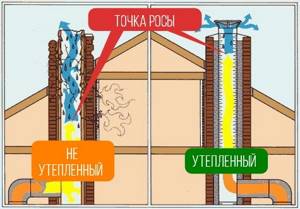

Very often, heating design in private houses requires mandatory thermal insulation of the chimney. This is a very important matter, since without adequate insulation, pipes can be damaged due to the constant formation of condensation.

Condensation forms only on the side of the passage of warm air. First of all, you need to insulate the warm side of the pipe that is in contact with the cold air of the environment. Considering that heated air passes through the chimney, flammable or fusible materials cannot be used as insulation.

Below we will look in more detail at how, with what and where you need to insulate.

Why insulate the chimney pipe from the outside?

Chimneys are made from various materials. It can be either refractory brick or metal, asbestos cement, reinforced concrete.

During operation of heating equipment, a large amount of combustion products and hot air masses move through the smoke channel. All this negatively affects the service life of the chimney, because... Corrosion processes are accelerated and the internal walls of the outlet channel are oxidized. If the pipes are made of metal, then there is also a high probability of a fire if there are errors during operation.

Most often, the chimney is damaged for a number of reasons:

- The presence of moisture in the chimney pipe means increased pressure and constant humidity. Due to the fact that the temperature inside and outside the chimney varies, moisture collects on the walls of the ducts, which negatively affects the condition of the structure.

- Chemical environment - when solid or liquid fuel burns, many aggressive substances appear that are dangerous to human health. If the chimney functions well, without failures, then all the formed substances are removed outside under the influence of natural draft. When the draft decreases and during the inactivity of the smoke exhaust structure, substances begin to accumulate on the walls of the smoke channel, this will lead to the pipe slowly beginning to collapse.

Insulating the chimney from the outside using modern thermal insulation materials significantly reduces the likelihood of damage and reduces the rate of corrosion processes.

Expert advice

Installation of thermal insulation of the boiler chimney must be carried out in compliance with installation norms and standards:

- the thermal insulation layer must be completely continuous, including in areas adjacent to the attic floor and roof elements;

- vapor barrier material is installed with the inscriptions facing out;

- the joining of sandwich pipe bends is carried out in such a way that the pipe of the lower bend fits inside the upper bend of the sandwich;

- external thermal insulation is carried out after the construction of the chimney, insulation from the inside is carried out during the process of its arrangement;

- if the roof is made of flammable building materials, then the chimney must be equipped with a spark arrester;

- All manipulations with mineral wool must be carried out using personal protective equipment to prevent particles from getting into the eyes and respiratory tract.

Insulation for chimney pipes and its advantages

Dew point of insulated and non-insulated chimney

Many users constantly wonder: is it necessary to insulate the chimney pipe from the outside? Of course, an insulated pipe has a number of positive properties. As already noted, timely thermal insulation of the chimney reduces the negative impact of many factors that negatively affect the material of manufacture. It is very important to choose the correct thickness of chimney insulation. This way you will completely get rid of the problem with condensation, because... the dew point shifts to a section of the pipe that is above the roof level.

In addition, chimney insulation performs a number of important functions:

- Thermal insulation materials do not allow moisture to accumulate on the pipe walls. Due to the same temperature regime of the chimney and combustion products, this prevents condensation from appearing and all harmful substances are removed outside.

- The difference in temperature limits between the hot gases and the smoke duct is reduced.

- Characterized by energy saving. During operation, the insulated chimney absorbs a small amount of energy that is generated during the combustion of fuel. Due to this, the consumption of fuel and energy, which is spent on maintaining a constant temperature regime in the furnace, is reduced.

- The design of the smoke channels becomes more durable.

You can read about stainless steel pipes here.

Types of materials

The material for insulating the chimney pipe of the heating system of private houses is selected based on the type of chimney, its location, as well as the material of its manufacture:

- broken brick;

- plaster;

- mineral wool;

- wooden boards;

- concrete;

- metal cases.

When carrying out insulation, you should strictly follow safety rules. It is very important that the chimney insulation is non-flammable. This is due to the fact that during operation of the heating device the temperature of the insulation will reach up to 100-150° C, and in the area where the pipe exits through the ceilings it can be even higher.

If the work of insulating the pipe will be carried out by one person, then it is better to give preference to a lighter and more solid material. Otherwise, during the insulation process you will have to face a number of difficulties that will negatively affect the final result.

Now let's look at the most popular methods of insulation:

- Plaster is used to insulate chimneys made of brick and stone. The solution is applied to a previously prepared reinforced surface.

- In order to insulate a brick chimney, broken brick is most often used. The material is poured into a casing that is fixed around the chimney. The minimum distance from the chimney is 60 mm. There are cases when slag is used instead of broken brick.

- Chimney insulation with basalt wool above the roof. This material is in great demand; it is produced in the form of mats/cylinders with different internal sections. The material is wrapped near the chimney and attached to steel crimp clamps. The material is inexpensive, but in terms of quality and efficiency it occupies a leading position.

Fireproof insulation

Currently, in private homes, the key element of the heating system is a factory boiler, the chimney of which is made of metal or asbestos cement.

Fire-resistant insulation for a chimney constructed from asbestos cement is carried out by covering the outside of the pipe with materials with high thermal insulation rates. The area that is located above the interfloor ceiling must be thoroughly cleaned of dirt, and then mineral wool must be laid. Afterwards, the entire structure must be placed in a steel casing.

When using non-flammable fireproof material to insulate the chimney, do not forget that the minimum distance between the outer wall of the pipe responsible for the removal of gases and the inner wall of the casing should be 60 mm.

Stages of insulation of a stainless steel chimney

First you need to familiarize yourself with the two main requirements for thermal insulation of stainless steel chimneys:

- If the stainless steel chimney is located outside, then the thickness of the insulating material should not exceed 100 mm.

- For pipe sections located inside, the thickness of the insulating material should not exceed 40 mm.

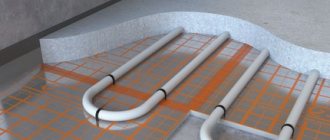

Method of thermal insulation using mineral wool:

- If it is a roll, then it is wrapped around the pipe (in several layers if necessary), and secured with wire or staples.

- If it is a cylinder, then it is mounted on top of the pipe. An important nuance: the shell must be selected strictly according to the outer diameter of the chimney: no more (so that it does not dangle) and no less (otherwise there will be a gap between the halves). The halves are fastened together either in grooves (if such fastening is provided by the manufacturer), or with glue, or with wire.

- Galvanization is attached over the insulation.

How to insulate a chimney pipe on a brick street?

Typically, brick chimneys are installed in old houses, which are built according to the type of classical architecture. To insulate such structures, it is best to use plaster.

You need to cover the pipe with several layers of a solution of slag and lime. The total thickness of the layer you will apply must be at least 40 mm. Moreover, it is important that each new layer is thicker than the previous one. When plastering the chimney, all cracks are well coated. Everything that is located above the roof must be covered with a protective layer of oil paint. This way you won’t have to worry about the material being damaged by bad weather.

If you insulate a chimney using this method, you can save up to ¼ of the generated thermal energy.

The second answer to the question of how to insulate a chimney is their location inside the boxes, which are installed around the latter. You can use asbestos-cement slabs, wood or sheet metal, from which the box itself is made. The insulation itself must be laid between the inner walls of the box and the chimney.

The following heat-insulating materials can be used: dry earth, broken glass, brick, mineral wool. By insulating in this way, you can save half of the generated thermal energy.

It is quite difficult to carry out insulation in this way; it is very important to observe all the proportions and execution technique. Therefore, it is better to entrust the work to specialists.

Working with bricks

Brick as a building material is still unrivaled: in brick houses, chimneys are also made of brick. Insulation of a brick chimney can be done in different ways.

Method one

The first method is plastering, which is easy to do with your own hands. A solution of lime and slag is prepared - it is applied to the outside of the brickwork in a layer of 3-4 cm. A layer of plaster will reduce heat loss by 25%. But in order for the plaster to hold up well under the influence of cold and moisture, it should be applied to a mesh.

The sequence of work can be described as follows:

- a reinforced mesh is attached to the brick surface;

- a slag-lime solution is prepared;

- 3-5 layers of plaster are applied to the mesh: the first layer is the most liquid, the subsequent ones are thicker.

Method two

A more effective material for a brick structure is chimney slab insulation.

The sequence is as follows:

- the brick pipe is covered with insulation boards (basalt or mineral wool mats);

- the insulation is lined with asbestos-cement slabs or brickwork;

- the structure is plastered.

This method is more complicated, but the efficiency of this design allows you to retain up to 50% of heat.

How to insulate a metal chimney pipe with your own hands?

In order to insulate a chimney made of metal, a material is used whose design consists of a pair of pipes with different diameters, mounted one inside the other.

Insulation materials such as mineral or balsate wool are placed between the pipes. It is important to choose the correct material thickness. For the inner part of the pipe that runs through the attic, the insulation thickness should be 50 mm, and for the section that is above the roof - 70 mm.

By insulating the pipe in this way, you will solve two problems at once: you will insulate the hood to the required condition, and also protect the structure from accidental fire.

Basalt wool for chimney pipes

Why does the structure collapse?

The chimney is designed to remove smoke and other combustion products into the atmosphere. When burning a stove or fireplace, oxygen vapor accumulates, the amount of which increases in winter due to the intensity of heating. In addition, when burning wood or coal, several types of acids are formed, which also fall on the walls of the structure due to steam condensation.

The result is a chemically aggressive mixture of condensate and acid, which quickly destroys building materials. And this is not the only problem - the formation of steam inside leads to smoke in the oven: you need to constantly ventilate the room. If the amount of steam reaches a critical level and the pressure increases, an explosion may occur.

Insulating the chimney will avoid such consequences. There are several options for insulating structures.

How to insulate a coaxial chimney of a gas boiler?

In winter, many owners of private houses have to deal with the problem that the coaxial chimney freezes. In such situations, you have to look for ways to insulate a coaxial chimney.

However, experts advise resorting to another method - reducing the size of the chimney. If the tip freezes due to condensate entering the air intake pipe from a pipe with combustion products, then the length of the inner pipe must be adjusted to the size of the outer one.

It is best to install two separate pipes and insulate them, because... an insulated coaxial structure is unlikely to save the situation.

As you can see, insulating a chimney is not such a difficult task. You just need to select all the materials correctly and follow the work technology.

Let's sum it up

So, when choosing insulation for a chimney, you should pay attention to several factors that will help you decide on the material.

- Chimney type – brick or metal (asbestos pipe).

- Outlet gas temperature.

- Internal or external chimney.

Do not rush into choosing the material and the method of its installation. Watch the video, we are sure it will help consolidate the knowledge of how to insulate a chimney acquired after reading this material.

General conditions for passing through a wall

In fact, the arrangement of a passage through a wall or through a roof can be done at the design stage. That is, the designer has every opportunity to include in the documentation the junction of the chimney through the wall. At the same time, he must and will be guided by the requirements of GOST, SNiP and SP for fire safety. Thus, the homeowner can be confident that this unit will be completely safe.

When crossing a wall, it is necessary to take into account that there should be no engineering structures near the pipe that are unprotected from heat. The minimum distance to them should be about 400 mm. If it is not possible to ensure this distance, then measures must be taken to additionally insulate the pipe.

The diagram illustrates how to pass a sandwich pipe through a wall

Passage through the wall of a log structure

Before laying a chimney through a wall made of logs or timber, it is necessary to prepare a hole. If the building is just being built, then, directly when assembling the crowns of the log house, using a gas or electric saw, cut a piece of log or timber in the laid crown. Its size must exceed the diameter of the chimney.

If you decide to go through the wall using a round hole, then before you start making it, it makes sense to drill a center hole; its presence will allow you to drill using core drills or “ballerina drills”.

Note: When arranging a junction through the wall of a frame-panel house, it makes sense to perform preliminary drilling and then mark it. The hole can be made using a ballerina or an electric jigsaw.

Passage through the wall of a building made of logs is carried out in the following ways:

- you can use a telescopic unit, that is, several pipes made of heat-insulating material and with a diameter exceeding the chimney. In this case, the pipes must be inserted into each other;

- the chimney can be routed through the wall, without the use of additional pipes, but the space between the walls and it must be lined with thermal insulation materials, such as basalt wool.

Passage through a brick wall

For arranging a passage through a wall built of brick or blocks with different fillers. Before carrying out its penetration, it is necessary to carry out markings. For these purposes, it is advisable to use a laser measuring tool. In this case, errors will be minimized. When making a hole, you must remember that such deformation of the load-bearing wall can lead to the appearance of cracks. Therefore, builders must take measures to prevent their formation, for example, install a pre-prepared frame in it, which will prevent the wall structure from sagging.

- The installation itself is carried out in several operations:

- a pipe must be installed at the outlet of the boiler;

- install a tee with a valve built into it;

- After installing the tee, pass a sandwich pipe through a pre-prepared hole and connect it to the tee.

The space around the pipe must be filled with fireproof material. It is necessary to install shields at the entrance and exit of the pipe to cover the transition. This shield can be made in several modifications, for example, it can be made of an asbestos sheet and a sheet of stainless or galvanized steel attached to it on top.

Subsequently, the chimney can be assembled like a children's construction set. After the wall has been passed, work begins on attaching the chimney to the wall.

The homeowner, when installing a chimney from sandwich pipes with his own hands, must understand that assembling a gas exhaust system is a very responsible undertaking and the safety of the building structure and the residents living in it largely depends on it.

Important points in the construction of a furnace

In order for the water circuit to function with maximum efficiency, not only the heating water system must be properly designed, but also the furnace itself. Just maintaining order is not enough

Full compliance with furnace construction technology is important

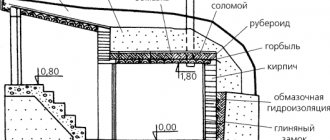

Foundation

Its type and thickness depend on the size of the stove. It is recommended to install a massive classic Russian stove on a solid strip foundation. For smaller modern heating structures, a concrete pad one and a half ten centimeters thick, sometimes on a frame made of reinforcement, is sufficient.

Brick

For external walls, ceramic refractory bricks are used. For the base - his own, possibly second-hand. Experts recommend that you always line the inner surface of the firebox with fireclay stone. For a more presentable appearance of the facade, it can be laid with facing bricks right away or this finishing can be done later.

Solution

The mortar for masonry is prepared traditionally: sand is mixed with clay, diluted with water and a little cement is added for strength. You can purchase a ready-made cement-based masonry composition with special additives.

Masonry

The main condition for a strong structure is the presence of high-quality ligation of seams. They must not coincide under any circumstances. It is ideal when the seams of the bottom brick row fall under the middle of the bricks lying in the next row. To do this, starting the rows, alternate whole bricks and their halves.

Stoves with a water heating body have a fairly simple and understandable design. They are popular due to their low cost and ease of use. And if you don’t like using natural gas to heat your home or don’t have access to a gas network, this heating option should be considered first. Built by a good craftsman, such a stove never disappoints its owners.

Conclusion

In conclusion, I would like to note that insulating the chimney will not solve all problems. After all, the chimney itself constantly needs timely maintenance. It is necessary to periodically inspect it, clean it and maintain it in proper condition.

If necessary, make proper repairs, which you now know how to do yourself. This will be the key to its high-quality, uninterrupted operation. And for you - a warm, cozy and safe home.

In the video presented in this article you will find additional information on this topic.

What material to use

First of all, it is important to choose a material that will not contain toxic substances, can safely contact the pipe, and is not affected by fungus

It is recommended to note that the material can be found on construction markets in the form of rolled rolls, sheets, slabs and mats

Thermal insulation cylinder

The use is relevant if the chimney is in the form of a metal structure. It consists of two pipes of different diameters: the first is smaller, acting as a chimney pipe.

Thermal insulation cylinder

Stainless steel is used as the main material. It withstands the effects of acidic substances, which often form on the inside of the chimney. To carry out lining, the pipe must have a large diameter of 6-10 cm, which will act as a casing. Basalt insulation is poured into the free space. Some craftsmen make this material themselves at home, or purchase it at construction markets.

Mineral wool

The material is suitable for insulating chimneys and stoves. This is due to the fact that the insulation is able to favorably withstand even the highest temperature fluctuations, exposure to chemicals, and is also used as internal or external insulation.

There are 4 types of insulation depending on the use of material, structure, length or thickness: slag wool, fiber, stone, basalt. Thermal insulation and chemical properties depend on the structural features. If you plan to carry out furnace insulation from the outside, it is better to use basalt mineral wool. This is a material that is optimally suited for brickwork, since basalt has low thermal conductivity, is heat-resistant, and does not contribute to the spread of mold or mildew.

Specialists cut the sheets to suitable sizes. The material is wrapped around the pipe, and then the insulation is secured with wire. If it is necessary to install sheets of greater thickness, then a metal grid is used, which is fixed throughout the entire area.

Gaps must be sealed. As a rule, a special substance or tape is used for this purpose. Brick is suitable as cladding.

EPPS

The optimal solution is if the chimney is made of brickwork. It has increased durability and is completely waterproof. Category G2 includes Technoplex, Penoplex. Thermal insulating and fire-resistant classes G3, G4 are considered to have lower ratings. For use in coal or wood stoves. The inlet gas temperature can reach 600 degrees. Non-flammable glue is often used for polystyrene foam boards. Stripes and free space are eliminated by insulation.

EPPS

Plaster

A brick chimney can be insulated from the outside using plaster and a special metal mesh. This option is considered one of the most common, since heat loss ranges between 25%. First you need to secure the reinforcement and apply a layer of plaster on top of it. It's better to use several layers.

As soon as the composition dries, to add aesthetics, it is recommended to paint it so that the structure is in harmony with the main color of the building. It is also recommended to use an anti-corrosion compound.

Thermal insulation made of basalt

It is customary to distinguish two types: cylindrical (where the internal diameter ranges from 18-89 mm, the cuts are longitudinal, which allows for convenient installation), semi-cylindrical (the range of used diameters is more than 89-273 mm, consists of two shells).

To carry out installation, you do not need to remove part of the chimney. For this, bandages are used to make the longitudinal joint isolated. In addition, there is no need to use a box for protection.

Stainless steel casing

Suitable for metal or asbestos pipes, the design will be the best choice. The diameter must be at least 5 cm larger than the main pipe. Basalt insulation is used to fill the empty space. If there is empty space left, it is usually filled with cement. It helps protect the pipe from sudden temperature changes.

Stainless steel casing

Cinder concrete

Using the material, parallel walls are built in relation to the main frame. However, a small space should remain during the work. The seams must be reinforced with wire. The free gap is filled with clay or gypsum.

Choosing a thermal insulation method depending on the chimney material

Gone are the days when chimneys were made primarily of brick. With the advent of gas and solid fuel boilers, they began to be made of metal, and asbestos pipes are also not uncommon. Insulation of different pipes requires an individual approach.

Insulation of metal pipes

To insulate the pipes of fireplaces and stoves that are not the main source of heating, but are used periodically, it is enough to plaster the pipe. This method is most often used for brick pipes, but is also applicable for metal ones.

For chimneys of furnaces and heating boilers, a different method is used. These are so-called sandwich chimneys. Such designs are available for sale, but they are not cheap. If you have a limited budget, you can make them yourself.

You should not use a galvanized pipe for the chimney. When exposed to high temperatures, zinc evaporates, forming toxic compounds that are harmful to health.

Asbestos pipes are also insulated using the same principle. In addition to mineral wool, you can use bulk insulation.

Thermal insulation of asbestos pipes

Mineral wool is considered the best insulation for asbestos pipes. This material is most often covered with a moisture-proof protective film, which is very important for asbestos because of its ability to absorb moisture. For thermal insulation with bulk material, a protective casing must be installed around the pipe, into which the insulation must be poured. To prevent moisture from entering from above, the gap between the pipe and the casing is filled with cement solution.

Insulation of brick chimneys

Brick, like asbestos, can become saturated with moisture, so it is important to think not only about insulation, but also waterproofing. The simplest way is plastering, but it is much more reliable to do this with mineral and basalt wool.

A brick chimney can be protected and insulated by plastering

Insulation with slag concrete slabs and mortar or panel materials is also suitable.

The method of insulation needs to be thought out at the stage of constructing the chimney; in some cases, it will be necessary to lay wire for fastening into the masonry in advance so as not to spoil the brick.