pipe ... The dependence on temperatures here is indirect, but on the height of the pipe and the atmospheric pressure itself is the most direct and obvious. Why are they bashfully silent about this in interpretations? Because otherwise the trick won’t work.

The formula is incorrect, but the main causes of natural draft were nevertheless forced into it - the presence of atmospheric pressure and elevation differences. After all, without them it is impossible to get at least some approximate calculation.

- How gravity disappears in a pipe.

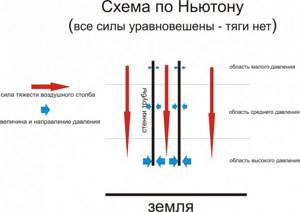

The picture shows a diagram of the action of atmospheric pressure forces, according to the concepts of modern science.

Newton's force of gravity acts on air masses in exactly the same way both inside and outside the pipe. Theoretically, it cannot disappear in the volume of the pipe. But it practically disappears regularly.

This is exactly how academics see the action of these forces. Where does the pressure difference come from if nothing is heated? All forces balance each other. So they resist and deny the phenomenon that we observe with our own eyes every day. They deny the presence of draft in an unheated stove, as if they do not notice the work of ventilation in our homes. They have nowhere to retreat. Otherwise, academics will have to admit that space is inhomogeneous, that pressure does not just change with a difference in height... and, in the end, that universal gravity is a myth .

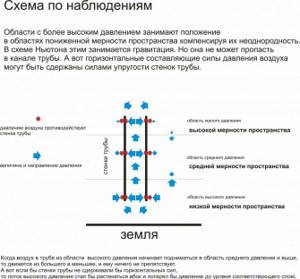

Here's a real diagram of how it actually works:

As you can see, in the proposed scheme there is no gravity, but there is another (real) reason for the difference in air pressure at different heights - the heterogeneity of space. This scheme differs favorably from the academic one in that it corresponds to reality.

Conventionally, the picture is divided into three areas of high average and low pressure. In reality, the change occurs smoothly, but it is more visible this way. The essence of the manifestation of space distortion is that it always interacts with the substance filling it.

If the dimensionality of space decreases, then it can be imagined as if the ruler (symbol of space) lying on your table suddenly shrank in its middle part and the distances between the divisions began to be located unevenly (decreased).

Now imagine that the tabletop (a symbol of any substance) is forced to submit to this change - it will begin to shrink, increasing its density and specific gravity in the curvature zone.

This is what happens in nature - low-dimensional zones are forced to fill with more dense matter, and high-dimensional zones with less dense matter. Gases show us this most clearly. It is the heterogeneity of space, and not the force of gravity, that causes them to compress towards the surface of the earth, forming a pressure difference.

- Every man knows, but science denies it.

The phenomena discussed above disprove the existence of the universal law of gravitation , as Newton defined it. Yes, in general, it shouldn’t exist. His discovery is actually a set of certain assumptions. All attempts to confirm the hypothesis (literally a non-statement in Latin) about gravity by Newton himself look frivolous.

He made calculations based on the sizes of the Moon, Earth and the distance between them. However, its own formula says nothing about size. Only mass is taken into account there. But the density of the substance of the Moon and Earth is still unknown to science. How can you get mass without knowing this? But Newton simply took it and ASSUED that the density was the same. It's easier to count that way.

Then this hypothesis magically, without any reason, turned into a theory. And even became the law of UNIVERSAL GRAVITY. And the entire academic fraternity excitedly admires how brilliantly Newton’s under-affirmation was later confirmed.

But this is a complete lie. Nothing could be confirmed, since there were no direct or indirect indications of the actual density of even our Mother Earth. After all, the soil is deeper than 12 km. failed to obtain. Moreover, no one weighed any of the planets of the solar system on “planetary” scales. They don't know anything! Only hypotheses, hypotheses, all sorts of assumptions, an avalanche of uncertainties, from which, on people tired of the empty ringing, a ready-made, recognized and authoritative law immediately jumps out like a jack-in-the-box.

about how “brilliantly” actually confirmed in the next chapter, using the example of how the scientific fraternity took aim at the Moon, using precisely the law of universal gravitation.

And now I would like to completely eradicate doubts in your heads about the deceitfulness of academicians. The brain is like that - it resists to the last, does not want to revise established ideas. Perhaps the writer simply cleverly juggled convenient facts. Listen to everyone here.

In general, you don’t have to believe me. It is enough to contact any man who has at least once installed a stove or installed ventilation. Start telling him about differences in temperatures and pressures, and he won’t listen. He will say that EVERYTHING depends on the height of the pipe, and the temperature is the tenth issue here.

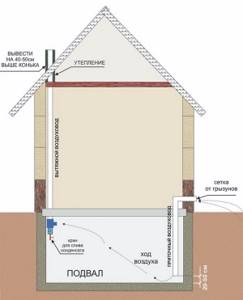

And he will be right. Here is a diagram of the ventilation in the house. Everything here is depicted very close to academic misconceptions. Blue air (cold, of course) is sucked into the warm (who doubted it) house, and without any contradictions with science, it is drawn out with red arrows through the ventilation channels.

You can, of course, assume that it is almost always warmer in the house than outside. But everything becomes not so rosy when we need to ventilate the basement or cellar.

Ventilation in the cellar works both in winter and summer. After all, no one rearranges the pipes depending on the season. But the situation with the temperature difference inside and outside changes to the opposite:

In winter, it is warmer in the cellar +10...+4 degrees C (-20 degrees C outside). In this case, the draft works to extract warm air from the exhaust pipe (as in the diagrams from science).

In summer it is colder in the cellar +10...+15 degrees C (outside +20 degrees C). The draft continues to work to extract, only now cold air from the same exhaust pipe, in the same direction. You won’t find such a formula from scientists, but natural ventilation of cellars, caissons, and vegetable pits works in millions of houses and garages in our vast country. After all, academics lie.

You will find understanding and peace when you finally come to terms with the curvature of space and throw out of your head the garbage that was crammed into you in physics lessons. And then it won’t seem strange to you that the height of the pipe is not exactly the same as its length.

- Space snipers, or how to get to the Moon at the tip of a pen.

And now, for dessert, I will tell you about the “successes” of theoretical calculations made on the basis of the “great” law of “UNIVERSAL” GRAVITY. The academicians have told so many lies that soon half of the text will have to be quoted.

It all started with the fact that when putting the first Soviet cosmonaut Yuri Gagarin into orbit, the calculation sector, armed with Newton’s formula, was shortchanged by 100 km. (ONE HUNDRED KILOMETERS) altitude. But the Russian man got out of it, somehow landed, and so as not to be ashamed of science, they blamed everything on the shortcomings of technology. Let the mechanics blush, they are no strangers to this. By the way, this is what they do today when Protons fall.

However, the accountants quietly made corrections, introduced (as always) coefficients, and learned how to place satellites into orbit quite accurately (contrary to Newton). But the party and government of the Soviet Union raised the bar higher - they demanded to fly to the moon. And it was here that all the “usefulness of the ingenious discoveries” of European scientists manifested itself, for centuries they “anticipated the achievements” of space technology, “unraveling the secrets of the forces that control the movements of the stars.”

The calculation sector calculated, entered verified coefficients, and on January 2, 1959, the unmanned interplanetary station “Luna-1” was launched directly into the Moon. The main task was to reach its surface. We wanted to hit it, but we missed it a little - by 6000 (SIX THOUSAND KILOMETERS).

Who do you think is left last this time? Newton? Academy of Sciences? No matter how it is! Unfortunately, no technical problems were found in the station system. And scientists, with some uncertainty, considered an error in the cyclogram to be the cause of the trajectory failure. They blamed it on the programmers.

Is it a lot or a little - 6000 km? It's like aiming 2 hulls of the Moon to the side. "Sniper" result. But what can you do, the formula is incorrect, there is no universal gravity at all. But you won’t fly far with corrections and coefficients alone. Therefore, the “scientific poke” method is still the main one, both on earth and in space.

And this time, the experience of adjusting calculations to actual trajectories again helped our Soviet theorists - they somehow pulled it by the ears. Already in September of the same year, Luna 2 finally hit the Moon.

The Americans either had less experience or had more faith in the inviolability of the laws of physics. But the first, second and third time they couldn’t bring anything beyond the curvature of space in the region of our planet. Their Pioneers were falling back. It took about 70 launches to zero in. Not all of them were workers; some of them became sighting workers.

And finally, Pioneer 4 broke out of this trough. His task was to fly at a distance of 30,000 km. from the surface of the Moon and photograph its far surface. As a result, the American settlement sector still missed the mark. The device flew 60,000 km. The miss was 30,000 (THIRTY THOUSAND KILOMETERS). That is, the Pioneer was supposed to fly at a distance of 11.5 lunar corps, but it turned out to be 23 corps.

The angular size of the Moon as observed from Earth is approximately ½ degree. Accordingly, the crooked eyes of domestic space mathematicians amounted to approximately 1 degree. And the overseas accountants bent all 5 degrees.

For comparison: if a hunter shoots a bullet from a smoothbore gun at a distance of 50 meters, he hits a circle with a diameter of about 10 cm. This is a common thing and the angular deviation of the trajectory is no more than 1/10 of a degree.

And if he shot like our space mathematicians, then from a distance of 50 meters he would only hit a circle with a diameter of 85 cm. Quite sour. Such a sniper can only hunt elephants. But if it were “accurate” like overseas accountants, it would only hit a huge banner measuring 4.5 meters from a distance of 50 meters.

Of course, I understand that the spacecraft were launched not by direct fire, but in a rendezvous orbit. But for mercy's sake, they had much better means of ensuring accuracy. What about mathematics, altimeters, telemetry, time counters? How about 70 attempts? In any case, you can’t miss by half the sky. In general, this is some kind of shame. It’s time to do hara-kiri to yourself with a stupid slide rule.

The mathematical prediction in the described cases completely failed. As a result, Newton's formula describing UNIVERSAL GRAVITY was simply spat on and stupidly shot at.

And yet, I have great respect for people who, despite the efforts of the Newtons, various academicians, and theorists, by eye, on a hunch, still did something that should never have happened - they ended up on the Moon. Heroes, creators, what can you say. It's people like these that the would-be theorists always target.

- Conclusion.

Natural traction is living proof of the possibility of using differences in heights (dimension levels) for your own purposes. A pipe placed vertically is a perpetual motion machine that many only dream of, but it exists and tirelessly works for us in ventilation and chimneys. Except that its specific power is not so great, although the pipes in large boiler houses already produce kilowatts of free draft.

This same phenomenon simply and clearly shows the falsity of the universal law of gravity. The world does not live by this law.

Natural craving is another disgrace of academic science, which everyone can see, and which they are trying with all their might to hide. And our shame is that they still manage to deceive us. We see it with our eyes, we feel it with our hands, and we don’t believe it ourselves.

Alexey Artemiev

Izhevsk

How to increase draft in a chimney with your own hands?

Many owners of private houses equipped with chimney pipes are interested in the answer to the question: how to increase draft in the chimney? As mentioned above, for normal operation of this system it is necessary that the rising air pressure be between 10 and 20 Pa.

To increase traction, you can use different methods, including installing a device such as a deflector

To determine the thrust indicator, you can also use special measuring instruments that can record this indicator - anemometers. The decision to increase or, conversely, decrease thrust depends on the anemometer reading. It is also worth noting that this takes into account one more point - the results of combustion of fuel raw materials in the heating device.

There are several ways to increase draft in a smoke exhaust structure. Consider these methods:

- extension of the chimney pipe;

- deflectors;

- weather vane;

- rotary turbines;

- smoke exhausters operating on electricity.

Note! Often, to increase draft it is only necessary to clean the internal chimney channel.

In addition, there are other methods that can cope with this common problem. It is recommended that you familiarize yourself with all the options for combating weak draft in the chimney system.

Rules for choosing pipe length

If the pipe comes out of the roof at a distance of 0.5 m to 1.5 m from the ridge of the roof, then according to the standards it should rise

above it by 0.5. This saves chimney material and provides the most efficient heating. During snowfall, the least amount of snow collects in this place, which eliminates leaks during melting. The standards stipulate that the resulting estimated length should not be less than 5 meters, if measured from the surface of the grate to the top edge of the pipe.

If the smoke duct reaches the roof surface at a distance of 1.5–1.3 m from the ridge, then to determine its height, draw a horizon line from the highest point, then set the height of the chimney head above this line. If there are parapets along the edge of the roof, then the pipe should be higher than them.

When the chimney exits

on a surface more than 3 meters from the ridge, you should draw a horizontal line from the highest point, and lower it by an amount of 10º relative to the horizon. Above it the head of the pipe ends. If other buildings are built nearby, then the height of the chimney is higher than the neighboring roofs. For very high neighboring houses, the 45º rule is used, that is, a straight line is drawn at this degree from the neighboring roof to the one where the chimney is made, and the head is arranged slightly higher than the mental straight line.

In addition to height, traction force is affected by

the shape of the internal section of the chimney. An oval passage is considered optimal, since as you gain altitude, the smoke begins to twist into a spiral and nothing prevents it from accelerating. Square and rectangular sections themselves become an obstacle due to the internal corners, so the surface must be smoothed as carefully as possible. Some masons select and lay bricks with the smooth side inward, while removing the mortar buildup.

Another important point is

chimney diameter size. Oval passages are made according to the size of one tenth of the area of this firebox parameter. Square pipes require an area size of one fifteenth of the firebox area. The general rule for all smoke ducts is that their diameter should not be less than the width of the upper exit from the ash pit.

In addition to the height of the pipe relative to the ridge, you should take into account its height from the location of the ventilation ducts

. Ventilation located nearby requires raising the height of the chimney by 20–25 cm from its horizon. If there is insufficient draft in the pipe, then the method of increasing the pipe height is used. But at the same time, you should remember the rule of relevance, that is, you should not make the height too large or insufficient.

Extending the flue duct

This method of increasing draft is considered the simplest, since to carry it out it is only necessary to mount a chimney pipe longer than originally planned. Due to the difference between the boiler and the chimney outlet on the roof, the difference in the pressure of the rising air flow also increases.

The height of the chimney should be no more than 6 meters, then the draft will be normal

It is worth noting the fact that for a chimney structure, the optimal height is no more than 5–6 m (if the minimum distance between the chimney section lying in a vertical plane and the heating device is observed). It is also worth noting that this option for increasing the draft in the chimney is suitable only if the communication is installed without bends, narrowings and other areas that may act as obstacles to the removal of combustion products.

A high roof contributes to the deterioration of smoke removal from the chimney structure. In addition, the location of a taller building in close proximity to the house in which the chimney is installed has a negative impact on the removal of combustion products. Extending the chimney pipe in this case is the surest solution of all.

But do not forget that excessive lengthening of this structure greatly enhances the natural draft, and this leads to heat dissipation outside the residential building. In such a situation, experts recommend using special dampers that reduce the volume of smoke emitted.

What affects cravings?

The size of the chimney is influenced by many factors.

The most important among them are the height and cross-section of the chimney channel. These two parameters are always interrelated and depend on the characteristics of the stove or fireplace. Their calculation requires extreme vigilance, since in case of error the thrust will be poor. And this will lead either to the reverse movement of carbon monoxide or to excessive burning of wood. Today there are entire tables that will allow you to correctly calculate the size of smoke channels. For example, in order to create adequate draft in a fireplace, you need to make sure that the exhaust duct has a cross-section that is less than 1/10 of the area of the firebox inlet. It seems that if you increase the cross-section of the exhaust duct, the draft should increase.

Deflectors

A deflector is a device that allows you to stabilize the air flows that occur in the smoke exhaust pipe. The name of this product is translated as a guiding device and fully corresponds to its operational features.

A deflector is a device that helps stabilize air flow in the smoke channel

It is necessary to note one important pattern: the simpler this device is, from a design point of view, the more efficient it is in operation. This is due to the fact that air masses redirected from the roof surface, together with side air flows, help remove smoke from the chimney.

Experts recommend using this device in windy regions, as it is not effective in calm conditions. When choosing this device, you need to pay attention to two main factors. Let's look at them:

- dimensions of the chimney pipe on the roof;

- wind load for a specific case.

In addition, it is worth saying that such a device can be made without much difficulty with your own hands. To do this you will need the following materials and tools:

- square;

- yardstick;

- scissors for cutting metal;

- regular hammer;

- riveter;

- hand-held electric drill;

- set of drills;

- drill-tip screws equipped with a press washer, which has a size of 15 mm;

- sheet of tin or galvanized steel with a wall thickness of 0.3 to 0.5 mm;

- fastening material.

Before assembling such a draft amplifier for a chimney with your own hands, you need to carry out calculations on paper and apply the necessary markings to a tin or galvanized sheet. The assembly diagram for this amplifier can be easily found on the Internet.

The size of the deflector must correspond to the diameter of the chimney

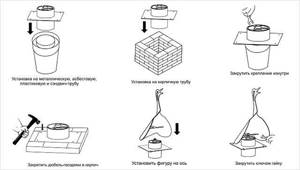

Next, we proceed to the direct assembly of the amplifier for the chimney with our own hands. Let's look at the stages of assembling this device:

- First, you need to cut out the parts of the future deflector from tin or galvanized sheets (based on the markings).

- Then you need to roll up the nozzle body and join the edges together using rivets or self-tapping screws.

- At this stage, the two cones of the product are joined.

- Studs are installed in the lower cone. This is necessary in order to dock the lower cone with the general body of the deflector.

- The lower cone is connected to the device body. It must be remembered that all connections in the device must be strong enough so that the deflector can withstand strong wind currents during operation.

Thus, it becomes clear how to increase the draft in chimneys with your own hands using a weather vane, however, there are still many devices and means that allow you to carry out such an event.

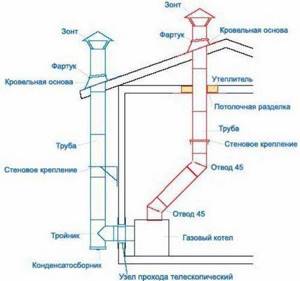

Step-by-step installation of a gas boiler chimney

Installation of the chimney

Installation of the chimney system is as follows:

- The passage of the pipe through the ceiling and roof is accurately marked - this process must be monitored repeatedly so as not to make mistakes.

- Next, holes are made according to the markings for the passage of the pipe.

- Install an adapter for the transition, which is connected to the pipe located on the boiler.

- Then a tee with a compartment for collecting moisture is attached and secured with a special bracket.

- The next section of the chimney is joined. If necessary, an element called a “knee” is used.

- If the pipe will pass through the ceiling, a special passage pipe must be included in the chimney kit. The pipe passes through a metal sheet in which there is a hole slightly larger than the diameter of the pipe. The sheet is attached to the ceiling.

- For reliability, the joints of two pipe sections are fixed with clamps and tightened with bolts.

- The chimney is fixed to the wall with special brackets in increments of approximately two meters.

- The design is completed by a cone-shaped tip.

- The last step is to insulate the chimney pipe from flammable materials at the transitions.

It is impossible not to highlight the nuances of choosing and installing a chimney, depending on its location. It can be installed outside and fixed to the wall (wall-mounted), or run inside the building.

Internal chimney

If heat must emanate from the chimney to all the rooms where it will pass, there is no need to choose a pipe with internal thermal insulation; it is insulated only from the outside. It should be taken into account that when the chimney passes inside the house, the risk of combustion products entering the rooms increases, and the fire hazard also increases.

Therefore, it is very important to perfectly fit the individual parts and secure them securely with clamps. Installation will require a larger number of different additional elements, since the pipe will pass through at least one floor and roof. We should not forget that if in the future it is necessary to carry out repair work on such a chimney, this will become quite a problematic task.

Comparison of external and internal chimney layouts

External chimney

- The external version of the chimney requires correctly calculated thermal insulation.

- The advantage is the safety of this heating element.

- Installing an external chimney is much simpler than an internal one.

- If repairs are necessary, they can also be easily carried out under any existing conditions.

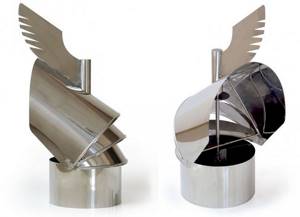

weather vane

A weather vane, like a deflector, enhances traction, depends on the strength of air flows and has a very simple design. However, unlike a deflector, a weather vane does not prevent the removal of combustion products from the chimney in calm weather.

The weather vane is simple in design and protects the chimney from the wind on only one side

Note! From a constructive point of view, a weather vane is a wing that is small in size and protects the chimney from the wind from one specific edge.

This device also has a special element called an auxiliary blade. The auxiliary blade is mounted opposite the place where the weather vane is attached to the chimney pipe.

The main function of the auxiliary blade is to protect the mouth of the chimney from air masses flowing around it and causing the occurrence of rarefied zones. Due to such discharged zones, the draft in the chimney pipe increases greatly, which, accordingly, negatively affects the heating.

Experts recommend using a weather vane in cases where the draft in the chimney is unstable, as well as in strong windy weather, which destabilizes the draft.

Rose of Wind

A situation when the prevailing winds blow directly into the chimney and reduce the draft or reverse it. The chimney is installed on the windward side, of course, if the wind directions are determined. If the chimney is located far from the ridge and below, the leeward side cannot be used. Multi-storey buildings and trees also affect traction. To compensate for gusts of wind and poor placement of the chimney, anti-wind deflectors are used. According to the standards, the chimney is installed half a meter above the ridge. If the distance from the ridge is 1.5 m - 3 m, then it is brought to the same level as the ridge. If the distance is more than 3 meters, then proceed according to the formula: from the horizontal drawn from the ridge, 10 degrees down. In practice, the chimney is made higher than the ridge, or at the same level as the ridge. It is important to use one chimney for one stove in the house.

Rotary turbines

A rotary turbine is a mechanism that increases draft in a chimney using the power of the wind. The nozzle on such a turbine always rotates in only one direction, regardless of which direction the wind is blowing. Thanks to this, the necessary vacuum appears above the chimney, which helps to increase draft in the system.

This chimney draft amplifier has a design that not only facilitates the removal of combustion products from the chimney, but also prevents it from clogging with leaves, branches and other debris.

A rotary turbine uses wind power to increase thrust by rotating in one direction

The main feature of such a device is that in calm weather it does not function, but during the non-heating season it helps remove air from the chimney duct. In addition, in windy weather such devices allow you to increase traction due to the vacuum effect.

It is strictly not recommended to install rotary turbines on chimneys that remove solid fuel combustion products. This is due to the fact that the operating temperature for such devices does not exceed 150–250 °C.

Rotary gate for a furnace in a bathhouse

The design of the damper, which looks like a special horizontal plate, changes the position of which increases or decreases the chimney clearance, which is quite important for adjusting the draft force. This plate has a special hole, thanks to which it is impossible to completely hermetically close the lumen of the chimney channel. This is necessary to comply with fire safety.

Quite often, such a horizontal damper is installed in brick stoves, but it is not uncommon in steel chimneys. The rotary gate is a plate attached to the axis. It is adjustable when turning. One of the disadvantages of this type of damper is welding burnout, and this phenomenon has recently appeared more and more often.

Both models have some differences: with the help of a horizontal damper, you can directly regulate the clearance of the chimney channel, but in the case of a throttle, you can only either open or close the channel. In extreme cases, you can fix the damper using a chain.

In order not to make a mistake when selecting a damper for the chimney duct, you need to decide what type of stove it will be, and in addition, take into account some other nuances. Installation of a damper is done on all types of furnaces, with the exception of some new models, where the combustion process is regulated by controlling the supply of supply air flow, and a deflector is used to perform this task.

A stove operating on gas must be equipped with a rotary damper, thanks to which the risk of completely closing the chimney is absolutely eliminated, which prevents the accidental release of flame through the ash pan. In the case when a damper is still used, you need to ensure that there is a gap of at least 30-40% of the cross-sectional area of the chimney duct.

There is no need to install rotary dampers for a sauna stove with periodic operation, since a closed damper will always allow steam to pass through when supplied. But there is an opinion that in the case when the rotary damper is open, the chimney channel located below the damper level is quite difficult to clean in the future.

Usually, a damper is also sold along with the chimney, since this is a mandatory part of the design. But this element is also sold separately in all specialized stores. The main thing is to know its correct dimensions.

Electric smoke exhausters

They are mounted on chimneys that remove combustion products from heating devices operating on solid fuel. The temperature of the working environment for electric smoke exhausters ranges from 650–800 °C.

In addition, an important advantage of these electrical devices is that they are able to fully automate the chimney structure. As a rule, such devices are equipped with special sensors that regulate the intensity of the electric drive. Let's look at what sensors electric smoke exhausters are equipped with:

- sensors that monitor the temperature of the working environment;

- sensors that set the strength of air flow.

In addition to the above options, there are other ways to enhance the natural draft in the chimney.

A decrease in draft in the chimney is often due to its clogging, so if problems arise, you should first clean it

Chimney installation

Pipe installation begins with the assembly of individual elements into a single channel. All joints are treated with heat-resistant sealant to avoid leakage of flue gases from the main smoke duct. The entire system can be installed both inside and outside the building.

If you have a channel of a different diameter than the boiler outlet, purchase an adapter. The next rule that needs to be taken into account is that single-wall, insulated chimneys are installed according to the “pipe to pipe” principle. All existing tees are installed based on the “smoke” principle, and the vertical channels “by condensate”.

The installation process can be divided into the following stages:

- all elements of a single system are assembled from the bottom up;

- clamps are used to fasten individual elements;

- all connections must be in accessible places;

- mounting on the wall must be done in such a way that there is no deflection of the main channel;

- close proximity to other energy supply utilities is prohibited;

- the joints should not be within the thickness of the roofing layer;

- If the roof contains flammable materials, a spark arrester is installed on the chimney.

To modernize the existing hood in the house, after installing newer heating equipment, special devices are used - fans. Smoke exhausters for solid fuel boilers are an excellent option to significantly increase draft. If natural draft is insufficient, the necessary effect is achieved with the help of a smoke exhauster.

Other ways to increase chimney draft

Let's consider folk methods of increasing draft in smoke exhaust communications:

- cleaning the chimney using a special metal ball, which is attached to a cable;

Helpful information! Garbage plugs in the chimney channel are broken quite simply: a ball, attached to a cable, is slowly lowered along the channel until 1-2 m remain before the expected obstacle. After this, you need to quickly lower this ball onto the blockage, which will allow you to break through it.

- ensuring the tightness of vulnerable areas of the chimney (holes, cracks, etc.);

- cleaning the weather vane from dirt or icing. In addition, it happens that the weather vanes fail, then it is necessary to take care of its repair;

- ventilation of residential premises, which will create the necessary draft support;

- creating additional vacuum through preheating. To warm up the communication, you can use several ordinary newspapers that need to be burned.

Any of the above devices or activities can help in a given situation. When organizing additional measures to increase traction, it is recommended to be careful and follow fire safety rules.

Head design rules

What functions are attributed to this device:

- protecting the chimney from rain, snow, leaves and foreign objects, reducing the impact of strong gusts of wind;

- thanks to protection from moisture and wind, increased draft in the smoke channel;

- roof decoration.

If the roof serves for the outlet of several pipes

, then identical heads will serve as a decorative detail and combine all outputs into one ensemble. There are various designs of caps; they are intended for ventilation ducts and chimneys, but their protective functions are necessary for the normal operation of the heating system.

At first glance, the chimney seems to be the simplest element of all housing construction. But this is only at first glance. A properly executed chimney is a rather complex engineering structure, on which the efficiency of the heating system, as well as the health and even life of the inhabitants of the house, depends. That is why all calculations related to the design, cross-section and height of smoke exhaust ducts must be performed by professionals.

Chimney options

If the fundamental structure of all chimneys is very similar, then the greatest and most obvious difference is found in the material.

The traditional material for chimneys has been and remains brick. It is still popular, although other solutions have emerged.

If you install a brick stove, then the chimney will most likely be made of brick too. But nothing prevents you from making a transition for the chimney from the pipe near the brick slab.

Chimney pipes are:

- Metal;

- Multilayer sandwiches;

- Asbestos-cement;

- Made of ceramics.

Chimney sandwiches are gaining popularity. The design consists of 2 steel pipes, one inside the other, and the gap is filled with thermal insulation material, usually basalt. During operation, the result is a pipe that is tidy on the outside. Such a chimney is very quick to build.

Main factors affecting pipe height

So, what facts must be taken into account when calculating the height of ventilation and chimney:

- Distance to roof ridge.

- Roof design and thickness – gable, single-pitch, combined.

- Fire safety rules.

- Section.

- Organization of proper ventilation of the furnace room.

If you decide to do everything yourself, then knowledge of the technology for calculating height, diameter and other parameters will not hurt.

The first parameter is the dimensions relative to the ridge

If the pipe is located at a distance of less than 50 centimeters from the ridge, then it is raised another half meter above the roof level. The diagram shows how easy it is to calculate the height, depending on the distance from the roof ridge.

A distance of one and a half to three meters is located at the level of the ridge, more than three meters is a slope of ten degrees down from the ridge, the required height is the intersection of the line of the angle of inclination and the top of the pipe.

The height of the pipe above the roof ridge is the most important calculation parameter. Good draft in the boiler and fuel economy depend on this value. When making calculations, one must be guided by the requirements recommended by the instructions for the boiler and SNiP41-01-2003, as well as SP 7.13130.2009 (basic building standards for ventilation).

Another very important rule is that the length of the entire chimney, from the boiler grate to the point where the smoke exits, must be no less than 5 meters. For a flat roof - at least 50 centimeters.

The diagram shows that the chimney from the attic is determined by the intersection point of an angle of 45 degrees from the valley and a vertical line down from the end of the slope at a distance of 50 centimeters.

It is almost impossible to describe these calculations in words; the diagram is more informative. For example, I didn’t complicate the process. A full calculation and a clear plan costs only 2,000 rubles - it is carried out by design organizations; it seems to me that the price is quite reasonable.

The second parameter is the roof structure

For pitched roofs, the height is calculated according to the standards, depending on the distance to the ridge. For flat roofs, the calculations are different.

The length of the chimney above a flat roof should not be less than 1 m 20 cm. If the pipe is higher, then it is necessary to install retaining clamps and guy wires made of strong wire for rigid, reliable fastening.

For roofs of complex multi-level structures, calculations are used taking into account height differences. But still, the highest point of the ridge is considered the base point. Multi-level structures must be calculated by specialists, since in this case many specific parameters must be taken into account.

The main problem with an incorrect chimney height is the risk of air turbulence. With strong gusts of wind, it can simply extinguish the fire in the boiler, which leads to very unpleasant consequences.

The third parameter is fire safety rules

There are quite a lot of fire safety requirements and all of them must be met:

- All structures adjacent to the pipe that may catch fire must be carefully insulated with asbestos sheets. Now fire safety requirements have changed, and many organizations do not allow asbestos, only galvanized iron. The same applies to chimneys.

- If the roof is made of flammable material and there are ventilation holes in the pipes, then the height should be increased by half a meter to prevent sparks from hitting the coating.

- A sheet of galvanized metal, no less than 1.5 x 1.5 meters in size, must be installed above and below the boiler.

- The distance from the chimney to the attic windows is at least two meters.

- The distance to tall trees and buildings is at least six meters.

Now, according to the changed standards, it is prohibited to install protective fungi on chimneys and ventilation outlets. The requirement is terrible, since birds and garbage clog the pipes every year, you have to constantly call a team to clean all this garbage.

The fourth parameter is the section

The photo shows a simple table for determining the required section and height

For rectangular brick chimneys, the standard is 1x1.5 cm (minimum 10 square centimeters). Corners must be rounded.

The chimney is round in shape - the minimum diameter is 15 centimeters, but in Crimea they usually require 30-35 cm. Why, I cannot answer.

There is one more unpleasant nuance - there are no adapters for passing a round pipe through the roof, only for square ones. Therefore, you will have to order such an adapter individually from tinsmiths.

Fifth parameter - ventilation

The height of the ventilation pipe above the roof according to SNiP should be calculated in principle in the same way as the chimney. The main requirement is one level in height of the ventilation and chimney pipes, if they are located no further than 3 meters from each other.

The diameter and dimensions of the ventilation must ensure ventilation of the boiler room space, and this depends on the volume of air contained in the room.

The required volume of air entering a residential room heated by a boiler is three cubic meters per hour per square meter of area. In utility rooms (boiler rooms), this standard is at least 180 cubic meters per hour.

The formula for calculations is based on the ratio of the total area of the room to the cross-section of the ventilation duct. The height of the ventilation pipe above the roof is determined according to the same principle as for the chimney.

Pros and cons of turbo deflectors for ventilation

The device does not require connection to electricity, as it works under the influence of wind

The devices help increase air exchange and prevent the formation of condensation in the space between the roof elements.

A turbofan on an exhaust pipe has advantages in application:

- does not require connection to electricity;

- has a long service life, depending on the material it lasts from 10 to 15 years;

- the channels where the rotary deflector is located are less often cleaned due to the exclusion of accidental ingress of objects;

- compact and lightweight devices do not put stress on the pipe;

- installation does not require special skills;

- the equipment hardly freezes up in cold weather due to constant mobility.

There are some disadvantages to using a turbo deflector. Due to strong draft in the channel, the burners of the gas boiler sometimes blow out. The turbine stops in completely calm weather, when the relative air humidity is increased to the limit or in severe frosts.

Installation of a chimney on the roof

There are two options for installing the deflector: connecting directly to the smoke duct and mounting it on a piece of pipe, which is later put on the chimney. The second method is considered the best in terms of convenience and safety, because the most troublesome stage of the work is performed on the ground, and not on the roof.

Standards according to GOST

Excerpts from current regulatory documents regarding the installation of a deflector on a pipe inform about the following:

- any nozzles on the smoke channel must be mounted in such a way that they do not block the path of fuel combustion products;

- on a flat roof, the mouth of the pipe should be placed above the fence;

There should be free space around the mouth of the pipe - on a roof with slopes, the chimney head must be located above the ridge, if the space between them is less than one and a half meters, or at the level of the ridge, when the gap from the pipe to the highest point of the roof varies within three meters;

- the deflector must not be installed in an area where an aerodynamic shadow is created due to neighboring buildings;

- the device body must be well ventilated regardless of the wind direction;

- rotating deflectors are not suitable for chimneys of stoves located in houses built in areas with cold winters;

- installation of a round deflector on a brick chimney involves the use of special transition pipes.

Required Tools

To install the deflector on the smoke duct, you need to find some tools and fasteners:

- electric drill;

- open-end wrenches;

- threaded rods;

- nuts;

- clamps;

- two ladders (one for climbing to the roof, and the other for moving along the roof).

In addition, to install the device on the chimney you will need a piece of pipe. Its diameter should be slightly larger than the size of the smoke channel.

Deflector mounting

The chimney is connected to the pipe, performing certain tasks:

- On the prepared section of pipe, 10 cm from the edge, mark the points where you need to drill holes for fasteners. Similar marks are left on a wide area of the diffuser.

- Holes are made in the pipe section and diffuser with a drill. The parts are temporarily connected to each other, checking that the upper and lower holes match. If this is not observed, then the product is considered defective, because the fastening elements cannot be inserted smoothly.

- Pins are inserted into the holes. On both sides, both on the diffuser and on the piece of pipe, the fasteners are secured with nuts. They are twisted evenly to protect the product from deformation.

- With the manufactured device they are sent to the roof. The structure is placed on the smoke duct and tightened with clamps.

If you install a deflector on a brick chimney, you will have to arm yourself with nails and a hammer

Proceeding as described above, you can mount any device except the weather vane deflector, since its design is rather non-standard.

In the case of using a device with a compass rose, 3 holes are created in the smoke channel with a drill. The holes are made at the same level so that bolts can be inserted into them a little later. These fasteners are immersed in the holes when the ring part of the deflector-vane is placed into the cut of the chimney. An axle is inserted into a bearing in the form of a ring, and a cylinder, a device blade and a cap are alternately attached to it. The elements of the weather vane deflector are combined with brackets or rivets.

The deflector can confidently be called a useful device that has a positive effect on the draft force in the chimney and the functioning of heating equipment. It is relatively simple to make and connect the device to the pipe; you just need to be “savvy” in choosing the type of deflector.