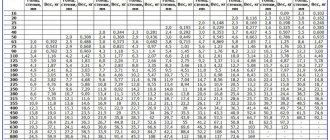

— outer diameter of stainless pipe: from 10.2 (mm) to 1016 (mm); — wall thickness: from 1.0 (mm) to 8.8 (mm); — weight of 1 meter of pipe: 0.230 (kg) to 199 (kg); — release is regulated by: GOST 9940 81.

It should be taken into account that actual production is not regulated by GOST, and the manufacturer can produce pipes of any length, thickness and diameter.

Full exact sizes are presented in the table below.

Steel pipes are products used in the installation of many communication systems: heating, water supply (hot and cold water supply), sewerage, etc.

In this regard, they are widely classified - the assortment depends on the specific application, design, and size of the products. The production of such products is determined by GOST, which normalizes production technology, material composition, and pipeline dimensions.

Diameters of stainless steel pipes - GOST and size table

Pipes made of stainless steel alloys are now actively used for the installation of heating, water supply and sewerage systems. By choosing the diameters of stainless steel pipes according to a special size table, you can successfully select such products to solve various problems.

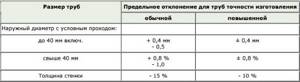

For each type of stainless pipes there are maximum permissible deviations from the parameters defined by the relevant standards

All pipes for the production of which stainless steel is used are produced in strict accordance with the regulatory document. GOST stipulates not only the chemical composition of the material for their manufacture, but also their production technologies, sizes and assortment.

Types of products and areas of their use

For the production of profile stainless steel pipes, complex alloy steel grades with a high content of chromium (17 - 19%) and carbon impurities (0.8%), titanium (0.5%), and nickel (8-10%) are used.

The alloying elements included in the alloy give these products:

- unusually high resistance to corrosive destruction;

- increased strength and wear resistance;

- good weldability;

- high technology;

- long service life without changing the original properties;

- aesthetic appearance;

- resistance to thermal influences;

- good impact strength;

- resistance to low temperatures;

- complete passivity to chemicals.

1.1. Types of rolled pipes

Stainless steel pipes are manufactured with a cross section of different shapes, depending on which there are:

According to forming technology, rolled stainless steel grades are divided into:

- welded;

- hot rolled;

- heat-deformed;

- cold drawn pipes.

Depending on the type of surface treatment, they can be:

- polished;

- matte;

- polished to a mirror finish.

1.2. Application of stainless steel pipes

Durability of use and excellent technical characteristics of rectangular pipes made of stainless steel alloys make them in demand in many areas of the national economy

:

- in the construction industry;

- automotive industry;

- furniture production;

- oil and gas industry;

- public utilities;

- production of medical instruments;

- for the construction of pipeline systems and equipment in chemical and food industries.

However, there are some restrictions on the use of certain types of pipes. For example, welded products with a rectangular and square cross-section cannot be used for the construction of pipelines intended for transporting media under high pressure.

Stainless steel pipes with a matte surface are used for the manufacture of metal structures, for which there are no special requirements for aesthetic appearance.

Products with a mirror surface are endowed with decorative qualities, so they are used in the manufacture of furniture and interior design. Mirror pipes 30x10x 1.5 mm can be purchased for installing fences, railings, cornices and canopies.

Stainless steel pipes with a rectangular profile and low weight have high strength characteristics and resistance to torsional forces.

They are used for the manufacture of:

- load-bearing metal structures: racks, beams, columns, trusses;

- frames of various configurations;

- vaulted structures;

- supports for equipment;

- stairs, etc.

Classification options

The entire range of pipes made from stainless steel is divided into several categories. The parameters by which this division is carried out are:

- design features (suture and seamless);

- production technology (cold rolled, cold drawn and hot rolled);

- cross-sectional shape (round and profile);

- wall thickness (thick-walled and thin-walled).

Stainless steel pipes of various sizes are actively used for arranging communications through which cold and hot water is transported, as well as for installing sewer systems. Such pipes, which have a significant diameter, are successfully used for the installation of main oil and gas pipelines.

The ratio of outer to inner diameter for thick-walled stainless steel pipes is in the range of 0.05–0.1

The high popularity of rolled pipes made of stainless steel is explained by a whole list of its advantages:

- exceptional durability;

- possibility of operation under high pressure;

- resistance even to significant temperature changes;

- high plasticity;

- resistance to corrosion, demonstrated even during operation in conditions of constant exposure to aggressive environments.

It should also be noted that the minimum service life of stainless steel pipes is 10 years.

Main characteristics

The main qualities of seamless stainless pipes are determined by the steel alloy from which they are made. The main advantage of stainless steel is its high resistance to corrosion.

The absence of a weld seam adds strength to the product. It can be operated at high operating pressure inside the outlet, under conditions of temperature changes and high ambient humidity.

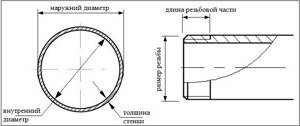

When choosing products, we are guided by:

- Outer diameter dimensions.

- Dimensions of wall thickness.

- Length and mass of segments.

- Manufacturing method.

Main varieties

GOST also stipulates the range of stainless steel pipes, which includes the following products:

- used for transporting liquid and gas media – water and gas pipelines;

- coated with a special anti-corrosion compound;

- characterized by a slight wall thickness and having threads at the ends (such steel pipes, the diameters of which can be different, also have a reduced weight);

- produced using welding technologies and having longitudinal seams;

- seamless, made using hot-rolled technology.

It is worth dwelling in more detail on each type of stainless pipes, the range and diameters of which are specified by GOST.

The diameter of pipes of this type, as indicated by GOST, can vary within a fairly wide range: 15–50 mm. Depending on the pressure under which they are intended, such stainless steel pipes are divided into light, standard and reinforced.

Parameters of water and gas pipes

GOST stipulates that the ends of water and gas pipes must be cut at an angle of 90°, and the welds on their surface must be completely welded and sealed. In accordance with the standard, there may be minor chips on the surface of such steel pipes, but in general their walls should be smooth and free of cracks.

Pipes with anti-corrosion coating

Such pipes, which are also listed in the stainless steel product range, are distinguished by the fact that their surface is coated with zinc, which provides additional corrosion resistance. In accordance with the regulatory document, they should not have areas not coated with zinc, coating blisters, burrs and other defects.

The dimensions of the thread, if applied to the ends of such pipes, should not exceed 10 percent of the length of the product itself.

Thin-walled pipes with threads

These pipes, produced in various standard sizes, are used in cases where it is necessary to carry out repairs or change the design of the pipeline. Products of this type, which make it possible to obtain reliable and tight connections, are not thick-walled and are not produced with large cross-sectional dimensions.

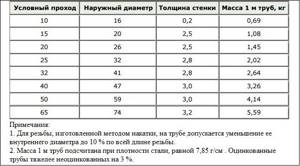

Parameters of light series pipes manufactured for threading

There are no welds on the surface of hot-rolled pipes, which can be thick-walled, which gives such products high tightness and allows them to withstand even very significant pressure. These products, the standard sizes of which are also specified in the assortment, are distinguished by smooth walls and a minimal coefficient of thermal expansion.

The most common areas of application for such pipes, the sizes of which can vary quite widely, are:

- installation of pipelines for supplying cold and hot water;

- arrangement of sewer systems;

- installation of heating networks and communications for other purposes.

Dimensions of seamless hot-formed stainless steel pipes

It should be borne in mind that both thin-walled and thick-walled pipe products produced by welding can be used to supply water used for technical purposes, and not for drinking or cooking.

Does stainless steel rust?

Stainless steel contains a high percentage (from 10%) of chromium. With its help, an oxide film is formed on the surface, which has corrosion-protective functions.

Rust occurs when there is either not enough chromium to form a protective layer, or this layer is damaged.

For example, corrosion may appear:

- When regular black steel comes into contact with stainless steel.

- In case of improper handling of the surface of the part or its design defects.

- If there are deposits or slag residues.

- When welding using flux-cored wire.

The simplest and most effective method of combating corrosion on stainless steel is to constantly keep the surface clean using ordinary water and further wiping.

Standard sizes

The list of standard sizes of stainless pipe products includes the following parameters:

- nominal diameter - internal diameter, which can vary between 10–150 mm (the larger this parameter, the higher the permeability of the pipes);

- thread sizes (in accordance with the requirements of the standard, this parameter can vary in the range of 3/8–6 inches);

- outer diameter, which, taking into account the size of the weld, can vary in the range of 17–156 mm;

- The outer diameter of steel pipes, which are made without the use of welded joints, is 16–159 mm.

Main dimensions of stainless pipes

Stainless steel pipes, depending on their type, are produced in accordance with the requirements of various regulatory documents:

- GOST number 3262-75 – water and gas pipelines;

- 10705-80 – obtained by welding;

- 20295-85 – intended for laying main pipelines.

Each of the above regulatory documents contains tables that indicate the range and standard sizes of such products.

Features of installation of pipes and their connections

When supplied from the factory, the ends of stainless steel pipes must be tightly closed with plugs, which are removed immediately before installation. When working with parts, they must be protected from impacts and scratches. Devices and portable trestles are equipped with wooden spacers.

On supports and hangers made of ordinary steel under stainless pipes, gaskets made of corrosion-resistant steel are placed.

The installation of welding joints is usually carried out with a tungsten electrode, and the welding itself is performed in an inert gas environment. The most effective way to qualitatively connect stainless steel elbows is plasma welding. Before welding work, the ends of the pipes are processed and chamfered.

Read also: How to make a jointer from an electric planer with your own hands

At home, where welding is not always possible, flanged or threaded fittings are used.

Types of stainless steel pipe connections

When laying a pipeline using stainless steel bends, the following types of connections can be used:

- Welded.

- Using flanges.

- Threaded.

- Fitting.

- Crimping.

Brands and guaranteed parameters

The tables contained in the regulatory documents for pipe products made from stainless steel contain various parameters. In particular, from these tables you can take information about the grades of steel used for the production of such pipes.

Permissible deviations from dimensions must be within the values specified in the table

Knowing the brand of material from which the pipe is made allows you to get an idea of which of its parameters are guaranteed. These include in particular:

- A – mechanical characteristics of the steel used;

- B – its chemical composition;

- B – the relationship between the chemical composition and mechanical properties of the alloy used.

Characteristics of seamless pipes

International standards:

- ASTM A312 - Seamless pipes (c/c) of austenitic stainless steel grades,

- ASTM A213 - Seamless Ferritic and Austenitic Alloy Boiler Parts,

- steam superheating and heat exchange pipes.

Surface: Matte Shape: round Length: 5-7m Standard sizes: diameter from 6 mm to 325 mm Wall thickness: from 1 mm to 13 mm

Diameters of stainless steel pipes: GOST and OST

The diameters of stainless steel pipes can be found in State and Industry standards. They can be very different, ranging from small ones of a few millimeters to large ones (several meters). Stainless steel pipes are used in a wide variety of sectors of the national economy and industry, which is why the range in size is so huge.

If you require a specific size, we recommend that you first refer to the regulatory documentation. Here is a list of basic standards that can serve as references when finding the required diameter:

GOST 14162-79. Small steel tubes (capillary) - determines the technical conditions for manufacturing and the range of capillary tubes made of stainless steel. The sizes of these products are very small.

Manufacturing methods and technologies

The technology for manufacturing seamless stainless steel pipe is a costly and labor-intensive process. It requires expensive equipment, high power consumption, and strict control at every stage.

Products are produced using one of two methods:

- Hot skating.

- Cold rolling.

Hot deformed

Hot-rolled products are produced from a billet of a certain grade of stainless steel.

It is heated to a plastic state, then a through hole is stitched through it with a mandrel.

Next, the resulting hollow sleeve is rolled and, using rolling equipment, the required standard dimensions are achieved on the final product.

At the final stages, the product is finally calibrated, polished, and cut into standard pieces.

The technology does not allow the production of round rolled products of small diameters. It is not always possible to guarantee dimensional accuracy or achieve a completely flat and smooth surface.

Cold-worked

The process of producing cold-rolled products is not much different from the previous one. Only here, after piercing, the part is cooled with water and rolled in a cold or warm state.

This technology makes it possible to produce rolled pipes with a smaller cross-section, thin walls, and a polished surface. The products are more durable, which is facilitated by additional heat treatment.

Solid drawn pipes are more expensive than their hot-rolled counterparts.

Availability in GOST is not a guarantee...

We want to clarify right away. As you can see, the number of different sizes in these standards is very large, but the number of factories that manufacture pipes is not so huge. In addition, any plant, first of all, cares about the economic efficiency of its production and tries to produce popular types of rolled metal.

Obviously, if the plant has all the above pipes in its assortment, it will be forced to curtail production. This will happen because a huge part of the produced goods will remain in warehouses unclaimed. In the real sector, only a limited number of diameters are used. And this can cause certain difficulties when searching.

Therefore, the presence of a size in the State or industry standard does not at all mean that it is available from suppliers. A size may be indicated in GOST but not be available on the market at all due to lack of demand.

The opposite is also true: the absence of a size in the standards does not mean that it is not on the market. The standards do not prohibit the production of pipes of intermediate diameters and thicknesses. Manufacturers often make such pipes because there is a demand for them and it is profitable.

Therefore, we want to give you one piece of advice: do not focus on standards when searching. Focus on the market itself and the capabilities of a specific supplier.

Non-standard diameters

Some sizes are much easier and cheaper to find on the market than others. For example, pipes with a diameter of 10, 20, 50, 100 mm are very easy to find. They are available from many suppliers. But if you're looking for a custom-sized stainless pipe, you may run into problems. It all depends on the demand and method of production of rolled products .

Hot-deformed and cold-deformed pipes of non-standard and unpopular sizes are much more difficult to find than electric-welded ones, since hot rolling technology requires special expensive equipment. Electric-welded pipes are much easier to produce, and therefore, even if you do not find the required size, it can always be made to order.

Making a batch to order can be a good solution if the required batch is quite large. However, this still involves additional difficulties: it is necessary to negotiate with the manufacturer and approve documents.

Therefore, we recommend that you avoid unpopular sizes where possible. This will save you from a lot of difficulties in the future. Well, if this fails, call our company. We will always help you.

To summarize we can say:

- Industry standards do not indicate all possible sizes of rolled products. What is specified in the standards and what is on the market are completely different assortments.

- The availability of a specific diameter on the market depends on many factors and, above all, demand.

- Custom electric-welded pipes are much easier to find than hot-rolled or cold-rolled pipes.

- If you can refuse to use unpopular diameters in your project in favor of more popular ones, then it is best to do so. This will save you a lot of time and money.

- If you still really need a non-standard or unpopular size, please contact us. We have extensive connections with manufacturers and other suppliers. We will try to help you in every way we can.

METAL TENDER

– metal trading system for buyers and sellers. All information on the site is for informational purposes only. For accurate data, please refer to the relevant GOST.

Our website uses cookies to improve your experience on the site. When you visit this website, you consent to the use of cookies in accordance with this cookie notice.

Add rolled metal to your request

The more detailed you fill out this form, the fewer additional questions our specialists will have and the easier it will be to find the required rolled metal.

Stainless steel pipes

| Seamless cold- and heat-deformed stainless steel pipes |

Stainless steel pipes

used in the chemical, petrochemical and pharmaceutical industries and are designed for transporting corrosive media.

Stainless steel pipes

are made by hot pressing from hard-to-deform corrosion-resistant, heat-resistant and heat-resistant steels and alloys.

Stainless steel pipes

supplied in length:

Stainless steel pipes

in a batch of unmeasured length, 5% of pipes not shorter than 0.5 m are allowed. Pipes are supplied in a heat-treated state.

Stainless steel pipes

made from corrosion-resistant steels, the chemical composition of which must comply with GOST 5632-72:

Stainless steel pipe range

unmeasured length from 1.5 to 9 m;

| ||||

hot pressing in combination with subsequent etching ensures high surface quality (roughness Ra - 1.1-1.6 microns).

| ||||

| Outer diameter, mm | Wall thickness, mm | Pipe length, m (no more) | ||

| 5 | 0,2-1,0 | 5-7 | ||

| 6-7 | 0,2-1,5 | 5-12 | ||

| 8-9 | 0,2-2,0 | 5-12 | ||

| 10-13 | 0,2-2,5 | 5-12 | ||

| 14-17 | 0,2-3,0 | 5-12 | ||

| 18-19 | 0,2-3,5 | 5-12 | ||

| 20 | 0,2-4,0 | 5-12 | ||

| 21-24 | 0,3-4,0 | 6-12 | ||

| 25/27/28 | 0,3-4,5 | 6-12 | ||

| 30/32-35 | 0,3-5,5 | 6-12 | ||

| 36 | 0,4-5,5 | 6-12 | ||

| 38/40/42/45 | 0,4-6,0 | 6-12 | ||

| 48/50 | 0,4-7,5 | 6-12 | ||

| 51/53/54/56/57 | 0,5-7,5 | 6-7 | ||

| 60 | 0,5-8,0 | 6-7 | ||

| 63/65/68/70/73/75 | 1,5-8,5 | 7 | ||

| 76/80/83/85 | 3,0-8,5 | 7 | ||

| 89/90 | 4,0-8,5 | 7 | ||

| 95 | 4,0-5,0 | 7 | ||

| 108-530 | 4,0-28,0 | on request |

Seamless hot-deformed pipes made of corrosion-resistant steel

Assortment

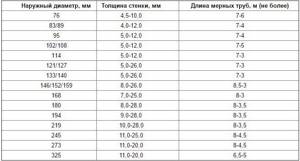

| Outer diameter, mm | Wall thickness, mm | Length of measuring pipes, m (no more) |

| 76 | 4,5-10,0 | 7-6 |

| 83/89 | 4,0-12,0 | 7-4 |

| 95 | 5,0-12,0 | 7-4 |

| 102/108 | 5,0-12,0 | 7-5 |

| 114 | 5,0-12,0 | 7-3 |

| 121/127 | 5,0-26,0 | 7-3 |

| 133/140 | 5,0-26,0 | 7-3 |

| 146/152/159 | 8,0-26,0 | 8,5-3 |

| 168 | 7,0-25,0 | 8-3 |

| 180 | 8,0-28,0 | 8-3,5 |

| 194 | 9,0-28,0 | 8-3,5 |

| 219 | 10,0-28,0 | 8-3,5 |

| 245 | 11,0-25,0 | 8-4,5 |

| 273 | 11,0-20,0 | 8-4,5 |

| 325 | 11,0-20,0 | 6,5-5 |

Electric-welded pipes made of corrosion-resistant steel

Inches vs mm. Where does the confusion come from and when is a correspondence table needed?

Pipes, the diameter of which is indicated in inches ( 1″, 2″ ) and/or fractions of inches ( 1/2″, 3/4″ ), are a generally accepted standard in water and water gas supply.

What's the difficulty?

Take dimensions from a 1″ (how to measure pipes is described below) and you will get 33.5 mm , which naturally does not coincide with the classic linear conversion table for inches to mm ( 25.4 mm ).

As a rule, the installation of inch pipes proceeds without difficulty, but when replacing them with pipes made of plastic, copper and stainless steel, a problem arises - the discrepancy between the size of the indicated inch ( 33.5 mm ) and its actual size ( 25.4 mm ).

Usually this fact causes bewilderment, but if you look deeper into the processes occurring in the pipe, the logic of the size discrepancy becomes obvious to a layman. It's quite simple - read on.

The fact is that when creating a water flow, the key role is played not by the external, but by the internal diameter, and for this reason it is used for designation.

However, the discrepancy between the designated and metric inches still remains, since the internal diameter of the standard pipe is 27.1 mm , and the reinforced one is 25.5 mm . The last value is quite close to the equality 1”=25.4 , but still it is not it.

The solution is that to designate the size of pipes, a nominal diameter rounded to a standard value is used (nominal diameter Dy ). The nominal diameter is selected so that the pipeline capacity increases from 40 to 60% depending on the increase in the index value.

Example:

The outer diameter of the pipe system is 159 mm, the pipe wall thickness is 7 mm. The exact internal diameter will be D = 159 – 7 * 2 = 145 mm. With a wall thickness of 5 mm, the size will be 149 mm. However, in both the first and second cases, the conditional passage will have one nominal size of 150 mm.

In situations with plastic pipes, adapters are used to solve the problem of inappropriate dimensions. If it is necessary to replace or connect inch pipes with pipes made according to real metric dimensions - copper, stainless steel, aluminum, both the outer and inner diameters should be taken into account.

Table of nominal diameter in inches

| Du | Inches | Du | Inches | Du | Inches |

| 6 | 1/8″ | 150 | 6″ | 900 | 36″ |

| 8 | 1/4″ | 175 | 7″ | 1000 | 40″ |

| 10 | 3/8″ | 200 | 8″ | 1050 | 42″ |

| 15 | 1/2″ | 225 | 9″ | 1100 | 44″ |

| 20 | 3/4″ | 250 | 10″ | 1200 | 48″ |

| 25 | 1″ | 275 | 11″ | 1300 | 52″ |

| 32 | 1(1/4)» | 300 | 12″ | 1400 | 56″ |

| 40 | 1(1/2)» | 350 | 14″ | 1500 | 60″ |

| 50 | 2″ | 400 | 16″ | 1600 | 64″ |

| 65 | 2(1/2)» | 450 | 18″ | 1700 | 68″ |

| 80 | 3″ | 500 | 20″ | 1800 | 72″ |

| 90 | 3(1/2)» | 600 | 24″ | 1900 | 76″ |

| 100 | 4″ | 700 | 28″ | 2000 | 80″ |

| 125 | 5″ | 800 | 32″ | 2200 | 88″ |

Table. Inner and outer diameters. Stacked water/water-gas pipelines, epectros-welded longitudinal, seamless hot-deformed steel and polymer pipes

Table of correspondence between nominal diameter, thread and outer diameters of the pipeline in inches and mm.

Nominal pipe diameter Dy. mm

Thread diameter G". inch

Pipe outer diameter Dn. mm

Water/water-gas pipes GOST 3263-75

Epoxy-welded straight-seam steel pipes GOST 10704-91. Seamless hot-deformed steel pipes GOST 8732-78. GOST 8731-74 (FROM 20 TO 530 ml)

General characteristics of stainless steel pipes

Stainless steel pipe is a hollow and straight profile of different sections. Taking into account the cross-sectional shape, profile and round products . Today, stainless steel pipes are manufactured using one of three methods. The first involves the manufacture of products by rolling up a strip with further soldering of the joint with copper. The result is a soldered, rolled stainless steel pipe.

Seamless pipe rolling is produced using centrifugal casting or cold or hot deformation. In this case, the production of welded pipes occurs using plasma or laser electric welding. During this, the stainless steel is exposed to inert gases or high-frequency currents. This method makes it possible to make the cheapest products, since the manufacturing process does not take much time. In each case, the stainless steel is pre-hardened. This is required so that the raw material loses a high level of hardness and strength during manufacturing.

Advantages of stainless pipes

Stainless steel pipes have many advantages. The main thing is that a stainless product has increased resistance to corrosion . And since it contains 20% chromium, it also provides excellent resistance to most negative environmental factors. Due to this, such rolled metal has an almost unlimited operating time. It can be used for more than 400 years.

Stainless steel products can easily be restored to their aesthetic appearance, since steel is a homogeneous composition. The resulting scuffs and scratches can be easily polished and sanded, giving these pieces an attractive finish. This pipe product combines perfectly with modern finishing materials. The price of rolled pipes is relatively inexpensive, and the range has been very wide for many years.

What kind of pipes are the railings made of?

Pipe elements are used in various fields of human activity. They have also found their application in the arrangement of railings. This option is classic, the most convenient, suitable for almost all buildings.

More often than others, details of standard parameters are used. We are talking about meter racks with a cross section of 38-40 mm, handrails, spans - 3 m or 4 m long with a cross section of 50 mm.

Railings made from stainless steel products have a number of positive qualities, among which we should highlight:

- increased strength;

- wide functionality;

- ease of installation;

- long service life;

- ease of care, as well as practicality.

Due to the beautiful appearance of stainless steel railings, they are used not only in large, respectable establishments, but also in private buildings. Such details can decorate any interior.

Structures made of corrosion-resistant steel can perform a protective function and facilitate safe and comfortable movement on bridges or stairs. To give the interior a special aesthetics and unsurpassed attractiveness, stainless steel railings are perfectly combined with glass, stone, plastic, and wooden elements.

Standard fencing includes handrails, vertical posts, and crossbars. The main fastening parts are the racks, and thanks to the handrails, the structure becomes more stable and reliable.

Crossbars are placed under the handrails, the main function of which is to give the fence rigidity and safety.

This is interesting: Do-it-yourself gabions: step-by-step instructions and manufacturing recommendations

Popular range of stainless steel pipes

Stainless steel pipes according to GOST-9941 81

This standard, certified in the mid-1980s, describes seamless cold- and heat-deformed tubular products made from general purpose corrosion-resistant steel. The diameter (outer) of these pipes varies from 5 to 273 mm , their walls have a thickness of 0.20-21 mm.

Pipe rolling products are manufactured in standard (5-7 meters), as well as multiple measured and unmeasured lengths. The standard is quite loyal to consumer demands for corrosion-resistant products, therefore it allows their production with a length of 0.5-15 m. However, the production of all non-standard pipe products by the plant must be previously agreed with the customer.

It must be said that in one batch of manufactured products of unmeasured length there may be pipes:

- 0.5-0.75 meters (walls less than 0.5 millimeters);

- 0.75-1.0 meters (walls 0.50-1.0 millimeters);

- 0.75-1.5 meters (when their wall is specified as thicker than 1 millimeter).

In a batch of rolled pipes with these dimensions there can be no more than 6%. All corrosion-resistant pipes are divided into high-, normal- and high-precision products. Taking into account this indicator, the following deviations (maximum) of pipe products in wall thickness are permissible:

- 0.05-0.15 millimeters (usual accuracy);

- 0.03-0.10 millimeters and from -11% to +12.4% (increased accuracy);

- from -11% to +12.4% (high precision products).

The outer diameter of the pipes can have a permissible error from 0.15 millimeters (high-precision) to 0.4 millimeters (regular) or 0.7-1.3%. For pipes made of steel 06ХН28 MDT with a cross-section of more than 30 millimeters, a deviation of 1.2% is possible, a cross-section of less than 30 millimeters is 0.45 mm.

Requirements for cold- and heat-deformed stainless pipes

The ends of the finished pipeline are cut off (cut angle is straight), burrs are removed from them, which can lead to the formation of a chamfer and the formation of surface roughness. This is allowed by regulatory documents. Sometimes even customers negotiate with the manufacturer the need for chamfering at the ends of pipe products where the walls are more than 5 mm , since it makes it possible to make pipeline connections using welding more efficiently and effectively.

On any section 1 meter long, a stainless pipe can have the following curvature characteristics:

- 1 millimeter (walls more than 0.50 millimeters, cross-section more than 5 millimeters);

- 2 millimeters (pipes with walls up to 0.50 millimeters and a cross-section from 15 millimeters).

If we consider structures with walls less than 0.50 cm with a cross-section up to 1.5 cm, then there is no special approval in GOST for this case. The main thing is that the products are made without sharp bends. The ovality of rolled pipe should be such that the diameter of the products does not exceed the permissible errors in the size of their outer diameter.

The described products are manufactured from stainless metal from the following steel grades : 17Х18Н9, 08ХН28МДТ, 08Х17 Н15М3Т, 12Х18 Н12Т, 10Х23 Н18, 08Х18 Н10Т, 04Х18 Н10, 10Х17 Н13М2Т, 08Х13, 12Х17, 12Х18 Н10, 08Х22 Н6Т, 12Х13, 15Х25 Т, and some other high-alloy metals. The density level of these alloys ranges from 7.6-7.97 g/cm. cubic meters, regarding tensile strength – 37-587 kgf/mm. sq. and elongation – 16-46%.

These steel grades may include a small addition of rare earth metals, and at the same time comply with all 5632 standards. Much attention is paid to the presence of sulfur in products; it cannot be more than 0.02%. The finished pipe product undergoes heat treatment.

Stainless steel pipes according to GOST-9940 81

The next GOST also describes stainless steel pipes, but here we are talking about products that are manufactured using hot deformation. The outer diameter of these products is 56-326 millimeters, the wall thickness is 3.4-32 millimeters , they are made from the same grades of steel that are described in GOST 9941.

In many respects, both standards are absolutely identical. Therefore, we will not repeat ourselves, but will talk about the acceptance of finished products. It occurs in batches (they are assembled from identical geometric dimensions, grades of the original alloy, and heat treatment of products). No more than 200 products can be assembled into one batch.

Product quality control involves testing for:

- stretching (two pipes);

- flattening and spreading (one);

- intergranular corrosion (two products from the batch).

A batch is of high quality when all tests have shown positive results. If at least one shows poor quality of the products, then another test is performed, but now they use a double number of products. It should be noted that absolutely all products from the batch are subject to analysis of geometric characteristics, hydraulic pressure tests and ultrasonic examinations.

The quality of corrosion-resistant pipes is checked in the following ways:

- micrometer and staples (sheet) - external section and ovality;

- tape measure - their size in length (GOST-7502);

- using a straight edge and a feeler gauge – curvature.

During testing, stainless steel pipes are held under pressure for 10 seconds or more, tensile analysis is carried out according to GOST-10006/19040, and flattening is analyzed according to GOST-8695.

Areas of use

Stainless steel pipe has a unique set of properties:

- Highest mechanical strength;

- Resistance to corrosion and aggressive environments;

- High melting point;

- When treated with surface it creates an attractive appearance.

The properties determine the areas in which the pipe marked “stainless” is used in the price list position:

- Water supply and heating systems;

- Pipelines in the food industry in contact with various products;

- The chemical industry with its extremely aggressive substances, which are often conveyed through pipes at high temperatures and pressures;

- Energy. What is needed here is the strength and heat resistance of stainless steel;

- Decor of interiors and buildings. Still, polished stainless steel pipes are not only wear-resistant, but also a very beautiful material;

- Medicine;

- Shipbuilding;

- Automotive industry;

- Heavy engineering. What else can hydraulic cylinders be made of where pressures amount to thousands of atmospheres?

Let's take a closer look at some of the areas.

Plumbing and heating systems

Made from stainless steel, they are almost eternal.

The list of advantages is long:

- The stainless steel pipe is not subject to corrosion and does not overgrow;

- pipe erosion by suspensions and microparticles is theoretically possible, but in practice it will take much longer than the lifespan of any building;

- A polished pipe looks very presentable and, with carefully made threaded pipe connections, may not be hidden under decorative boxes.

The most simple threaded fittings for water supply can be used. However, stainless steel water pipes are often assembled using welding.

Tip: When using threaded connections, do not use synthetic sealing tapes or threads. TO

In fact, the old-fashioned method, proven over decades, will be more reliable: ordinary linen winding soaked in paint or drying oil.

The only downside to using stainless steel pipe when creating your home plumbing is how difficult it is to machine. Trying to thread it by hand is simply futile; making pipes and bends on a lathe will require especially durable tools.

Fittings for threaded connections are also made of stainless steel

Recently, corrugated stainless steel pipes for water supply systems using threaded clamp fittings have appeared on sale. Reviews for them have been rather mixed so far, so you should probably refrain from using them for now.

Use in the food industry

Stainless steel food pipe is, as a rule, a seamless pipe. The food industry can also use welded pipes, but only those produced by TIG welding - a tungsten electrode in an inert gas environment. This limitation is due to the strength of the seam and its tightness .

In addition, in the food industry, only polished pipes are used, and, of course, the inner surface is also polished. This is due to the fact that bacteria do not multiply on a perfectly smooth pipe: there is simply nothing for them to eat there. There are no, so to speak, folds of the terrain in which the remains of organic matter get stuck.

At food processing enterprises, a significant part of the equipment is made of stainless steel. Of course, pipelines are no exception.

Chemical industry

But here the strength of stainless steel and, most importantly, its ability to work in aggressive environments come first. Pipes made of steel 12x18n10t can withstand temperatures up to 350C in solutions of acids and alkalis!

Of course, here we see exclusively seamless pipes: after all, leakage of even a few molecules of the contents of the water supply is sometimes unacceptable. And the pressures can be enormous.

A stainless steel pipe leads to the dismantled chemical reactor. The reactor vessel is made from it

Energy

And here, too, you need the strength of stainless steel and its resistance to temperatures. Heat-resistant grades of stainless steels are capable of operating at temperatures up to 1100 C. They are used, for example, to create cooling circuits for nuclear reactors.

Decorative Applications

And in this area, the spectacular appearance of stainless steel pipes and its wear resistance are in demand. Of course, only pipes with a treated surface are used here; Often the use of profile pipes is also used.

In particular:

- polished oval pipe is often used for railings and decorative fences;

- square polished pipes 10 10, 20 20 and 40 40 can be found as frames for chairs, bookcases and other furniture;

- larger pipes - 50 50 and 60 60 - are popular as beautiful, extremely reliable handrails that do not lose their shine over time in supermarkets and sports facilities.

Furniture made from profile pipes turns out to be very impressive

Often made from stainless steel:

- Shelving and other commercial equipment;

- Furniture stands and legs;

- Frames for canopies and cornices;

It turns out beautifully, doesn't it?

- Mufflers for cars and motorcycles and much, much more.

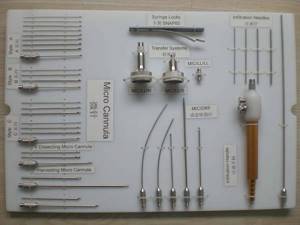

Medicine

The absolute chemical stability of stainless steel makes it an ideal material for a variety of implants, prostheses implanted into the body and other medical equipment.

The most popular and well-known products made from stainless steel pipes are ordinary medical syringes. Or rather, needles for them.

From a production point of view, any needle in the hands of a surgeon is a thin seamless stainless steel tube

Stainless steel pipe range

Rolled pipes made from high-alloy steels have unique performance characteristics: stainless steel pipes made of 12Х18Н10Т steel (one of the most common grades of stainless steel) can be used at temperatures from −196 to +600°С. In highly aggressive environments, the operating temperature for stainless pipes reaches + 350°C; in nitric, phosphoric, acetic acid, in solutions of salts and alkalis, the average annual corrosion rate is only 5-20 microns per year (µm/year). Such properties, combined with wear resistance (the tensile strength of steel 12Х18Н10Т is 510 MPa), make stainless pipes indispensable in the construction of industrial facilities, in aviation, mechanical and instrument making, petrochemical and chemical industries, pharmaceutical and food production.

Alloyed pipe products are distinguished by production method:

- cold and heat deformed stainless steel pipes GOCT 9940-81;

- hot-rolled stainless steel pipes GOCT 9941-81;

- electric welded pipes made of corrosion-resistant steel grades GOCT 11068-81.

Depending on the class, the scope of application of stainless steel pipes has distinctions: cold and heat-deformed pipes are distinguished by high manufacturing precision and a mirror (shiny) surface, due to which they are used for the production of furniture and interior decoration; hot-rolled steel is used for installation of process pipelines, equipment production, and construction; electric welded pipes are not intended for operation under conditions of high pressure (design working pressure up to 16 MPa), as a result of which they are not used for critical pipelines.

Where can I buy

It is safer and cheaper to buy goods from manufacturers directly. Among the most well-known and proven companies are:

- TMK is a Pipe Metallurgical Company, the leader in the country in terms of production volume.

- OMK is the United Metallurgical Company, specializing in the production of large-section pipes.

- ChTPZ is an association of metallurgical plants. Produces all types of seamless pipe products, including stainless steel.

- Sinarsky Pipe Plant, which supplies pipe products from the most popular brands.

These enterprises sell their products both directly and through their dealers. Purchasing a product here guarantees that you will receive a quality product in accordance with the stated characteristics.

Brief overview of the most popular types

Almost 70 percent of stainless products are seamless pipe products made from 10Х17Н13М2Т alloy. Its constituent nickel, titanium, chromium, and molybdenum provide the rolled product with anti-corrosion properties, ductility and strength. Products from this brand are in demand in medical institutions, chemical and food industries.

Pipes made of alloy 12Х18Н10Т are distinguished by their resistance to rust and durability. They are used for transporting drinking and process water, both outside and indoors.

For work in aggressive environments, products 06ХН28МДТ are used. They are in demand at metallurgical plants and petrochemical plants.

In combustion chambers, furnace equipment units, and high-temperature pipelines, the best solution would be to use grades 20Х23Н18 and 10Х23Н18.

Hot Rolled Stainless Pipe Dimensions

Hot-rolled alloy pipes in accordance with GOCT 9940-81 are produced in the following size range:

- outer diameters of stainless steel pipes (hot rolled)

: from 76 to 325 mm, permissible maximum deviations ±1.5% for normal manufacturing accuracy and 1% for high accuracy. Pipes with a diameter of less than 76 mm (from 53 to 73 mm) are manufactured in individual cases in agreement with consumers. - wall thickness

: from 3.5 to 28 mm, maximum deviations, depending on the manufacturing accuracy and the wall thickness itself, range from minus 15% to plus 20%. - measured length

: from 3 to 8.5 meters, with a minimum multiple of 300 mm. The unmeasured length is regulated in the range from 1.5 to 10 m, the limited length means a deviation from the measured length plus or minus 500 mm (deviation is allowed at one end).

Hot-rolled stainless steel pipe, assortment according to GOCT 9940-81

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 3,5-8 | 8,5-10 | 11-12 | 13-14 | 15 | 16-20 | 22-26 | 26-30 | 30-32 | |||||||

| 76 | 7 | 6 | – | – | – | – | – | – | – | ||||||

| 83 | 7 | 6 | *** | – | – | – | – | – | – | ||||||

| 89 | 7 | 6 | 5 | 4 | *** | – | – | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 5-8 | 8,5-10 | 11-12 | 13 | 14 | 15-16 | 27-20 | 22 | 24-26 | |||||||

| 95 | 7 | 6 | 5 | 4 | 4 | 4 | – | – | – | ||||||

| 102,108 | 7 | 6 | 5 | 4 | 4 | 4 | 4 | – | – | ||||||

| 114 | 7 | 6 | 5 | 4 | 4 | 4 | 4 | 3 | – | ||||||

| 121 | 7 | 6 | 5,5 | 5,5 | 5 | 5 | 4 | 3 | 3 | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 5-8 | 8,5-10 | 11-13 | 14-17 | 18, 19 | 20 | 22-26 | – | – | |||||||

| 127 | 7 | 6 | 5,5 | 5 | 4,5 | 4 | 3 | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 4-8 | 8,5-10 | 11-13 | 14-17 | 18, 19 | 20 | 22-26 | – | – | |||||||

| 133, 140 | 7 | 6 | 5,5 | 5 | 4,5 | 4 | 3 | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 4-5,5 | 6-7 | 7,5-8,5 | 9-9,5 | 10-11 | 12-14 | 15, 16 | 17, 18 | 19 | 20-24 | 25, 26 | |||||

| 146, 152, 159 | 7 | 8,5 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 3 | ||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 7-8,5 | 9-9,5 | 10-11 | 12-14 | 15-16 | 17-18 | 19 | 22-24 | 25-26 | 28-32 | ||||||

| 168 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 3 | *** | |||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 8-8,5 | 9-9,5 | 10-11 | 12-14 | 15-16 | 17-18 | 19 | 20-24 | 25 | 26-28 | 30-32 | |||||

| 180 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | ||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 9 | 9,5 | 10-11 | 12-13 | 14 | 15-16 | 17-18 | 19 | 20-24 | 25 | 26-28 | 30-32 | ||||

| 194 | 8 | 7,5 | 7 | 6,5 | 6,5 | 6 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | |||

| 219 | – | – | 8 | 7,5 | 7 | 6,5 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | |||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 26 | 28 | |

| 245 | 8 | 8 | 7,5 | 7 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 5 | 4,5 | 4,5 | – | – |

| 273 | 8 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5,5 | 5 | 4,5 | – | – | – | – | – |

| 325 | – | 6,5 | 6 | 5,5 | 5 | 5 | – | – | – | – | – | – | – | – | – |

Note: the mark *** means that this size is produced only by agreement between the customer and the manufacturer.

Requirements for this range

Stainless steel pipes GOST 9941 81 are manufactured in compliance with the following requirements:

- The extreme parts of the finished product are cut at right angles, and they are carefully cleaned of burrs. This sometimes causes a slight roughness to appear on the surface and a chamfer is formed. The described standards allow the presence of such formations. Often, customers specifically discuss with the manufacturer the presence of a chamfer on a product that has a wall thicker than five mm, as this makes it possible to more effectively fasten the structure together by welding.

- On a meter-long piece, these pipes may have a slight curvature. This is two millimeters for a structure with a wall of 0.05 cm and a cross-section of 1.5 cm. It is also one millimeter for options with a wall of more than 0.05 cm and a cross-section of more than 0.5 cm.

- The steel grades taken for the work for these pipes may contain small inclusions of metals belonging to the rare earth group. But sulfur may contain no more than 0.02%.

- All finished products must undergo heat treatment. This is not carried out only by individual agreement with the consumer. In this case, the curvature and mechanical characteristics of the goods are discussed with each client separately.

- The presence of sunsets, both on the outside and on the inside of this assortment, is not allowed. There should also be no cracks or flaws. When removing these defects, the dimensions of these tubular products should not exceed the limits stated by the requirements.

How is finished goods accepted?

Stainless steel pipe GOST 9941 81 is accepted in batches. They are assembled according to the thermal finishing option, the original alloy and geometric shapes. One batch of stainless steel goods cannot contain more than 200 tubular products.

Quality control of stainless steel products includes the following procedures:

- Check for intergranular corrosion. For control, two pipe blanks are taken from the batch.

- Distributing and flattening. One tubular product is taken for testing.

- Stretching. Two blanks are taken for this test.

If all testing procedures were successful, then such a batch of stainless steel goods is considered to be of high quality. If the testing reveals unsatisfactory quality, then another check is carried out - this is an ultrasonic examination, hydrotesting and analysis of geometric dimensions. And the final size check is carried out on the entire batch of stainless steel products without sampling.

Products 19277

GOST 19277 73 defines seamless stainless steel pipes. In this case, there is no welding seam, therefore, the strength of the finished product is many times higher. GOST 19277 73 applies to the following options: cold-deformed, heat-deformed and hot-deformed.

Pipe metal products GOST 19277 73 show all the best indicators of types of steel products.

Pipe products GOST 19277 73 are produced:

- thin-walled options;

- thick-walled assortment;

- capillary pipe rolling.

The features in this case are as follows: with a similar external volume, this assortment has a greater wall thickness than options produced by the electric welding method.

Accordingly, these products are characterized by a higher strength index and the ability to withstand heavy loads. On larger walls of steel grade GOST 19277 73, you can make a threaded joint and use special reinforcement.

In terms of length, these options are produced in unmeasured form. Their size range ranges from 1.5 to 10 meters. Small volumes include options from 8.9 to 10.8 cm, they are made in segments of seven meters. Large-diameter species reach nine meters in length.

Stainless steel pipes GOST 19277 73 are used in conventional and nuclear energy, in aircraft and automotive industries. They can be found in the oil refining and gas industries. In addition, they are indispensable in various sectors of the national economy.

Dimensions

The dimensions and dimensions of stainless steel pipe assortments can be viewed in special tables that provide all the indicators in detail. Here are some of them:

- Stainless steel pipe GOST 9941 81 has the following dimensions: external volume from 5 to 273 mm. Seamless blanks according to the same standards have a wall thickness of 0.2 to 22 mm.

- This rolled pipe according to GOST dimensions is characterized by a weight that depends on the actual volume and dimensions of the walls, as well as the presence of a coating. For example, similar dimensions of the galvanized version will differ in heavier weight.

All products, which are distinguished by their compliance with standards, have precise dimensions and excellent characteristics. But, when choosing, you need to be able to navigate the wide range of offers from manufacturers. And consultants can help with this, ready to come to the client’s aid at any moment.

Watch the video

Areas of use

Stainless steel pipe GOST 9941 81 has unique characteristics that determine the use of these products. They can be seen:

- In the food industry.

- In the heating and water supply lines.

- In the energy industry.

- In chemical production.

- In medicine.

- When decorating the interior.

- Car structure.

- Sudo - mechanical engineering.

To what has been said, we can add that such communications last forever and look presentable. You can choose any fitting connections for such a water supply system, but most often welding is used for connection.

In the food industry, seamless types of pipe rolling are often used. In addition, the assortment must be polished not only on the outside, but also on the inside. All for the reason that a smooth surface is a bad option for the growth of bacteria and fungi.

Chemical production. In this case, the determining factor is the strength of the pipe assortment and its ability to withstand aggressive chemical substances.

The resistance of stainless steel structures to high temperatures is successfully used in the energy industry; here they can withstand loads exceeding a thousand degrees.

No less often you can find this rolled metal in decorative design. And here, presentable appearance and wear resistance come first. It is clear that only a range with a treated surface part is suitable for such purposes.

When talking about the use of this pipe range, we cannot ignore medicine. The chemical stability of this rolled metal has found its application here.

It is an excellent material for implants inserted into prostheses. By the way, it will be said that the most popular type of such tubular product is an ordinary medical syringe (i.e. its needle).

Stainless steel pipe GOST 8639 is actively installed in a wide variety of pipelines. This is facilitated by the excellent resistance of these products to corrosion processes and ease of use. This unique type of assortment has gained its popularity well deservedly.

Dimensions of Cold Rolled Stainless Steel Pipe

Stainless steel pipe GOCT 9941 81 cold-rolled is produced according to the assortment and has some differences from the size range of hot-deformed pipes:

- cold-rolled stainless steel pipe, outer diameters: from 5 to 273 mm, permissible deviations depending on the diameter and manufacturing accuracy from ±0.15 mm to ±1.2%.

- wall thickness: from 0.2 to 22 mm, permissible maximum deviations: from ±0.03 mm to ±12.5%, depending on the class of manufacturing accuracy and the wall thickness itself.

- measured length: from 4 to 7 meters, with a minimum multiple of 300 mm. Non-standard length is established by the standard from 0.75 to 12.5 m. Pipes of larger non-standard length (16 m) are produced by agreement with the consumer.

Assortment, cross-sectional dimensions and cost of profiled pipes

All profile stainless steel pipes, in addition to excellent technical characteristics, have precise dimensions of profile edges and wall thickness, determined by the corresponding assortment.

3.1. Standard dimensions of square pipes according to GOST 8639 -82

| Geometric parameters of the section (AxAxS), mm | |||

| 10x10x0.8 | 35x35x1.4 | 50x50x5 | 100x100x3 |

| 10x10x0.9 | 35x35x1.5 | 50x50x6 | 100x100x4 |

| 10x10x1 | 35x35x2 | 50x50x7 | 100x100x5 |

| 10x10x1.2 | 35x35x2.5 | 50x50x8 | 100x100x6 |

| 10x10x1.4 | 35x35x3 | 60x60x2 | 100x100x7 |

| 15x15x0.8 | 35x35x3.5 | 60x60x2.5 | 100x100x8 |

| 15x15x0.9 | 35x35x4 | 60x60x3 | 100x100x9 |

| 15x15x1 | 35x35x5 | 60x60x3.5 | 110x110x6 |

| 15x15x1.2 | 40x40x1.4 | 60x60x4 | 110x110x7 |

| 15x15x1.4 | 40x40x1.5 | 60x60x5 | 110x110x8 |

| 15x15x1.5 | 40x40x2 | 60x60x6 | 110x110x9 |

| 20x20x0.8 | 40x40x2.5 | 60x60x7 | 120x120x6 |

| 20x20x0.9 | 40x40x3 | 60x60x8 | 120x120x7 |

| 20x20x1 | 40x40x3.5 | 70x70x3 | 120x120x8 |

| 20x20x1.2 | 40x40x4 | 70x70x3.5 | 120x120x9 |

| 20x20x1.4 | 40x40x5 | 70x70x4 | 140x140x6 |

| 20x20x1.5 | 40x40x6 | 70x70x5 | 140x140x7 |

| 20x20x2 | 42x42x3 | 70x70x6 | 140x140x8 |

| 25x25x0.8 | 42x42x3.5 | 70x70x7 | 140x140x9 |

| 25x25x0.9 | 42x42x4 | 70x70x8 | 150x150x7 |

| 25x25x1 | 42x42x5 | 80x80x3 | 150x150x8 |

| 25x25x1.4 | 42x42x6 | 80x80x3.5 | 150x150x9 |

| 25x25x1.5 | 45x45x2 | 80x80x4 | 150x150x10 |

| 25x25x2 | 45x45x3 | 80x80x5 | 180x180x8 |

| 25x25x2.5 | 45x45x3.5 | 80x80x6 | 180x180x9 |

| 25x25x3 | 45x45x4 | 80x80x7 | 180x180x10 |

| 30x30x0.8 | 45x45x5 | 80x80x8 | 180x180x12 |

| 30x30x0.9 | 45x45x6 | 80x80x9 | 180x180x14 |

| 30x30x1 | 45x45x7 | 80x80x10 | 150x150x8 |

| 30x30x1.2 | 45x45x8 | 80x80x11 | 150x150x9 |

| 30x30x1.3 | 50x50x2 | 90x90x3 | 150x150x10 |

| 30x30x1.4 | 50x50x2.5 | 90x90x4 | 180x180x8 |

| 30x30x1.5 | 50x50x3 | 90x90x5 | 180x180x9 |

| 30x30x2 | 50x50x3.5 | 90x90x6 | 180x180x10 |

| 35x35x0.8 | 50x50x4 | 90x90x7 | 180x180x12 |

| 35x35x0.9 | 50x50x4.5 | 90x90x8 | 180x180x14 |

The standard also provides for the production of stainless steel pipes with a square section of special sizes: 32x32x4, 36x36x4, 40x40x2, 55x55x3 and 65x65x6.

3.2. Standard sizes of rectangular stainless steel pipes according to GOST 8645-82

According to this range, rectangular pipes are manufactured with the following parameters

:

| Maximum wall thickness, mm | Dimensions of edges, mm |

| 2 | 15x10; 20x10; 35x30; 60x20 |

| 2,5 | 20x15; 25x10; 25x15 |

| 3 | 30x10; 30x15; 30x20 |

| 3,5 | 35x15; 35x20; 35x25 |

| 4 | 40x15; 40x20; 40x25; 40x30; (42)x20; (42)x30; 45x20; 45x30; 50x25; 50x30; 50x35; 50x40; 80x50; 100x60 |

| 5 | 60x25; 60x30; 60x40 |

| 6 | 70x30; 70x40; 70x50 |

| 7 | 80x40; 80x60; 90x40; 90x60; 100x40; 100x50; 100x70; 110x40; 110x50; 110x60 |

| 8 | 120x40; 120x60; 120x80; 140x60; 140x80 |

| 9 | 140x120 |

| 10 | 150x80; 150x100 |

| 12 | 180x80; 180x100; 180x150 |

Standards allow the production of stainless steel rectangular pipes with special dimensions.

They can be manufactured with wall thicknesses from 0.8 to 20 mm and cross-sectional parameters ranging from 28x25 mm to 230x100 mm.

Stainless pipe weight

The weight of one linear meter of round pipe made of alloy steel grades is calculated by the formula:

- Mpm is the required weight of a linear meter in kg;

- Dn is the outer diameter of the pipe, mm;

- Tc—wall thickness, mm;

- ρ—specific gravity of the metal grade, g/cm³, reference value;

- π is a constant equal to 3.14.

| Metal grade | 08Х17Т | 04Х18Н10 | 08Х18Н10Т | 12Х18Н10Т | 10Х17Н13М2Т | 08Х18Н12Т |

| Specific gravity, g/cm³ | 7,70 | 7,90 | 7,90 | 7,90 | 8,00 | 7,95 |

For example, a stainless steel pipe 12Х18Н10Т ГОСТ 9941 81 with an outer diameter Dn=89 mm, Tc=3.5 mm, the weight of a linear meter will be equal to:

The calculated weight may differ slightly from the actual weight within the permissible deviations in length, outer diameters and wall thicknesses established by GOST 9941-81 and GOCT 9940-81.

You can also:

Atlant-Metal LLC © 1994–2011 All rights reserved.

Article rating:

Save to:

Stainless steel pipe diameters table Link to main publication

Classification and types

Based on the manufacturing method, seamless pipes are divided into two types: hot-rolled and cold-rolled.

Depending on the wall thickness, they are divided into thick- and thin-walled bends.

The first include products in which the ratio of outer diameter to wall thickness is 6-12.5. This coefficient determines the scope of application of rolled pipes.

The cross-sectional shape of pipes is round, square and rectangular.

In accordance with the type of processing, the surfaces of products can be:

Difference between hot and cold rolling

The difference lies in the temperature conditions of production. The hot method involves strong heating and further processing of the workpiece at high temperatures. This simplifies the process, but does not always make it possible to achieve precise geometric parameters.

Cold-rolled products differ from hot-deformed ones in having a smoother and cleaner surface and strength. Products with a smaller and more profile cross-section are produced only in the cold way.