Draft in the smoke ventilation system of a boiler or furnace is an independent complex aerodynamic process, the movement of fuel combustion products from an area with a high level of air pressure in the furnace to the lowest area at the exit of smoke into the atmosphere. Therefore, the draft in the boiler smoke path is considered a particularly important indicator when designing the heating of a private house. The diameter of the chimney for the stove determines the speed of movement of the gas-air environment and, as a result, creates draft in the chimneys. It must be sufficient to ensure complete combustion of fuel in the firebox.

Why do you need to know the diameter?

Beginners do not understand the importance of the chimney cross-section for a stove and why it is so important to correctly calculate not only the internal size, but also the height of the pipe. When developing an individual project for an autonomous heating system for a residential or industrial premises, the level of traction and performance of the unit depends on the accuracy of the data.

Inexperienced builders can make a pipe with a large or insufficient cross-section. In any such option, the operation of the heating device is disrupted, and you are simply throwing money away. For optimal operation of the home heating system, it is important to carry out an accurate calculation and familiarize yourself with the recommendations of regulatory documents.

Important! Fire safety at home, work productivity, comfortable temperature - the solution to all these issues depends on the correct determination of the size and length of the chimney.

The meaning of chimney parameter calculations

If the boiler equipment is incorrectly calculated, a reverse draft effect will occur when flue gases are not discharged into the atmosphere, but enter the living rooms. In such a situation, there is even the possibility of creating a fire hazard if hot smoke enters the room. As a result, when building a chimney, it is important to accurately calculate its geometric characteristics, which guarantee the creation of a working draft sufficient to completely remove flue gases and ensure a high efficiency of a heating unit running on natural fuel.

The operation of a thermal energy source operating on solid, liquid or gaseous fuel depends entirely on the following parameters of the chimney:

- Pipe length. First, you will need to establish the greatest height of the building, as well as the size in meters to the roof ridge at the point where the design chimney is planned to be installed. As a result, all the most important parameters of the chimney system under construction are associated with this indicator. It must be taken into account that excessively high smoke channels will literally “eat up” the vacuum in the smoke ventilation tract; as a result, the source of thermal energy will not be able to efficiently burn the fuel from the pipe and black smoke will pour out of all the cracks. Exorbitantly low pipes in relation to the roof are no less dangerous.

- Chimney diameter for a wood-burning stove. With regard to this size, it is not the specific number that will need to be taken into account, but rather the geometry of the chimney. Stove-maker specialists say that a high-quality smoke exhaust system, functioning according to all the laws of aerodynamics and thermal engineering, has a circular cross-section. In this case, soot deposits are not retained in the channels to such an extent, so such a system requires less cleaning. Regarding the specific size, it should be selected according to the cross-section of the main outlet pipe of the boiler or other heat source. The use of larger or smaller pipes is not recommended by the manufacturer due to the high risk of depressurization.

- In addition to determining the D of the pipe, it is necessary to take into account the traction force. To do this, Bernoulli's law is used, data on the temperature of the external and internal air, as well as the pressure of the environment, is entered into the formula. The final calculation takes into account the total loss of air pressure at two points: in the combustion chamber and at the exit from the chimney. The final size of the draft for furnaces must exceed all pressure losses in the gas-air path.

When calculating the diameter of the chimney for a stove, the length of the pipe is taken into account

What should be the diameter of the chimney for a stove?

The size of the chimney can be calculated in several ways. The simplest one is to determine the cross-section of the chimney depending on the size of the combustion compartment. Solid fuel consumption is determined by this characteristic, and based on these data, the volume of exhaust gases can be determined.

If you have an open firebox and the chimney is made of a round steel pipe, these values should be in a ratio of 10 to 1. For example, the dimensions of the combustion chamber are 50/40. Such a stove must be equipped with a chimney with a cross-section of 180 mm.

If we make a pipe from brick, its internal size should exceed the size of the ash pan or ash door by one and a half times. The minimum size of a square cavity for gas removal is 140/140 mm.

What are pipes made of?

There are four main building materials from which chimney pipes are made: galvanized steel, ceramics, stainless steel, clay-based brick.

Square chimneys, built of brick in accordance with all standards for furnace work, are characterized by high fire safety and the absence of the ability to accumulate soot deposits on the walls. In addition, the material is quite heat-intensive and strong by mechanical standards. The only drawback of brick is its susceptibility to destruction due to the destructive effects of chemical reactions between water and sulfur oxide.

Steel chimneys are convenient because they allow you to create a channel of any configuration. The disadvantage is the short service life, since the metal tends to burn through and corrode. Stainless steel elements are more stable.

Pipes made of ceramic material can easily withstand elevated temperatures and the aggressive environment of settling condensate. It is difficult to assemble such a structure due to the large mass of the elements, where a frame of steel rods is used for strength.

Sandwich chimney

Asbestos-cement pipes

Steel chimney

Brick chimney

Calculation methods

Exact method + formula

Calculating a chimney for a stove is not a task for beginners. It is better to entrust such work to professionals. But if you decide to calculate this parameter yourself, you will need knowledge of basic data and several formulas:

- To determine the volume of exhaust gases, it is important to know the power of the heating unit. For calculations we use the formula:, where:

- B is the combustion rate coefficient of solid fuel. This value is determined based on the data in table No. 10 of GOST 2127;

- V – level of volume of fuel burned. This value is indicated on the tag of the industrial device;

- T – heating level of exhaust gases at the exit point from the chimney. For wood stoves – 1500.

- The total area of the chimney. It is calculated based on the ratio of gas volumes, this value is designated “Vr”, and the speed of their movement in the pipeline. For a household wood-burning stove, this number is 2 m/sec.

- The diameter of a round pipe is calculated using the formula – d² = (4 * Vr) / (π * W), where W is the speed of gas movement. It is better to perform all calculations on a calculator and carefully enter all values.

Calculating the optimal amount of thrust

This operation is performed to control the calculations of the optimal height and cross-section of the chimney. This calculation can be carried out using 2 formulas. We will present the basic, but complex formula in this chapter, and we will present the basic, simple formula when performing a trial data calculation:

, Where:

- C is a constant coefficient equal to 0.034 for wood-burning stoves;

- The letter “a” is the value of atmospheric pressure. The value of natural pressure in the chimney is 4 Pa;

- The height of the chimney is indicated by the letter “h”.

- Т0 – average level of atmospheric temperatures;

- Ti is the amount of heating of the exhaust gases as they exit the pipe.

Example of calculating the cross-section of a chimney

We take as a basis:

- the potbelly stove runs on solid fuel;

- within 60 minutes, up to 10 kg of hardwood firewood burns in the stove;

- fuel moisture level – up to 25%.

Let's look at the basic formula again:

The calculation is carried out in several stages:

- We perform the action in brackets – 1+150/273. After calculations we get the number 1.55.

- We determine the cubic capacity of the exhaust gases - Vr = (10*10*1.55)/3600. After calculations, we obtain a volume equal to 0.043 m3/sec.

- The area of the chimney pipe is (4*0.043)/3.14*2. The calculation gives a value of 0.027 m2.

- We take the square root of the chimney area and calculate its diameter. It is equal to 165 mm.

Now we determine the amount of thrust using a simple formula:

- Using the formula for calculating power, we calculate this value - 10 * 3300 * 1.16. this value is equal to 32.28 kW.

- We calculate the level of heat loss for each meter of pipe. 0.34*0.196=1.730.

- The level of gas heating at the exit from the pipe. 150-(1.73*3)=144.80.

- Atmospheric gas pressure in the chimney. 3*(1.2932-0.8452)=1.34 m/sec.

Important! Using the data from your furnace, you can perform the calculation yourself, but to be on the safe side, it is better to consult with specialists. The safety of your home and the economical operation of heating devices depend on the correctness of the calculation.

Swedish calculation method

The size of a chimney for a stove can be done using this method, but the main purpose of the Swedish method is to calculate the chimneys of fireplaces with an open firebox.

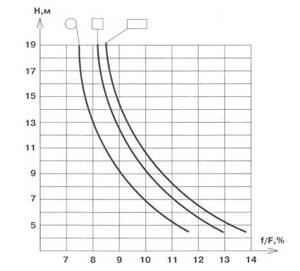

In this calculation method, the size of the combustion compartment and the volume of air in it are not used. To determine the correctness of the calculation, use the following graph:

What is important here is the correspondence between the area of the combustion chamber (“F”) and the opening of the chimney (“f”). For example:

- firebox dimensions 770/350 mm. We calculate the area of the compartment - 7.7 * 3.5 = 26.95 cm2;

- chimney size 260/130 mm, pipe area – 2.6*1.3=3.38 m2;

- We calculate the ratio. (338/2695)*100=12.5%.

- We look at the value 12.5 at the bottom of the table and see that the calculation of length and diameter was made correctly. For our stove it is necessary to build a chimney 5 m high.

Let's look at another example of calculation:

- firebox 800/500 mm, its area is 40 cm2;

- chimney cross-section 200/200 mm, area 4 cm2;

- We calculate the ratio (400/4000)*100=10%.

- Using the table, we determine the length of the chimney. In our case, for a round sandwich pipe it should be 7 m.

Careful calculations must be made before purchasing materials.

Below we describe how to calculate a chimney for a gas boiler. Formulas for calculating the cross-section and power of the heater are presented. In addition, you will be able to superficially familiarize yourself with the types of materials used for the construction of chimneys and their designs, as well as the requirements for the exhaust system.

First, let's look at the materials of pipes for the chimney of a gas boiler. Brick ones have not been used for these purposes for a long time. This is due to the fact that the smoke released during combustion has a relatively low temperature, about 150 degrees. Based on this, its speed in the system will also be low. The smoke has time to cool down to the dew point temperature and condensation forms along the internal diameter of the chimney of the gas boiler. Moisture has an extremely destructive effect on brick. If it is possible to use a brick structure for the above-mentioned type of equipment, then only with a liner inside. Prefabricated structures are the most widely used. These are metal double-circuit pipes and three-layer ceramic ones. Therefore, you should choose one of them as a pipe for the chimney of a gas boiler.

| Monday | Open 24 hours |

| Tuesday | Open 24 hours |

| Wednesday | Open 24 hours |

| Thursday | Open 24 hours |

| Friday | Open 24 hours |

| Saturday | Open 24 hours Now open |

| Sunday | Open 24 hours |

What to do if the chimney cross-section is square?

Cylindrical chimneys, especially after the advent of sandwich pipes, are the most common types of devices. But when building a brick kiln, you have to lay out a square or rectangular shape.

In such chimneys, turbulence is formed, which prevents the normal passage of exhaust gases and reduces draft. But for wood stoves or fireplaces, rectangular pipes remain the most popular shape. Such devices do not require an increased level of exhaust gas extraction.

The calculation of a chimney for a wood-burning stove with a square or rectangular cross-section is made taking into account the ratio of the dimensions of the pipe to the size of the blower hole on the stove. This proportion is 1/1.5, where 1 is the internal cross-section of the pipeline, and 1.5 is the dimensions of the blower or ash pan.

Why are solid fuel devices considered?

It's simple - there are always more problems with them in these matters compared to gas ones. Let's explain why:

- First of all, gas heating appliances are almost always factory-made products. That is, they must have a pipe of a certain cross-section for connection to the chimney. The cross-sectional area of the channel is also specified in the technical documentation of the model. That is, everything is quite simple - it is not allowed to narrow the channel in any of the sections of the upward chimney.

Factory-assembled boilers or stoves always have a pipe for connecting the chimney. That is, there is no longer a problem with the cross-section of the chimney - it should be no less than that specified in the technical documentation.

- The temperature of the gas combustion products leaving the chimney is disproportionately lower than that generated during the combustion of wood or other solid fuel.

- It is also difficult to compare the volumes of gas mixtures formed during the combustion of “blue” and solid fuels. The difference here is quite significant!

But solid fuel heating devices, stoves or boilers, are very often created independently. Or they are “inherited” from the former owners of the house. And here it is never superfluous to check the parameters of the chimney connected to such a device.

However, what concerns the height of the pipe and checking draft can probably be fully attributed to gas heating equipment. The cross section is known, but it wouldn’t hurt to check the rest.

But let's start with the section.

What should be the height of the chimney pipe for a stove?

Calculation of this parameter allows you to avoid the occurrence of backdraft and other possible troubles. This issue is regulated by the rules of SNiP and other documents.

Why is this parameter needed?

In order to understand the importance of this factor, let's take a closer look at several physical laws and the consequences of incorrectly made chimneys. As heated gases pass through, the temperature drops, but warm air or gases always rise.

At the outlet of the pipe, the temperature drops even more. Exhaust gases located in a pipeline with a reliable layer of thermal insulation have a high temperature and a column of heated smoke, rising upward, increases the draft in the firebox.

Let's analyze the situation - we reduce the internal cross-section of the pipe and increase the height of the pipe above the roof ridge. If you think that the volume of heated gas increases, the cooling time of the smoke increases and the draft increases, this statement is only half true. The traction will be excellent, even with a large surplus. Firewood will burn quickly and the cost of purchasing fuel will increase.

An excessive increase in the height of the chimney can cause an increase in aerodynamic turbulence and a decrease in the draft level. This is fraught with the occurrence of reverse draft and smoke escaping into living spaces.

SNiP requirements

The length of exhaust gas exhaust pipelines is regulated by the requirements of SNiP 2.04.05. the rules require compliance with several basic installation rules:

- The minimum distance from the grate in the firebox to the protective canopy on the roof is 5000 mm. Height above the level of the flat roof covering 500 mm;

- the height of the pipe above the roof slope or ridge must correspond to the recommended one. We will talk about this in a separate chapter;

- if there are buildings on a flat roof, the pipe should be higher. In this case, with a large pipe height, it is secured with braces made of wire or cable;

- if the building is equipped with a ventilation system, their height should not exceed the exhaust gas outlet hood.

Self-calculation method

How to independently calculate the height of the smoke channel, for this you will need to perform a calculation using the formula:

, Where:

- “A” – climatic and weather conditions in a given region. For the north, this coefficient is 160. You can find the value in other areas on the Internet;

- “Mi” is the mass of gases passing through the chimney in a certain time. This value can be found in the documentation of your heating device;

- “F” is the time for ash and other waste to settle on the walls of the chimney. For wood stoves the coefficient is 25, for electric units - 1;

- “Spdki”, “Sfi” – level of concentration of substances in the exhaust gas;

- “V” – exhaust gas volume level;

- “T” is the temperature difference between the air coming from the atmosphere and the exhaust gases.

Important! Independent calculation will require finding a large number of quantities and performing complex calculations. Therefore, we recommend turning to professionals.

There is no point in giving a trial calculation - the coefficients and other values will not be suitable for your unit, and extracting square roots will require downloading an engineering calculator.

Table “Height of the chimney above the ridge”

The table of the height of the chimney above the roof structure will help you determine the size of the pipes without making complex calculations. First, we will analyze the selection of pipe length for flat roofs.

| Selection of pipe length for flat roofs. | Min. pipe height in mm |

| There are no parapets or other structures or devices on the roof. | 1200. |

| A protective curb or other structures are built on the roof and the distance to them is up to 300 mm. | 1300. |

| Excess over other ventilation ducts | 500. The minimum distance to the ventilation shaft is 5000. |

| For pitched types of roof structures. | Min. pipe height in mm |

| The chimney exits to the roof at a distance of 1500 mm from the ridge. | 500. |

| The pipe is located at a distance of 1500-3000 mm from the ridge. | The pipe is brought out to the level of the roof ridge. |

| The distance from the ridge to the passage of the exhaust pipeline is over 3000 mm. | We set aside 100 from the ridge cavity. The top of the pipe should be at the level of this line. |

Requirements for the installation of a chimney for a gas boiler

- there must be good traction;

- reliability and durability;

- corrosion resistance;

- resistance of the exhaust pipe for a gas boiler to chemically aggressive environments;

- ability to withstand high temperatures.

The height of the pipe depends on the cross-section and power of the equipment

In modern construction, only round or oval chimneys are used as outlets for fuel combustion products in heating systems. Almost no soot settles on their walls. It is also important that the surface of the internal diameter of the chimney pipe for a gas boiler is smooth. Structures with a square cross-section are more problematic to operate. Soot gets packed into the corners, then you have to get it out of there somehow, this causes a lot of hassle. Ideally, if you constantly use the heating system, you should inspect the exhaust pipe for the heating boiler twice a year. It is carried out by a knowledgeable person, a master. If the cross-section is round, then you can get by by calling a specialist only once a year.

Engineering communications service Heating, water supply, drainage, sewerage systems

around the clock tel: 8

INSTALLATION, REPAIR, MAINTENANCE, MODERNIZATION, REPLACEMENT

Be sure to carry out preventive maintenance every year if we are talking about the house in which you live permanently. Call a professional before the start of the heating season. Otherwise, the soot, having accumulated, will reduce the diameter of the chimney for the gas boiler.

Determining the size of the chimney for an open type gas boiler

Unlike the previously mentioned units, such devices receive combustion air from the premises where they are located. To determine the transverse parameter, use two simple methods:

- On the installed boiler, they are guided by the size of the pipe for removing combustion products. The cross-section of the chimney should be equal to it or slightly larger.

- When there is no boiler yet, but its characteristics are known, or a chimney is installed for two heaters, its cross-section is determined by multiplying the power by 5.5. The result is obtained in cm2. For calculations, the passport parameter is taken, not the thermal parameter, which can be an order of magnitude larger.

To calculate the diameter of the chimney, use the formula for the area of a circle S = πr². Then r = √S/π. Substituting the previous result, you get the radius in cm. Multiplying by 2 and 10, you determine the diameter in mm. The calculated result is adjusted according to the table above.

Chimney installation

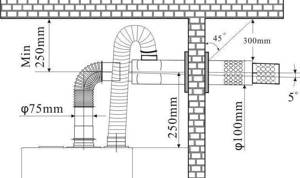

If you decide to install a coaxial chimney for a gas boiler, then you need to study the basic installation requirements:

- the height of the horizontal pipe must be more than one meter, the vertical chimney - five meters;

- the pressure with which gas is supplied into the pipe should not exceed 0.03 kgf/cm2, this parameter is indicated by manufacturers of heating installations;

- the possibility of horizontal installation only provided that the boiler produces up to 30 kW, with

- for a larger indicator, it is necessary to install only a vertical chimney with an exit through the roof;

- When installing the structure, you need to calculate the length so that the connecting elements do not intersect with partitions, walls, or roofing.

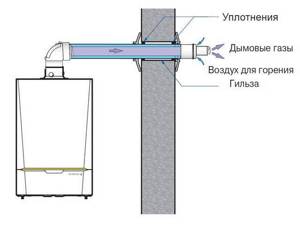

Installing a coaxial chimney on a heating stove

The most commonly used is a coaxial chimney for a gas boiler with a closed combustion chamber. Such installations are characterized by forced removal of gases and combustion products, since their design does not provide for the presence of reverse draft. Floor-standing boilers are usually installed with a closed chamber; a coaxial chimney can be connected from above, from the sides and, less often, from below.

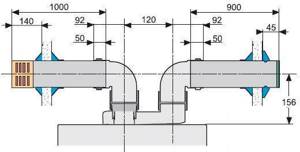

The requirements for installing a chimney on such structures are increased, since horizontal removal of combustion products is less effective than vertical, and when installing a chimney, a certain slope must be observed. For such boilers, it is optimal to use pipes with a diameter of 60 mm for the internal and 100 mm for the external. The design can be supplemented with special bends, which are located at angles of 90° and 45°, but during installation it should be taken into account that such bends will significantly reduce the total length of the chimney.

A right angle will shorten the length by one meter, and a slope of 45° will shorten the length by half a meter.

Overall dimensions of a horizontal coaxial chimney made of enameled steel

For a device with a closed combustion chamber, you can use coaxial pipes made of enameled steel - external, and aluminum - internal

Vertical chimneys are used less often for such heating devices; they are installed when it is important not to spoil the facade of the building or to ensure environmental friendliness, since smoke escaping above the roof dissipates faster and unnoticed by humans

The installation of a coaxial chimney must be preceded by preparatory work:

- calculation of footage and number of required elements;

- preparation of holes in the wall, ceilings, roof, along the entire length of the chimney;

- It is necessary to provide for the possibility of installation at a slight slope, this is necessary so that the formed condensate drains freely.

Equally important are the requirements for the height of the chimney pipe - it should be 1.5 meters higher than the level of the combustion chamber, such placement will create more efficient draft and reduce the likelihood of fires.

Elements of coaxial chimney pipes with gaskets

When assembling a coaxial chimney, it is advisable to use rubber gaskets at the joints; thanks to them, the structure will be more airtight and there will be no risk of smoke at all.

If you take into account all the requirements when installing a coaxial chimney and carry out all the steps correctly, you can ensure long and efficient operation of heating installations, whether they are floor-mounted, wall-mounted or built-in.

Optimal chimney diameter parameters

A complete calculation of a chimney is quite difficult for a non-specialist to perform. To do this, it is better to use the advice of heating engineers on choosing the optimal indicator:

- With a maximum thermal power of the heating device of up to 3.0 kW, pipes with a diameter of 140 mm will be sufficient.

- If the boiler has a power of up to 4.5 kW, the optimal dimensions of the chimney are no less than 140 mm.

- When using a high-power boiler device of 7.5 kW, the diameter of the chimney pipe must be at least 150 mm.

A user who knows the thermal power of the boiler can make an approximate calculation of the chimney using the optimal values and coordinate it with the indicator of the boiler outlet pipe. You can also refer to the manufacturer's instructions, which regulate the installation diagram with all the parameters of the smoke ventilation system. In cases where the heating capacity is unknown, calculations are made based on the hourly consumption of fuel burned by the installation, or this indicator can be determined from the passport for the heat generator.

An equally important indicator for accurate calculation of the geometric parameters of the chimney is the temperature of the flue gases at the entrance to the pipe part. This parameter is related to the type and quality of the fuel burned and the efficiency of the boiler heating surfaces. For properly configured equipment it should be within 150-200 C.

For fireplaces, the indicator of the optimal speed of gas movement through the smoke exhaust system is also important; usually this indicator is taken to be 2 m/s with an indicator of natural stove draft of 4 Pa per 1 m of chimney.

Date: September 25, 2021

How to choose a chimney?

Coaxial chimneys are part of the gas boiler delivery package and are manufactured by the vast majority of boiler equipment manufacturers.

The diameter of the coaxial pipeline is indicated as the value for the inner and outer pipes, written as a fraction (for example, 110/150). To determine the required diameter, you do not need to perform any calculations, since the selection tables are indicated in the manufacturers' instructions.

In addition to the diameter of the sections, the determining parameter of the chimney is its total length. This value is determined as the sum of the lengths of the components of the chimney and should not exceed the limit value specified in the installation instructions for the system. The maximum permissible length is measured in equivalent meters (Em). For chimneys that serve boilers without a fan, a minimum length requirement is put forward to create natural draft.

Passage of a horizontal section through a wall.