The German company is a world-famous manufacturer of heating equipment. A special place in its range is occupied by the category of gas-fired boilers. The company offers a fairly wide range of its products on the Russian market. But what’s surprising is that the company has been developing, producing and selling gas boilers for more than a hundred years, and the equipment came to Russia only 15-20 years ago. But the Russians were immediately convinced that the Vaillant gas boiler is a modern unit, with all the ensuing consequences.

Currently, the manufacturer offers two positions:

- Wall-mounted (single-circuit and double-circuit).

- Floor-standing (single-stage and two-stage).

Attention! The “Wyland” floor-standing gas boiler must be installed only in a separate room intended for the boiler room.

Types of gas boilers from the manufacturer Vailant

Depending on the installation option, floor-standing and wall-mounted devices are distinguished.

Floor-standing ones are larger, so many people opt for wall-mounted options. The units are also divided into single-circuit and double-circuit. Boilers also differ in configuration and power level. Vailant floor-standing gas boilers are designed for heating large areas. There are three floor-standing models: AtmoCRAFT, AtmoVIT, AtmoVIT Exclisuv. They differ in power and a number of technical characteristics. Cast iron is used as the manufacturing material. It is this that gives high reliability and ensures a long service life. All modifications are characterized by a natural type of air supply and exhaust.

There are models of such powers: 36, 28, 24 and 12 kW. The range includes options with both a natural type of air supply (exhaust) and those equipped with a fan. Vaillant gas heating boilers are divided into double-circuit and single-circuit. Wall-mounted boilers are often installed in residential apartments with central heating. This allows the heating season to start earlier and end later. In addition, not only heat the room, but also dry it in the rainy, cold summer.

The Vaillant “VU” single-circuit wall-mounted gas boiler is marked. Such units only perform heating of the apartment. But they can also produce hot water for domestic needs. However, in this case, additional installation of a Vailant water heater will be required.

But the Vaillant double-circuit wall-mounted gas boiler is marked “VUW”. A series of such devices not only provides heating, but also supplies the house with hot water. Regardless of the number of circuits, all models are equipped with an LCD display, which greatly simplifies the operation of the boiler. There are temperature control sensors. Many consumers prefer the dual-circuit type of units. Moreover, Vaillant sets prices for gas wall-mounted double-circuit boilers that are quite acceptable for Russian buyers.

Let's consider single-circuit options. There are two models here:

- AtmoTEC plus VU 240-280. The unit can have a power of 28 and 24 kW, which can be adjusted using a modulating burner. Boiler with chimney. There is a water heater. Therefore, in addition to heating, the Vailant single-circuit gas boiler can also supply hot water. The tank is expanded and closed.

- TurboTEC plus VU. The characteristics are almost the same as the first model. But the power range is wider: 36, 28, 24, 20 and 12 kW. A distinctive feature of this series is that the device can operate in dusty buildings.

Double-circuit options are represented by the following models:

- TurboTEC plus VUW 202-362. The series is represented by the following power values: 36, 32, 28, 24 and 20 kW. Removal of combustion products is forced.

- AtmoTEC pro VUW INT 240. Equipment power is 24 kW. This Vailant double-circuit gas boiler is equipped with the option of automatically switching to water heating mode. Water consumption is approximately 1.5 liters per minute.

- TurboTEC pro VUW. Power – 24 kW. The device heats domestic water and heats the house.

- AtmoTEC plus VUW 200-280. There are three power levels: 28, 24 and 20 kW. The boiler is characterized by natural removal of combustion products into the chimney. Such units are not suitable for cascade installations. Plate heat exchanger, flow-through. Thanks to this, scale accumulation does not occur.

For the gas wall-mounted double-circuit turbocharged Vaillant boiler, the price is ideally combined with quality, which makes it possible for every consumer to install such a unit for efficient heating of the room. The same applies to single-circuit models, which are also widely used by domestic consumers. Of course, the price for a Vaillant double-circuit gas boiler is slightly higher than for single-circuit analogues. But excellent functionality and high power justify such financial costs.

Gas boilers are considered the most suitable option for the climate of our country.

Electric boilers are also available for sale. They are much more environmentally friendly and more economical because they do not use gas. But natural gas is affordable and widespread in the country. Therefore, there are no problems with gas boilers. Many experts advise buying a Vailant double-circuit wall-mounted gas boiler to equip a reliable heat supply system.

Nuances of the installation process

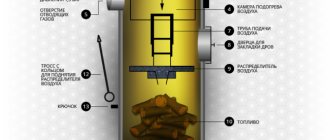

Like all brands of gas boilers, Vailant units are heating devices that are quite complex in their internal design. You can see this by looking at the picture above. It contains a lot of different components and parts. And although the connection requires only four water pipes and one gas pipe, a chimney and an electrical supply system, it is still not recommended to do this yourself.

- Firstly, for this you will have to find specialists with access to this type of work.

- Secondly, obtain permission (in the new house) to connect gas equipment.

- Thirdly, obtain a certificate that confirms that all work was carried out legally and by specialists.

If at least one of the three above points is not met, then you will definitely have problems with the gas service of the area. So you shouldn't do it on your own. It is better to do everything within the law.

Owners' opinions

Sergey Moskalev, Krasnoyarsk.

Gleb Pashirov, Nizhny Novgorod.

“I have lived all my life in a house with central heating.

Several years ago I paid attention to gas boilers - I was tired of the hot water being constantly turned off. I read various reviews for a long time, and in the end I decided to buy Vaillant AtmoTEC Pro VUW, so that the batteries would heat up and there would always be warm water in the shower. The price suited me, the characteristics were also suitable

I had to change my habits a little - I need to handle it with care, I can’t constantly force it to boil water and then dilute it in the tap. It is better to select the desired temperature on the unit itself. It is difficult to cause malfunctions - the quality is German, everything works like a clock. If something happens, the Vaillant gas wall-mounted boiler turns itself off - if there is no electricity, gas or there is not enough draft to remove the smoke. So safety is at the highest level - you won’t suffocate and you definitely won’t burn the house down. Due to natural circulation, it is necessary to ventilate the room well - gas boilers of the latest models have two inputs: one takes air from the street, the second from the apartment. Overall, it’s extremely convenient equipment – I really like controlling the heating myself. Reliability is also good"

The price suited me, the characteristics were also suitable. I had to change my habits a little - I need to handle it with care, I can’t constantly force it to boil water and then dilute it in the tap. It is better to select the desired temperature on the unit itself. It is difficult to cause malfunctions - the quality is German, everything works like a clock. If something happens, the Vaillant gas wall-mounted boiler turns itself off - if there is no electricity, gas or there is not enough draft to remove the smoke. So safety is at the highest level - you won’t suffocate and you definitely won’t burn the house down. Due to natural circulation, it is necessary to ventilate the room well - gas boilers of the latest models have two inputs: one takes air from the street, the second from the apartment. Overall, it’s extremely convenient equipment – I really like controlling the heating myself. Reliability is also good."

Oksana Bakunina, Yekaterinburg.

Yulia Samoilova, Moscow.

https://youtube.com/watch?v=Tij_4a4lxuY

Typical faults

Despite the high reliability inherent in all products of the Vaillant brand, there are several disadvantages. More often than others, users note:

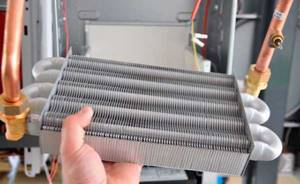

- Plate heat exchangers quickly become clogged with scale, which is why it is necessary to install special filters that soften the water.

- Increased noise level during operation of the built-in fan.

- Water gets inside the pump, which is caused by insufficient reliability of its seals.

- unstable operation of electronics caused by voltage fluctuations in the centralized power grid. These types of shortcomings are eliminated by installing a voltage stabilizer.

Correctly performed installation work will allow you to avoid troubles during operation.

After installing and connecting the boiler to existing communications, the following work must be performed:

- check the correct installation of the check valve in the heating system;

- remove air from the heating system;

- Before starting the boiler for the first time, carefully check all settings of the heating circuit;

- carry out a test run, during which check the functioning of all systems in heating and water heating modes;

- check the operation of all automation, control and protection systems.

It is better to entrust the above work to a qualified specialist who is authorized to perform such work.

troubleshooting

If a boiler malfunction occurs, the system displays relevant information on the display screen

All Vaillant boilers are equipped with a built-in fault testing system. If any error occurs, the system displays relevant information on the display screen. Errors that block the operation of the boiler can occur due to unstable power supply or broken contacts in the connections of the wires going from the sensors to the electronic module. Such faults can be eliminated by checking the signal lines for the presence of:

- wire breaks or oxidation of lamellas and contact groups;

- short circuits of wires to the body or to each other;

- damage to wire insulation;

- loose contact in the connectors.

Having eliminated the identified faults and ensured the supply of stabilized power, you can reset the error by pressing the “Reset” button.

Unit connection diagram

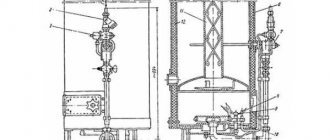

The connection diagram of the unit will depend on several factors, the first and most important, of course, is the type of heating system. There are three types of them:

- Those that use natural circulation. The movement of heat is ensured by the difference in water pressure that occurs in the line due to the expansion of coolants due to increased temperature. Installation of such a line is cheaper, but you will not be able to regulate the temperature using a radiator; accordingly, the second type is used on higher-quality automation.

- Forced circulation is carried out by special pumps, so you can freely regulate the amount of heat. Accordingly, the method is the most effective of those on the market, but the connection diagram is much more complicated and installation is more expensive. In addition, the system is completely dependent on electricity, and if it is turned off, the unit simply ceases to perform its functions.

- Hybrid circulation. Nowadays there are practically no devices with this type of heating on the market, but such a device combines the advantages of both of the above. In the event of a power failure, the boiler freely switches to the mode of natural distillation of water through pipes.

You might be interested >> Characteristics of a single-circuit gas boiler with an indirect heating boiler

Accordingly, the connection diagram is available depending on the type of heating selected by the user.

Types of pressure

Why does the pressure drop in a wall-mounted unit? First, let’s figure out what types there are and how they affect the operation of the equipment.

- Static. The higher the height, the higher the performance. With every meter there is an increase of 0.1 bar.

- Dynamic. Forced operation of the pump creates the rated pressure in a closed system.

- Working. Includes the two options above.

- Excessive. Determined by a pressure gauge as the difference between atmospheric and fixed.

- Nominal. The one indicated by the manufacturer in the documentation for a specific model.

- Maximum. The maximum that is allowed to avoid breakdowns and accidents.

- Crimping. Used in production when testing equipment.

In the heating circuit, indicators are measured in atmospheres

They may vary; It is important that the value does not exceed the permissible maximum and minimum thresholds. A low value is only possible when coolant is pumped into the circuit

In other cases it should not deviate from the norm

In other cases, it should not deviate from the norm.

Boiler models

Vaillant heating devices come in a variety of designs. Models of different price ranges are presented. They differ in power, type of burner, smoke exhaust, and the presence or absence of additional useful functions.

Marking:

- VU – one circuit;

- VUW – two circuits;

- AtmoTEC - atmospheric type;

- TurboTEC – turbocharged type;

- Int – international version;

- ECO are boilers that are particularly environmentally friendly;

- Pro – budget-level version;

- Plus – equipped with a quick start function;

- “ATMOGUARD” is a security system with which the latest models are equipped (has two temperature sensors).

Marking on the example of Vaillant turboTECplus VUW INT 242/ 5-5 indicates: turboTEC - series name, Plus - premium product, VUW - two circuits, INT - international version, 24 - power, 2 - closed chamber, /5 - generation, - 5 – plus series.

Wall-mounted boilers AtmoTec and TurboTec, Turbo fit pro and plus series (12–36 kW)

Presented in the pro (simplified version) and plus series. Available with 1-2 circuits. There is an internal expansion tank, an adjustable bypass, a safety valve, and an automatic air vent. Power modulation from 34 to 100%. Copper heat exchanger, chromium-nickel steel burner. There is automatic pressure control.

The boilers are equipped with a switching valve, eBus (except TurboFit), DIA diagnostic system. There is protection against pump jamming and low temperatures, electronic ignition.

Boilers with 2 circuits have a flow-through water heater and an LCD display (not available in the pro series). An external water heater with built-in control can be connected to single-circuit ones. Plus models have the function of maintaining a constant coolant temperature and “hot start”; there is a circulation pump with the ability to switch stages.

Floor-standing boilers atmoVIT, atmoVIT vk classic, atmoCRAFT vk (15—160 kW)

These are boilers with natural removal of combustion products. They can operate on natural and liquefied gas. They have an efficiency of 92–94%, 1–2 burner power levels, a cast iron heat exchanger, a boiler temperature sensor, an electric ignition function, a flame control function, an STB temperature limiter, a weather-dependent calorMATIC (VRC) regulator, and low temperature protection. Equipped with DIA system. The coolant is heated using an external water heater. The boilers have low emissions.

Condensing boilers EcoTEC pro and plus series (16–120 kW)

Wall-mounted gas condensing double-circuit boiler ecoTEC pro

Models with 1-2 circuits are presented. They utilize the latent heat in the boiler by condensing water vapor in the exhaust gas. They have an efficiency of 98–100%. The burner is closed. Power control range 20-100%. The AquaPowerPlus function allows you to increase productivity by 21% when heating water. The AquaСondens system uses the condensation function when the DHW mode is turned on.

The water collection and condensation collector prevent the accumulation of liquid in the system and its penetration into the device, which provides reliable protection against corrosion. Ventilation works in every mode. Circulation water flow measurement is provided in the device circuit, which protects the primary heat exchanger from exposure to hot liquid.

A circulation pump with an automatic stage switch, an internal expansion tank, an automatic air vent, a safety valve and a siphon, and a condensate drain are absent only in VU models with a power of 48 kW or more, but they do have a flow sensor and a place for a multiMATIC regulator. EcoTEC VUW models do not have protection against jamming of the electronic ignition and pump.

Floor-standing condensing boilers ecoCOMPACT vsk, ecoVIT vkk (20-280 kW)

EcoCOMPACT gas boilers with built-in boiler

The efficiency of these devices is much higher - up to 109%. They are equipped with an LCD display, pressure control, and constant protection against low temperatures. Water heating is possible in the ecoVIT series using an external device. The ecoCOMPACT series is equipped with an expansion tank for the heating system. VSC series – with layer-by-layer heating water heater.

Device and technical characteristics

Single-circuit boiler Hearth for heating a house

The heating boiler can be single-circuit, double-circuit or combined.

Single-circuit boiler

It has a cast iron heat exchanger and uses natural gas for heating. This is a complex configuration and requires a large number of parts to install. Its functions include heating only. For hot water supply, a boiler is additionally installed.

Double-circuit boiler

Equipped with two heat exchangers. Used for central heating and hot water. Natural gas is used for heating. This is a compact installation that operates automatically. To simultaneously heat the heating batteries and produce hot water, a heat accumulator is installed.

In the absence of a heat accumulator, when the hot water tap is opened, the pressure in the heating system drops and the temperature decreases. If the boiler is located far from the place of consumption, hot water will not appear immediately.

Combined installations

These are universal boilers with a steel heat exchanger (KSTG, KSTG). The unit can operate on fuel oil, solid fuel, and natural gas. Used for heating rooms with an area of 400 m2 and hot water supply, it has an internal water heater. Equipped with gas automatics, which reduces the gas supply when pressure increases.

The gas boiler Ochag has the following technical characteristics:

| Characteristics | Boiler brand | ||

| KSG-7AT | KSTG-16 | KNG 24 | |

| Type | Convection gas heating | ||

| Fuel used | Natural gas with conversion to liquefied | Natural gas or solid fuel | Natural gas with conversion to liquefied |

| Purpose | Heating | Heating | Heating and hot water supply |

| Mounting method | Floor | Floor | Wall |

| Efficiency | 85 % | 75% | 90% |

| Power | 7 kW | 16 kW | 24 kW |

| Power supply | Absent | Absent | 220 V / 50 Hz |

| Life time | 15 years | ||

| Guarantee | 36 months |

The parameters of three commonly used brands of Ochag heating unit are given.

Single circuit types

Single-circuit models are manufactured to provide space heating. They represent one of the simplest and most reliable gas boiler design options.

The absence of additional structural elements contributes to less wear, and there is no unnecessary consumption of thermal energy. Existing structures, in conjunction with underfloor heating systems, provide significant savings on heating.

The most common model of a single-circuit boiler is a 24 kW unit, which allows heating rooms up to 240 m2.

They demonstrate the optimal combination of price and functionality, which contributes to their popularity and high user ratings.

Single-circuit models

The most common models of single-circuit heating devices are:

- The power of Atmo Tec plus units does not exceed 28 kW. To adjust this parameter, a modulating burner is used. In some cases, the boiler is equipped with a chimney and a water heater. Therefore it can be used to heat water;

- The power range of Turbo Tec plus units is wider. This parameter can reach 36 kW. Such devices can operate in dusty conditions.

Wall-mounted gas single-circuit boiler Vaillant atmoTEC plus VU 240/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015251

- Country of origin: Slovakia

- Thermal power 25 kW

- Combustion chamber type Open

- Efficiency 90%

- Fuel type Gas

- Number of circuits Single circuit

Price: 61,026 rub.

Wall-mounted gas single-circuit boiler Vaillant turboTEC plus VU 202/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015254

- Country of origin: Slovakia

- Thermal power 20 kW

- Combustion chamber type Closed

- Efficiency 91%

- Fuel type Gas

- Number of circuits Single circuit

Price: 61,132 rub.

Wall-mounted gas single-circuit boiler Vaillant turboTEC plus VU 242/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015255

- Country of origin: Slovakia

- Thermal power 26 kW

- Combustion chamber type Closed

- Efficiency 91%

- Fuel type Gas

- Number of circuits Single circuit

Price: 67,108 rub.

Wall-mounted gas single-circuit boiler Vaillant atmoTEC plus VU 280/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015252

- Country of origin: Slovakia

- Thermal power 28 kW

- Combustion chamber type Open

- Efficiency 90%

- Fuel type Gas

- Number of circuits Single circuit

Price: 67,796 rub.

Wall-mounted gas single-circuit boiler Vaillant turboTEC plus VU 282/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015256

- Country of origin: Slovakia

- Thermal power 28 kW

- Combustion chamber type Closed

- Efficiency 91%

- Fuel type Gas

- Number of circuits Single circuit

Price: 73,665 rub.

Wall-mounted gas single-circuit boiler Vaillant turboTEC plus VU 322/5-5

- Manufacturer Vaillant

- Manufacturer's article number 10020413

- Country of origin: Slovakia

- Thermal power 32 kW

- Combustion chamber type Closed

- Fuel type Gas

- Number of circuits Single circuit

- Installation type: Wall mounted

Price: 77,473 rub.

Wall-mounted gas single-circuit boiler Vaillant turboTEC plus VU 362/5-5

- Manufacturer Vaillant

- 2 year warranty

- Manufacturer's article number 10015258

- Country of origin: Slovakia

- Thermal power 36 kW

- Combustion chamber type Closed

- Efficiency 0.91%

- Fuel type Gas

Price: 88,155 rub.

Prices: summary table

| Model | power, kWt | Efficiency, % | Gas consumption, m³/hour | DHW capacity, l/min | price, rub. |

| atmoTEC pro VUW 240/5-3 | 24 | 91 | 2,8 | 11,4 | 53 000—59 000 |

| atmoTEC plus VUW 240/5-5 | 24 | 91 | 2,9 | 11,5 | 65 000—70 000 |

| turboTEC pro VUW 242/5-3 | 25 | 91 | 2,9 | 11,5 | 57 000—62 000 |

| turboTEC plus VUW INT 242/5-5 | 25 | 91 | 2,9 | 11,5 | 69 000—73 000 |

| ecoTEC plus VU INT IV 346/5-5 | 34 | 107 | 3,7 | — | 105 000—112 000 |

| atmoVIT VK INT 254/1-5 | 25 | 92 | 2,9 | — | 97 000—103 000 |

| ecoCOMPACT VSC INT 266/4-5 150 | 25 | 104 | 3,24 | 12,3 | 190 000—215 000 |

Vaillant boilers are considered the standard of heating equipment. Indeed, for many years they continue to be leaders in their field. If you are looking for a reliable and comfortable boiler, then Vaillant is ideal for you.

About company

Vaillant is a brand of the famous concern Vaillant Group. The history of the company began in 1874, when its founder Johann Vaillant began manufacturing sanitary equipment. Today, the Vaillant Group is a large company that manufactures heating devices, ventilation and air conditioning systems and occupies a leading position in the global market in this area. The company has branches in 20 countries and exports products throughout the world. Vailant also has offices and service centers in Russia.

The concern is constantly working on its product range, has many developments in the field of using renewable energy sources, considering this direction one of the main ones in its activities in the future. However, the production of gas boilers still comes first and is a priority in the company's work.

Vaillant has several scientific laboratories that study and implement innovative technologies developed by company specialists. The Vaillant Group is currently building a large research center to create the devices of the future.

The company produces energy-saving heating systems and gas equipment. Vaillant's main strategy is to follow the principles of an environmentally friendly lifestyle. All gas boilers of this company are made taking into account advanced eco-technologies. The devices have a very low noise level and CO2 emissions into the atmosphere, saving resources. Vailant boilers use the resulting energy with maximum efficiency and provide high efficiency of the heating and hot water system.

User manual

Operation of floor-standing units does not require any special actions from the user. After installation and initial setup, which must be performed by the technical staff of the service center, the owner only adjusts the temperature that is most comfortable for himself .

You don't need to do anything else. Moreover, independent intervention in the operation or design of the boiler will mean termination of the warranty agreement.

In any dubious or incomprehensible situation, you should immediately invite a specialist from the warranty workshop, otherwise there is a high risk of serious breakdowns and expensive repairs.

Download instructions

Operating instructions for Vaillant floor-standing boiler.

How to choose a Vaillant wall-mounted gas boiler

When selecting a suitable heater, pay attention to several thermal characteristics and parameters:

- Features of the heated building - technical conditions in apartment buildings will not allow installing a boiler with an atmospheric combustion chamber. For an apartment, models from the turboTEC series are optimal.

Functional purpose:

- The wall-mounted gas single-circuit boiler Vailant is installed in rooms where there is no need to heat hot water, or it is planned to additionally connect an indirect heating boiler. Heaters with one heat exchanger are characterized by high performance, therefore, they are used for heating large buildings.

The Vaillant wall-mounted gas double-circuit boiler satisfies the room's need for heat and the residents' need for hot water supply. The heat generator heats the water using a flow method. In the summer, the boiler operates on the principle of a conventional gas water heater.

Modification - the main difference between the PLUS and PRO series lies in the installed equipment and the degree of automation:

- PRO models are equipped with the equipment necessary for work, without any special “frills”.

The PLUS series provides maximum operating comfort and is equipped with weather-sensitive automation and other useful devices.

After determining the basic operating parameters, the device is selected according to power and price range.

How to calculate what power a boiler needs

The easiest way is to calculate a wall-mounted single-circuit gas boiler Vaillant. For this, the formula is used: 1 kW = 10 m² + 10% reserve capacity in case of severe cold. Calculations will help you find the approximate power value, given the average thermal insulation of the building and a ceiling height of no higher than 2.7 m.

If the heated area is 100 m², an 11 kW boiler will be required. In the model range there is no standard power size that exactly corresponds to the result obtained. Therefore, a boiler is selected with productivity rounded up. For indoor use, turboTEC plus VU / 5-5 at 12 kW or an analogue with an atmospheric combustion chamber is optimal.

Determining the required power of a boiler with two heat exchangers is a little more difficult. When calculating, the thermal energy costs for heating the hot water supply are taken into account. Typically, another 15-30% is added, depending on the actual needs of residents for hot water.

For a room of 100 m², you need a wall-mounted double-circuit gas boiler Vailant, with a capacity of 10 kW + 10% power reserve + 20% average DHW value. In total, it turns out that 13 kW will be enough. We round the power up. You will need to purchase a 15 kW boiler.

Price range for mounted boilers

Prices for wall-mounted gas heating boilers Vailant are standard for equipment of this class produced by a European manufacturer. You can buy the boiler you like starting from 45 thousand rubles. and higher.

Several factors influence the price:

- Burner type.

The principle of removal of combustion products.

Degree of automation and equipment configuration.

Power.

If we take into account that heating costs after installing Vailant boilers will decrease by 25-40%, the full payback of the equipment will be achieved after 2-3 heating seasons.

Stages of connecting a double-circuit gas boiler

If you have already decided that connecting a double-circuit gas boiler may take up a lot of your time, but you urgently need it, then it is worthwhile to figure out in advance what stages you will have to go through. The correct connection looks like this:

- First you need to contact an organization that supplies natural gas. She must issue a permit according to which you can use gas wall-mounted double-circuit heating boilers; The connection diagram must also be described in the application.

- The company will provide you with technical specifications, and the wall-mounted double-circuit gas boiler, which will be installed in the house, must be connected to the gas mains according to the instructions.

- As soon as the engineers approve the project and you figure out how to connect a double-circuit gas boiler to heating, specialists will arrive to install the device on an external network.

When you contact the company, do not forget to take copies and originals of technical documentation for the right to own the site, as well as the passport that is attached to the purchased boiler. Without them, engineers will not be able to select the optimal connection option, and the procedure can be seriously delayed. Design firms are best chosen by employees of a gas organization, since they have experience and many contractors who can be advised. Therefore, do not hesitate to ask them who is better to choose for installation, as well as clarify other details.

If you do not indicate this in the plan or try to do everything using a makeshift method, then the gas service employees simply will not agree to connect the main pipes to the device, since this will violate safety regulations and could cost you your life. Therefore, approach this issue responsibly.

You might be interested >> The operating principle of a single-circuit wall-mounted gas boiler

It is best to install gas boilers on the street or a couple of steps from the house; installing them in a home is not worth it.

It is the responsibility of the design engineer to advise you on the requirements for boiler installation, but these should be reviewed in advance and prepared for the meeting. You need to observe the following things:

- If the heat generator does not exceed a power of 60 kW, it is allowed to be installed even in the kitchen. And if up to 150 kW, you should allocate a separate room, or better yet, build a special furnace room or make a small extension to the house.

- The building where you install the boiler must have ceilings of at least 2.5 meters in height. If this is a kitchen, then its volume should be 15 square meters or more.

- The room should also be well ventilated; it is worth installing a hood capable of moving 3 volumes of the room in an hour. To this amount should be added the air consumed by the boiler itself. You can find detailed information on this topic in the technical data sheet of the device.

- Walls and ceilings in flammable areas must be protected from fire or ensured that they are non-flammable.

- The transparent part of the windows must be at least 3 hundredths of a square meter for each cubic meter of combustion space.

- The passage to the heating unit should not be blocked, and there must be a space of 1 meter on the sides so that full maintenance can be performed.

- There should be up to 3 meters between the boiler and the vertical chimney, otherwise air exhaust will be ineffective.

All this should be taken into account so that your project is accepted, and at the same time you have peace of mind in terms of the safety of autonomous heating. Also, you should not skimp on the boiler itself, and it is better to buy modern automation, which, if the flame blows out, will turn off the gas and keep the room temperature at the same level. It’s better to spend money once than to regret later and suffer with a Chinese boiler that refuses to work according to the technical specifications. passport and hardly produces the declared power. You should also study the device connection diagram in advance.

Most common error codes

It is much easier to identify a breakdown when it is indicated on the display as an error. Let's look at the most popular mistakes of Vaillant boilers.

+ Error F22 - lack or lack of water in the boiler. First check the pressure in the system. It should be 1-2 bars. When the readings are lower, you need to top up the heating. If the situation occurs frequently, there may be a leak in the system. This error often appears when a pump or electronic board breaks down. They will have to be changed. To resolve this error, sometimes it is enough to do a reset.

+ Error F28 - unsuccessful attempt to ignite. This happens when the gas cannot reach the burner. For example, if the tap is not fully open or the gas valve is broken. The ignition electrodes may become clogged or damaged. Then they should be cleaned or replaced.

+ Error F28 also appears at low voltage. Installing a stabilizer will help here. Well, the most unpleasant reason is a breakdown of the electronic board.

+ Error F29 – the gas burner does not turn on. This error is often confused with F28. It usually appears after three unsuccessful ignition attempts. The most common reason is a drop in pressure in the gas pipeline. But the culprit may also be the ionization sensor. During operation, carbon deposits form on it, which should be removed. When a gas valve is not set correctly, it may work for a while without problems. But then error F29 will still appear. Correct adjustment will help correct the situation.

We recommend: How to insulate the basement of a house from the outside: step-by-step instructions for choosing and installing thermal insulation

+ Error F75 - violation of coolant circulation You might think that the cause is the pump. Sometimes this is true. But the most common case is a clogged pressure sensor membrane. And even replacing it saves the situation for a short time. Fortunately, there is no such error in fifth-generation boilers. If you have a third generation boiler, you will have to figure it out. By the way, there is a small mesh filter installed in front of the sensor. Check to see if it is clogged.