Recommendations for choosing a pump

A circulation pump installed in the heating system of a private house must perform its basic functions well. Each such device has certain requirements.

- The unit must have the required productivity or performance. This parameter is calculated under conditions of minimal load on the device.

- Another selection criterion is the pressure that provides the required pressure in the pipes and the entire system. In this case, the operating conditions must be taken into account. They depend on the volume of the premises, the type of liquid in the system, the ambient temperature and the coolant itself. The diameter of the pipes used is of great importance.

- When purchasing, you must take into account external factors related to the size of the unit, the noise level during operation, and the difficulties of maintenance.

The correct choice of pump ensures its reliable and stable operation, long-term operation in difficult conditions.

Pump installation options and features

Early models were installed exclusively on the return line, at the entrance to the boiler, since the coolant temperature at this point was minimal. A modern heating circulation pump has a fairly high temperature limit and can be installed at any suitable point in the heating circuit.

Thanks to the wide variety of models, it is possible to use combined systems in which a powerful pump is installed for general circulation, and an additional device is allocated for heating the underfloor heating circuit, heating the pool or utility rooms. How to choose circulation pumps for heating systems is decided individually in each case.

The installation point must comply with the following rules:

- The installation location should be located below the maximum height of the system;

- no air should enter the pump;

- An emergency stop of the pump should not cause a critical increase in water pressure in the system.

To remove air and steam from the water along the flow, an expansion tank with a manual or automatic air vent is installed at the highest point. And at the highest points of each individual branch of the general circuit, it is advisable to install additional air vents.

To protect against water hammer during a sudden stop of the motor, you can use a check valve connected in parallel to the heating pipe system. When the circulation pump for heating systems is turned on, the valve will be closed under the influence of excess pressure. And when turned off, water will begin to flow freely through the valve, bypassing the impeller. Special ball valves for heating systems are ideal for this purpose.

Important!

Since the shut-off ball shuts off the water under its own weight, the valve is installed in the heating system only vertically. In the position where the arrow on the body points upward.

How to choose a pump for a heating system

The selection of a pump for a heating system begins with an analysis of the parameters of the room and the installed water heating equipment. Additionally, they determine what functions, in addition to increasing the coolant speed, the installed module should perform.

There are several types of circulation pumps offered by different manufacturers. When choosing, you should focus on the quality and reliability of the product, as well as performance parameters.

When choosing a circulation pump for heating a private house, consider the following points:

- Power.

- Equipment manufacturing company.

- Functionality.

How to calculate the power of a circulation pump

An accurate selection based on the area of the house is made only after a thermal audit of the room and heating system. Often, the procedure is expensive and is performed for industrial facilities and apartment buildings. For domestic buildings with a relatively small area, there is a method for calculating a pump without formulas.

You can independently select the power of the circulation pump as follows:

According to boiler performance

The calculation of a circulation pump for the heating system of a private house is carried out taking into account that 1 kW of water heating equipment power corresponds to a throughput coefficient of 1 l/min. Accordingly, for a 25 kW boiler, you will need to install a pump with a rating of 1500 l/hour. Calculation of the pressure of the circulation pump of the heating system

The technical documentation indicates the pressure parameter in meters of water column. Using this parameter, you can determine the length of the water circuit and calculate the required number of pumps in the system. It is believed that for 10 l.m. pipeline, 0.6 m of water column pressure is required. The optimal choice of pump for a 1-story building is standard models with 6 m.v. Art. The stations are suitable for rooms with a pipeline of up to 100 lm. If the pressure is not enough, install a second pump or select a more powerful model. The same calculation principle is used when choosing a pump for a 2-story house.

Which brand of circulation pump to choose

The cost of a circulation pump, performance, and operating time directly depend on the manufacturer of the equipment. It is wrong to focus only on price. When choosing a model, it would be a good idea to find out about consumer reviews regarding quality, technical and industrial characteristics.

Judging by the number of sales, the following companies offer the best circulation pumps:

- Grundfos is the world's largest manufacturer of pumping equipment. According to recent estimates, about 50% of all products sold belong to this brand. Grundfos models are distinguished by high reliability and performance. The company has developed and implemented several energy-saving technologies. German pumps are guaranteed to operate for at least 10 years.

- Wilo is another leader in the production of circulation equipment. The German company currently has factories located in several countries, which, however, does not affect the quality of the products. Wilo's product range includes domestic and industrial stations, as well as electronically controlled models.

- DAB is an Italian company with many years of experience in the production of circulation equipment. Since 2002, the operating principle of DAB pumps has been improved at the company's factories, which has led to an increase in the reliability and performance of the equipment, and also reduced noise.

- UNIPUMP is a Russian competitor to well-known foreign brands. The equipment is being manufactured. The product range includes submersible and surface pumps. The main advantage of UNIPUMP is considered to be the low cost of the equipment and full adaptation to the conditions of domestic operation.

- Oasis is a model that is often offered as a Russian product, but actually comes from China. It has factory assembly and quality. The cost, even compared to Russian analogues, is approximately 30% cheaper, which explains the high popularity of the brand. Oasis models are guaranteed to last their entire service life. The equipment is inferior in performance and thermal characteristics to previous manufacturers.

- Wester is another brand that is promoted as English, but actually belongs to the group. Sufficiently reliable models for heating and hot water systems. Wester pumps are suitable for domestic and industrial use, the only drawback is the limited range of products.

Popular manufacturers

The question of how to choose affects not only the technical characteristics of the device. Most often, consumers understand this as a brand or manufacturer. The modern market offers a fairly wide range. There are both foreign and domestic analogues here. Here are just a few models.

Italian pump Aquario

Its model AC204-130 is one of the most popular. Used for small private houses. Its power is 2.4 m³/h, pressure up to 3 m, power consumption 0.64 kW, weight 3.4 kg.

The connection is flanged and has three speed modes.

Italian DAB device VA-VB-VD

It has a wide range of technical characteristics: pressure up to 6 m with power from 0.5 to 3.3 m³/h.

This sample is equipped with a special thermal relay that turns off the pump if it starts to overheat. Many experts advise choosing this particular model.

Grundfos

The Danish company Grundfos offers pumps in five modifications. In Russia, the UPS model has gained great popularity as the most economical in terms of electricity consumption (0.55 kW).

At the same time, its head is 3 m, and the volume of pumped coolant is 3 m³/h.

Russian models

Among domestic manufacturers, it is necessary to highlight pumps of the “Khozyain” brand from Podolsk and “Tsirkul” from. Several technical characteristics:

- Owner 4.25.180 – head 4.2 m, power 3 m³/h;

- Owner 8.32.180 – head 8 m, power 9.6 m³/h;

- Compass 25/40 (pressure 4 m, volume 2.5 m³/h) - the smallest sample;

- Compass 32/80 (pressure 8 m, volume 3.2 m³/h) is the largest.

Both brands produce pumps that are connected to the pipeline with a flange connection. So, knowing the brands and models offered by manufacturers, you can choose the right pump, taking into account not only its technical characteristics, but also the price.

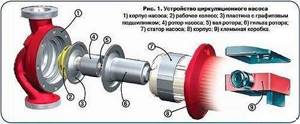

Types of circulation pumps

The design of a typical circulation pump consists of a housing made of stainless metal, a ceramic rotor and a shaft equipped with a wheel with blades. The rotor is driven by an electric motor. This design ensures that water is taken from one side of the device and pumped into pipelines from the outlet side. The movement of water through the system occurs due to centrifugal force. In this way, the resistance that arises in individual sections of the heating pipes is overcome.

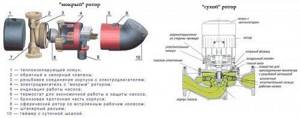

All such devices are divided into two types - dry and wet. In the first case, there is no contact of the rotor with the pumped water. Its entire working surface is separated from the electric motor by special protective rings, carefully polished and adjusted to each other. The operation of dry-type pumps is considered more efficient, but during operation there is quite a lot of noise. In this regard, separate isolated rooms are equipped for their installation.

When choosing such models, you should take into account the presence of air turbulence generated during operation. Under their influence, dust rises into the air, which can easily get inside the device and break the tightness of the sealing rings. This will lead to failure of the entire system. Therefore, a thin film of water is present between the rings as protection. It provides lubrication, preventing premature wear of the rings.

Wet-type circulation pumps have a distinctive feature in the form of a rotor that is constantly located in the pumped liquid. The location of the electric motor is securely separated by a sealed metal cup. These devices are usually used in small heating systems. They make much less noise during operation and do not require additional maintenance measures. Typically, such pumps are periodically repaired and adjusted to the required parameters.

A significant disadvantage of these pumps is considered to be the low efficiency due to the insufficient tightness of the sleeve separating the stator and the coolant

When choosing the right model, you should pay attention to the fact that the pump has not only a wet rotor, but also a protected stator

The latest generations of circulation pumps are almost completely automated. Smart automation ensures timely switching of winding levels and significantly increases the productivity of the device. Such models are most often used when water flow is stable or slightly varying. Thanks to stepwise adjustment, it is possible to select the most optimal operating modes and significant energy savings.

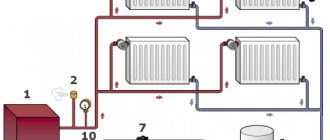

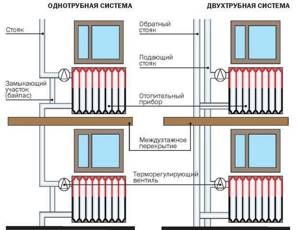

Do-it-yourself pumping equipment installation diagrams and standards

Circulation pumps are installed in two ways. The first connection diagram for the unit is two-pipe. This connection method is described by a high temperature difference in the system and variable coolant flow. The second scheme is one-pipe. In this case, the temperature difference in the heating system will be insignificant, and the media consumption will be constant.

Installed circulation pump

Connect the pump yourself according to the instructions that come with the unit. It also indicates the installation procedure for the functional reinforcement chain. Before installing the pump, be sure to drain all water from the system. Often there is a need to clean it. During the operation of the heating boiler, a lot of debris accumulates on the internal surfaces of the pipes, which worsens the technical performance of the system.

Experts advise placing the circulation unit in front of the boiler - on the return line. This is done in order to eliminate the risk of boiling of an open type heating system due to the vacuum that is created when installing the supply pump. In addition, if you install a circulation unit on the return line, its trouble-free operation will be significantly increased due to the fact that it will operate at lower temperatures.

Types of circulation pumps

A pump with a “wet” rotor is made of stainless steel, cast iron, bronze or aluminum. Inside there is a ceramic or steel motor

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the fundamental design of a heating system based on a heat pump does not change, the two types of such units differ in their operating features:

- A pump with a “wet” rotor is made of stainless steel, cast iron, bronze or aluminum. Inside there is a ceramic or steel motor. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously functions as an engine cooler and a lubricant for the working elements of the device. Since the “wet” device circuit does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment only works in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of a wet pump are that it does not require maintenance and also has excellent maintainability. However, the efficiency of the device is only 45%, which is a minor drawback. But for domestic use this unit is perfect.

- A pump with a “dry” rotor differs from its counterpart in that its motor does not come into contact with the liquid. As a result, the unit has less durability. If the device operates “dry,” then the risk of overheating and failure is low, but there is a risk of leakage due to abrasion of the seal. Since the efficiency of a dry circulation pump is 70%, it is advisable to use it to solve utility and industrial problems. To cool the engine, the device circuit provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since in this unit water does not serve as a lubricant for working elements, during operation of the unit it is necessary to periodically carry out technical inspection and lubricate parts.

In turn, “dry” circulation units are divided into several types according to the type of installation and connection to the engine:

- Console. In these devices, the engine and housing have their own place. They are separated and firmly fixed on it. The drive and working shafts of such a pump are connected by a coupling. To install this type of device, you will need to build a foundation, and maintaining this unit is quite expensive.

- Monoblock pumps can be used for three years. The body and engine are located separately, but are combined by a monoblock. The wheel in such a device is installed on the rotor shaft.

- Vertical. The service life of these devices reaches up to five years. These are sealed advanced units with a seal on the end side made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, and aluminum are used. When the device is running, these rings rotate relative to each other.

There are also more powerful devices on sale that have two rotors. This dual circuit allows you to increase the performance of the device at maximum load. If one of the rotors fails, the second can take over its functions. This allows not only to enhance the operation of the unit, but also to save energy, because with a decrease in heat requirements, only one rotor works.

Criteria for proper selection of equipment

All installation efforts will be reduced to zero if the equipment is selected incorrectly. In order not to make a mistake, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

Main types of pumps

According to their design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet type pumps . This option is suitable for private homes. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high productivity - the maximum efficiency of modern models reaches 52-54%.

Pumps with a dry rotor are productive, unpretentious to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal position on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are installed on a foundation or metal support frame.

For installation of console, monoblock or “In-line” models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³/h is required, that is, for servicing groups of cottages or apartment buildings.

Brief overview of technical characteristics

When choosing a pump, you should definitely study the technical characteristics and compare them with the requirements of the heating system.

The following indicators are important:

- pressure , which covers hydraulic losses in the circuit;

- productivity - volume of water or supply over a certain time interval;

- operating coolant temperature , max and min – for modern models on average +2 ºС… +110 ºС;

- power – taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet/outlet diameter of the pipes. For heating systems, the average parameters are 25 mm and 32 mm.

An example of a unit for equipping a residential heating network with an area of 100 m² is a Grundfos UPS with a 32 mm pipe connection, a capacity of 62 l/s and a weight of 3.65 kg. The compact and low-noise cast iron device is inaudible even behind a thin partition, and its power is sufficient to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information on the calculation and selection of a circulation pump for heating is presented in the articles:

How to install heating batteries

Radiators are designed to transfer thermal energy from the coolant to the room. In fact, they compensate for heat losses in the building. Therefore, before installing the heating radiator, you should choose its location correctly.

The best option is considered to be the place of greatest heat loss in a house or apartment - external walls and window structures. This must be foreseen at the heat supply design stage. Then you need to decide how to install the heating batteries correctly and choose the connection method:

- Upper. Used for vertical piping;

- Side. The method is suitable for horizontally located highways;

- Lower. The best option for hidden installation of pipes.

The efficiency of the battery depends on the correct choice of this parameter. The figure below shows how to correctly install the heating radiator in relation to the method of connection to the system.

Another important point is the location of the heating device relative to the walls and window structures. It is necessary to install the heating radiator so that it provides free air circulation. Almost all heating batteries operate on the converter principle. Those. air flows should pass through the maximum area of the devices. In order to correctly install heating batteries, you should adhere to the following recommendations:

- The distance to the window sill is at least 10 cm. In this case, it should cover only 2/3 of the battery.

- The distance of the lower part of the radiator from the floor is 12 cm.

For proper installation of a heating radiator, it is necessary to first insulate the walls. You can increase the heat transfer rate using a reflective surface. Most often, penofol with a foil layer is used for this.

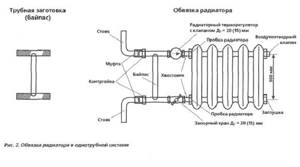

Heat supply radiator piping

Ensuring normal operation of radiators is only possible with correct piping. Its elements must perform the functions of protecting and regulating the degree of heating of the heating device.

Correct installation of heating batteries depends on its type and design. Most often, manufacturers indicate optimal installation schemes in the instructions. The following components are used to tie batteries:

- Mayevsky crane. Designed for timely removal of air pockets;

- Thermostat. Necessary to regulate the volume of coolant flow;

- Shut-off valves. With its help, you can disconnect the radiator from the general heating system for further repair or replacement.

Upon completion of installation, the tightness of all components is checked and the device is pressure tested.

During installation, the radiator or battery must not be tilted. This can lead to air locks and also degrade the performance of the heating system.

The video shows how to install a heating radiator yourself.

Position of the water pump in space

We have already decided where to install the circulation pump for heating and have developed brief instructions - if the circuit does not branch, we place it on the return line. In the case of several circuits, the connection diagram will be different - we install a pump on the supply pipes in each direction.

Regardless of where the water pump for home heating will be installed, its rotor axis must be located strictly in a horizontal position. Along other axes its position can be arbitrary. But its electrical circuit should not be located at the bottom, for which there is a completely logical explanation - if the unit fails, the electrical circuit will be flooded with coolant, which will cause a short circuit.

What are the benefits of pump heating systems?

30 years ago, so-called steam heating was common in private homes, where a coolant was used that circulated through pipelines and radiators by gravity, and the heat source was a gas boiler or wood stove. Pumps for pumping water were used only in district heating networks. When more compact units appeared, they migrated to private housing construction, as they provided the following advantages:

- The speed of coolant movement has increased. The heat generated by the boiler has become faster delivered to the radiators and transferred to the premises.

- Accordingly, the process of heating the house has accelerated significantly.

- The higher the flow rate, the greater the throughput of the pipe. This means that the same amount of heat can be delivered to rooms through lines of smaller diameter. Simply put, the pipelines have become half the size thanks to the forced circulation of water from the pump, which is cheaper and more practical.

- Highways can now be laid with a minimum slope and water heating circuits can be made as complex and extensive as desired. The main thing is the correct selection of the pumping unit in terms of power and pressure created.

- The household circulation pump for heating has made it possible to organize underfloor heating and more efficient closed systems operating under pressure.

- It was possible to remove from view the ubiquitous pipes that run through the rooms and do not always harmonize with the interior. Increasingly, heating communications are laid in walls, under floor coverings and behind suspended (suspended) ceilings.

Note. A minimum slope of 2-3 mm per 1 m of pipeline is needed to empty the network in case of repair or maintenance. Previously, it was made at least 5 mm / 1 m.p.

Pumping systems also have disadvantages. This is a dependence on electricity and its consumption by the pumping unit during the heating season. Therefore, if there are frequent power outages, the circulation pump must be installed together with an uninterruptible power supply unit or connected to an electric generator. The second drawback is not critical; if you select the power of the device correctly, then the electricity consumption will be acceptable.

For reference. Leading manufacturers of heating equipment, such as Grundfos or Wilo, have developed new models of units that can save energy. For example, if you buy and install an Alpfa2 circulation pump from the Grundfos brand, it will automatically change its performance depending on the needs of the heating system. True, its price starts from 120 USD. e.

New generation products from Grundfos - models Alpfa2 and Alpfa2L

About the choice of equipment and the rules for its independent calculation

The key indicator that determines the efficiency of the circulation pump is its power. For a household heating system, there is no need to try to purchase the highest-power installation. It will only make a loud noise and waste electricity.

Mounted circulation pump

You need to correctly calculate the power of the unit based on the following data:

- hot water pressure indicator;

- pipe section;

- productivity and throughput of the heating boiler;

- coolant temperature.

Hot water consumption is determined simply. It is equal to the power indicator of the heating unit. If, for example, you have a 20 kW gas boiler, no more than 20 liters of water will be consumed per hour. The pressure of the circulation unit for the heating system for every 10 m of pipes is about 50 cm. The longer the pipeline, the more powerful the pump you need to purchase. Here you should immediately pay attention to the thickness of the pipe products. The resistance to water movement in the system will be stronger if you install pipes with a small cross-section.

In pipelines with a diameter of half an inch, the coolant flow rate is 5.7 liters per minute at the generally accepted (1.5 m/s) speed of water movement, with a diameter of 1 inch - 30 liters. But for pipes with a cross-section of 2 inches, the flow rate will already be at the level of 170 liters. Always select the diameter of the pipes in such a way that you do not have to overpay extra money for energy resources.

The flow rate of the pump itself is determined by the following ratio: N/t2-t1. In this formula, t1 refers to the temperature of the water in the return pipes (usually it is 65–70 °C), and t2 is the temperature provided by the heating unit (at least 90 °C). And the letter N denotes the boiler power (this value is in the equipment passport). The pump pressure is set according to the standards accepted in our country and Europe. It is believed that 1 kW of power of a circulation unit is quite enough for high-quality heating of 1 square meter of a private home.

Pump device

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- wheel with blades or impeller;

- engine.

Typically, an impeller is a structure of two parallel disks that are connected to each other by means of radially curved blades. One of the disks has a hole for liquid to flow through. The second disk secures the impeller to the motor shaft. The coolant passing through the engine acts as a lubricant and coolant for the rotor shaft where the impeller is fixed.

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite bearings for sliding.

Installation diagram

In practice, two schemes for installing a circulation pump are used in a single-pipe and two-pipe heating system. Before carrying out installation work, you must carefully study the attached instructions. At the preparatory stage of work, water is drained from the system and the pipes are cleaned of contamination by additional pumping of liquid. The pump is installed according to the attached diagram, then coolant is poured into the circuit and the unit is turned on.

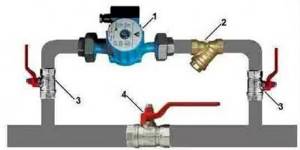

As we have already said, it is best to install the pump on the return side using a tap or, as it is also called, a bypass. Such a device is necessary to shut off the water and replace the pump in case of breakdown. The diameter of the outlet pipe should be smaller than that of the central pipeline.

Installation diagram of an additional pump in the heating system

At each edge of the bypass, before entering and after exiting the pump, taps are installed for emergency shut-off of the coolant. Another valve is installed on the central line to direct the flow of liquid through the pump. Before entering the pumping equipment, a special filter is attached that will accumulate harmful particles in the water.

Carrying out installation work

The water pump is installed in the heating system through a bypass. Take a look at its drawing and familiarize yourself with the main elements:

The connection diagram with a bypass is good because it allows you to switch from natural circulation to forced circulation at any time. It will also help you replace the water pump without stopping and draining the entire heating system.

- The circulation pump (1) is the main “person” in the system;

- Shut-off valves (3) – disconnect the pump from the heating;

- Bypass valve (4) – ensures that the coolant moves only through the pump or along both channels;

- Dirt filter (2) – provides coarse filtration from large mechanical contaminants.

Let's see how to connect a pump to a heating boiler and what is needed for this. First, we inspect the installation site to find free space to place the bypass. At the next stage, we assemble the bypass elements, prepare the taps, nuts, drains and dirt filter. We will also need a set of keys to connect individual units, and seals.

Let's start assembling the bypass - we form a section with a water pump, screwing a dirt filter and taps to it. Next, we proceed to inspect the section of the pipe where the insertion will take place. We cut out a piece for the bypass tap, take the area with the pump, and cut holes for it. Next, we weld all the elements and only then tighten all the threaded connections with wrenches - this cannot be done before welding.

Having connected the water pump to a floor-standing or wall-mounted boiler, we proceed to electrical work - we connect electrical wires with power to the terminals. Here it is recommended to install a separate RCD, choosing a 1 or 2 kW sample.

The next step is to start the water pump. To do this, you need to fill it with water, removing air from it. The air plug is removed through a built-in bleeder or through a plug screw. We open all the taps, open the drain or unscrew the screw plug, wait until the air comes out and water flows. After this, we seal the system and try to start the water pump. If the device is noisy, it means that not all of the air plug has come out - partially unscrew the plug screw and keep the system open until the air bubbles disappear.

Next, all that remains is to adjust the shaft rotation speed so that the productivity is slightly less than normal. There is nothing wrong with installing a water pump in a heating system with your own hands - you just need to know how to work with tools. If problems arise, consult with specialists.

Conclusions and useful video on the topic

Theoretical knowledge is quickly absorbed when accompanied by an interesting video that reveals the sequence and features of the work on installing devices.

Video review of the WILO pump – configuration and installation:

Practice shows that advanced home improvement enthusiasts can handle installing a circulation pump on their own.

However, if difficulties arise, it is better to turn to specialists: only qualified craftsmen know how to properly tie and install a heating pump, observing all the nuances of the chosen scheme.

Do you have personal experience installing a circulation pump? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

Installing a circulation pump in homes with an individual heating system ensures uniform and high-quality heat distribution throughout all rooms of the house.

Where to install the pump?

In order for the entire system to be correctly connected, it is necessary to draw a diagram and position the unit so that it can be approached (for maintenance).

Today, there are wet-type pump designs on sale that can be mounted both on the return and supply pipelines.

In order to increase the pressure in the suction section, it is necessary to install the pump on the falling pipeline, near the connection of the expansion tank. In this case, the main thing is that the pump can withstand the strong pressure of hot coolant.

For quick installation, you must purchase a unit with selected detachable threads. Next, study the instructions and connection diagram, and if you are not sure that you can do the work of installing the pump yourself, then contact a specialist.

With warm floor

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

In small private houses, a gravity heating system is installed, which operates on the principle of random circulation of coolant caused by the masses of cold and warm water entering the system.

But such a network is not able to heat a large building or a two-story house, since this requires installing a circulation pump.

This device makes it possible to distribute heat evenly throughout the entire wiring.

Unit selection

Installation of a pump into an existing distribution system or a heating system that is still being designed begins with the selection of a device. There is no need to purchase a large design with huge performance. After all, it is expensive and will create a lot of noise.

It is important! Before purchasing, you must correctly calculate the power of the unit for a specific case. The main performance parameters are water temperature, pipeline diameter and pressure level of liquid circulating through the system. In order to correctly determine the coolant flow rate, it is passed through a closed loop of the system and compared with the liquid flow rate for the boiler.

The boiler power is set by determining how many liters of coolant passes through the heating system per minute. They also calculate the amount of liquid required for the high-quality operation of each battery and ring of the system.

The performance indicator depends on the length of the pipeline; note that half a meter of pumping pressure is required per 10 m.

Let's consider what a pump for a heating battery can be like, or rather, what types of pumps exist:

- Dry - does not come into contact with the coolant during operation. These are noisy units, so they are usually installed in enterprises or production workshops;

- Wet - for work they are immersed in water, installed in private homes. To prevent the unit from being damaged by water, it is produced in brass or bronze cases, and the parts are made of stainless steel.

Advantages and disadvantages

The advantages include:

- The ability to normalize the operation of the system, organize uniform and stable movement of the coolant.

- The ability to change the operating mode, which saves fuel.

- The high speed of movement allows you to heat the room in a short time.

- Some pipeline design flaws can be corrected after circulation is started.

- Reliability, ability to work in difficult conditions.

- Durability, undemanding, long service life.

- The ability to choose a model that is affordable and has suitable characteristics.

Disadvantages of devices:

- To operate the pump, you must be connected to a power supply.

- Electricity consumption increases, which will require additional costs.

- If there is a sudden power outage, the coolant circulation stops.

- Purchasing and installing the device into the system will also require certain expenses.

Expert opinion

Kulikov Vladimir Sergeevich

Despite some disadvantages, circulation pumps are popular devices, without which no system can be operated.