Functions

A water heated floor differs from a traditional heating system in that the length of the circuits is significant - up to 120 meters at maximum, and the diameter of the pipes is usually small - 16-20 mm. Each circuit has many turns. Therefore, it becomes clear that for normal heating operation, forced circulation will be required. And it is the pump for the water floor that ensures the speed of movement of the coolant through the pipes sufficient for normal temperatures. Moreover, to maintain a stable temperature, it will be better if the pump has several speeds. Such devices are called adjustable and their operation can be controlled manually or using automation.

Choosing a pump for a heated floor is a rather complex and responsible task.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

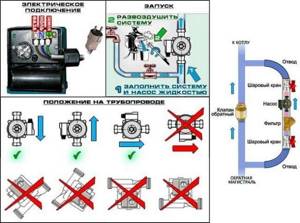

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

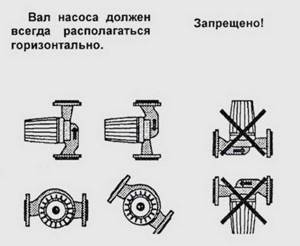

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Calculation of pump parameters

Circulation pumps are installed in heating systems. They do not create excess pressure, but simply push the coolant at a certain speed. Since the need for heat changes depending on weather conditions, the speed of movement of the coolant must also change. Therefore, it is better to install adjustable pumps - three-speed.

Before purchasing, you should decide on two main parameters: performance (flow) and pressure. If the coolant is water, the pump performance is calculated using the following formula:

Q = 0.86*Pn/(trev.t - trev.t)

- Pн — heating circuit power, kW;

- trev.t - temperature of the coolant in the return

- tpr.t — supply temperature.

If there are several circuits, determine the flow rate for each of them and add them up. The sum of the flow rates of all circuits will be the required performance of the unit.

The temperature difference in water heating systems is usually 5 ° C, the power of the circuit most often depends on the heated area, therefore, to simplify the selection of a pump for a water heated floor, you can use the table. But it must be taken into account that the calculations took average figures for central Russia. Therefore, if your house is not well insulated, or you live significantly north or south of the middle zone, you will have to adjust the result (or calculate it yourself). In general, this parameter is taken with a margin of 15-20% in case of abnormal cold weather.

Table for determining pump performance depending on the heated area

The second characteristic by which a pump is selected is the pressure it can create. Pressure is necessary to overcome the hydraulic resistance of pipes, fittings, and other system components. The system resistance depends on the pipe material and its diameter. The value of the hydraulic resistance of the pipe is available in the accompanying documents (averaged data can be used). Also taken into account is the increase in resistance on the valve (1.7), on the fittings and fittings (1.2) and on the mixing unit (required when using a high-temperature boiler and the coefficient for it is 1.3).

H= (П*L + ΣК) /(1000),

- H—pump pressure;

- P is the hydraulic resistance of a linear meter of pipe,

- Pa/m; L is the length of the pipes of the longest circuit, m;

- K is the power reserve factor.

To calculate the required pressure in the circuit, the nameplate hydraulic resistance of a meter of pipe is multiplied by the length of the circuit. The value is obtained in kPa (kilopascals). Convert this value to atmospheres (pump pressure is measured in atmospheres) 100 kPa = 0.1 atm. The found value, depending on the presence of fittings and valves, is multiplied by the corresponding coefficients. After all the operations, you have found the operating point of the pump.

Select a model based on graphic characteristics

But the calculation of the pump for the heated floor is not finished yet. Now you need to select a model. To do this, find the characteristics of the pump in the catalog of the manufacturer you like. It is presented in the form of a graph. Select the model so that the found operating point is in the middle third of the characteristic. If you are installing a three-speed option, then select a model with the second speed - this will ensure an optimal, and not at the limit, operating mode and your pump will last a long time and provide a normal temperature even on cold days.

Pump Specifications

To install heated floors, circulation pumps are used, the characteristics of which are quite sufficient to ensure complete and efficient heating. The intensity of coolant movement through the pipes is affected by its temperature and pressure in the system. The normal functioning of a heated floor assumes that there will be no water hammer in the circuit, and the pump will respond in a timely manner to changes in the system. As a rule, automation is connected to the heating system, which monitors a number of parameters and sends the necessary commands to the pump.

Pump power is calculated using the formula:

- Q = 0.86 x Рн / (topr.t – tort.t), where

- Рн – maximum power of the heating system,

- topr.t – coolant temperature at the outlet to the circuit,

- tort.t – coolant temperature at the system outlet.

When connecting several circuits, their indicators must be added up so that they are taken into account in the calculations. Experts recommend installing a separate heated floor circuit in each room - this ensures a maximum degree of control over the operation of the system, allowing you to adjust the microclimate depending on the characteristics and purpose of individual rooms.

The temperature difference in the supply and return pipes varies depending on the following factors:

- Outline length. An increase in the length of the circuit is usually associated with a large area of the heated room. Of course, under such conditions, heat transfer will be quite intense, and the temperature of the water leaving the circuit will decrease.

- Quality of insulation. Installation of heated floors must be carried out competently and taking into account all the requirements for these systems. In particular, if thermal insulation is not sufficiently reliable, the level of heat loss will have a noticeable impact on heating efficiency. To compensate for heat losses, the pump will have to pump more liquid.

- Climatic conditions in the region. If the building is located in a region characterized by severe cold, then the heated floor must have increased power. In such conditions, the circulation pump must also have a power reserve. It is recommended to purchase devices whose power is at least a quarter higher than required. High-quality and reliable Grundfos pumps are quite suitable for underfloor heating (more details: “What are Grundfos heating pumps - types, advantages of Grundfos circulation pumps”).

In addition to power, any pump has another important characteristic - the pressure of the coolant flow. The amount of pressure must be sufficient to overcome the hydraulic resistance of the coolant. The level of hydraulic resistance is determined by the length of the circuit, the diameter of the pipes used and the speed of the coolant.

To calculate the pressure in the system, you need to use the following formula:

- N = (P x L + K) / (1000), where

- N – circulation pump pressure,

- P – hydraulic resistance per 1 m of pipeline (determined by the diameter of the pipes, the material of their manufacture and the speed of movement of the coolant),

- L is the total length of the pipeline, taking into account each section of the system,

- K – power reserve factor of pumping equipment.

When all calculations are completed, you can start choosing the most suitable device for a particular situation.

Marking and case material

These are two or three numbers like: 25/40, 25/60-130 or 32/80, etc. The first number is the diameters of the inlet/outlet holes in millimeters. That is, in the given markings the connecting dimensions are 25 mm and 32 mm. The second number is the lifting height that this model provides. In the example given, these are 4 meters, 6 meters and 8 meters. If we translate atmospheres, then this is 0.4 atm, 0.6 atm, 0.8 atm. The third number is the installation length, that is, the size of the entire device from one end to the other. In our example it is 130 mm.

Installation nuances

Installation of a water heated floor should take place according to a pre-designed scheme. The collector requires a place equipped for installation; this can be either a boiler room or a compartment hidden in the wall. The rationality of installing intermediate collectors depends on whether savings are ensured compared to laying pipes from a central distribution center, and also whether such an increase in the length of the largest loop is permissible. It is recommended to supply pipes to heating zones in rooms that do not require targeted floor heating: storerooms, corridors and the like.

Heated floor tubes should only be attached to a special installation system. Perforated tape or mesh provides precise adjustment of the installation pitch, reliable fixation while the mixture hardens and the gaps necessary for temperature control.

The installation system is fixed to the floor through the insulation without significant pressure. You need to fasten it into the holes formed after bending the petals to crimp the tubes. Thus, the attachment points are located closest to the heating elements, which eliminates their floating, displacement or lifting of the entire system when pouring the concrete mixture.

Kinds

All circulation pumps that are produced for heated floors are similar to each other. Of course, every manufacturer wants to create a unique product, but no one has yet managed to make a breakthrough in this area. A general classification applies to all models, after studying which it will be easier to select a circulation pump.

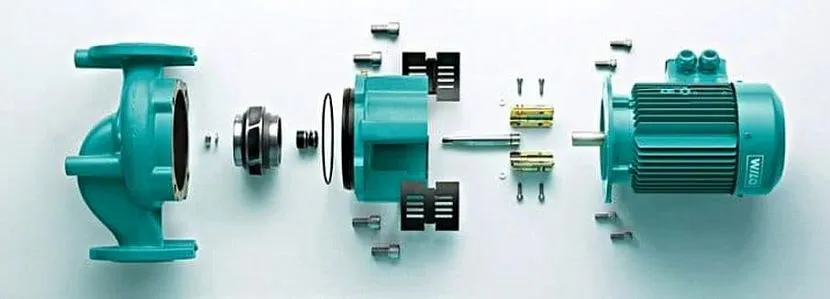

With wet rotor

This type of device is mini motors. Their dimensions are reduced due to the close location of the impeller to the rotor. In some models, these two elements are located in the same housing. To prevent water from entering the engine, manufacturers place a reliable oil seal on the drive shaft. It is made from especially durable rubber, which is highly resistant to external factors.

Some models have double water protection . Due to the fact that the motor is small, it can be installed in a heated room. It operates silently, has low power consumption, and is lightweight.

With dry

Devices with a dry rotor have a separate housing for working elements. They have great power, so they are chosen for large rooms.

To install such pumps, a separate technological room is required (most often a boiler room). Installation is carried out on a separate frame.

The weight of these devices is impressive, the operation is accompanied by noise, it is advisable to use them for large areas, therefore they are chosen extremely rarely for private buildings. Glanded rotor pumps are supplied with an additional protection kit for electrical components.

Industrial

For such objects, pumps of the same name are produced. They are secured by connecting flanges with a diameter of more than 50 mm. Such pumps have a dual design , which is convenient in severe frosts and increased load on the system. At the right moment, the second pump is activated, as a result, performance increases, the coolant circulates more actively through the system. If one motor breaks down, you can turn on the second one.

Models are divided by the number of speeds. Single-speed varieties are designed to work with one temperature regime. Multi-speed ones are designed to work in any different-temperature heating system (for heating various objects).

For uniform heat transfer, it is necessary to ensure a stable speed of movement of the coolant.

How to choose

During installation work, the question arises of how to choose a pump for a warm water floor, because there is more than one design type.

They can be with dry or wet rotor.

Circulation pumps with a wet rotor imply the rotation of the structure in the coolant. This is done using a special lubricant, and the stator is protected by a sleeve. The advantages of a wet rotor are its small size and weight, silent operation and simple design.

Read more about the types of circulation pumps here

When installing a “warm floor” system in a country house, pumps with a wet rotor are popular.

Circulation pumps with a dry rotor require an electric motor, which is connected to the pump using a mechanical seal. In this case, the pump does not come into contact with the liquid. The engines here are more powerful, which means they are able to function more efficiently and supply more heat energy. The disadvantage of a dry rotor is its loud operation in the system

Pump group kit

Also, choosing a pump for underfloor heating should be done taking into account the following characteristics:

- Since the liquid contains oxygen, it is impossible to use a cast iron body in the design.

- You should not install a high-power pump for normal fluid circulation.

- If the water is very hard, salt deposits may appear on the rotor. This happens when the liquid temperature rises to 55 °C and above. In order to prevent the appearance of deposits, thermostats are installed. They turn off the circulation pumps when a certain temperature level is reached.

- When using boiler equipment that is not equipped with a controlled panel and does not support connecting a pump, purchase a timer. If the device is connected to a modern panel, then everything is solved using the software level.

You can read about the criteria for choosing pipes for underfloor heating here.

The best pumps for heated floors

There are several good pumps for heated floors - decide for yourself which one to choose. An article on the Brigadir-info.ru website and guidelines on the website of the Russian Ministry of Construction will help us understand this issue.

Grundfos

A brand from Denmark that has been producing pumping equipment for more than 70 years. Its circulation devices have good consumer reviews. They are also valued around the world for their optimal price-quality ratio. Currently, models are manufactured not only in Denmark, but also in Serbia, Germany, and China. They are silent, economical, and available in a wide range. Some have a display with a digital indicator that shows energy consumption and power.

Other advantages of the Grundfos pump for underfloor heating:

- overheat protection;

- summer mode – protects against jamming in case of prolonged inactivity;

- three speeds;

- proportional and constant pressure modes;

- AUTO ADAPT function - provides automatic operation, determining what the heating system needs at a given time.

You can control all indicators using a special smartphone application.

Wilo

Wilo brand underfloor heating pumps are valued for their high energy efficiency and durability. The brand has existed for about a century, supplying high-quality pumping equipment for heating systems.

Advantages:

- protection of the housing from corrosion and thermal insulation;

- engine overheat protection;

- wide range of models – there are “wet” and “dry” type devices;

- minimum power consumption – about 3 W;

- ease of maintenance;

- low noise level.

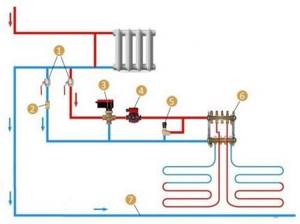

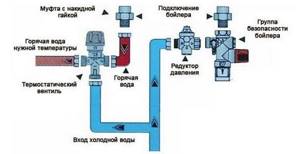

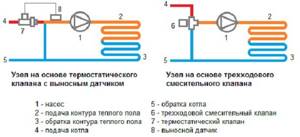

Connection diagram for a heated floor from a heating radiator

Sometimes, instead of the “boiler - mixing-collector unit - circuits” diagram, other options for connecting a heated floor are used. And the most common of them is connecting the ETP circuit to a heating radiator.

The diagram looks like this:

The connection is made to the return pipe: 1 – shut-off ball valves; 2 – check valve; 3 – three-way mixing unit; 4 – circulation pump; 5 – air valve; 6 – collector unit; 7 – pipe to the boiler

The disadvantage of the scheme is the seasonal use of heated floors. As you know, heating radiators are not used in the summer, therefore, the floor will also remain cold.

To prevent the coolant temperature from rising above normal, a special sensor with a valve is included in the circuit. It automatically shuts off the flow of water as soon as it becomes too hot. When the coolant has cooled to an acceptable temperature, the thermal valve opens again.

This type of VTP can be organized without a pumping and mixing unit. The only adjustment tool is a thermostatic device installed on the supply pipe.

How to choose?

In order not to make a mistake with your choice, you need to study the advice of professionals that we have selected for you:

- The purchase of a pump must be made simultaneously with all structural elements of the future system. This will ensure maximum efficiency of the system and ensure its longevity. Repair work will be expensive, so it’s better to protect yourself right away.

- The choice of pump should be based on the performance of the unit. This parameter can show productivity in liters or cubic meters. It all depends on the amount of coolant that will be in the system. We multiply this value by 3 and obtain the required pump performance.

- The pressure must be selected in accordance with the parameters of the pipes that make up the system (taking into account diameter, length, material).

- A small pump is easier to place indoors, but the size of the unit is directly related to its power. Small pump - limited power.

- The phasing also influences the choice of pump. Typically, single-phase units are chosen for private facilities. But industrial areas require the installation of pumps with a three-phase motor.

- Foreign pumps are not always better than their domestic counterparts. The products of our manufacturers are designed for low water quality and usage characteristics typical for our area.

Where to install the pump for supply or return

Despite the abundance of information on the Internet, it is quite difficult for the user to understand how to correctly install a heating pump in order to ensure forced circulation of water in the system of their own home. The reason is the inconsistency of this information, which causes constant debate on thematic forums. Most of the so-called specialists claim that the unit is installed only on the return pipeline, citing the following conclusions:

- the coolant temperature in the supply is much higher than in the return, so the pump will not last long;

- The density of hot water in the supply line is less, so it is more difficult to pump;

- The static pressure in the return line is higher, which makes the pump easier to operate.

Interesting fact. Sometimes a person accidentally ends up in a boiler room that provides central heating for apartments, and sees the units there embedded in the return line. After this, he considers this solution to be the only correct one, although he does not know that in other boiler houses centrifugal pumps can also be installed on the supply pipe.

We respond to the above statements point by point:

- Household circulation pumps are designed for a maximum coolant temperature of 110 °C. In a home heating network it rarely rises above 70 degrees, and the boiler will not heat the water more than 90 °C.

- The density of water at 50 degrees is 988 kg/m³, and at 70 °C – 977.8 kg/m³. For a unit that develops a pressure of 4-6 m of water column and is capable of pumping about a ton of coolant in 1 hour, the difference in the density of the transported medium is 10 kg/m³ (the volume of a ten-liter canister) is simply negligible.

- In practice, the difference in static pressure of the coolant in the supply and return lines is equally insignificant.

Hence the simple conclusion: circulation pumps for heating can be installed both in the return and supply pipelines of the heating system of a private house. This factor will not in any way affect the performance of the unit or the heating efficiency of the building.

Boiler room made by our expert Vladimir Sukhorukov. There is convenient access to all equipment, including pumps.

The exception is cheap solid fuel direct combustion boilers that are not equipped with automation. When overheated, the coolant in them boils, since burning wood cannot be extinguished at once. If the circulation pump is installed on the supply side, then the resulting steam mixed with water enters the housing with the impeller. The further process looks like this:

- The impeller of the pumping device is not designed to move gases. Therefore, the performance of the device decreases sharply, and the flow rate of the coolant drops.

- Less cooling water enters the boiler tank, causing overheating to increase and even more steam to be produced.

- An increase in the amount of steam and its entry into the impeller leads to a complete stop of the coolant movement in the system. An emergency situation occurs and, as a result of an increase in pressure, a safety valve is activated, releasing steam directly into the boiler room.

- If no measures are taken to extinguish the firewood, the valve cannot cope with the pressure release and an explosion occurs with the destruction of the boiler shell.

For reference. In cheap heat generators made of thin metal, the response threshold of the safety valve is 2 Bar. In higher quality TT boilers, this threshold is set at 3 Bar.

Practice shows that no more than 5 minutes pass from the start of the overheating process to the valve activation. If you install a circulation pump on the return pipe, then steam will not enter it and the time period before an accident will increase to 20 minutes. That is, installing the unit on the return line will not prevent an explosion, but will delay it, which will give more time to fix the problem. Hence the recommendation: it is better to install pumps for boilers running on wood and coal on the return pipeline.

For well-automated pellet heaters, the installation location does not matter. You will learn more information on the topic from our expert’s video:

Where is the pump for heated floors installed?

Before connecting the pump to a warm floor, it is important to determine the optimal location for its installation. There are 2 options for this:

- On the supply side - that is, next to the mixing unit.

- On the return line - that is, in front of the boiler.

In a conventional system, installers always use the second option - it is optimal to place the pump in front of the boiler, from where it will circulate the water, which will ensure its uniform heating. But in the case of heated floors, it is better to choose supply installation. This is done in order to avoid air getting into the system as much as possible.

Important! If the floor pump is too noisy (rotary), it is better to install it under the floor. For medium-sized premises (1-2 floors, up to 300 m2), the equipment can be placed in other places.

What are the criteria for choosing water floor pumps?

How to choose a pump for a warm water floor

As mentioned earlier in the article, the best option is to purchase a pump complete with a specific heating system. If this is not possible, then before purchasing you need to familiarize yourself with the following indicators.

| Criterion | Description |

| Performance | It is determined in cubic meters or liters of pumped liquid per hour of operation. To ensure normal heating of the room, the pump must pump at least three times the volume of liquid in the floor heating circuit per hour. Experienced installers strongly recommend making a reserve of at least 25% for this parameter. The fact is that long-term operation of the pump at maximum levels leads to its premature failure. The insulation of the stator and rotor windings overheats and rapidly loses its original characteristics, and this causes a short circuit. |

| Maximum head | Selected taking into account the length, diameter and material of the heating circuit pipelines. Insufficient pressure levels also cause overheating with all the ensuing negative consequences. |

| dimensions | Depends on the location of the pump, the smaller the pump, the easier it is to find a place to install it. But you need to remember that small devices cannot have high performance. |

| Current phase | For most residential applications, pumps with a single-phase motor are sufficient. For very large buildings, you need to buy pumps driven by a three-phase motor. |

A floor heating pump that is correctly selected in all respects will ensure the required efficiency, reliability and durability of the system.

How to install a pump on a heated floor

Once the location has been chosen, installation should begin. The algorithm of actions is as follows:

- First, a bypass - a bypass pipe - is installed in the location to be mounted.

- To do this, you need to cut the main pipe.

- Form a thread at its ends.

- Install the ball valve and install the pump.

- Open the tap for water access.

- Open the air bleed screw.

- After installing the circulation pump on a heated floor, you must test the system. First, the work is checked at low speed.

Scheme of correct installation of a pump for a heated floor

What data is printed on the pump housing?

Standard markings should indicate all technical characteristics of the pump. The first upper number on the pump indicates the mounting diameter of the water pipes, the second the maximum height of liquid lift (pressure), the third the total length of the unit in operating position. The following numbers indicate the operating voltage and oscillation frequency in the network, the phase displacement coefficient. As additional information, changes in the maximum height of water rise depending on the diameters of the pipelines can be given.

Circulation pump for heated floors

Some pumps have two motors, which allows them to pass peak loads without overheating the windings by automatically turning on the second one. In addition, the second engine serves as additional protection for the heating system in the event of failure of one of the engines. Such protection will prevent the system from freezing in winter.

Rules for caring for a pump for a warm water floor

The pump for heated floors is durable, provided that it is installed correctly and there are no manufacturing defects. However, it also needs maintenance. During operation you must:

- Periodically (1-2 times a month) bleed air from the circuit using a special tap. If this has to be done too often, there are errors in installation. It is recommended to install additional separators or air valves.

- Lubricate the operating mechanism annually - this is especially necessary for a pump with a dry rotor.

- As for the wet rotor, it is necessary sometimes (for example, once every 2-3 years) to clean it of scale and other deposits.

Important! Do not change pressure or temperature suddenly. If some place is frozen (or after a long break), heating is carried out very slowly so that the water gradually acquires the desired temperature.

Operation and care

To extend the service life of pumping equipment in heated floors, during installation, operation and maintenance, a number of rules must be followed:

- Do not tighten the connecting parts tightly, since modern models are made of alloys that do not have great strength. To ensure the tightness of the system, it is not recommended to use tow, but it is better to use modern tapes that can withstand high pressure well, and do not require tight tightening of the connecting nodes.

- Install the device in an accessible place so that in case of breakdown it can be easily replaced. Also, it needs constant preventive maintenance, which consists of inspecting the oil seal. When there are large amounts of impurities in water, they harden and cause damage. These deposits must be removed, and to reduce the amount of their formation it is better to install a filter.

- Bleed the air before starting the system, and prophylactically once a month, by opening a special tap. Air in the line complicates the movement of water, and this provokes the formation of cold spots. At the same time, the automation sends a command to the pump, and it is switched on unexpectedly, thereby starting it more often. This reduces its resource, and accordingly the service life decreases.

- Lubricate the mechanism once a year, especially the “dry” type device.

It is not recommended to suddenly switch pressure or temperature in the system. And when it freezes, or after summer, the temperature should be increased gradually.

In conclusion, we can say that water floors will not function effectively without circulation equipment. It’s up to you to decide which pump to choose for underfloor heating. But if you are not sure that you can install the equipment yourself, it is better to invite professionals.

Let's learn how to select a pump and a three-way pump for a heated floor! Warm floors from A to Z - part 3

Where is the best place to put the pump?

In conventional heating systems, the circulation pump is placed exclusively on the return line, directly in front of the boiler. But in the case of heated floors, this option is far from the best.

The pump connection diagram provides for the installation of pumping equipment on the coolant supply. This is due to the peculiarities of the operation and operation of the water circuit.

Violations of the tightness of threaded connections, the presence of differences in the height of the pipe laid in the floor, malfunctions of the heating system - lead to the appearance of air locks. The pump is set to supply to prevent airing of the system as much as possible and, if necessary, squeeze out air. {banner_downtext} Other options for connecting the pump also exist. But as practice shows, if you start a pump that is supplying coolant, you can achieve better results.

Purpose

The main function of the circulation pump is to ensure optimal pressure in the pipeline so that the circulation of coolant in the line is uninterrupted. This will minimize disruptions in the operation of the warm water floor due to airing of the pipes.

Refusal of the unit in order to save money when constructing heated water floors (in any of the rooms - kitchen, bathroom) will affect the efficiency of their operation.

Why does the pump become airy?

The reasons for airing both the heating system and the pump itself usually lie in violation of the rules for installation and operation of the equipment. Some homeowners have to bleed the air several times during the week.

What can help avoid this?

- Remove air pockets from the water circuit. This must be done before turning on the heating of the coolant for the underfloor heating system.

- Install separators or air valves.

- Carry out station maintenance from time to time. Service is especially necessary if the power consumption of the pump has increased (affected by energy consumption) or unheated zones have appeared.

- It is prohibited to suddenly change the temperature and pressure in the system.

The operating instructions provide a detailed description of how you can independently remove air trapped in the pump housing.

Water heated floors cannot operate normally without circulation equipment, except when the water circuit is connected to an already operating central heating system.

The principle of operation of the circulation pump in a “warm floor” heating system

The name of the device, circulation pump, speaks for itself. Due to the operation of the rotor with the impeller, the moving and rotating part of the device, the circulation of the coolant liquid in the pipeline is ensured. It is appropriate to recall here that for a hot water main, the presence of a circulation unit is not necessary. Thanks to the centralized supply, the necessary working pressure is created in the system, ensuring a sufficiently intense flow of coolant in the pipelines.

Pumps used for heating systems can work with both boiler water and other liquid media used as a coolant. However, the device, which is a pump, only works on water. You should remember this.

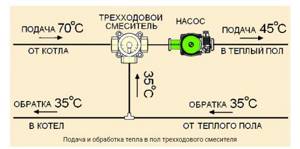

The unit is installed immediately behind a three-way valve, which introduces cool water into the system. For heated floors, it is necessary to select a pump that will meet the relevant parameters of the entire autonomous heating system. The unit installed in the system must draw out the liquid obtained as a result of mixing for subsequent supply to the collector. Due to the fact that the impeller is equipped with blades, during rotation of the rotor a low pressure zone is created inside the working cavity. As a result of the rotation of the rotor with the impeller, the liquid entering the body of the device, under the influence of the laws of physics, continues further, only more intensely at an increased speed.

Together with the safety valve, bypass and expansion unit, the pump forms a single set of equipment - a pumping and mixing unit. As a result of the operation of the pumping group, optimal operating pressure is created in the loops of the water circuits, thanks to which water enters each heating water circuit at the required speed and intensity.

Trouble-shooting

The main factor that negatively affects the functioning of the pump is the quality of the water entering the water heating circuit. If the pump operates continuously, salt deposits reduce its performance to a lesser extent than during periods of shutdown.

Connection diagram of the circulation pump to the electrical network

Sometimes, after turning off the heated floor for the summer period, the next time it is turned on, the pump stops pumping water due to the fact that the rotor does not turn. You need to carefully turn the impeller several times using available tools. If the pump does not start to function, professional help will be required.

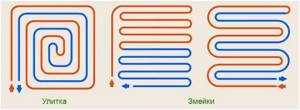

Water circuit installation diagrams

If the installation of warm water floors is carried out using a well-established, traditional technology in a clear sequence, then the installation of a heating pipe can be carried out in various variations. The main goal pursued when installing heated floors is to uniformly heat the entire area of the heated room. Laying a pipeline just the way you want means deliberately creating problem areas throughout the entire structure. The coolant tends to quickly lose temperature as it flows, so the pipes must be laid starting from the walls, then moving towards the entrance to the room or to its center. For this purpose, specially developed optimal schemes for laying the water circuit, each of which has its own characteristics.

The mixing unit and manifold are the beginning of the entire heating system. Water circuits are connected in a clear sequence. The beginning of the pipeline is to the inlet pipe, the end of the pipe is connected to the check valve.

You can install a warm water floor with your own hands, the contour of which will be laid as follows:

- pipe installation according to the snake pattern"

- laying the pipeline according to the snail pattern;

- combined scheme.

When installing heating in corner rooms, a pipe laying scheme is used for enhanced heating.

In each individual case, we can talk about the advantages of one or another scheme. For example: a snail is the simplest circuit. The bend of the pipe here reaches 900, while in a snake the heating pipe will be bent by 1800.

Note: the “snake” type water circuit can be powered by a low-power circulation pump. For a bathroom or children's room, this installation scheme looks preferable.

Where heated rooms have a linear slope, it is better to install the pipe according to the “snake” pattern. The pipeline is laid in the direction from the mixing unit towards the slope. Air pockets in this version can be easily removed, which cannot be said about a pipe laid in a snail pattern. In sloping rooms, removing air pockets can be problematic.

For large premises where it is necessary to use several water circuits of the same length for heating, the “snake” pipeline laying scheme is very convenient. Thanks to this installation method, it is possible to achieve balanced operation of the entire heating system.

Heating pipes laid on a prepared base are connected to a manifold that distributes the supply of coolant to the system. The distribution cabinet together with the mixing unit is installed either in the heated room or next to it, which significantly reduces the number of pipes and the consumption of other materials. The bends of the water pipe at the point of connection to the collector are sewn into a special protective box.

In each individual case, a certain order of laying the water pipe should be followed. When working with a snail circuit, the pipe is first laid along the perimeter of the walls, after which a turn follows from the farthest wall. In the opposite direction, the pipe is laid in a spiral, reaching the center of the heated room. For the snake circuit, the water circuit is laid out as follows. The pipe is laid along the perimeter of the walls, after which uniform bends are made in the opposite direction.

The combined installation schemes of heating pipes for heated floors, used in some cases, involve the simultaneous use of both options. One half of the room can be heated by a water circuit laid in a snake pattern, while the other part of the room will be heated by a pipe mounted in a snail pattern.

Which mixer is better to choose?

It is necessary to select a thermal mixer taking into account the characteristics of the heating device. When choosing distribution equipment, you need to take into account the method of mixing - central or lateral.

If the area is large, with several separate circuits, then it is necessary to install a mixing unit with a three-way valve. This unit can handle large volumes of liquid perfectly. For a single-circuit floor, a manifold with a two-way mixer is suitable.

You can make a pumping and mixing unit for heated floors with your own hands, but if you buy a ready-made one, we recommend these models:

- VT.COMBI and VT.COMBI.S - for the preparation of low-temperature coolant, a two-way valve is used, it is controlled by a thermal head or servo drive. The temperature sensor is not included in the package - must be purchased separately.

- VT.COMBI - the unit is equipped with a balancing valve, with the help of which the pressure in the system is adjusted.

- VT.COMBI.S - for this NSU model, the collector can be connected both at the input and at the output. Therefore, it is used for two types of heating (radiator and TP).

- VT.DUAL - the mechanism includes two modules (pumping and thermostatic), with a manifold group located between them. Mixing is carried out by a three-way valve with a thermal head.

NSU VT.COMBI.S

These are proven models and it is better to buy them.

Features of design and installation

Circulation pumps must be installed so that the rotor axis is in a horizontal position. It doesn’t matter what type of pipe connection to the pump is - horizontal, vertical, at an angle - the rotor must be horizontal.

The pump may have a hole closed with a plug to release air.

Typical breakdowns of circulation pumps include clogging with deposits. During the warm season, when the pump is stopped, salts fall out of the water, and they can get stuck on the rotor shaft. Due to the low power, the pump may not start in this state.

The circulation pump does not turn on - what should I do? All that remains is to close the supply taps, open the plug and turn the impeller, after which the pump, as a rule, works.

How should the pump be installed correctly?

When installing the pump, the main thing is to do everything correctly. It is important that the rotor is horizontal. Today, modern pumps are produced with a wet rotor, through which the surfaces that rub are washed. The terminal box that is installed on the rotor should be located on the top or side. It is not permissible to place it at the bottom because it will not be convenient to service it, and in case of a breakthrough it may flood. As we found out earlier, it doesn’t matter at all whether there is a pump on the supply or return . Something completely different is important, namely the pump should be located between the boiler and radiators. It can be in front of the radiators or after them, and the flows will be exactly the same. Under no circumstances should the pump be placed in the middle of the system, because low pressure flows will form.

This is all general information, but what to do if you have a solid fuel boiler.

Design and principle of operation

The device includes elements:

- frame;

- a motor equipped with an impeller and connected to the housing;

- parts for connecting parts.

Sometimes the pump is equipped with an air vent, but this is rare. More often they use a special nut - if you unscrew it, the air comes out of the system on its own.

The principle of operation of the mechanism is simple: the liquid is directed into the housing, where, thanks to the rotation of the impeller, it is picked up and released further by pressure. Due to this process, forced circulation of water occurs.

Some pumps have 2 motors installed - this way the equipment will continue circulation even at maximum loads. The second engine is connected if necessary and takes on part of the work. The device is also considered more reliable due to the reserve. However, equipment with 2 motors is more expensive and the owner will have to decide for himself whether such a purchase is reasonable.

The pump is installed at any point in the system - usually at the edge of the supply or return circuit. It is recommended to select the location for installation of overclocking equipment individually. There are no special requirements - the operating temperature is not important, but it would be wiser to install the device where it is lower.

How to calculate a pump

Attention should be paid to flow and pressure - productivity. The hydraulic resistance overcome by the pump is equal to the maximum pressure in the pipes, and the flow rate is 0.

The selection of the model is based on the volume of the coolant. Based on this, the hydraulic resistance is calculated. Heat loss is affected by:

- thermal conductivity of materials;

- fencing;

- location of the house relative to the cardinal directions;

- temperature in the environment.

After calculating the coolant flow, it is necessary to determine the resistance parameter in the heated circuit. For this, standard tables are used. Once finished, you can begin choosing a model.

As an example, we can take a pump for a house with an area of 200 m2. Inside the equipment there is a two-pipe system of pipes with a diameter of 32 mm, length - 50 m, material - polypropylene, temperature chart - 70-90 degrees. The losses are equal to 24 kW at a mass flow of 1.03 m3/h. Further, the table determines the hydraulic resistance, in this case - 1.8 mbar/linear. m. For a length of 50 meters, the result is 90 mbar. It is necessary to sum it up with the resistance of the system parts, for example, it will be 1 m. As a result, the owner will need a productivity of 1.1 m3/h with a pressure of 2 m. Based on the obtained parameters, you can purchase a device with sufficient characteristics.

Possible problems

The equipment works in the winter and does not cause problems, but in the summer the pump stands idle. Hardness salts begin to deposit in the system, especially in the housing. When the heating season begins, the engine is activated, but the impeller does not rotate due to blockage. A low-power motor will not be able to crank it.

You need to unscrew the nut - there will be a cutout for a key or a screwdriver. Then you will have to manually turn the shaft with the impeller. The main thing is to move the mechanism a little, and then the motor will handle it itself. If it still doesn’t work, you’ll have to disassemble the box and clean the parts from deposits.

With the correct arrangement of the system and the purchase of a pump with the required characteristics, operating a heated floor will not cause difficulties.

To ensure the operation of the mixing unit, which lowers the temperature of the coolant for the heated floor, an additional circulation pump is required. Which basically ensures the movement of the coolant along the contours (loops) of the heating pipeline.

In the case when the temperature of the coolant is formed not by the mixing unit, but in some other way (RTL regulation, boiler, solar collector, external mixer), then a pump in the heated floor circuit will most likely not be needed; the general one in the heating system will be sufficient.

But most often, heated floors are created with their own pumping and mixing unit.

Which pump is suitable?

The mixing unit for underfloor heating uses a conventional circulation pump, which is also suitable for a radiator heating system.

These units are characterized by low power, low pressure and low fluid consumption. Accordingly, the power consumption is insignificant (40 - 150 W), and there is almost no noise during operation.

All circulation pumps for a household heating system (including those for heated floors) are designated by a pair of numbers, for example - 25/40.

Where the first 25 is the diameter of the connection thread in mm (otherwise - 1 inch). An inch connection is the most common in everyday life for main lines; the thread diameter is the same, for example, in manifolds for heated floors….

The second number indicates the pressure in dm. those. 40 - 4 meters of water column, or 0.4 atm.

Marking 25/60 means a more powerful model - giving a pressure of 6 meters.

Pressure and power

The required characteristics of the pump and its brand must be determined in the project for a heated floor based on heat loss, area, number of circuits, pipe brand, pipe diameter, loop length, temperature difference...

But purchasing a project, or even carrying out simple calculations, is not a desirable investment of time, money and effort for many.

Many people want to know “here and now immediately” - which pump to choose for a heated floor.

But the question is not difficult - you only have to choose between 25/40 and 25/60 (for large areas it is better to install two or more “small” pumping and mixing units) - it is simply difficult to find other suitable options.

Is it necessary to install a pump?

For some types of heated floors, you can do without installing a water floor pump. However, there are situations when it is necessary. This happens, for example, in the following cases:

- The installation of a heated floor requires ensuring the optimal location of the pipes. It is important that the heating of the floor, air and objects in the house is uniform. If this rule is violated, materials may be damaged. For example, exposure to heat can deform parquet. The connected pump will increase the circulation rate of the coolant and prevent overheating in certain places.

- If the pipes for fluid circulation have a small cross-section, this increases energy losses. A pump for a water heated floor will speed up the movement of water, and this will ensure a more uniform heat transfer. If this is not done, the boiler will overheat, which will lead to increased wear and tear.

- Rooms may have floors made in different ways. For example, one room may have laminate flooring, while another may have parquet. Their heat capacity will differ, which will ensure uneven heating. Increasing the rate of fluid circulation will lead to a more harmonious distribution of heat between rooms.

If the rooms have a large area, then if the water flows slowly, it will give off heat too quickly. If you install a pump, this will increase the speed of its circulation.

How and why to bleed air when the circulation pump is running can be found in the video below.

Possible faults

With use over time, the user may encounter problems. The most common of them are described below.

Tap water is often used as a coolant. During operation, salts will be deposited on the blades. This gradually leads to a decrease in the quality of work and increased wear. Often this problem is encountered with the onset of autumn.

After a long break in operation, deposits appear on the blades. This may result in the pump not starting one day. After switching on, it will begin to hum, but there will be no movement of water. If you turn the impeller manually several times, it will begin to rotate and the pump will be ready for operation.

Internal structure of a floor pump Source prouteplenie.com

Pressure calculation

If a circulation pump is installed during the installation of the main heating equipment, there is a need to calculate the pressure relative to the specified apparatus. This activity is carried out using the following formula:

H=(R*L +Z')/p*g.

Here are the following quantities and values:

R is the resistance indicator relative to the straight section of the pipeline.

L is the length of the pipeline itself.

Z - resistance caused by various obstacles present in the path of the circulating substance (fittings, fittings).

p is an indicator of the density of the coolant at a specific temperature.

g is an indicator of acceleration relative to free fall.

When calculating a pump installed in an already functioning heating system, approximate data are used:

H=R*L*ZF

The following parameters are present here:

R is the resistance of a straight pipe. The approximate value of this value is 100-150 Pascal per meter. It should be displayed in pressure readings. Then it will take the following form: 0.010-0.015 meters per meter of pipeline.

In this case, you need to start from the maximum value. Such actions will not have a negative impact on energy consumption.

L is the total length of the pipes. If we are talking about a two-pipe heating system, the duration of the supply circuit and the return circuit should also be taken into account.

ZF is a multiplication factor that greatly simplifies the process of performing calculation operations. Its meaning depends on the following circumstances:

- if the system is equipped with conventional ball valves that prevent a decrease in clearance, as well as fittings with appropriate dimensions, the multiplication factor is 1.3;

- when the system contains a throttle or thermostatic regulator that breaks the circuit, an additional value of 1.7 is applied;

Calculation example

If the total area of a square room is 150 m2, then the length of each wall will be 12.25 meters. Consequently, the total length of the pipeline is quite simple to calculate: 12.25 must be multiplied by 4, the result is 49 meters.

It is worth noting that the chokes are mounted directly on heating devices. In this case, rupture of the main ring should be completely excluded.

By substituting the available values into the appropriate formula, you can determine the desired pressure:

0,015*49*1,3=0,9555.

It is important to note that the purchased circulation pump must have a headroom reserve, the value of which is at least ten percent. A circulation pump is a mandatory element of a water heating system for a house with forced or combined (combined) circulation

And in order for it to work effectively, it is necessary to choose the right model with the most suitable characteristics. From this article you can learn how to independently select a circulation pump for a heating system

A circulation pump is a mandatory element of a water heating system for a house with forced or combined (combined) circulation. And in order for it to work effectively, it is necessary to choose the right model with the most suitable characteristics. From this article you can learn how to independently select a circulation pump for a heating system.

Pump operating principle

If a pump is installed in the system, it helps push water through the pipes. This mechanism is not intended to create excess pressure. The speed of fluid passage depends on how strong the heating should be. Therefore, it is more profitable to install pump models on heated floors in which this parameter is adjustable. For example, three-speed models meet such conditions.

The video below describes in detail the features of the GRUNDFOS ALPHA brand pump.

Installation features

The pump is mounted between the three-way valve and the system manifold. Only then will the whole structure work. If you install equipment between the connection to the radiator network and the valve, the mixing unit will not be multifunctional, and the heating will be ineffective.

The equipment is attached to the flanges using union nuts - they are supplied in a box. Installation usually does not cause difficulties if the liner is arranged correctly and maintains sufficient distances.

Diagram of a heated floor with a three-way valve

Mixing fluid flows, which a thermostatic mixing valve allows, makes it possible to direct flows with a stable, standard temperature into the underfloor heating system. This operation is performed automatically. For mixing that takes place inside the device, already cooled liquid from the “return” is added to the hot water.

- Operation occurs in the following sequence:

- hot water flows to the collector included in the underfloor heating system;

- when passing through the thermo-mixing valve, the degree of heating of the liquid is determined;

- if the water temperature is higher than the set one, then a passage opens into which the cooled liquid enters;

- two flows are mixed inside;

- after reaching the desired value, the cold water passage closes.

The mixing pump can be replaced with a three-way mixer, which performs the same function, only without a pump (used when there is good circulation that does not require an additional pump). The installation of a three-way mixer is carried out in the same place as the pumping and mixing unit, i.e. at the outlet of the return manifold.

On the one hand, the collectors are connected to pipes from heating equipment, and on the other hand, a splitter must be installed on each collector. An air vent is connected to the top side of the splitter. A drain valve is installed on the bottom side of the splitter.

Among the disadvantages of three-way valves, there is the possibility of sudden temperature jumps that occur during the start-up of heated water, which negatively affects the condition of the pipeline.

This faucet, made of brass, has three strokes in its design, which determine the use of different methods of mixing liquid flows, depending on which there are three types of three-way valves.

Valve with the thermostat function required for heated floors. Such a device not only regulates the intensity of the mixed flows, but also ensures that the system maintains a given temperature.

This function is facilitated by the presence of a heat-sensitive element, which, by detecting the degree of heating of both flows entering the tap, changes the cross-section of the holes.

The three-way thermostatic valve of the second type is distinguished by the fact that it provides regulation of the supply intensity of only the hot flow. The package includes a thermal head with a remote sensor. You can also select a mixing valve from the assortment of three-way models that does not automatically maintain the set temperature.

- Depending on the direction of flow, the thermostatic valve is available in two models:

- T-shaped or symmetrical design. With this connection, hot and cold water enters through the side holes, and after mixing, the liquid flows out through the central passage.

- L-shaped or asymmetrical design. In this case, hot water comes from one side, and cold water from below. Subsequently, the mixed flow exits from the second side passage.

- Considering the mixing unit, we can distinguish the following components in it:

- Check Valve;

- temperature sensor;

- circulation pump;

- three-way mixing valve.

The connection diagram includes a circulation pump mounted on the supply. Then a temperature sensor is installed, which is necessary to determine the degree of heating of the incoming water. After this comes the thermostatic valve.

A check valve with an outlet is mounted on the “return”, which is connected to a pipe with circulating cooled liquid directed to the mixing valve.

- With a similar connection diagram, the coolant moves along the following route.

- Pumping hot water using a circulation pump into the equipped heated floor system. The coolant temperature can reach 80°C.

- Mixing with cold water through a three-way valve. As a result, the desired temperature is achieved.

- Distribution of coolant through underfloor heating pipes.

- The return of the cooled water to the “return”, from where it is taken into the three-way valve for subsequent mixing with the hot liquid.

With such a connection, the temperature sensor regulates the degree of heating of the water entering the water circuit.

There are other ways to control. The most ineffective is the manual method, when you need to change the flow by turning the handle. There is a control option using a servo drive, commands to which are received from the controller in accordance with signals received from sensors.

The thermostatic tap plays an important role when installing a water heated floor. By preventing the coolant entering the pipes from overheating, it saves fuel. In addition, safety is ensured during the operation of a rather complex heating system and the trouble-free service life is extended.

Selection criteria

When choosing a mixing valve, it is advisable to focus on several indicators.

- Room area.

For small rooms - bathroom, toilet, it is not always recommended to purchase a more expensive thermo-mixing valve, since it is enough to install a familiar valve. Large rooms with warm water floors will require mixers that automatically regulate the temperature of the heating fluid.

- Cross-sectional dimensions.

This indicator must be taken into account when selecting a thermostatic valve, ensuring precise connection to the heating system. If there is no device with the required diameter in the assortment offered in the store, then special adapters are purchased.

- Possibility of obtaining an automatic operating mode.

- Bandwidth.

This parameter is calculated at the design stage of the heated floor. Based on the obtained values, a mixing valve is selected that can withstand the required load.

Installation Features

Wherever you place the circular pump, its rotor should be directed horizontally. In principle, vertical installation is possible, but then when choosing, you need to take into account that in this option it will lose about 30% of power.

When installed in a water floor system, the pump is often placed in the supply pipeline, but after the mixing unit (here the temperature will be normal for it). Although there are schemes in which it is in the “return” or in the mixture bypass. Some schemes provide for the presence of two pumps. So it is recommended to install two autonomous devices in a two-story house: one on each level. This makes it easier to regulate the pressure in each branch.

Most often, the circulation pump is installed in the supply pipeline after the crossbreeding group

When filling the system, there will definitely be air in it. Its presence can block the movement of the coolant: an air lock is formed. Not all collectors have the ability to bleed air. Therefore, many pumps have a special outlet valve. This is a small disk on the faceplate that has a groove on it. Press the screwdriver into the groove and turn the disc slightly counterclockwise. The air begins to come out (place some dishes, because water will gradually begin to come out with air bubbles). When the water flows in a continuous stream without bubbles, close the valve, restart the system and try to release the air again. Sometimes the procedure may need to be repeated several times before all the air is removed.

There is one more feature of water heated floor systems. If you do not use low-temperature sources (condensing gas or electric boilers), then before supplying water to the floor pipes, cooled water from the “return” is mixed into the hot water from the boiler. Everything, of course, can be assembled from individual elements, but you can also buy a pumping and mixing unit (or pump group) assembled. They come in different compositions and, accordingly, prices, but they perform the main function: they maintain the water temperature you set at the entrance to the collector unit. But this group of devices is based on the same pump, and you need to select it according to the parameters that we calculated above.

What should be the flow rate and pressure?

Based on the experience of creating underfloor heating, we can say that the pump performance for sufficient heating of a “moderately insulated building” in a central climate should be approximately the following.

Those. – for an area of 100 sq. m. a private house in the middle zone will require a pump group with a capacity of 1.5 m3. at one o'clock.

For example, 7 heating circuits are used, if the flow rate is divided approximately equally, then it is a little more than 0.2 cubic meters per hour in each circuit.

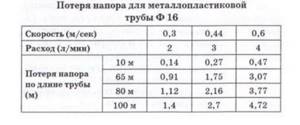

The plate shows approximate data on the pressure drop in underfloor heating circuits using a 16 mm pipe.

Probably, loops with a length of 70 - 80 m are installed. The flow rate in each circuit is about 3 liters per minute (0.18 cubic meters per hour), respectively, the maximum pressure according to the table is about 2 m. Art.

Therefore, for 100 sq.m. For this “medium-cooled” area, we need a pump that would provide a flow rate of 1.5 cubic meters at a pressure of 2 meters of water column.