When undertaking a major renovation, we often think about creating a comfortable microclimate and maintaining an acceptable optimal temperature. A pressing issue for most families where there are small children playing and crawling on the floor.

One of the low-budget solutions seems to be cross-linked polyethylene - water heated floor Rehau . At the present stage, the technology of laying heated floors has become widespread. Due to the advent of temperature control and management systems, as well as thanks to Rehau plastic pipes, warm water floors are being introduced as a complete and independent heating system. Installing a heated floor requires extensive knowledge, calculations and time.

Our company is ready to professionally provide installation services for the Rehau heating and sewerage system in country cottages or townhouses.

Make the right decision based on our installation prices and decent experience.

Warm floor Rehau

Warm floors are convenient and comfortable

Rehau technologies are of excellent quality and are designed in accordance with international standards for heating equipment. The cost-effectiveness and reliability of the systems allows you to reduce installation costs by up to 50% and reduce the amount of consumables by up to 25%.

All systems for monitoring, regulating the supply of water and electrical energy can reduce the cost of operating a heated floor by up to 60%.

Advantages and disadvantages

Advantages:

- Electrical safety. This is one of the most important advantages. Radiation protection is provided by various components of the system. The most important element is the cable frame, made of high quality copper. Special insulating material is designed to prevent overheating and destruction of the cable.

- System reliability. When manufacturing the design of the water floor system, the most modern and high-quality technologies are used, providing excellent performance characteristics and a guarantee of long service life. The main feature of the cable is the presence of a special core, which is reliably protected by reinforced Kevlar. This element has excellent hardness parameters when compared with the rest of the structure, therefore it provides reliable insulation from damaging factors. During operation, there is no need for regular maintenance of heated floors. After their purchase and installation, repairs will not have to be carried out for a long time.

- Uniform heating distribution. Flooring completely replaces the need to purchase additional heating. The temperature during system operation rises evenly throughout the entire space, which allows all users to feel comfortable.

- No contamination. The features of the system eliminate the continuous circulation of air in the heated space, so there is no additional dust or dirt, which makes the use of heated floors most convenient.

Rehau warm floors are suitable for almost any surface

You can install Rehau heated floors in rooms where there may be allergy sufferers, since dust that irritates the lungs does not appear in the space.

What materials are recommended to be used for heated floors can be read here.

Flaws:

- When installing any heated floors, in particular, Rehau, the space is partially cluttered, that is, the total height of each room becomes several millimeters smaller. The developers of Rehau underfloor heating tried to minimize this feature, but upon detailed calculation it becomes noticeable.

- To carry out the correct installation of the system, it is necessary to familiarize yourself with the rules and read the instructions for the use of all fasteners, since some of them are manufactured according to the latest standards.

- Before installing the system, it is necessary to thoroughly clean the coating from previous materials.

Overview of the heated floor system from Rehau:

Peculiarities

Rehau warm floors have become famous all over the world thanks to their reliable pipe design and universal technology for connecting them. Recently, this popular piping system has been improved with a sliding sleeve made of polymer.

You can learn about plastic air ducts for kitchen hoods here.

Rehau heated floors are available as a complete set

When connecting pipes, the exclusive Rehau technology is used on a sliding sleeve, in which there is no need for sealing rings. All sleeves and fittings are designed using new generation systems, therefore they are of high quality and reliability.

Click to enlarge

The materials used for production are special polymer materials, high quality brass, bronze and steel. Shaped elements have increased resistance to coating cracking or erosion.

The connections formed during the installation of the system, with high-quality installation, have a tightness that is maintained for as long as possible. A unified program for the arrangement of shaped elements has been developed. It is allowed to connect Rehau pipes to the general heating system.

Additional items

Installation of the Rehau water heated floor pipeline is carried out using special fasteners.

- Varionova mats are made of polystyrene foam and are equipped with clamps designed for securing pipes. In addition to the main function of facilitating installation, these elements are equipped with heat and sound insulating properties. The mats are fastened together using a connecting strip using the seam method.

Mats with clamps and thermal insulation Rehau Varionova

Panel with Varionova fasteners without insulation

The advantages of using Raufix tires lie in their design features

Rehau water heated floor is a ready-made system, equipped with all the necessary fasteners designed for fixing mats and pipes on mats and panels. These include:

- harpoon clamps designed for fixing pipes;

Tece harpoon bracket for heated floors

Insulating nails and clips for underfloor heating

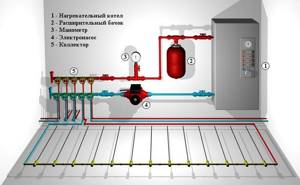

Hydraulic underfloor heating from Rehau is controlled using a distribution manifold, available in various modifications. The most popular among consumers is the assembled manifold, equipped with a thermostat and a flow meter.

Types of heated floors Rehau

The company produces two types of heating systems:

- Electric heated floors.

- Water heated floors.

Click to enlarge

Electric floor

The underfloor heating system is based on SOLELEC. During operation, electrical energy is reorganized to heat the space. A cable is used as a heat generator. It is made of elements that have high resistance, which causes the device to heat up when electric current passes through it.

Reviews about water filters for geyser sinks can be read by clicking on this link.

The kitchen will be very comfortable

The heat generated by the cable not only warms the floor, but also spreads throughout the room, penetrating through it. People hardly notice the difference between the temperature of the floor covering and the air in the room, since it differs by only a few degrees. This has a beneficial effect not only on people’s mood, but also on people’s health.

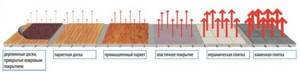

The manufacturer allows almost all common materials as finishing floor coverings, so owners are not limited in their choice of room design.

You can read about sliding doors between the kitchen and living room in this article.

This kitchen will be cozy

The SOLELEC system is very widespread, as it is actively used for the following purposes:

- Floor heating with maximum comfort for people.

- Heating of the room, including as the main source of heat.

How to properly connect the Rehau system to heating:

Components of an electric underfloor heating system

Heating mats and cables.

The entire branched system is based on the principle of constructing cables using a two-core shielded pattern. This ensures maximum protection from electromagnetic fields for users. The mat has a thickness of 3.5 mm. It is buried in a layer of tile adhesive or a specially created thin screed. The mats are equipped with a self-adhesive backing. Thermostats. There are standard and more advanced models in which thermostats can be adjusted both by the insulation of the floor and by the temperature of the air masses in the room. Sometimes it is possible to set special heating modes, in which the temperature is adjusted depending on a specific time or date.

Warm floors from Rehau are suitable for almost any surface

Installation kit. It is used when installing floor coverings for warm electric floors. The set contains the following elements:

- Socket box for installing a thermostat.

- A protective tube with an aluminum tip for installing a special sensor that constantly detects the temperature of the coating. Aluminum has a high thermal conductivity, which allows you to easily and accurately determine the exact temperature, and, if necessary, remove this element from the floor for repairs and maintenance. In this design, all of the listed indicators are at a higher level than when the sensor is located in a corrugated pipe.

- A 90-degree rotation lock for the special temperature sensor tube, which serves as its protection and is located in the gap between the floor and the wall.

- Corrugated pipe used for installing a cold cable in a wall structure.

Click to enlarge

Advantages:

- The main advantage of two-core shielding cables is to minimize the level of electromagnetic radiation. This makes the underfloor heating system completely safe for use in children's rooms, the most frequently visited areas. There is no risk of radiation exposure for animals or potted plants placed on the floor.

- The cables are equipped with Teflon coating and additionally have Kelaur reinforcement. These elements are mechanically strong and can withstand the highest possible temperatures for a long time. This factor is of particular importance for system elements, the removal of which presents certain difficulties, which does not allow for their timely repair.

- When purchasing an electric underfloor heating system, the client receives separate heating cables and special mats. These elements are small in thickness, so they practically do not change the overall height of the room after the renovation is completed.

Rehau gives a 50 year guarantee

The SOLELEC system can be used in any type of premises, including those with high humidity, so you can install heated floors in all rooms of the apartment and even in industrial buildings.

Laying heated floors under laminate:

Water floor

How to make a collector correctly. Click to enlarge

This is a favorable solution for underfloor heating, which can make the atmosphere in the room more favorable. The design of the heating system pipes allows them to be quickly and easily placed in the floor, without damaging or changing the interior.

When the system operates, constant and soft heat is supplied, which allows for a moderate temperature in the entire room, without creating a contrast between the heating of the floor covering and the environment. A water heated floor is also useful in the summer, as it can be used to lightly cool the room. A smooth transition of the overall temperature down several degrees is ensured, without the appearance of drafts or pockets of sudden cooling. This procedure is carried out practically free of charge, since the system in this case works very economically.

The water heated floor is constructed with REHAU RAUTHERM S pipes. They have a characteristic red color and are designed specifically for organizing heated floors. These pipes have an important difference from others, as they are equipped with an internal self-supporting coating mounted from PE-Xa polyethylene film.

An interesting option for how to arrange a collector

This layer is sufficient to guarantee high structural strength and resistance to any temperature. The system allows heating up to 90 degrees and an internal pressure of no more than 6 bar.

Advantages:

- Installation takes 4 times less time than when laying heated water floors from other companies. This effect is achieved through the use of special mats with REHAU Varionova fasteners. This allows you to install REHAU RAUTHERM S pipes reliably and economically.

- The floor is constructed from special blocks with standard parameters. They are installed layer-by-layer along the fixation line and secured using the snap-in method.

- The cost-effectiveness of the coating is manifested due to the complete absence of material waste, since each subsequent row is a continuation of the previous one.

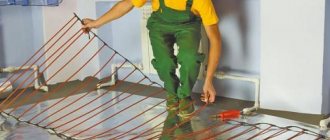

Installation process

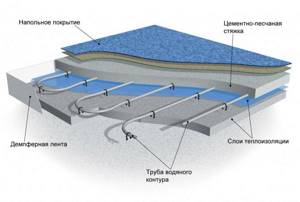

To prevent such heating from causing trouble in the future, its installation should begin with leveling the subfloor by applying special solutions and laying a damper tape, or a special profile for an expansion joint around the perimeter of the room and between the contours of the water-heated floor. In this way, it will be possible to compensate for the expansion that occurs during the heating of the pipe and avoid cracking of the concrete screed.

Laying scheme for water heated floors

When the base dries, thermal insulation in the form of sheets of expanded polystyrene is laid on it. And a polyethylene film is laid on top of it, on which the functions of waterproofing will be assigned. Moreover, thermal insulation is required only if the Rehau heated floor is planned to be laid on a film panel or tires. If mats are purchased, then the need for additional thermal insulation disappears.

Now you can begin installing the distribution manifold, which is connected to the heating boiler. Next, mats or panels with tires intended for securing the pipeline are laid. Pipes begin to be laid by connecting to the collectors. During the installation process, the pipes are secured to the mats using special fasteners.