SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

To ensure uninterrupted movement of the coolant, excluding leaks and pipe ruptures, an open type expansion tank or a closed container is used for heating. The device is designed to compensate for excess liquid as a result of its expansion, which occurs when water is heated. The criteria for choosing a container and the features of installing the tank can be found in this article.

The expansion tank is an integral part of the heating system

Purpose of the expansion tank for water

The expansion tank for the boiler is an essential element of the heating system, which protects it from breakdowns. They can arise as a result of an increase in pressure and volume of the coolant, which occurs when it is heated.

The expansion tank serves to accumulate liquid during system operation

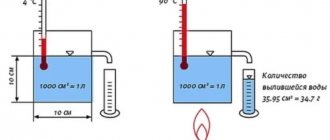

When the temperature of the liquid in the system increases during its circulation, the volume of coolant increases by 4-6%. This is a fairly large value, which can cause a powerful water hammer, since there is no free space in the system of pipes and radiators to collect excess fluid. To accumulate it, an expansion tank is used, where the coolant cools down and returns to the system. This is necessary to replenish its full volume.

Important! If the liquid evaporates, it is necessary to replenish its supply in the system.

If a water hammer occurs, radiators and fittings may break, pipes may rupture, and gaskets may be squeezed out, which will require expensive repairs. The expansion tank is available in two varieties: open and closed. In the first case, the design is represented by a single-volume container that communicates with the atmosphere. An expansion tank for an open-type heating system is installed at the highest point of the system, which will ensure natural return of excess coolant back into the network after cooling.

Closed-type expansion tanks are represented by sealed vessels, in which one part is filled with gas or air, which is under a certain pressure, and the other with liquid. When heated, the coolant enters the expansion chamber, compressing the gas. After the liquid has cooled, it is returned to the system again, and the difference in volumes is compensated by gas.

An expansion tank must be installed in heating systems that are installed over large areas characterized by a significant volume of liquid. An expander is also necessary for long pipe lengths to control the pressure in the system. The tank must be installed when using a gas boiler, since the gas strongly heats the coolant, which contributes to a rapid increase in internal pressure.

Internal arrangement of a 25 l expansion tank

Selection of volume

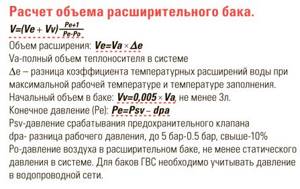

Let's consider separately how to calculate an expansion tank for heating of sealed and open types.

Since the design and principle of operation of such tanks are completely different, although both perform the same function. Open tank

The dimensions of the expansion tank for an open heating system, by and large, determine its volume, since the design of such a tank is quite simple. It is made from sheet metal. There is a hole in it through which the coolant enters and goes back into the pipes. They can also be equipped with an overflow hole through which excess water is discharged into the sewer.

It happens that automatic recharge is supplied to the tank. But the main thing is how the expansion tank in the heating system is designed, or rather, its volume. Let’s take the same system with one hundred liters of water. After heating, the liquid will increase by five percent, maybe more, depending on the temperature in the circuit. It turns out that the volume of the expansion tank for this open heating system should be at least five liters, preferably more. And the calculation of the expansion tank for the heating system comes down to the following algorithm:

- five liters is the expansion of water;

- a couple of liters should always be in the tank - this is to prevent air from entering the circuit;

- We need to make three liters in reserve.

Based on the results of calculating the volume of the expansion tank for heating, ten liters are obtained. By the way, this is the simplest and most common method of selection - ten percent of the amount of water in the circuit.

For closed systems, in addition to the simple, folk method of calculating the volume of the expansion tank of a heating system, there are more accurate methods. To use them, you need to know several meanings. These include:

- How much does the volume of water (W) increase when heated? Answer: five percent. The value is rounded to the nearest whole number without fractions for convenience. If a non-freezing liquid, antifreeze, circulates in your circuit, then this value will be greater;

- how much water is in the circuit (VC). Such data should already be available from the design stage. Since the selection of the heater is carried out based on this value. If it happens that you don’t know how many liters there are, all you have to do is measure. The first thing that comes to mind is to completely drain all the liquid from the circuit and fill it again. The number of liters can be measured in buckets, or you can use a special counter that is installed on the stream;

- What is the maximum pressure the circuit and boiler (DC) are designed for? This value can be read in the heater documents, or on the heater itself. It is unlikely that there will be no documents or information on the boiler body. But if this happens, then the Internet will help you;

- what is the pressure in the air chamber of the expansion tank (DB). This is also indicated in the technical documentation.

To calculate how much expansion tank volume is needed for heating, you should perform a simple mathematical calculation:

OB x VK x (DK + 1) / DK – DB

Based on the results of calculating the capacity of the expansion tank for heating, you will receive the exact value. The question of the appropriateness of such complex calculations remains open. Undoubtedly, according to the results of this formula for calculating the expansion tank of the heating system, the result will be a smaller value than according to the results of the “folk” method. But an error on the larger side is not an error. If the tank is larger than necessary, it’s okay, you just need to configure it correctly.

Expansion tank for open type heating: device characteristics

An open expansion tank for heating has a simple design in the form of a rectangular or cylindrical container equipped with a lid that prevents dirt particles from entering the system. The expander must have a pipe to which the pipe from the heating system will be connected. The container should also be equipped with a drain valve, which will be needed to drain the liquid into the sewer if it accumulates in large volumes.

For safe operation, the expansion tank must have an overflow pipe to drain excess water into the drain network in case the tank overflows. A water supply pipe must also be connected to it to replenish the heating system with water.

Important! Only ordinary water can be used as a coolant in a heating system with an open type expander, since modern antifreezes evaporate quickly, which will require constant replenishment of the liquid and will increase heating costs.

Expansion tanks for open heating can be made of any material. It can be sheet steel, stainless steel or plastic. The main condition is that it must be heat-resistant, since the coolant heats up to high temperatures.

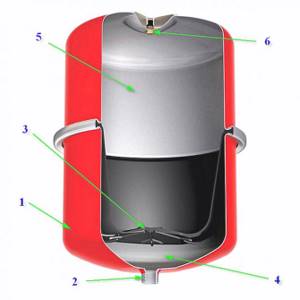

The structure of a membrane-type expansion tank: 1 – metal body, 2 – pipe, 3 – membrane between two chambers of the tank, 4 – chamber filled with coolant, 5 – air chamber, 6 – nipple

Important! Metal containers must be coated with an anti-corrosion compound to prevent premature destruction of the container.

The principle of operation of the expansion tank of the heating system

The principle of operation of the tank is as follows. A liquid heated to a significant temperature begins to increase in volume, thereby increasing the pressure in the system. Excess liquid is squeezed into the expansion tank, where it will remain until it cools, after which it will return by gravity back to the heating system. This process is performed cyclically.

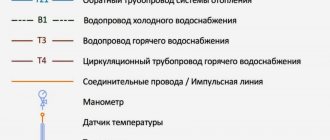

The expansion tank for an open heating system is equipped with several pipes:

- for connecting the expansion pipe through which the coolant flows;

- for a circulation pipe that removes water from the system;

- control pipe designed to regulate the fullness of the system and

- eliminating air from it;

- overflow pipe to remove excess liquid.

The design also provides a spare pipe with a tap through which water is discharged during system repairs.

The principle of operation of the expansion tank of the heating system

If the liquid reaches the maximum level, water will flow through the overflow pipe into the sewer system, if connected to it. If a pipe with a tap is installed on the overflow, it is necessary to periodically check the water level in the tank by simply opening the shut-off valve. When installing an expansion tank for heating, it can be equipped with upper and lower level relays, which can give an audible or light signal when the liquid reaches the maximum level at the overflow point, or the minimum.

Since the expansion tank is not sealed, part of the liquid, arriving in contact with air, evaporates, which requires compensation for normal operation of the system. This occurs with the direct participation of a person who must control the volume of water in the system and, if necessary, replenish it.

Advantages and disadvantages of an open dilator

The main advantages of the expansion tank of an open type heating system are the simplicity of the design and the complete autonomy of the device, the operation of which does not depend on the performance of the system. All processes in it occur according to the natural cycle, without the use of pumping and other equipment. We are also pleased with the affordable price of an expansion tank for open-type heating, which starts from 1,500 rubles.

The disadvantages of such a container include:

- the need for thermal insulation of the tank to reduce heat loss;

- installation of additional pipelines, which spoils the aesthetic appearance;

The expansion tank has a fairly simple design

- the tank is not sealed;

- the need to periodically replenish water in the system as a result of liquid evaporation. Since water comes into direct contact with air, this can cause corrosion of the steel container, which will lead to a decrease in heat transfer, noise and a decrease in its service life.

Helpful advice! It is advisable to use an open-type expansion tank in a heating system for small areas, no more than 100 m², in which case the structure should be one- or two-story.

In a private house, an open-type heating expansion tank is installed in the attic, staircase or specially equipped box, which is installed on the roof of the house. If the building is of sufficient height, it can be placed inside a living space in a bathroom or utility room.

Important! If the expansion tank is installed outside the heated part of the house, the tank should be additionally insulated, which will help reduce heat loss in the system.

The expansion tank is installed next to the heating boiler

Expansion tank from a cylinder

The expansion tank can accommodate both a 50-liter and a 27-liter cylinder. Only in the first case will a section 25-30 centimeters high be sufficient, but in the second case you will have to use the entire balloon.

Therefore, from the point of view of saving material, it is beneficial to use 27-liter or even 12-liter containers. After all, not even the largest 12-liter option can be connected to a system into which up to 240 liters of water have been poured. And the process of transforming the cylinder into a tank occurs according to the following scheme:

First, open the valve and release the remaining gas. Then twist the vanilla and pour off the fragrance, which is added to the cylinders to form the specific aroma of the gas. It is better to drain the fragrance away from your home.

Before work, be sure to bleed off any remaining gas.

Secondly, pour water into the cylinder through the valve hole, filling it to the very top. After 5-10 hours, drain the water away from your home.

Thirdly, cut off the conical part of the valve and weld it onto a fitting of the required diameter with a squeegee - this is how you will design the entrance to the tank. If the welding does not work out, use the valve as an input, using a bellows liner to connect to the system, which can be screwed onto the external fitting of the valve.

Fourth, weld the legs to the cylinder body, orienting the container with the valve down. In this case, the legs from the corners can be fixed using metal screws, using silicone washers for tightness.

Fifthly, cut a hatch with dimensions of 50x50 millimeters at the top point of the almost finished tank (from the bottom of the cylinder). Through the hatch you can pour water into the system or bleed steam or air from the coolant. In open tanks this part must be present.

As you can see, assembling a tank from a cylinder is not so difficult, but there is an even simpler manufacturing method that involves using a polymer container as the base.

Features of an expansion tank for closed heating

The closed expansion tank is a sealed vessel made of steel. It is partially filled with liquid and partially with inert gas, which is pumped through a special valve. Closed expanders, depending on the type of division of the internal volume, are either membrane or membraneless.

In membrane-free containers there is no mechanical separation of space, so the coolant is in direct contact with the gas. To maintain the pressure in a given range, when connecting the expansion tank, a gas cylinder or compressor is used, which is located outside.

Note! Gas supply and pressure control in the system are carried out automatically.

Most modern closed-type expansion tanks are equipped with flexible butyl or ethylene-propylene membranes that separate the internal space of the vessel. They can be dish-shaped or pear-shaped. In the first case, the membrane has the shape of a hemisphere and is mounted in the middle part of the tank. Depending on the temperature of the coolant, it can take on a concave or convex configuration.

Expansion tank for closed heating

A pear-shaped membrane, repeating the shape of the vessel, is attached to opposite ends of the tank. In this case, the coolant entering the vessel does not come into contact with the walls of the cylinder. It fills a flexible membrane, and the space between it and the walls of the tank is filled with gas. This feature of the internal structure eliminates the possibility of corrosion and helps to increase the service life of the device. The price of expansion tanks for closed-type heating with a pear-shaped membrane will be higher than with a disc-shaped membrane, and starts from 3.5 thousand rubles.

Note! The pear-shaped membrane can be replaced with a new one, but replacement of the disc diaphragm is not provided.

The advantages of membrane tanks include compact dimensions, minimal heat loss, which eliminates the need for thermal insulation, the ability to operate at high pressure, minimal risk of corrosion on the walls of the device, and durability. Among the disadvantages, it is worth highlighting the high cost, the need to periodically pump gas into the system, and monitor the pressure in it.

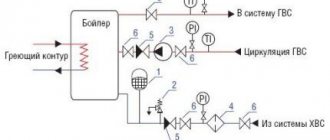

Expansion tank for domestic hot water

In the hot water supply system, which is provided by a boiler connected to the boiler, an expansion tank is installed. Its main task is to maintain working pressure in the network. The expansion tank protects the water supply system from water hammer, protects the pump from increased loads, and protects it from breakdowns.

Expansion tank for hot water supply system

For hot water supply, a closed tank with a pear-shaped membrane is used, which divides the internal space into two parts: air and water. It can be made of rubber, artificial or natural rubber. The first two options have high performance properties. Both materials can withstand different coolant temperatures, up to a boiling state, without losing their original characteristics. A membrane made of natural rubber exhibits a negative reaction when in contact with hot water.

The expansion tank is selected based on the volume of excess water that will flow into it when the pressure in the system increases. Experts advise choosing a tank with a volume of 10% of the volume of the hot water boiler. The hot water tank is mounted between the boiler and the valve, which prevents the backflow of hot water into the cold water supply system. The price of an expansion tank starts from 2.2 thousand rubles.

What are the functions of an expansion tank in a home water supply system

So, first of all, let’s figure out what functions the expansion tank of the plumbing system should cope with.

Such a tank is a reservoir for accumulating a certain supply of water, ready for use. That is, if for some reason the pumping equipment does not work (a common situation for many villages is power outages), the owners have some water reserve at their disposal.

An expansion tank is always a decent supply of water at the required pressure, sufficient for the operation of many plumbing fixtures.

- By installing such a tank, a stable pressure in the system is achieved, which is necessary for the correct operation of plumbing fixtures and household appliances: up to certain limits - even when the pump is turned off.

- The already mentioned water supply and the pressure created in the system make it possible to minimize the number of starts of pumping equipment. This means that the equipment will last longer.

- Finally, any pump start is always accompanied by a sharp jump in pressure in the system, a water hammer, sometimes reaching 10 atmospheres or more. This does not benefit either the pipes or plumbing fixtures. The expansion tank acts as a damper that absorbs such surges, and they become safe for the system.

An expansion tank is often included in the piping of a direct or indirect heating boiler.

Such a tank can also be installed in the circuit of a storage water heating device (boiler), providing autonomous hot water supply. In this case, a compensation function for the thermal expansion of water is also added to prevent the safety valve from operating too often.

But you should not confuse extended tanks for the plumbing system with those designed for heating circuits. Despite all their external similarities, their performance indicators are completely different. This will be discussed below.

Safety group for heating with expansion tank

For a heating system with an expansion tank, the safety group is represented by a set of units that perform a protective function. It consists of three separate devices, which are combined in a special manifold. The group includes a pressure gauge, an air vent and a safety valve.

The pressure gauge is designed to monitor the coolant pressure in the system in order to maintain it at a safe level. It is equipped with two arrows: one shows the working pressure, the other shows the set pressure. An air vent in the form of a Mayevsky tap, which operates in automatic mode, is used to remove air bubbles from the liquid in the heating system. It is mounted at the highest possible height. The safety valve is used to control pressure indicators in the network. If it increases sharply, the valve opens, which helps remove some volume of fluid from the system.

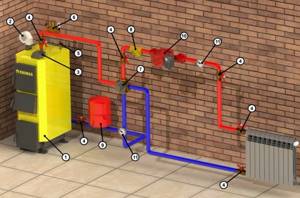

Safety group for heating: 1 - solid fuel boiler, 2 - fan, 3 - shut-off valve, 4 - safety group, 5 - overpressure relief valve, 6 - circulation pump, 7 - filter, 8 - expansion tank, 9 - check valve

The principle of operation of the security group is as follows. When an emergency situation occurs in the heating system, which leads to the cessation of coolant movement, the pressure in it quickly increases. Part of the steam from the hot liquid is captured by an air vent, which is equipped with a special float. He goes down and opens the valve. The steam is quickly released, which helps reduce the pressure in the system.

In the event of ineffective operation of the Mayevsky tap, which contributes to a further increase in pressure, a safety valve is activated, which opens, providing the opportunity to drain liquid from the system until the pressure stabilizes. The protective block is mounted on the supply pipeline, at a distance of more than 50 cm from the heat source. The air vent is installed exclusively in a vertical position. A flexible hose can be attached to the safety valve, through which water will flow in the event of an emergency.

Related article:

Heating meter for an apartment: the best way to save

Where to install and which option to choose. Main advantages of use. Installation features and legal side of the issue. Cost of devices.

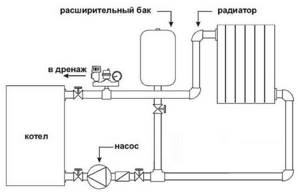

Using a tank in a closed system

For closed-type heating systems, appropriate closed tanks are designed. By their design, they look like a hermetically sealed capsule, consisting of two sections separated by a rubber membrane. That is why professionals quite often call such a unit a membrane expansion tank.

A practical location is suitable for installing a closed tank. The only important point is that the tank cannot be installed immediately behind the circular pump, because such placement will cause excessive pressure drops in the heating system.

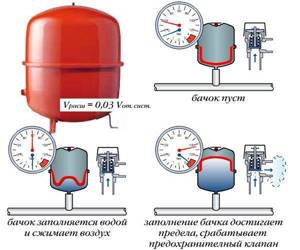

The expansion tanks under consideration operate according to an extremely simple scheme: the coolant is heated, resulting in an increase in its volume, then the excess coolant fills the space in the installed membrane tank. This helps prevent pressure in the system from increasing above the permissible level.

To make the functions and procedure for using the tank more clear, you should consider these points using the example of the most popular unit - a double-circuit boiler running on gas. Closed systems are equipped with additional tanks in situations where the usual capacity of a gas heating boiler is not enough to normalize the pressure.

The physical properties of water are such that as its temperature increases, it increases in size. To compensate for the excess generated during the heating process, gas units are equipped with stationary tanks. If the expansion of water begins to lead to an increase in the pressure level in the heating pipes, a special valve opens and a certain amount of coolant enters the tank you have installed. When the temperature drops, the liquid leaves the tank and goes into the batteries. That is, the heating radiators always maintain the same amount of water required for uniform and high-quality heating.

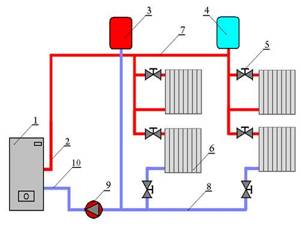

Visual heating connection diagram

The standard volume of a stationary expansion tank included in a double-circuit gas boiler is about 8 liters. For normal operating conditions, this capacity is more than enough. But if it is necessary to provide heating for large areas, it is necessary to install an appropriate number of batteries, which leads to an increase in the volume of coolant, i.e. water. And in such situations, the volume of the stationary expansion tank may be too small.

Calculation of tank volume

If the tank volume is insufficient, there is a high probability of an emergency release of liquid from the heating boiler, which is absolutely unacceptable. As a result of an emergency release, the pressure level in the system may decrease so much that the unit simply cannot start operating in automatic mode. And if the owner does not add the missing liquid in a timely manner, the system may defrost or even fail completely.

An additional tank can be installed in any part of the circuit

To avoid such adverse consequences, the system must be equipped with an additional expansion tank. When the main tank is completely filled, the coolant will begin to flow into an additionally installed container, which will prevent an emergency release of water from the boiler. The volume of coolant and pressure in the heating system will be maintained at a constant level.

Before installation, the tank must be adjusted. The whole setup boils down to turning it upside down and removing the plastic plug from it. There is a nipple under the plug. An ordinary pump is connected to this nipple and the air is bleed from the container. Next, the container needs to be pumped with air until the pressure level in it rises to 1.1 kPa. In the heating system, the pressure should be 0.1-0.2 kPa higher than that for the installed expansion tank. Only after such adjustment can the container be placed in the designated place.

How to choose an expansion tank for heating

To ensure safe operation of the heating system, it is important to choose the right expansion tank. The container is selected based on the required volume of liquid that will circulate during system operation. To do this, the expansion tank for heating is first calculated. The next criterion is the case material and its coating, which must be resistant to corrosion.

When choosing closed tanks, special attention should be paid to its main working part - the membrane. The instructions for the tank indicate what material it is made of, what pressure and temperature range it is designed for.

Expansion tank Gileks

Helpful advice! It is better to choose expansion tanks that have the ability to replace the membrane, which will simplify and reduce the cost of repairing the device.

It is also worth paying attention to the weight of the expansion tank. This indicator will indicate the reliability of the tank and the duration of its operation.

Closed expansion tanks can be oval or rectangular in shape. The latter option is more compact, so it will take up less free space, which is especially important for cramped conditions. You should also take into account the design of the container, which will determine the installation option. The easiest to install are tanks on metal supports, which do not require additional fastening.

Note! For membrane tanks for heating systems, the body is painted red, and for hot water supply - blue.

When choosing a container, you should give preference to models from well-known manufacturers who have proven themselves to be the best in the market. You should also pay attention to the price of the expansion tank for heating. Cheap options are less reliable and durable.

Expansion tank Reflex NG 100

How to calculate an expansion tank for heating

For long-term operation of the heating system and its uninterrupted functioning, it is important to correctly calculate the volume of the expansion tank for heating. Since open-type containers have a simple design, choosing the required dimensions is quite simple. For a more accurate result, you can use special formulas, which must be used when calculating an expansion tank for closed-type heating.

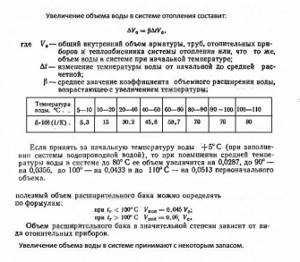

To perform calculations, you need to know the volume of water in the heating system, the temperature regime and the coefficient of linear expansion of the liquid when it is heated to a certain value, which is given in a special table. In addition, it is necessary to take into account the safety factor, which is equal to 1.2.

The increase in the volume of water in the system is calculated as the product of the total volume of liquid and the coefficient of volumetric expansion depending on the change in temperature from the initial to the maximum value. A simpler method is to approximately calculate the volume of the expansion tank for heating. For this purpose, 10-12% of the total volume of liquid in the heating system is determined. The resulting value will be the minimum volume for the expansion tank.

Helpful advice! The amount of water in the system can be determined at the design stage by adding up the volumes of all components of the system, or experimentally by draining all the water from the system and refilling it using a meter or container of known volume.

Before choosing, you must correctly calculate the volume of the expansion tank

It should be remembered that the durability of its operation depends on the correct calculation of the expansion tank for a closed heating system. A tank that is too small in volume will cause the safety valve to break, which will trip frequently. A container that is too large will require sufficient space for its installation and additional financial costs.

The best membrane expansion tanks

An ideal option for the heating system of a private home would be a Gilex 100 expansion tank with a capacity of 100 liters and designed for a maximum operating pressure of 6 bar. The body is made of steel 1 mm thick. The phosphate paint coating reliably protects it from corrosion. The tank is installed vertically on three support legs. This model is capable of working with surface and submersible pumps. The cost of the tank is 6900 rubles.

The expansion tank for heating Reflex NG 100, with a capacity of 100 liters, is no less popular among consumers. It has a metal body, inside of which there is a pear-shaped rubber membrane. The Reflex expansion tank is designed for a maximum operating pressure of 6 bar and a temperature range of 0-70 degrees. You can purchase this model for 5,500 rubles.

The Wester WRV 50 expansion tank from a Russian manufacturer is distinguished by high build quality and a wide temperature range from -10 to 100 degrees in which it can operate. The capacity is 50 liters. The maximum operating pressure is 5 bar. The container can work with ordinary water and antifreeze with a glycol concentration of 50%. The body is made of carbon steel and covered with epoxy polyester coating. Inside there is a membrane made of monomer. You can buy a tank from 3800 rubles.

Expansion tank Wester

A good model is the expansion tank Stout STH-0006-000050, with a volume of 50 liters. The maximum operating pressure is 6 bar, the temperature range reaches from -10 to +100 degrees. The body of the container is made of carbon steel, inside of which there is a pear-shaped membrane made of natural rubber and butyl. The tank is installed on metal supports. The cost of the model starts from 3200 rubles.

How to make a calculation?

As mentioned above, any expansion tank used for open heating is characterized by simplicity of design and manufacture. And calculating the dimensions of such a product is no more complicated.

For this purpose, you can use formulas or a method that involves approximate calculation of the working volume of the tank.

An example of using a formula to calculate the required tank volume. Based on the actual volume of water circulating in the circuit, only its increase when heated to a certain temperature is calculated, rounding up. Then add the result obtained to the volume of coolant in the heating system and add an arbitrary number of liters “in reserve”

In reality, to determine the required capacity of the tank, the owners of a small country house use formulas extremely rarely. Most often, the approximate volume of the expansion tank is calculated, to which any number of liters can be added for insurance.

Reason: in the case of open tanks, the extra volume does not significantly affect the cost, and in some cases does not lead to an increase in price at all.

As a result, the entire calculation of capacity comes down to determining 10% of the volume of the entire coolant, which should be its minimum value for the expansion tank.

The easiest way to do this is at the time of designing and creating a heating system, when all the parameters of radiators, pipes and other structural elements are known or can be easily found out by taking measurements. And then simply adding up the volumes of all components.

Although open expansion tanks and the systems for which they are intended have long since become obsolete, their availability and, most importantly, high autonomy make them in demand in conditions that are far from ideal. For example, if there is a problem with stable electricity supplies or the owners of the premises do not live there permanently

If the source data is unknown, then the most practical method of calculation is experimental. Why do you need to drain all the water from the system and then refill it with coolant?

In this case, measurements must be made, which can be done using a meter or using containers of known volume. After that, all that remains is to find out the required 10% of the coolant volume, which serves as a guideline when making or purchasing a tank.

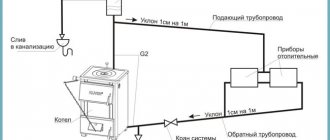

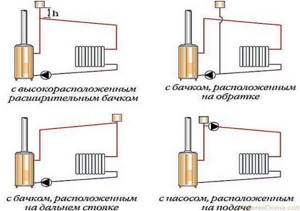

How to install an open type expansion tank

The general layout of a heating system with an open type expansion tank consists of a heating boiler, radiators, pipelines and a tank. To install the tank, the highest point of the house is selected so that the tank rises above all the components and components of the heating system. If the tank is located in an unheated place, its body should be reliably insulated to eliminate the possibility of water freezing.

There are several installation options: supply, return, and combined. In the first case, the tank is located above the boiler. This classic option involves the flow of coolant not only along the circuit, but also its penetration into the tank, where a characteristic noise is created, reminiscent of water boiling in a kettle. Installing a container on the return line eliminates problems with boiling, which occurs as a result of the reduced temperature of the liquid.

The combined installation option involves the installation of two expansion tanks. One will be located at the fluid supply point, and the other at the return point. This scheme will avoid the formation of air pockets in the system. After selecting the installation option, the expansion tank for heating is selected.

When installing an expansion tank, you must adhere to certain rules

The tank is installed on a clean, flat surface. It is connected to the heating system using couplings with threaded connections or steel pipes by welding. The connection between the tank and the boiler must be made using a vertical pipeline. The pipe connecting the container to the system and the discharge line should be insulated.

Installation location

An expansion tank for closed-type heating is installed in a straight section in front of the circulation pump. Before, in the sense that the pump drives water from the expansion tank, and not into it. In this case, the expander works more correctly.

Place for installing a membrane expansion tank

To install a membrane tank, install a tee, from which comes a pipe to which the container is connected. The installation height does not matter. But it is better to install shut-off valves in front of and behind the tank. The membrane fails every few years. Even more often you have to check it and pump it up. To avoid having to stop and drain the system for maintenance, a shut-off valve is installed. It is blocked off and the tank can be removed, checked, and repaired.

At the highest point

In open-type systems, the installation location of the expansion tank is selected based on other considerations. It is placed at the highest point of the system. In this case, it also works as an air collector. Air bubbles tend to rise, and if there is an expansion tank at the highest point, they rise to the surface, escaping into the atmosphere. So such a tank is deliberately made leaky so that the air from the heating system can escape naturally.

The expansion tank used for the heating system serves to compensate for the expansion of the volume of the boiling coolant as a result of its heating. Its function is to reduce pressure in the wiring itself. For this reason, such a tank should be used for both types of heating systems. A tank for installation in a closed system can quite realistically be made as a homemade expander with your own hands. The second option is to use ready-made containers.

Rules for installing a closed expansion tank

The installation of a membrane expansion tank must be carried out strictly according to the instructions. The container must not be disassembled or opened beforehand. The tank can be mounted in any convenient location that is comfortable for maintenance and setup. The container is installed before the system is branched.

Important! Expansion tanks with a volume exceeding 30 liters must be installed on supporting legs and not attached to the wall.

According to the instructions, all communications are connected to the expander. After this, a pressure gauge should be installed. A check valve must be installed at the entrance to the tank.

Many people recommend installing the expansion tank for heating in such a way that the supply pipe is on top and the air chamber is at the bottom. In this case, air will be easier to remove from under the membrane. However, experienced experts insist that the tank should be positioned so that the supply pipe is at the bottom. This option will extend the life of the container in case of damage to the membrane, since air will penetrate into the coolant more slowly.

The expansion tank must be installed at the highest point of the system

Helpful advice! The supply pipeline and tap should not overload the container with their weight, so separate fastenings should be provided for them.

DIY expansion tank from a canister

Metal makes a reliable and durable structure, but not everyone knows how to work with this material, so we suggest you read the step-by-step instructions and learn how to make a tank from a canister:

We immediately draw the reader’s attention to the fact that a plastic canister will not last long, a maximum of 2 winters. Therefore, although this option is fast, it is not durable.

In any case, the time will come when you have to replace the old tank with a new one. You will need a canister with a volume of 10 liters; there is no need to cut a huge hole, but in the lower part, closer to the bottom to the right, we cut out a neat hole. This can be done easily with an ordinary construction knife. Check whether the fitting fits well into the finished hole; if not, then you need to cut off a little more excess plastic. The canister has 2 holes - the first is factory-made, the second we made at the bottom. You need to insert a wire and a fitting into both holes so that it slides along the wire directly into the lower hole. You need to insert the fitting and install the rubberized gasket, then the nut and tighten the thread thoroughly. You can connect such an expansion tank to the heating system using a piece of rubber hose (install clamps) or take a piece of plastic pipe and make the structure solid.

DIY expansion tank. Photo:

Expansion tank for heating with your own hands: its capacity and installation | Heat monster

In our life, everyone dreams of a house built with their own hands. Its construction is associated with various problems.

Figure 1. Heating system of a house on the water.

An important place among them is occupied by the problem of improving an effective heating system with your own hands.

Only in a warm home can you create cozy and comfortable living conditions. There are several options to help solve this problem.

Traditional heating options

Figure 2. Diagram of a heated hydraulic floor.

Very often the house is equipped with traditional heating. The options are as follows: connect to the water supply and sewerage system, if such an opportunity exists, and create individual heating. To connect to the centralized system, you need to complete some documents and obtain the necessary permissions. Independent heating systems have a number of completely solvable problems that require investments of money, a little calculation and a lot of work.

Traditional heating equipment requires some preparation work. More often, a system of convective circulation of a coolant is used, which in most cases is considered to be simple water. There is no need for auxiliary pumps here. Cooled water flows from the batteries into the boiler and displaces hot water, which enters the heating batteries. This kind of circulation happens all the time. To do this, the temperature difference between hot and cooled water should be approximately 25 degrees.

A similar result can be achieved by placing the heating boiler in the basement of the house. If this does not work, then the boiler is placed on the lower floor no higher than the radiators. This system is called a two-pipe system, since hot and cooled water is supplied through a wide variety of pipes.

Heating system installation

Figure 3. Do-it-yourself heat supply for a personal home.

It makes sense to start installing a heating system by drawing up a diagram that should indicate detailed piping and heating devices, all the calculations that are necessary for this regarding the amount of materials. An example of a similar diagram is in Figure 1. Heating appliances are usually placed under the windows.

Care must be taken to place the pipes in such a way as to avoid unnecessary bends and turns, leading to a decrease in the operating efficiency of the heating system. It is necessary to mark the maximum point of the system on the diagram. An expansion tank for heating is installed here.

Laying pipes is not particularly difficult. The pipe from the boiler is led to the heating device. The heating device itself is installed and attached. Then comes the laying of the pipe to the next battery. The procedure is repeated a couple of times. It would be a good idea to equip each heating device with a tap, thanks to which it will be possible to get rid of possible air pockets during operation of the heating system.

Layout diagram of hydraulic heated floor heating elements.

The circuit is closed in the same boiler where the wiring originated. It is recommended to equip the boiler with a water purification filter, and sometimes with a pump to move water through a closed circuit. In the heating system, you need to plan the installation of drainage systems and filling it with water. It would be a good idea to do the first start-up of the system in the presence of a qualified technician.

Instead of installing classic heating devices, you can equip a warm heated floor by laying metal-plastic or polypropylene pipes under the floor covering. Hot water will circulate through the pipes and transfer its own heat to the room. Heated floor diagram in Figure 2.

In general, it would be a good idea to arrange heat supply with the involvement of a person skilled in these matters, so that later you do not encounter unnecessary problems during operation. Traditional heating is approximately 20 percent more affordable than stove heating. The return line lies close to the floor, sometimes under it. Hot water supply pipes are located above heating appliances, in most cases under the ceiling. It would be a good idea to insulate sections of pipes located under the floor or in the attic to prevent them from freezing during the winter.

Pipes can be used steel or metal-plastic. Is the diameter suitable for risers? or 1 inch. Half-inch pipes are suitable for wiring. Horizontal pipes are laid with a slope of 0.1 degrees in the direction of the movement of hot water.

Expansion tank

Diagram of the expansion tank.

In any heating system filled with water, it is impossible to do without an expansion tank. When water is heated, it increases in volume. The tank is designed to compensate for excess water. An industrial gas boiler is equipped with such a membrane type tank.

In most cases, its capacity is 6-8 liters. For heating a large house, this may be very little. In order for the heat supply to work uninterruptedly, it is necessary to install an additional expansion tank. Otherwise, an emergency spillover from the system may occur. This leads to its complete stop.

It is better to install an additional expansion tank of a fairly significant volume - 10-30 liters. It can be purchased ready-made, welded from sheet metal, or a container of appropriate volume can be adapted. To install it into a working system, you need to turn off the boiler and drain the water. To avoid these difficulties, it is better to install an expansion tank when the heating system is being installed.

It is placed in the place of the system where the pressure is minimal. In other words, the return line is considered such a place. In a private home, it is often installed in the attic. There he doesn’t bother anyone and doesn’t take up living space. The remaining water formed as soon as the temperature increases will flow into this container, the system will operate smoothly. Through the same tank you can fill the system at the beginning of the heating period. Installation diagram of the expansion tank in Figure 3.

The expansion tank can be closed or open. Open ones are used in systems with convective circulation of the coolant, closed ones – in systems equipped with pumps. Open tanks are placed at the highest point of the system, very often in the attic of a personal home. A closed tank can be placed in any place, very often somewhere in the corner of the house on the floor. Such a tank is attached to the return branch of the system with pipes with a diameter of at least 20 mm.

The absence of an expansion tank can lead to a significant increase in pressure in the system due to an increase in the volume of heated water, which will cause pipe rupture. And this leads to high costs for repairs.

Traditional heating installation.

For an open system, a common method is to install a variety of ready-made and home-made containers as an expansion tank. This design is very simple. It is easy to add water to such a tank, which evaporates a little during heating operation.

The expansion tank is calculated according to the rule: its capacity should be equal to 10 percent of the capacity of the entire heating system. How to determine the capacity of the entire system? The most common way is to take readings from the water meter when the system is filling. There is no point in presenting more accurate mathematical methods of calculation, since they are incredibly complex.

When using antifreeze as a coolant instead of water, it is necessary to make an expansion tank twice as large in volume. You can use a fuel tank from a truck or a stainless steel tank from a washing machine. You can weld it from steel sheets 2-4 mm thick, from a metal barrel or a large-diameter round. The main riser of the system is connected to the bottom of the tank or to its side.

A traditional heating system makes it possible to provide comfort in the home. However, without an expansion tank, it can quickly fail. Building such a tank is not a problem. It can be created from sheet metal. Even correct calculations are not required for this. Many people successfully use suitable containers in the form of automobile fuel tanks and other capacious vessels. Their installation significantly increases the operating life of the heating system.

Most Requested Blog Posts in Seven Days

A few important notes

In order for the system and expansion tank to function normally, it is necessary to take into account such points as setup, maintenance and calculations of pressure and coolant volume.

Setting up the tank for operation in the heating system, taking into account differences and pressure levels

How to start the tank after installation? It is necessary to correctly calculate the pressure level in the network, taking into account the following indicators:

- Pst is the static pressure, which will be equal to the height of the water column, determined by the height of the overall heating system from the point of installation of the tank to the top element;

- P0 is the air pressure in the gas (air) chamber of the tank;

- Pstart is the initial pressure for recharging the equipment;

- Pext – settings for the pressure created in the system;

- Pkon – the level of pressure that is created as a result of additional replenishment;

- Pkl – pressure level for the safety valve (for private houses this pressure can be 3 bar);

- Pmax is the level of maximum operating pressure for which the boiler heat exchanger is designed (it is the element of the entire heating network that is most sensitive to this parameter).

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heating device, as well as significant energy consumption.

The required amount of coolant is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

Calculating the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio in which 1 kW of thermal energy is enough to effectively heat 10 m2 of living space. This ratio is fair in the presence of ceilings whose height is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

Pipes

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S – cross section;

- π is a constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the cross-sectional area of the pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

You can determine what capacity the expansion tank should have by having data on the coefficient of thermal expansion of the coolant. For water this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K – expansion coefficient;

- D – efficiency of the expansion tank (indicated in the technical documentation).

Radiators

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first count their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the product technical data sheet. In the absence of such information, you can navigate according to average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 = 12 liters.

Self-production

After the volume of the container has been determined, they begin to manufacture an open-type expansion tank with their own hands. So, a heating system that holds 100-150 liters of coolant will need a 10-15 liter tank. To make such a tank using a welding machine, it will be enough to prepare a sheet of metal measuring 50x75 cm and 2 mm thick.

The sheet is unraveled using a cutter or a grinding machine with a cutting disc into two blanks 25x75 cm. Six identical squares are cut from them, and a threaded fitting is cut into one blank, which will serve as the bottom of the structure.

A cube is welded sequentially from the squares, and the top cover is installed. The container must be checked for leaks. This results in an expansion tank of 15.6 liters, which is quite enough for this heating system.

It is much faster to make a container from a ready-made container, for example, a liquefied gas cylinder of a suitable volume. The only drawback of such a tank is the large weight of the structure. After completing the welding work, the expansion tank is installed in the heating system.

The direct purpose of the expansion tank is to receive excess water that is formed as a result of heating this coolant. The fact is that water molecules expand slightly when hot, and if there were no such receiving device, the moisture would find the weakest point of the line and a leak would form at this point.

In addition, the device performs one more function - after the coolant cools down, it seems to “give” the missing amount of liquid to the system.

This element, in fact, is an ordinary container that is installed above the entire heating line. But, of course, there are nuances here. Let’s look at everything consistently and in detail.

Calculation of the expansion tank for a system with a 31 kW boiler

Before making calculations for selecting an expansion tank, you should know that most wall-mounted boilers are equipped with built-in expansion tanks. The volume of the built-in tank is indicated in the technical documentation of the boiler. When recalculating the volume of the heating system based on the boiler power (by multiplying 1 kW of heat power by 15 liters), the tank’s compliance with the volume of the system being constructed is checked. If there is a shortage, an additional tank is installed. Its volume is calculated minus the built-in expansion machine. Floor-standing boilers, as a rule, do not have built-in equipment.

The calculation looks like this:

K = (DM – DB)/(DM+1) = (3.0 – 1.5)/(3.0 – 1) = 0.375

3.0 – pressure in the system, maximum, atm.;

1.5 – air pressure behind the membrane, atm;

Equipment and principle of operation

The expansion tank, in addition to the housing, includes a membrane (cylinder or diaphragm), the upper part of which is filled with inert gas or air. The lower compartment of the sealed container is intended for coolant.

Along with an increase in temperature, the water expands, and the excess mass of the coolant enters the membrane. The volume of the chamber with air decreases, and the pressure in this part of the closed system increases, compensating for the pressure in the line. When the coolant temperature decreases, the reverse process is observed.

The expansion tank can be equipped with a replaceable (flange) or permanent membrane. The second type of product is cheaper.

The membrane in the tank is pressed tightly against the inner wall, since its entire volume is filled with gas.

When water gets inside, the pressure increases. At the moment the heating starts, there is a risk of damage to the diaphragm from a pressure surge, and then the pressure gauge gradually changes the readings and the integrity of the part is out of danger.

To avoid damage to the membrane, it is necessary to install a pressure gauge safety valve that reacts to increased pressure (for private houses the norm is from 3.5 to 4 bar).

Advantages of the flange model

The advantages of flanged devices include the following characteristics:

- withstands greater pressure inside the system than a device with a constant diaphragm;

- it is possible to replace the membrane if it is damaged;

- horizontal and vertical installation of the device.