Carrying out major repairs in residential premises of apartment buildings or private buildings involves replacing (upgrading) elements of the heating system. The need is associated with reducing energy costs for further operation and giving an aesthetic appearance to the rooms.

Sometimes owners decide to hide heating pipes under the floor covering or in the walls of the room. In this regard, they are interested in the possibility of using plastic pipes for these purposes and the question, can a polypropylene pipe be filled with concrete? How long is the service life of communications located under the screed limited?

Hidden placement of pipes

Can polypropylene pipes be filled with concrete? What conditions are necessary for this?

Carrying out major repairs in residential premises of apartment buildings or private buildings involves replacing (upgrading) elements of the heating system.

The need is associated with reducing energy costs for further operation and giving an aesthetic appearance to the rooms. Sometimes owners decide to hide heating pipes under the floor covering or in the walls of the room. In this regard, they are interested in the possibility of using plastic pipes for these purposes and the question, can a polypropylene pipe be filled with concrete? How long is the service life of communications located under the screed limited?

Hidden placement of pipes

How to hide or disguise pipes

Any apartment has, if not heating pipes, then definitely water pipes. Even twenty years ago, the only solution to make them less conspicuous was to paint them the same color as the walls, using oil paint (or enamel). And the pipes were almost all metal.

Today, almost everyone uses metal-plastic pipes, neat and light. But what to do if you don’t even want to leave white ones in sight? Hide it of course!

Laying pipes in the toilet - under the tiles

A groove in the wall will help to hide the water pipes, but this method brings some problems with possible water leakage. Especially if you live in an old-style apartment building. Although from an aesthetic point of view, the closed installation method is more correct.

Characteristics and application of polypropylene pipes

To determine the possibility of installing polypropylene pipelines under a screed, it is worth referring to their characteristics. Note that polypropylene is one of the polymer options, the components of which are combined with derivatives of ethylene gas. The material is resistant to interaction with aggressive environments and alkaline solutions, while the operating conditions declared by the manufacturer allow a difference in operating temperatures from -10 to +110 degrees.

- the service life under thermal loads without changes in quality and appearance is at least fifty years, and when organizing cold water supply it is twice as long;

- operating pressure in the water supply or heating system can reach 20 Bar;

- constant contact with the water mass of the internal part does not provoke the formation of scale;

- the noise of flowing water is absorbed by the walls of the products;

- propylene has the properties of low thermal conductivity, which prevents the formation of condensation on the outer walls;

- the product is lightweight and requires installation even by one person;

- when using a special tool, the products are connected and mounted in their standard places in a short time;

- elasticity helps to give the turns the desired bends;

- After installation of the products, no additional maintenance is required;

- reasonable price of the product and fastening elements.

Polypropylene pipes of different colors are found on the construction market. This fact does not determine the properties of the material from which they are made, with the exception of black - which helps protect against ultraviolet radiation. The properties of the product are determined by the markings applied to the surface:

- RRV. The defining characteristic is increased mechanical strength due to reinforcement technology during manufacturing. Recommended for use in heating and water supply systems, including under concrete screed.

- RRN. The marking is applied to products of significant diameters, the size of which allows them to be used in ventilation, sewerage, and cold water supply systems.

- RRK. The most commonly used brand of polypropylene products. Can be used in cold and hot water supply and heating systems. Easily tolerates thermal and mechanical loads.

Important! The price of polypropylene pipes and connecting elements differs in each region of the country. In this regard, before purchasing, it is recommended to familiarize yourself with the characteristics of the products presented in stores and choose copies that are optimal in price and quality.

Myths about polypropylene - looking for the truth

Myth one.

“Polypropylene is universal. Suitable for installation of water supply and heating systems at any facility.”

This is wrong. Polypropylene pipes can be safely used by owners of private houses who independently set the pressure and temperature parameters in the systems, as well as residents of apartment buildings where polypropylene is included in the project. In other cases, laying pipes from this material is a certain risk.

Much in the operation of pipes depends on temperature and pressure parameters. They are most often regulated by a centralized heating system (provides up to 70-95% of the housing stock of the Russian Federation). As is known, the operation of the system is associated with interruptions in the supply of coolants - either seasonal disasters or testing of thermal routes. How does this affect the pipes? As pressure increases, the service life of polypropylene pipes sharply decreases. If at a pressure of 1-2 atmospheres the pipes will last more than 50 years, then at 10-12 atmospheres, which is typical for a centralized heating system, the period is reduced to 5-10 years.

The story with temperature is even more complicated; for polypropylene it should not exceed 75.80 °C. But for a single-pipe system, a coolant temperature of 105 °C is permissible, according to SNiP. That is, the pipes simply won’t hold up.

Go ahead. Polypropylene is sensitive to external high temperatures and is not suitable for fire hazardous areas. It is also sensitive to ultraviolet radiation and is not suitable for laying external water supply, for example, in a garden plot. When exposed to sunlight, polypropylene takes a long time to degrade, but a house is not built to last for 2-3 years.

|

|

Myth two.

“Polypropylene is the most durable material.”

It depends what we're talking about. Polypropylene pipes have high chemical resistance and are good because they do not crumble when deformed. However, they are very vulnerable to shocks, water hammer, and mechanical loads. When working with such pipes, pay close attention to the manufacturer and the quality of the material. Often on the market there are thin-walled pipes that do not withstand any criticism and are cut right through with any awkward movement.

In addition, there is always a risk of damage to materials on a construction site. A banal brick can fall from above or a heavy tool. And if nothing happens to steel pipes, then polypropylene pipes will live a long time.

Polypropylene has low structural rigidity, so the pipes in the system sometimes sag. The picture no longer looks as neat as it did immediately after welding and installation, and indicates a breakdown.

Myth three is the most important.

“Easy to assemble and install compared to steel pipes.”

The main complaint about steel pipes is the long, labor-intensive assembly. Welding pipes requires proper skills and equipment. However, they can be assembled using threaded connections. Previously, before the arrival of a new generation of sealants on the market, flax strands or FUM tape were used to seal threads and assemble joints. The application technology required special knowledge and experience.

Modern sealants - anaerobic gels or plumbing polymer threads - are applied within a few minutes. They are easy to use and accessible not only to professionals, but also to amateur craftsmen. Just read the instructions.

There is already an equal sign between the assembly time of a system made of steel and polypropylene. Moreover, polypropylene pipes do not bend and fittings are also used for their installation.

It is interesting that the installation of polypropylene pipes is directly related to such a concept as the personal responsibility of the resident.

Steel is included in the projects of approximately 90% of the housing stock in Russia. The apartments have steel pipes for heating, water and gas supply systems.

When replacing, for example, steel water supply risers with polypropylene ones, all problems that may arise during operation - leakage or pipe rupture and consequences - are resolved by the apartment owner at his own expense. Water supply risers are common household property. Their replacement with similar ones should be carried out by the management company free of charge. She is also responsible for the quality and strength of the risers.

Polypropylene pipes are an alternative, but not a replacement for steel ones. Let's not forget that the Russian market is huge and heterogeneous. Elements that are used to assemble a high-quality system are not available to consumers everywhere, and the quality of contractors’ work may leave much to be desired. Often, a team working with welding steel pipes can have much greater competence than the repair worker who installed sockets for you yesterday, and today undertakes to install the pipeline. Therefore, acting “the old fashioned way” in order to make your home comfortable and safe is not retrograde, but a reasonable approach.

If you still decide to install polypropylene pipes in your home, then do not forget to take care of reliable sealing! To do this, you will need a sealing thread - an indispensable assistant for polypropylene threaded connections. You can buy it on our website!

Source: re-st.ru

Features of application

The manufacturing technology of polypropylene pipes does not exclude linear expansion of the product when exposed to high temperatures. Correct selection of pipes with the necessary properties and installation of supports with the organization of compensators will allow you to compensate for this drawback. Any system includes branches from the central pipeline, direct connections and the creation of turns at different angles, while differences in pipe diameters are not excluded. The solution of these problems is simplified by the use of fittings, which are divided into the following types:

- flange type;

- crimping device;

- using a threaded connection;

- welded structure.

Fittings made of polypropylene are used to connect pipes made of the same and other materials. This effect is achieved by placing chrome or brass inserts in the interior, which determine the technical possibility of connecting to plumbing fixtures and creating transitions.

Fitting

Practice shows that the main reasons for ruptures of heating pipes under screeds are gross violations of installation technology and poor-quality soldering of fittings at the joints of products.

The soldering process is not difficult for home craftsmen. The device for connecting pipes is represented by a benchtop soldering iron with marked nozzles of various diameters. Before industrial soldering, it is recommended to carry out a trial thermal connection of materials on small pieces of pipe and unused connecting elements. Using combined fittings, it is possible at the design stage to ensure optimal pressure in all parts of the heating structure, while preventing unnecessary costs for using pipes of larger diameter than necessary.

Scoring walls for pipes

Grooves in the bathroom

Pipe laying stages

The hidden pipe laying technique includes several stages, each of which is necessary:

- developing a wiring diagram, clarifying all the circumstances and creating a plan;

- gating for pipes;

- cleaning and strengthening the created channel;

- laying and installation of pipes;

- securing the knees inside the channel with plastic clamps;

- connecting system inputs and outputs;

- test start-up of communications and tightness control;

- masking the cavity and creating inspection holes;

- decorative wall decoration

Equipment and tools

When deciding how to groove a wall for a pipe, you need to find out the characteristics: material, density, composition of mixtures. Grilling is performed:

- manually with a hammer and chisel;

- grinder;

- impact drill or hammer drill;

- with a special wall cutter.

The first method is the most labor-intensive; it is only suitable for fairly soft walls that do not contain reinforcement inserts. Manually chipping dense concrete will take a lot of time and effort. The advantage of technology is the accuracy of the work.

Working with an angle grinder is complicated by the need to control the pressure on the tool: creating a uniform depth throughout the entire length of work is problematic. Detailed finishing and leveling are carried out with a chisel. The grinder reduces the time spent on creating the main track and gives a fairly even cutting line for the material.

Working with a wall chaser

Dots are punched into the material using a drill or punch. The distance between them should be 1-2 cm. Then the recesses are deepened and combined with a spatula-shaped attachment.

A wall chaser is a professional tool designed specifically for this type of work. Only he can provide a channel that is even in depth and shape, maximizing the efforts of the master. The lines are cut with a wall chaser, then the middle of the cavity is selected. The quality of work is superior compared to other techniques.

A professional wall chaser, which can be rented if there is no need to purchase, is equipped with a special vacuum cleaner. Using a petal mask does not exclude this. Gouging under pipes is a dusty job. It is worth covering not only all objects in the room where work is being done, but also upholstered furniture in neighboring rooms with a film that prevents damage to surfaces.

Video: rules for wall slitting

Grooving walls for water supply refers to a major renovation of the premises. Using a professional tool will significantly reduce the duration of work and the likelihood of critical errors when laying communications. A preliminary consultation with a specialist will simplify the task and save time.

Installation technology

Polypropylene pipes for organizing heated floors are included in a separate category. Their characteristics allow installation in a concrete screed without fear that the system will break. The basis for this statement is the pipe laying technology, in which the joints are located above the floor surface, and only entire sections of the pipeline are silted with the mixture.

The installation procedure when laying a water-heated floor is represented by the following measures:

- It is advisable to carry out a full calculation of the required material and accessories and draw up a diagram for laying polypropylene pipes. When calculating the number of products, take into account the shape of the installation (serpentine, spiral and other optimal for a given room).

- The surface of the rough screed is cleaned of construction debris.

- The waterproofing layer is laid sequentially, then the thermal insulation material is installed.

- As a base, a metal mesh is laid over the entire area of the room covered by the heating circuit. Products are directly attached to it using plastic clamps or iron wire.

- Connect all heating circuits to a pre-formed manifold. The system is tested with higher than operating parameters. The temperature is raised gradually to operating temperature.

- After checking, the final screed is poured and the floor covering is laid.

Important! If there are signs of a pipe break under the screed, it is necessary to identify a local area of the floor surface where the pipe damage occurred, using the installation diagram, and open the surface. Dry the affected area and carry out repair measures.

The information presented above indicates that the use of polypropylene products when installing individual heating systems is a reasonable and correct decision. Compliance with installation rules and high-quality soldering at the joints of connecting elements ensures a long period of trouble-free operation. The technical characteristics of polypropylene elements, which determine their reliability, make it possible to place communications in wall cavities and under concrete screed.

One of the options for laying polypropylene pipes is presented in the video below.

Video 1. Installation of plastic heating pipes.

The principle of operation of “warm floor”

Why is laying heating pipes in a screed called the right choice?

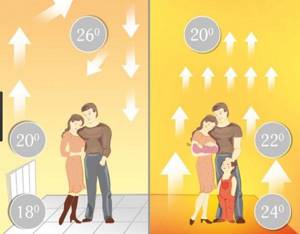

After all, there is an easier way out - replacing the batteries. Yes, this is easier to do, but it does not mean it is more effective than this installation, because no one has yet canceled the laws of physics. The operating principle of heating systems is completely different. Traditional heating radiators give off heat. It then passes along the walls to the ceiling area. It turns out that it is the ceiling zone that warms up first.

Afterwards, the air moves to the lower region, but it gets here already cold. Thus, the following situation arises - in the ceiling area it is warmer, but below the temperature is much lower. The same applies to the convection principle.

But installing underfloor heating changes everything. The maximum heat is located at the bottom, and then, when it cools, it moves to the top. This principle of heat distribution greatly increases the comfort of housing. Accordingly, such a system seems to be the most effective.

Heating

We want to fill the polypropylene horizontal wiring with a screed, and now the question arises: does such a solution fit into the standards?

If you don't mind, please provide a link to the relevant document.

Message from Mikhail : they have a large coefficient of linear expansion

Not only according to this (criterion). There should be no options here other than the traditional one.

Actually, this is what “warm floors” do. It seems that the manufacturers have had no problems so far.

I don't know the rules. Offtop: Sorry for the flood. By the way, have you looked at the SNiP on the floors?

4.23. When laying hidden water pipes from PPRC pipes with concrete or cement-sand mortar, the pipes must be thermally insulated from elastic foam plastic.

VSN 47-96 Departmental building standards for the design and installation of internal water supply systems made of polypropylene pipes "Random copolymer" (PPRC)

Message from: When laying a PPRC pipeline in concrete or plaster, special expansion joints, as a rule, are not required: temperature fluctuations in size are compensated by the elasticity of the material of the pipes and fittings. However, if the length of the laid pipe exceeds 2 m, it is recommended to place between pipe and concrete layer of elastic material, such as thermal insulation (see Fig. 11).

from the installation recommendations.

Message from: for the experimental construction of internal cold and hot water supply systems (temperature up to 75 ° C) for residential and civil buildings in Moscow

But TR 125-02 “Technical recommendations for the design and installation of internal water supply, heating and cooling systems from combined polypropylene pipes”, which

Message from: applies to the experimental construction of internal cold and hot water supply systems (temperature no more than 75 ° C) and heating (temperature no more than 90 ° C) of residential and civil buildings in Moscow from pressure combined polypropylene pipes: “Fazer” (hereinafter pipes "PP-R80-GF") and "fusiotherm-shtabi" (hereinafter referred to as pipes "PP-R80-AI") and are a development of industry standards VSN 47-96 and VSN 69-97.

Just semi-permanent: polypropylene, however. But in the version of the “author’s” application = . If someone does this “for themselves,” this does not mean that... . No need to invent

arguments.

Installation requirements

When laying pipes in the wall, it is recommended to use shock-absorbing materials. For example, energyflex, polyurethane foam. These materials will serve as a gap between the wall and the pipe; accordingly, there will be no pressure on the concrete when the pipe expands.

The fewer connections, the better. Connections are the most vulnerable part of polypropylene systems, least protected from leaks and having low pressure resistance.

Pipes must be selected in accordance with the conditions of further operation.

Based on wall thickness, all PPR pipes are divided into categories from PN10 to PN25.

- PN10 pipes are thin-walled, designed for cold water supply or for heated floors and other low-temperature, low-pressure systems.

- PN16 and PN20 are used for water supply with pressure up to 1.5 MPa and heating systems with pressure not exceeding 0.8 MPa.

- PN25 is reinforced with a layer of fiberglass or aluminum, which increases strength and temperature range. Accordingly, the products can be used in central heating systems at pressures up to 1.5 MPa, and in cold water supply up to 2.5 MPa.

Polypropylene in floor screed

To install polypropylene in a screed, you need to know the features of this material:

- High coefficient of thermal expansion. When exposed to high temperatures, the plastic begins to expand, causing it to put pressure on the concrete.

- Low thermal conductivity. The material conducts heat poorly, which reduces the efficiency of its use in heating circuits.

- Prolonged exposure to high temperatures (above 95 degrees) leads to a decrease in the strength of polypropylene.

Specifics of materials

When designing a system, it is necessary to take into account the specifics of the pipe material. They will be immersed in concrete, so there will be no possibility of correction. You need to pay attention to the following factors:

- thermal expansion of materials. Since the pipes will be tightly filled with concrete, there will be no room for them to change sizes. In this regard, plastic channels pose a particular danger. They have a high coefficient of thermal expansion. If the screed layer is thin, cracks or tears in the surface may appear;

- load-bearing capacity or strength of pipe walls. If cast iron ducts are used, no problems can be expected. Plastic parts are weaker and may not withstand the pressure of concrete or other structures. They need to be reinforced with corrugation;

- adhesion of plastic elements to cement is low. If cast iron combines well with the solution, then PVC or propylene pipes easily lag behind it.

Given these features, it is recommended to use cast iron pipes. they are more reliable, stronger and better connected to concrete. If you are building a sewer system in the floor of an apartment where large loads on the system elements are not expected, you can install plastic parts. Before pouring, it is recommended to apply a layer of concrete contact primer to them.

Labeling and selection principles

When choosing polypropylene pipes that will be installed in a floor screed, you need to study the product labeling:

- PPH is a plastic that cannot withstand high temperatures. Used for the manufacture of cold water supply systems.

- PPR is a material that is resistant to pressure changes due to the ethylene molecules contained in the products. Such tubes are used for the manufacture of water pipes operating with cold water.

- PPB is a plastic that is suitable for making underfloor heating systems because it is resistant to high temperatures.

- PPs are polypropylene, which has a high temperature resistance threshold.

There is a separate marking for the technical characteristics of the material. For the manufacture of heating lines, it is necessary to select products designated PN20-PN25. They are resistant to high temperatures and pressure surges.

Manufacturers

In construction and plumbing stores you can find a wide range of components for the manufacture of pipelines. Manufacturers of polypropylene pipes:

Pros and cons of heated floors

Tubes made from polypropylene have a number of strengths and weaknesses. Advantages:

- high strength;

- durability;

- resistance of the material to rust and chemicals;

- ease of pipeline installation;

- a light weight;

- immunity to water hammer and high pressure.

- high coefficient of thermal expansion;

- low thermal conductivity;

- the material does not withstand prolonged exposure to high temperatures.

Advantages and disadvantages of polypropylene

One of the most popular types of water heating is heated floors made of polypropylene pipes. Among the many available materials, it is chosen due to its many advantages:

- No corrosion or deposits.

- Chemical inertness, the material does not oxidize when interacting with concrete.

- Reinforced pipes have the strength necessary for safe operation of the system.

- The high thermal conductivity of polypropylene ensures rapid heat transfer.

- Long-term operation of heated floors. With proper installation, the service life is 25-30 years.

- Affordable cost of polypropylene products.

- The material is resistant to temperature fluctuations and does not tear when water freezes.

- Polypropylene for heated floors is not flexible, so connecting fittings are required when installing the circuit.

- High coefficient of expansion when heated.

- To install the system, you must be able to operate a soldering machine.

When choosing a material for installing a heating system, take into account the thickness and diameter of the pipes.

Can polypropylene pipes be filled with concrete?

To understand whether polypropylene products can be poured with concrete, you need to understand their technical characteristics and application features.

Characteristics and scope of application of polypropylene pipes

Material specifications:

- resistance to alkalis, acids;

- no rust;

- withstand pressure up to 20 Bar;

- Temperature conditions during operation are from –10 to +110 degrees.

Constant overheating of the material will lead to deterioration in strength and the appearance of leaks at the joints.

Areas of application of polypropylene pipes:

- drainage structures;

- heating circuits;

- hot and cold water supply systems;

- technical, food pipelines.

They are often used to make water pipes on ships.

Features of application

When installing polypropylene heating pipes, you need to take into account several nuances:

- If the length of the circuit exceeds 10 meters, a compensating coupling is installed, to which there must be free access. If there is no coupling, use a sand cushion.

- It is advisable to place connecting fittings and shut-off valves in an insulating corrugation to protect the system from destruction.

- Tubes with a diameter of 15 mm are suitable for heating rooms where the temperature does not fall below 15 degrees.

It is best to choose products in white or gray.

Installation technology

Step-by-step guide for installing polypropylene pipelines:

- Clear the rough screed of debris and remove any unevenness. Cover cracks and recesses with cement.

- Draw a drawing of the location of pipeline elements. Count their exact number.

- Cover the base with a layer of waterproofing, then lay a heat-insulating layer.

- To strengthen the future screed, a reinforcing mesh is laid on the thermal insulation.

- Polypropylene parts are secured to the mesh using plastic clamps.

- When all pipeline elements are connected, a test run should be carried out to check for leaks. It is necessary to slowly raise the fluid temperature to operating level.

If everything works correctly, you can fill the system with cement mortar and wait for it to dry completely.

Polypropylene pipes have gradually replaced metal products. This is due to their low price. Plastic tubes are suitable for the manufacture of underfloor heating systems. To do this, it is important to choose the right material according to the markings and take into account the installation features.

Like, subscribe to our channel and you won’t miss many more useful articles! And visit our website, there is still a lot of useful information regarding pipes.

Pros and cons of methods for hiding heating pipes

Plasterboard and laminate structures

Many people choose this method of hiding heating pipes in a new building with laminate, making a box out of it. In this case, the structure turns out to be designed like the floor. If, in addition to heating pipes, there are other communications in the house, it is best to hide them using a false wall made of gypsum plasterboard.

The considered method has a number of disadvantages, for example:

- not suitable for metal-plastic and polypropylene pipes. which are connected by collapsible fittings;

- if the pipe is old, putting the pipe into the box is very risky: a leak that occurs can cause a lot of trouble;

- before hiding stainless, copper and steel pipes behind a decorative box, it is better to cover them with heat-insulating material;

- false wall equipment reduces the space of the room.

But the niche created as a result of the construction of a false wall can be used to advantage. For example, by laying a layer of insulation, you can improve light and sound insulation. You can use this place for a night light or place a stereo system. Using a niche to your advantage, false wall equipment will be a completely justified option for hiding heating pipes.

Hiding highways in the wall, floor

This method of hiding heating pipes in a floor screed or in a wall is not suitable for all pipelines.

Heating pipes in the wall have pros and cons that you need to know before choosing this method of masking the line. The main advantage of the method is that the design of the room will not be disrupted or overloaded with additional details. True, there are also disadvantages. For example, the complexity of installation. If the pipe leaks, the wall will have to be demolished to make repairs.

For a private home, this is a very practical option.

Application of decorative elements

Decorative rosettes for heating pipes are an excellent option for hiding pipes.

Thus, today there are many ways to hide heating pipes in a private house. It is advisable to close the highways at the construction stage. But even after construction you can decorate the pipes. Each method has its own advantages and disadvantages. And which one to give preference depends on the type of pipeline, operating conditions and the chosen room design.

Source

Is it possible to pour polypropylene pipes into a screed?

Heating systems installed in private houses and apartments are being improved every year, resulting in modern products that are not only convenient, but also economical. To make the room even more comfortable, it is now popular to install a “warm floor” system.

The pipes are laid in a concrete screed, which is heated by circulating hot water. The heat gradually rises, causing the floor to heat up first, and then the entire room. The described heating system is considered more economical. But the question remains whether it is possible to pour polypropylene pipes into the screed and how to do it correctly.

Features of warm water floors

Heating of the room occurs due to the circulation of coolant in a circuit placed in a concrete floor screed. Water is heated in a heating boiler connected to the system. The movement of liquid along a closed circuit is ensured by a circulation pump. The heated floor scheme also includes a distribution manifold, shut-off valves, and fittings.

The base of the floor is insulated and waterproofed before installation. After laying, connecting and checking the system, the pipes are filled with concrete screed. Heat is evenly distributed throughout the entire thickness of the formation, accumulated and transferred to the room. This is the best option, heating the house using the convection principle. In well-insulated rooms it can serve as the main source of heating.

Warm water floors are usually installed in private homes. Systems are not prohibited in apartments, but residents encounter some difficulties when installing them.

The water circuit must not be connected to the central heating system, so an autonomous boiler must be installed. In addition, it is necessary to find out whether the ceiling can withstand the weight of the concrete screed. One of the main disadvantages of the system is the difficulty of repair in case of leakage. In an apartment building, the problem will result in flooding of neighbors.

Polypropylene pipes in a heated floor system

Polypropylene pipes are known to many, mainly because they are popular for organizing plumbing systems. However, if a “warm floor” system is planned for the home, the use of these products still gives rise to controversy. The main advantage of the material is its affordable cost, the disadvantage is the low level of thermal conductivity when compared with metal-plastic products.

Important! Some craftsmen are worried that pouring polypropylene pipes with concrete is dangerous, which damages both the screed and the products themselves. However, it should be remembered that the operating temperature of the heated floor is +45 degrees Celsius, so the likelihood is minimal.

Some enthusiasts tried to combine heated floors with central water supply. However, current laws prohibit this. In addition, there will be no possibility to regulate the temperature of the coolant - this is where the main difficulties lie. The project, as a rule, is implemented on the basis of an autonomous boiler.

Installation nuances

If the sewer pipe is installed in the floor, the system does not need to be secured. This is required only in difficult places, where there is a high probability that the pipeline will bend and access will be needed for further work. It is important to remember that polypropylene pipes have a high coefficient of thermal expansion. Thus, when installing such a system, the following recommendations are taken into account:

- If the installed pipeline with a total length exceeds 10 meters, then a compensation coupling is installed on the site. Filling the coupling with a screed is not allowed. An alternative option here is a sand cushion.

- All kinds of components are installed on the pipeline, that is, elbows, tees and other fittings. They are placed in an insulating box or corrugated pipe. If there is too much tension in the system, this will lead to leakage or destruction of both the products and the screed itself. In the worst case, improper installation will ruin the floor covering.

- If you want to install heating pipes made of polypropylene in the floor, then it is better to use a cross-linked type of product. This material is characterized by strength, reliability and resistance to high temperatures. But, it is important to know that in cement floors these products will not hold their shape well, so they are fixed with fasteners, which may be needed in large quantities.

- If the polypropylene line has a diameter of 15 mm, the branches will be 120 cm apart from each other, and this is not the best option if you want to effectively warm the room. Installation of heated floors using such products can only be carried out if the temperature in the home is at least +15 degrees Celsius.

Basic requirements for hidden communications

Construction codes and regulations, which include the normative document SNiP 2.04.01-85, regulate the rules for the location of water pipes in the walls - it is useful to know them when carrying out installation work. The documentary acts indicate the following basic standards for the installation of water lines in the walls:

- It is prohibited to chip load-bearing walls, as this reduces their strength and, accordingly, leads to a decrease in the stability of the entire structure.

- Only solid structures connected by soldering or welding are allowed to be laid in walls. If the connection is removable, access to it is provided by installing inspection hatches or removable panels.

- When laying a pipeline from metal-plastic or metal elements, the placement of electrical wiring should be taken into account; during gating, the electrical line at the work site must be de-energized.

- The groove must be laid taking into account the expansion of the pipeline material when heated; its depth and width are calculated to maximize the increase in the diameter of the passing pipes. It is recommended to install a compensating junction for every 3 linear meters of pipes carrying hot water.