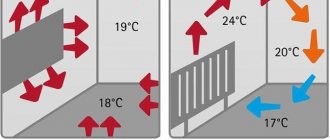

Technological progress in the heating equipment segment is developing in different directions. Some manufacturers rely on improving the performance characteristics of the element base of units, others promote the latest automatic control devices, and still others are also engaged in design optimization at a basic level. The last group of developments includes a bithermal heat exchanger. What it is? Essentially, this is a heating chamber capable of performing two different tasks - preparing water directly for heating, and for the needs of hot water supply, that is, for domestic consumption.

General information about bithermic heat exchanger

Classic heat exchangers for boilers provide for the separation of heating chambers. That is, one chamber is intended for servicing heating circuits - usually the main one, and for hot water supply - a secondary radiator. This design has many advantages, however, against the backdrop of combined heating chambers, its weaknesses also become obvious. In this case, it would be incorrect to assume that in the second case the water is mixed - this principle does not allow a bithermic heat exchanger. What is this in terms of approach to water maintenance? This is the same radiator equipment, but with a common housing, which contains both chambers for heating the coolant and compartments for preparing domestic water. In bithermal systems, the principle of separating service areas of different environments also applies, but this applies specifically to the internal delimitation of chambers. While a standard split heat exchanger initially contains two different chambers.

Which option is better?

It is impossible to answer this question unambiguously. If high-quality equipment is chosen, and the water inside the system is of good quality (without foreign impurities), then both boilers will do their job perfectly. There is a slight difference in their operating modes, but they are practically invisible to the consumer.

The main advantage of a bithermal heat exchanger is its cost. It is this criterion that buyers most often pay attention to. But, at the same time, we should not forget that due to the combination of contours, the width of the channels in them is smaller, which leads to their rapid clogging.

But it is worth noting that double-circuit boilers are also susceptible to scale deposits on the walls. Therefore, it will not be possible to avoid repairs by choosing such equipment. The cleaning principle is the same for both devices.

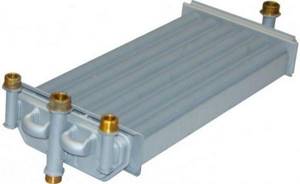

Structural device

Now it’s worth understanding the design features of bithermal radiators, which allow it to separately heat different environments. Experts characterize such structures with the concept of “pipe within a pipe” or “section within a section.” If a conventional heat exchanger assumes a set of pipes that have a hollow niche, then the bithermic device is distinguished by its internal division into several segments - these are zones in which water circulates for hot water supply and heating without mixing. And according to the classical scheme, copper fins-plates are also attached to the pipes, increasing the heat transfer coefficient. Obviously, depending on the method of integration into the target equipment, other design features of the radiator will be provided. In particular, the design of the bithermic heat exchanger of a gas boiler is oriented towards heating by a burner, so the housing can provide additional layers of protection. It is mandatory for all heat exchangers to provide safety measures against electrical short circuits. Since the circuits can interface with other utility lines, grounding and the presence of fuses in boiler stations are also mandatory.

How to properly install equipment

You can install such equipment either independently or with the help of boiler installation specialists. The only condition that cannot be violated is to include the boiler in the gas system itself, because such work will have to be entrusted to a specialist. Moreover, such people must have special permits and certificates. If the homeowner violates this provision, then first of all, he will be disconnected from the system, and secondly, a very large fine will be imposed. But in order to independently connect a cast-iron gas boiler, you will still need construction skills.

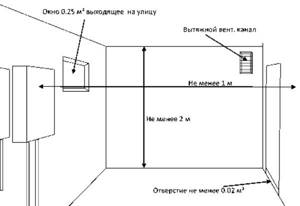

And such technical premises have special requirements:

The ceiling height in the boiler room must be at least 3 meters, and the room must be at least 4 square meters. meters. These parameters are suitable for an average-capacity boiler, but the larger the boiler, the more space there should be around. Usually such things are recommended by the manufacturer themselves; the presence of at least a single window, because there must be air flow. The door opening must be 80 cm wide and the gap between the floor and the door leaf must be at least 35 mm; the distance to electrical and gas installations or appliances must be at least 3.5 meters; on the floor, in the place where the cast iron boiler is planned to be installed, a cement screed is poured, and this place is reinforced with a steel plate

It is important to remember that the steel sheet must be located under the entire surface of the bottom of the heating installation, and also protrude 3-4 cm beyond its front side; With materials that have fire-resistant qualities, it is necessary to strengthen the entire part of the wall where the chimney pipe will pass.

You may be interested in >> What to do if the boiler blows out in the wind

The main document when independently preparing a boiler for mounting it into the system should be an accompanying document in the form of instructions developed by the manufacturer.

Such a document gives parameters and regulates the procedure for connecting the boiler to the main pipeline, to the chimney system, as well as to the return and supply systems.

How does a bithermal heat exchanger work?

The operating modes for heating and hot water supply have several differences. In the first case, standard heating of water occurs during the combustion of gas - if we are talking about the same gas boilers, for example. That is, in heating mode, the coolant is directly heated, which then circulates along its circuit. As for the operating mode in the DHW format, this function is in some way secondary. The primary heating of the coolant also occurs, and from it the heat is transferred to the sections with water intended for hot water supply. In this case, the heating heat exchangers do not distribute the heating water through the corresponding circuits - it remains in its section. For almost all bithermic boilers, one rule applies - only one of the two circuits can operate at the same time. Simultaneous circulation of water for heating and hot water supply is unacceptable.

Advantages and disadvantages

The main advantage of bithermal radiators has already been announced. They are cheaper and at the same time lose little in performance. Combining the heating and hot water circuits has virtually no effect on the heating rate of running water and at the same time does not reduce the amount of heated water. Comparing boilers of the same power from the same manufacturer, you can see that the permissible hot water consumption is practically the same.

The second aspect is the method of heating the water. Due to three or four precise fastenings of the inner tube to the outer one, the area of contact of the coolant with the heat exchanger increases. In fact, the heat from the plates is distributed not only over the surface of the outer tube, but also partially transfers to the inner tube. This increases the heating rate.

In the DHW circuit, when using only heating, the water warms up to the set heating temperature and does not take away heat until the hot water tap is opened.

As soon as the hot water tap opens, there is already well-heated water in the pipes. The heating circuit is closed, and the remaining water inside the heat exchanger additionally releases heat without preventing its transfer from the plates to the hot liquid in the internal cavity.

We recommend: Features of exhaust pipes for heating boilers

What about the cons?

And they also exist. The complex shape of the surface inside the tubes potentially increases the rate of salt deposition. Especially if the heating temperature is set to a high temperature up to 95°C inclusive. However, this is largely a problem not of the heat exchanger, but of water preparation.

In heating, by definition, the coolant must be filled in prepared. To do this, the liquid is removed from excess salts, iron and other inclusions, or at least softened, antifreeze and other additives are added to prevent the formation of scale. Even if you do not prepare the water, it moves in a closed circuit in the heating system and over time salts leave it, the total amount of which is not replenished.

With regard to hot water, it all depends on the adequacy of the user and the presence of pre-treatment and filtration. If there is a suspicion that the water is hard and contributes to the formation of scale, then a single-circuit boiler with a large channel cross-section in the heat exchanger will be at risk.

Scale in the heat exchanger

In any case, a filter or filter station should be installed before the boiler to prevent the ingress of salts and lime into the hot water supply and, of course, into the consumer’s tap.

Another feature is the separate operation of the heating and hot water supply circuits:

- At the first moment, while the hot water is open, with the heating running, almost boiling water will flow (depending on the set heating parameters).

- The coolant does not warm up when using hot water, but water heating, even with a very small volume, still has high heat capacity and inertness. You will have to use hot water for a very long time to feel the decrease in heat in the room in winter.

But in the end we can talk about the last advantage of the bithermic heat exchanger. In summer there are no problems with obtaining hot water. The source of heat for it remains the same combustion of fuel, and there is no need to warm up the entire circuit or even a specially prepared limited bypass circuit in order to please yourself with a hot shower.

Boilers with bithermic heat exchangers

The use of bithermal radiators in boiler systems is becoming increasingly widespread. Often, large manufacturers themselves develop model designs using their own components, including heat exchangers. One of the leaders in the segment is Immergas, which offers boilers with heat exchangers with 6 tubes. This design offers an advantage over 4 and 5 tube heat exchangers, since the expanded section can be located close to the burner flame. However, it is necessary to take into account the thermal power that will be provided by the 6-tube heat exchanger of the boiler. The bithermal operating principle in this case is capable of producing about 24 kW and this may be excessive for private houses and large country cottages. The companies Vaillant, Navien, and Protherm are also developing bithermal units. The products of these manufacturers are distinguished not only by their modern design, but also by their functionality. Engineers strive to provide models with the ability to smoothly adjust the flame, the option of cooling the heat exchanger, etc.

Advantages and disadvantages of the device

Advantages of single block radiators:

- low level of heat loss.

- Reliability of materials - there is only one connection that connects the block with the system channels.

- High efficiency of heat supply in two directions.

- The orientation of the control thermostats to a single unit provides 100% accuracy in obtaining data.

Disadvantages of bithermal radiators:

- Limited operation of the layers - liquids for supplying hot water supply and heating cannot be allowed to circulate at the same time.

- Coaxial circuits can quickly fail due to scale formation or corrosion of metal parts. Therefore, it is necessary to additionally use neutralizing inhibitors.

- Productivity is slightly reduced compared to boilers with separate blocks - for hot water supply and space heating.

Advantages of bithermic units

The advantages of heat exchangers with a single block extend to both heating efficiency as such and ease of control, not to mention the higher reliability of the units. As for efficiency, bithermic radiators operate with a lower heat loss coefficient. If a system divided into two blocks requires heating of two blocks, then in this case the filling of one housing is serviced - accordingly, the volume of heat generated increases. In terms of control, a bithermal heat exchanger is more profitable for the same reason. Thermostats are guided by the indicators of one solid block, which affects the accuracy of the data obtained. Reliability, in turn, is achieved by minimizing the connecting infrastructure - in fact, only a connection between the heat exchanger and supply channels is required.

Design flaws

The main disadvantage of the bithermic design is the limitation when working with liquids saturated with salts. In this context, one can note the imperfection of the monoblock case and the coaxial circuits inside, which quickly become covered with scale. In addition, a bithermic heat exchanger is not able to provide the same performance as in the case of divided radiators. This applies specifically to hot water supply, since the design itself involves a smaller volume of water served for such tasks.

Comparison with split heat exchanger

If the water quality meets the requirements and the use of filtration and softening, the bithermal exchanger will provide good efficiency and quickly heat the liquid. It is also advisable to provide it with preventative washing every two years, but without consulting a specialist and knowing the intricacies of technology, you should not undertake this. In terms of maintainability, the device is much inferior to a separate one: the latter can be easily repaired even at home, and if the operating conditions are not met, the coaxial exchanger often has to be replaced with a new one.

The operation of the boiler depends on the design of the exchange mechanism and its material. Copper, from which bithermal products are usually made, has a high heat capacity, which makes it possible to make compact units suitable for wall mounting or placement in the kitchen. Exchangers are also available in aluminum and steel. Stainless steel is often used in separate structures. Its heat capacity is lower than that of copper, it is susceptible to corrosion and requires large volumes of coolant. Durable cast iron exchangers were widely available on the market in the past, but have now been replaced by lighter weight options.

Bithermal heat exchangers have high efficiency; their design allows the design of more compact and lightweight boilers. The disadvantage of such devices is the susceptibility to overgrowing of the walls with lime deposits.

Consumer Reviews

Users themselves mainly emphasize the energy efficiency of this solution. Boiler and boiler owners who have previously dealt with traditional split heat exchangers point to both high heat output and low gas consumption. But this applies to cases where a gas supply infrastructure is used, into which boilers with a bithermic heat exchanger are installed. Reviews from owners who rarely use the heating function, on the contrary, indicate that such units are unprofitable. The fact is that boilers with divided heating allow you to work specifically on one of the tasks - heating or hot water supply, which turns out to be more economical.

Heating devices made of steel and copper alloys

Since mass production of household appliances is focused on the production of heat exchangers made of ferrous metal, gas boilers with a copper heat exchanger are considered a prestigious product. Copper has high heat transfer characteristics. Therefore, to heat a large house, you can use small boilers with a small amount of coolant. As a result, the devices are very compact.

That is, to heat an equal amount of a substance, copper needs to transfer less heat than steel. Accordingly, the inertia of the heating system, where there is a steel heat transfer unit, is greater. The boiler automation, working with a copper heat transfer block, responds faster to an increase in coolant temperature. This ultimately leads to fuel savings. An even greater reaction of the heating system to heating occurs when the pump is running. In addition, it ensures improved circulation even with broken pipe slopes and prevents water from boiling.

Comparing copper heat exchangers for boilers with steel ones, we can say that the latter are more ductile. This factor is important because there is a constant process of interaction with open fire. As a result, thermal stresses in the metal develop and cracks appear. Steel is more durable in this regard and can withstand a large number of cycles: heating - cooling.

The note! The disadvantages of steel, in addition to inertia and increased specific heat capacity, include: susceptibility to corrosion; increased volume of the heater surface; a large amount of coolant; a significant mass of heating devices.

Nuances of operation

Manufacturers of bithermal equipment note that rapid wear of the heating filling can be prevented by following several operating rules. These include, in particular, ignoring preventive checks of circuits. Most often, a bithermal heat exchanger is installed on a heating and hot water system with the expectation of long-term and regular operation. In intensive operation, even relatively clean water can negatively affect the condition of the radiator pipes. Accordingly, periodic cleaning of the surfaces of the sections is required.

It is not recommended to sharply increase the heating temperature. Unlike divided heat exchangers, monoblock systems require more time to prepare DHW. When heat exchangers are used for heating, this is practically unnoticeable because the water is heated quickly for such tasks. But liquid for household needs, as already noted, is heated secondarily.