Since we are talking about calculations, it means that initial data figures will be required. Each person uses water differently. For some, it’s enough to stay in the shower for 5 minutes, while others swim in the bath twice every day.

If you decide to purchase a boiler and choose a type and model, first of all study your needs. At least measure your bathing and dishwashing time. Let's calculate how much hot water is needed, what volume of boiler is needed for this and its power. How much and what he will take from the boiler and what the boiler will need for this.

Quantities

We consume water in liters, and measure its temperature in degrees. Water, in order to heat up, uses thermal energy in Joules based on its mass in kilograms. A water heater produces power in Watts, and efficiency is calculated as a percentage. Let's translate these units of measurement into one, understandable plane.

- According to the laws of physics, in order to increase the temperature of 1 kg of water, which is equal to 1 liter, by 1°C, 4.187 kJ of thermal energy is required, which is 0.001 kW/h of the power of the heating device. Type, manufacturer and losses are not taken into account. No matter who makes the heater and no matter what conditions this mechanism is in, the water always needs exactly that much energy.

- The water entering the boiler in winter (the boiler does not work in summer) has a temperature of about 10°. Insulated supply pipes will reduce the temperature difference at the inlet and outlet of the boiler and help save fuel.

- The number 60° is set on the control panel of the device. This means that the liquid in the unit will be heated to this temperature. Therefore, 60-10=50o. It is not worth setting a large heating value. Such a load will entail increased wear and tear on the equipment.

- The temperature needs to be raised by this amount. Let's multiply the found difference in degrees by the energy needed to produce each of them - 50 * 0.001 = 0.05 kW/h of power the boiler will need for such work.

So, to heat 1 liter of water to 60 o

you will need 0.05 kW/h of boiler power, and to increase it by 1 o - 0.001 kW/h of its effort.

The hot water that we take from the tap to wash our face or wash dishes has a temperature of about 40°. It will be hot above, cool below. In order for the calculation of the operation of a boiler, not only indirect heating, but also any other type of heater, to be correct, it is necessary to take into account that we are mixing two waters, each of which has its own temperature.

- Hot water is thermal energy. We calculated that 1o = 0.001 kW/h .

- The water we want should be 40°, which means 40 * 0.001 = 0.04 kW.

- Cold water has 10°, which means there is already 0.01 kW/h. This is 25% of the required heat volume.

- This means you need to add another 75% of the temperature, which will be 0.05*75%=0.0375 kW/h.

Thus, 1 liter of the desired mixture (hereinafter we will call it warm water) will contain 0.75 liters of fully heated water from our unit and 0.0375 kW/h of its power.

Which water heater to choose?

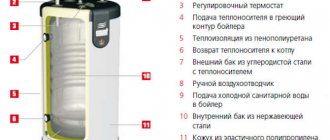

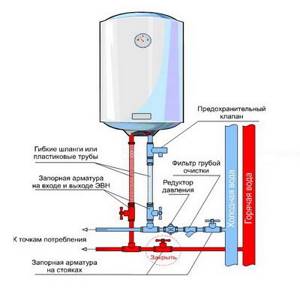

Boiler diagram.

Depending on the task assigned to you, calculating the boiler that is right for you can be done in two ways. In the first case, the stored volume of water is taken into account and the power of the heat exchanger and power source is calculated. In the second, the volume of the water heater is calculated to accumulate heat generated over a certain time by a source of a certain power.

It should be understood that no matter what method you use, the accumulating capacity of water is always characterized by its heat capacity. This value is constant and is equal to 4.187 kJ.kg/°C. This means that, for example, to heat 1 kg of water by 1°C, it is necessary to provide an amount of heat equal to 4.187 kJ. And this requires 1,163 kWh.

Electric boiler device.

For example, if you have a water heater with a volume of 1000 liters, and you need to heat the water to 50°C, then the need for thermal energy is calculated as follows: 1000 × 50 = 58 kWh.

The power of the heat exchanger depends on the temperature difference between the heated and heated water, as well as on the heat transfer coefficient. For each specific heat exchanger, the heat transfer coefficient will be individual. Therefore, there cannot be a universal formula for calculating a water heater. And the easiest way to select a heat exchanger is the diagrams that manufacturers indicate in the technical specifications for their water heaters.

Having remembered this simple truth, you can move on to considering individual characteristics.

Design of a standard electric boiler

In our country it is generally accepted that a water heater and a boiler are different devices. But in fact, the only difference is that the boiler has a storage tank for heating and storing hot water. That is why in the technical literature they are called “storage-type water heaters”. Boilers also differ in their heat source. Now there are direct and indirect heating systems. If the device itself generates heat using a thermoelectric heater or gas burner, then it is a direct heating system. Indirect heating occurs due to the coolant supplied from the heating boiler, heated to a certain temperature. Storage water heaters are most often used; you can see their diagram in Image 1.

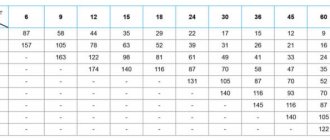

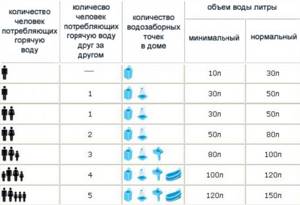

Storage water heater calculation table.

Before making a decision to purchase a specific water heater, it is necessary to calculate all the parameters and take into account the features of your home and the conditions of future operation. Be sure to evaluate the following parameters:

- condition of electrical wiring;

- possible load on electrical wiring;

- availability of connection to gas communications;

- the serviceability of all equipment serving the house (including water pumps, if any).

In addition, it is necessary to take into account the number of people who will use the water heater and approximately plan how much hot water they will consume every day. After this, you can begin to select a specific model.

In order to choose a water heater that is right for you, you should first decide on its main characteristics, namely:

- the most suitable energy source;

- required volume of heated water;

- coolant consumption;

- heating time.

Based on these parameters, the water heater is calculated.

Energy source for heating water

Gas and electricity are used as the main energy sources for water heaters. There are also more exotic sources like solar panels, but they are not very common in our country. Therefore, in order to make an accurate calculation, it is necessary to compare the advantages and disadvantages of gas and electricity.

- Electric water heaters are available in capacities from 1 to 6 kW. The power of a gas boiler starts at 4 kW.

- As a rule, gas storage water heaters have a larger hot water tank (up to 150 liters), while electric ones rarely exceed 100 liters.

- The cost of gas in Russia is much cheaper than electricity.

It seems that the choice is obvious and there is no need to make complex calculations. To obtain 100-150 liters of hot water using a gas water heater, it will take approximately half the time than using an electric system. But electrical devices do not require an additional power line - a simple outlet is enough for them. There is no need to invite specialists to install such a boiler. Whereas a gas water heater must be connected to a gas pipeline, which is not available in every country house. In addition, the safe installation of a gas-fired water heater requires the construction of a chimney.

It is impossible to compare prices for boilers with different power sources. The cost of electrical systems depends primarily on the power of the heating element and the volume of the tank. The price of gas-fired water heaters depends on the type of combustion chamber. They are internal and external. Installation of equipment with an internal chamber requires minimal effort and time. But such devices cost about twice as much as boilers with an external chamber.

One more condition must be taken into account. Gas boilers can significantly heat the air. In a country house and small rooms, this feature can become a real problem if you place the water heater, for example, in the kitchen.

Therefore, it is impossible to give clear recommendations on choosing a boiler with a specific energy source.

Amount of power consumption

Having decided on the need to purchase and calculating the volume of an indirect heating boiler, you need to calculate how much warm water is needed for normal existence. Let's imagine a family of 4 people and carry out an average daily analysis for a week and a peak (workday morning) study of hot water consumption.

- Weekly analysis

- To wash dishes you will need about 5 liters of warm water per minute. The rinsing time is taken into account, it is about 5 minutes. We wash the plates twice a day, and we get 50 liters of warm water per day for kitchen utensils. Let's multiply by 7 days a total of 350 liters per week.

- Each person takes a bath 2-3 times a week, spending about 170 liters. 4*2.5=10*170=1700 liters in 7 days.

- Another 4-5 showers for 10 minutes at a flow rate of about 12 l/min. 4.5*10*12=540 per family member, respectively, for all 2160 liters per week.

- Minor hygiene (wash hands, shoes, clean the house) - about 10 liters per day per person will amount to 280 liters for the study period.

Total - 350+1700+2160+280=4490 liters per week. Let's add in the guests who came in and the reserve just in case, we get an approximate figure of about 5000 liters per week. But the boiler counts in hours, you need to convert it to its units. 5000 / 7 / 24 = 30 liters per hour of warm water is the average consumption of a family of 4 people.

Based on our figures for the relationship between temperature and power, we obtain the required average power consumption - 30*0.0375 = 1.125 kW/hour.

Calculation based on the rated power of the boiler

How are boilers for hot water supply with indirect heating boilers of significant volume and high water consumption from the hot water system calculated?

The calculated power is equal to the sum of two terms:

- Heat needs of the house without taking into account the safety factor;

- Nominal power of the boiler. On average, it is 15 kilowatts per 100 liters of volume.

Indirect Gorenje GV 100 (17400 watts)

Nuance: 20% is subtracted from the addition result, since the boiler heat exchanger will not provide heating and hot water around the clock.

So, when installing the notorious Gorenje GV 100 in our house in Sevastopol, the boiler power for water supply and heating will be 10 (heating heat requirement +17.4 boiler heat requirement)) * 0.8 = 22. The figure is given rounded to the nearest kilowatt.

Is it possible to install a boiler with a capacity greater than the calculated one in a DHW circuit with an indirect heating boiler?

It is possible, but unprofitable for two reasons:

- The price of the boiler itself increases rapidly as the rated power increases;

Following the performance of the boiler, the number on the price tag also increases

- Classic solid fuel boilers, when operating with heat transfer below the nominal value, reduce efficiency due to incomplete combustion of the fuel. Reducing heat generation is achieved in them in the simplest way - by limiting the air supply with a damper.

Change in the efficiency of a solid fuel boiler with a change in heat transfer

Peak consumption

Based on the above, it seems that even the smallest heater will be sufficient. Alas, not everything in life is so smooth. When calculating the volume of the tank and the required power of the unit, it is necessary to take into account that in the morning the whole family wakes up and gets ready for work or school at approximately the same time. There is simply no time to wait until the water in the boiler is completely heated. There should be enough stock of accumulated liquid and heating of the flowing liquid during the time it is consumed by consumers.

- According to statistics, utility services morning hot water consumption is about 30%-40% of the average daily value for 1.5 hours. The period taken is from 7:00 a.m. to 8:30 a.m. Let's take the average figure of 35% and find that our family will use 5000 / 7 * 35% = 250 liters in 1.5 hours, which is equal to 170 liters per hour of warm water. For this amount we will need 170 * 75% = about 130 liters of hot water and 170 * 0.0375 = 6.5 kW of water heater power.

- But that's not all. As fully heated water from the tank is consumed, cold water will be added to it, which needs to be heated, and this takes time.

- The average heating rate in flow mode depends on the temperature of the coolant and the surface area of the circuit. Since the heating liquid comes from the boiler, its temperature will always be about 70 - 75o, and the heat exchanger is calculated relative to the volume of the tank and the declared power of the device.

- The average figures are approximately equal for devices from all manufacturers and are about 0.3 l/min for a boiler with a heat exchange circuit load of 10 kW at a temperature difference of 50° that we set. In one hour, the volume of heated running water will be 60 * 0.3 = 18 liters.

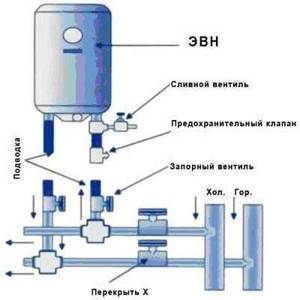

Installation and connection

A floor-standing water heater is installed on a small stand or floor. For a boiler, the level of inclination is important so that the equipment stands without distortion.

Hot water is connected to the hole marked in red, and cold water is connected to the blue one. Shut-off valves are installed on both lines to facilitate maintenance and operation of the device. Check relief valves will be required to prevent overheating or overpressure.

Step-by-step installation of the heater:

- Connecting the tank to cold water using a tee attached to the inlet pipe of the tank.

- Installation of an emergency drain tap.

- Connection to the bottom of the tee of the non-return safety valve.

- Installation of shut-off valve.

- Connection of the boiler with the cold pipeline.

- Hot water connection with installation of a shut-off mechanism.

After power is applied, accumulated air is removed from the secondary circuit. The water heating line is filled with liquid; the hot water tap must remain open.

Coolant flow

Since thermal energy is taken from the heating device, it means less of it will enter the home heating system. But only the average flow rate will affect the overall temperature in the room; peak readings are short-term and will not have much impact on the heated heating system.

- We calculated that the average power consumption would be 1.125 kW per hour. But after dispensing hot water in the morning and evening, the tank will be filled with cold liquid, the unit will heat it up and maintain the temperature all night or day.

- This means that you should take into account the idle heat consumption for at least two full cycles per day, which will be 200 * 0.0375 / 24 = about 0.3125 kW/h.

As a result, we get the result that to ensure uninterrupted provision of hot water to the family, the boiler will produce about 1.125 + 0.3 = 1.5 kW/h of its power. If we add the heat loss during transportation through pipes, through the boiler body and unexpected water consumption (congestion of guests for an anniversary, shoe cleaning, etc., etc.), it would be more correct to take the figure 2 kW/h.

When conducting this study, average figures were taken into account. To obtain a more accurate calculation of an indirect heating boiler, the calculator, presented by power and manufacturer, takes into account the features of each specific heater model and specific operating conditions.

In order to calculate the volume of a storage water heater, we use the formula:

Water heater volume = R. water × (t° – t1) : (t2 – t1),

- Water flow

– planned water consumption; - t°

is the water temperature that must be obtained at the point of water collection; - t1

is the temperature of cold water in the pipeline, which will dilute the hot water coming from the water heater; - t2

– temperature of water heated by the water heater.

Let's consider calculating the volume of a water heater using the following example.

Conditions: family of five, required amount of warm water – shower, washing dishes.

Shower water flow averages from 4 to 8 liters per minute, depending on the nozzle used. Let's take a maximum of 8 liters. Let's say each family member showers for 10 minutes.

Consumption of warm water for shower: 8 × 10 × 5 = 400 l.

Let's assume that it will take 15 minutes to wash the dishes, using 3 liters of water per minute.

Consumption of warm water for washing dishes: 15 × 3 = 45 l.

In total, the estimated consumption of warm water is 445 liters.

The temperature range that is comfortable for a person is approximately 30 – 40 °C; for calculations we will take 35 °C (t°).

Storage water heaters, depending on the model, can heat water to a temperature of 35 – 80 °C. It is usually recommended to set the water heater thermostat to an average value, approximately 55 - 65 °C, to eliminate the possibility of thermal injury if the tap is accidentally opened. For calculations, we take the temperature t2 = 65 °C.

The best models of floor heaters

You can get detailed advice before choosing a heater from the KVANTA + company.

Thermex ER 300V

The volume of ER is 300 l, which is heated by a heating element with a power of 6 kW. The inside of the tank has an antibacterial coating, which, together with a magnesium anode, protects the device from rust.

Model of the Thermex ER 300V floor-standing water heater with an antibacterial coating of the tank from the inside.

Thermex Champion Floor ER 200V

A 200 liter heater is capable of heating the full volume of liquid to +70°C in 2 hours. Several water points make it possible to use the device in several rooms at the same time. Safety is ensured by safety valves and power cut-off relays. The tank is protected from corrosion by a layer of glass ceramics.

The Thermex Champion Floor ER 200V floor water heater is designed to serve several water intake points.

Roda Kessel ILW 200 B

Indirect heating heater with a volume of 200 l. The inside of the container is covered with protective enamel. It is possible to control the degree of heating up to a maximum temperature of +65°C. The design allows you to install an additional heating element.

Roda Kessel water heater with the possibility of installing an additional heating element.

Timberk SWH RS5 300 V

The boiler capacity is 300 liters; it will take 105 minutes to heat the water to +30°C. The tank is made of stainless steel, the seams are treated with a special compound to prevent corrosion. The heat is retained thanks to 45 mm thick thermal insulation foam.

Floor standing boiler made of stainless steel – model Timberk SWH RS5 300 V.

Protherm FS B500S

Water heater with a capacity of 100 kW per 500 l. The liquid heats up to +60°C in 16 minutes. The maximum water heating temperature is +80°C. The surface has an enamel coating, and a titanium anode provides additional protection against rust.

Protherm FS B500S is a high power floor water heater.

Drazice OKCE 250S/2.2kW

A 250 liter tank heats water to +80°C in 420 minutes. The boiler is equipped with a ceramic heating element placed in a special tank, which allows servicing the element without draining the liquid.

Drazice OKCE 250 – water heater with ceramic heating element.

Baxi UBVT 200 DC

The model is made of steel, coated with titanium enamel on the inside. The boiler raises the water temperature to +65°C using one heating element.

Boiler model Baxi UBVT 200 DC.

Atlantic Steatite Exclusive 200

Despite the capacity of 200 liters, the device is economical, which is reflected in the heating time. The temperature of +65°C is reached after 5 hours of operation of Steatite Exclusive. During a day of inactivity, the water in the tank cools down by 5°C. Atlantic implements mechanical control of the device.

Atlantic Exclusive is a water heater with economical energy consumption and mechanical control.

Haier FCD-JTLD 150

The three-layer 150 l tank is protected from corrosion by a magnesium anode. High efficiency is achieved due to the stainless steel from which the boiler is made. The maximum heating temperature is +75°C, it is maintained thanks to the heat-insulating layer. The device is controlled mechanically. A distinctive feature is the maximum working pressure of 8 at.

Boiler model Haier FCD-JTLD 150 with high efficiency.

Ariston Ti Tronic Industrial 300 STI

The reservoir holds 300 liters of water, which is heated by a 3 kW heating element. Titanium enamel and anode protect against rust. The maximum water temperature is +75°C.

Ariston Ti Tronic Industrial boiler with a 300 liter tank.

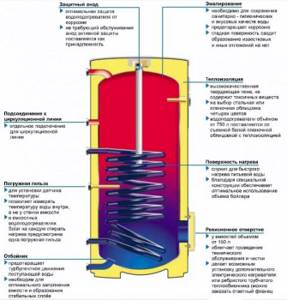

How to calculate the volume of an indirect heating boiler

Regulatory documents on which the main principle of calculations is based: SNiP 2.04.01-85 “Internal water supply and sewerage of buildings” and designer’s handbook, part 2.

The selection of a boiler begins with determination of hot water consumption. A properly selected boiler must meet the following requirements:

- A sufficient amount of hot water supplied simultaneously to several water points. It is generally accepted that maximum costs are achieved when the bath is filled.

- Heat the hot water supply to the required temperature for comfortable showering and washing dishes.

- Short waiting time between opening the tap and the arrival of hot water.

The average family uses hot water at least 12 times a day. Average consumption by the number of people in a family and calculation of the volume of an indirect heating boiler is performed using the following tables:

Number of family members

Boiler tank volume (l)

Sink, shower, bath

Approximate water consumption (l)

Water consumption at t=60°C (l)

For further calculations, you can use the formula for calculating the volume of the tank:

Water heater volume = water volume x (t° – t1): (t2 – t1)

- R. water - planned consumption of hot water supply;

- t° is the temperature of the heated water supplied to the user;

- t1 – cold water temperature in the pipeline (when calculating the flow rate of cold water admixture, the value is usually taken as 10°);

- t2 – temperature of water heated by the water heater.

The specified calculation formula is used to determine the constant performance of the water heater. Let's try to perform calculations for a family of 5 people, provided that the hot water supply will be used for showering and washing dishes:

- Water consumption - for a shower taken for 10 minutes, one person spends about 80 liters. water, or 400 l. per family. For washing dishes, taking into account three meals a day, about 45 liters are spent. Accordingly, the daily consumption will be 445 liters.

- The temperature comfortable for washing will be on average 35°C (t°). To prevent burns, the DHW is set to heat no higher than 65° (t2). Cold water for mixing is 10°C (t1).

- The calculation is carried out using the formula: 445 x (35 – 10): (65 – 10) = 200 liters. The calculations included maximum values that provide some power reserve.

Based on calculations, for a family of 5 people it will be enough to install a BKN with a maximum capacity of 200 liters, which is possible if the boiler to which the water heater is connected has a power of at least 33 kW.

When determining the volume of the future boiler, you need to take into account the power of the boiler. As practice shows, this criterion is often ignored when choosing a water heater, however, it directly affects the performance of the BKN. The selection of an indirect heating boiler based on boiler power is carried out according to the table:

not less than 16 kW

not less than 16 kW

not less than 23 kW

not less than 23 kW

not less than 33 kW

There is a direct relationship between the boiler capacity and the boiler power. Of course, you can connect a larger volume BKN to the boiler, but it will not produce the required volume of water. By installing a water heater with excessive capacity, the consumer will be faced with an increase in the heating time, which will lead to excessive energy consumption and increased costs.

The choice of BKN volume begins with a thermal engineering calculation based on boiler performance. Typically, the given values are sufficient for the average user to select a boiler for domestic hot water. Construction companies additionally take into account several more technical parameters and perform:

- Calculation of heat exchanger area.

- The thermal conductivity and heat capacity of water are taken into account when calculating the boiler - this value is necessary to determine the peak and constant load on the water heater. Basic values are calculated according to the table:

Which BKN is better - vertical or horizontal, wall or floor

When choosing the type of construction, many factors are taken into account: the availability of free space for installation, the required volume of displacement of the BKN, the material from which the load-bearing walls of the building are made.

Water heating time

It makes no sense to calculate the rate of water heating using the characteristics specified in the accompanying documents. All manufacturers enter absolute values there. In reality, most models of modern water heaters bring 100 liters of water to a temperature of 60°C within 5 hours. Thus, when mixed with cold water, up to 250 liters of warm liquid are obtained in summer and about 200 liters in winter. Therefore, the real values differ from the calculations, since as the hot water in the tank decreases, cold water is added, which means the overall temperature decreases.

The material from which the tank is made may influence the choice of a specific heater model. The most durable water heaters are made of stainless steel. Also an important advantage is the presence of a removable heat exchanger. This part makes it possible to clean it yourself. Models that use foam rubber as insulation should be avoided, as it wears out quickly.

https://1popechi.ru/youtu.be/Uts2EWEBGIM

But in any case, you must choose a water heater based on a cold and balanced calculation. Then the boiler will last for many years.

Which BKN tank material is better?

The best indirect heating boilers offered by European manufacturers are made with glass-ceramic coating. Stainless steel products are much more expensive, although they have a long service life.

There are budget BKNs with a protective layer of enamel (the same as for metal bathtubs). Each option has its own advantages and disadvantages:

- Stainless steel - the approximate cost of a European BKN with such a tank will be 2-3 times more expensive than an enameled boiler. There are budget versions made in China on the market, but one important nuance must be taken into account. There are several dozen brands of stainless steel, and only one grade is suitable for the food industry. There is no guarantee that exactly this kind of metal is installed inside a tank manufactured in the countries of the Asia-Pacific region.

- Glass-ceramic tanks are considered the best and most reliable tanks in terms of cost and quality. The service life is slightly shorter than that of stainless steel boilers. The glass-ceramic coating, a derivative of the original enamel, is applied in two ways. European companies spray the protective layer exclusively using a dry method, which ensures high quality, uniform application thickness and long service life of the finished tank. The wet application method leads to uneven application of glass-ceramic enamel, which somewhat reduces the service life of the water heater.

- The main disadvantage of an enameled tank is that the coating is susceptible to temperature influences. Even the most flexible types of heaters last no more than 5 years during intensive use. The advantage is the affordable price. Titanium powder is added to the modern enamel coating, which significantly increases the working life of the tank.

The golden mean is to buy a water heater with a tank coated with a glass-ceramic protective layer. There is no point in buying budget enamel heaters. The costs for them are not recouped due to their short service life.