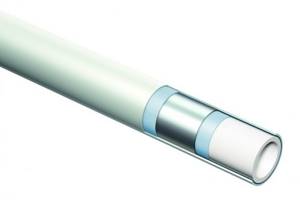

Metal-plastic pipes can be used in domestic and industrial construction of water supply systems, heating systems, heated floors, as well as for connecting gas supplies. They are durable, practical, easy to install and at the same time have an affordable price.

Metal-plastic pipes and fittings

The choice of manufacturers of these products is quite large and developers are often faced with the question: what is best to purchase for installation in a house or apartment.

Major manufacturers of metal-plastic pipelines

Regardless of what brand of metal-plastic pipes you purchase, this is a high-quality and reliable material that is resistant to various external influences. All manufacturers of these products strive to maximize the technical characteristics of their products, increase their service life and increase functionality.

Metal-plastic pipes are manufactured by the following companies:

- Valtec;

- Ape;

- Henco;

- Uponor;

- Rehau;

- Kermi;

- Viego;

- Hydrosta;

- Opentrop Copipe;

- Sanha.

Viega metal-plastic pipes

Which brand of pipeline to choose depends on the industry where the products are used, the expected cost, and individual preferences.

Products made in Italy by Valtec and Ape

Valtec piping is made from high quality polyethylene and pure aluminum foil. The strong connection of layers of Valtec brand products guarantees the complete absence of delamination even with repeated temperature changes.

- Valtec pipes are used in the following industries:

- Cold and hot water supply;

- Heating;

- Transportation of carbon fuels;

- Cooling;

- Transportation of food and non-food products in production;

- Heated floor systems.

Metal-plastic pipes VALTEC

A small coefficient of linear expansion allows the use of Valtec lines for laying under a concrete screed, and in addition to this, the positive characteristics include:

- Resistance to corrosion, chemical and temperature influences;

- Long service life of Valtec products, which is more than 50 years;

- Full compliance with domestic and international quality standards, as best evidenced by the certificate of the Research Institute of Plumbing;

- The operating temperature of the Valtec pipeline is 95 degrees.

Valtec is the optimal material for developers who value, above all, the quality of the product, regardless of how much it costs.

Italian Ape pipes can be used in apartments, houses, cottages and various industrial premises. Ape products can be used for the following systems:

- Drinking, cold and hot water supply;

- Heating;

- Conditioning.

Metal-plastic pipe Ape

The Ape pipeline has high ductility and can be installed with a minimum number of components. Ape systems are supplied complete with brass fittings. Ape pipes do not rust, are not susceptible to corrosion and silting. Ape is high quality, affordable price and manufacturer's warranty.

Specifications

During installation work, metal-plastic pipelines with diameters of 16 and 20 mm are popular. The species have wall thicknesses of 2.0 and 2.25 mm, respectively. The thickness of the aluminum alloy layer is 0.2 and 0.24 mm. The mass of 1 linear meter is 115 and 170 g. 1 m of pipeline holds up to 0.113 and 0.201 liters of liquid.

What pressure the pipeline can withstand depends on the diameter of the model, the dimensions of the walls, the aluminum alloy layer, and the temperature characteristics of the compounds transported through the pipe. When the liquid temperature in the pipelines is about +95°C, the functional pressure characteristics are maintained at 10 bar. When water with a temperature of +25°C passes through pipes, the pressure characteristics should reach 25 bar.

The pipelines can withstand short-term temperature increases up to +110°C. However, long-term maintenance of high pressure (95 bar) and water temperature of about +20°C will destroy the integrity of the structure over time.

The service life of products depends on the thickness of the raw materials and manufacturing methods, the maximum value reaches 50 years. Pipelines are produced in packages with lengths from 50 to 200 m.

The world famous Henco pipeline

Henco metal-plastic pipes combine all the advantages of metal and plastic pipes better than others. Due to this, they are used in a wide variety of engineering networks, namely:

- Cold and hot water supply;

- Heating;

- Conditioning;

- Heating of staircases, swimming pools, stadiums;

- Technological water treatment systems.

Henco metal-plastic pipe

Henco metal-plastic pipes are electrically safe, silent and easy to install products. The pipeline costs little money compared to how long it will last without the need for regular repairs and without loss of quality.

Distinctive German pipe quality

Uponor brand pipelines are used in more than 60 countries around the world, thanks to high-quality raw materials and high-tech production. Uponor proves every year that it is significantly better than its competitors and outperforms them in all respects. The main advantages of Uponor products are:

- High quality;

- Safety;

- Easy installation;

- Ease of maintenance;

- High product flexibility.

Uponor metal-plastic pipe

Uponor pipeline diameter ranges from 16 to 110 mm, which allows you to select the necessary material for any communication system. Uponor systems are supplied as a kit with all necessary fittings. This allows installation of the Uponor brand highway to be carried out not only by professionals, but also by anyone interested.

The famous German brand Rehau produces several systems for connecting heating and water supply. Rehau systems are comprehensive solutions that include not only the pipeline, but also fittings, plumbing fixtures and components. The Rehau Rautitan Stabil and Rehau Rautitan Basic systems, which consist of 5 layers, are widely used.

The Rehau pipeline consists of the elements shown in the figure:

Rehau pipeline

Rehau differs from its competitors in the highest degree of cross-linking of polyethylene and the unique property of shape memory. No less important advantages of the Rehau metal-plastic system are:

- Insensitive to scratches;

- Ability to bend without special tools;

- Resistance to high loads;

- Compliance with international quality standards.

The Rehau metal-plastic pipeline has a service life of up to 50 years and improved characteristics in comparison with products made from other materials.

Aluminum thickness

This metal is present in the structure to protect its components from various damages, including fractures during installation, changes in fluid pressure and mechanical loads. It is important to prevent linear expansion and create a barrier to oxygen penetration. The thickness of aluminum in modern pipes can vary. Usually it is 0.15−0.6. It is undesirable to give preference to materials where aluminum has a layer less than 0.3 mm, since it is brittle.

It is better to purchase materials with values from 0.3 to 0.55 mm. If they have acceptable strength indicators, installation will not be a hassle. These pipes will remain flexible for a long time. When aluminum has a thickness of more than 0.55 mm, a lot of effort will have to be made during the installation process. Pipes are considered expensive, but experts recommend them as the most durable. After welding, the aluminum foil turns into a solid tube. To carry out such processing, you can resort to several methods:

- Laser welding. After it, the elements are joined end-to-end, and no seams are formed. Finished pipes have excellent performance properties and smooth walls. Aluminum can be of any thickness.

- Ultrasonic welding. The ends of the foil are overlapped here. To prevent excessive thickening in the areas where materials meet each other, the thickness of the aluminum in these areas should be reduced. Ensuring perfect evenness is problematic. Pipes prepared in this way are considered economical, but they are less durable compared to seamless ones. Their installation is more complicated, and their wear resistance indicators are not so impressive.

If there is a need to arrange systems that require great responsibility, you should opt for seamless models.

Other manufacturers from Germany

Kermi metal-plastic pipes are also produced in Germany based on innovative developments. The EVON waterproofing layer protects metal-plastic pipes from the destructive effects of oxygen.

The next German-made pipeline is the Viega metal-plastic pipe. Ease of installation and the possibility of subsequent control are ensured by the presence of a special inspection hole on the press sleeve. It is through this that the correctness of the line connection is assessed before crimping.

Metal-plastic pipe Oventrop Copipe

Oventrop Copipe is one of the best pipelines for water supply and heating systems not only in our country, but throughout the world. Oventrop Copipe pipes are available in diameters from 16 to 63 mm and are connected using press fittings. Oventrop Copipe systems are supplied as ready-made kits, which consist of fittings and the pipeline itself.

Oventrop Copipe is excellent quality at an affordable price. The three-layer construction of the Oventrop Copipe pipe is resistant to oxygen diffusion and has a maximum operating temperature of 95 °C.

The Oventrop Copipe system piping is supplied in coils. The kit is completed with press fittings for connecting the elements.

Sanha products are in high demand among consumers. All Sanha products have German quality certificates and are suitable for use in the following utility networks:

- Water supply;

- Heating;

- Cooling;

- Transportation of raw materials in industry.

For the production of Sanha pipes, the latest modified polymers and optimally selected wall thickness of the aluminum layer are used. The design of the Sanha pipeline is shown in the figure:

Sanha pipeline design

Sanha products have many positive reviews among European consumers. The Sanha pipeline provides the following benefits:

- High quality;

- Affordable price;

- Operating temperature up to 95 degrees;

- Maximum pressure 12 bar;

- Long term of use.

Installation of metal-plastic fittings

The word fitting literally means “to mount”, “to install”. Fittings are elements that are installed at the ends of pipeline sections. The most common fittings are coupling connectors, transitions to threaded connections, tees, elbows, expansion joints.

This manipulation is carried out using special pliers or a hydraulic press tool. This connection is durable, but completely eliminates disassembly in the future. If it is necessary to replace, for example, an elbow with a tee, it will be necessary to cut off an expensive disposable fitting and press a new one.

Pipe and fitting connection diagram

At the same time, in parallel with press fittings, a collapsible compression fitting is also used. This connection consists of several components: a bushing, a union nut, rubber O-rings and a retaining collet. A union nut and locking ring are placed on the end of the pipe, subsequent tightening securely fixes the pipe and fitting, and sealing is achieved. The advantages of this type of connection are:

- no special knowledge or skills are needed for independent installation;

- no expensive tools are required (only an adjustable wrench, plastic pipe scissors and a calibrator);

- the connection can be quickly disassembled at any time, achieving the “American” effect.

Flaws:

- Over time, especially with irregular heating use and poor installation, the fitting may become loose.

- Rubber O-rings will require replacement over time, this depends on the individual characteristics and operating conditions of the pipeline, however, once every 10 years it may be necessary to replace gaskets or tighten nuts.

Previously, adhesive fittings were also used, but due to the inconvenience of installation and low reliability, this type of connection quickly disappeared from the shelves of plumbing stores.

Metal-plastic products have proven themselves well in use for heating, water supply and irrigation. This is an inexpensive, but at the same time reliable solution that will allow you to do all the work yourself.

Active competition with PPR systems has shaken the position of metal-plastic, but there are still installation organizations and plumbers who prefer this type of pipeline installation.

Asian products from Hydrosta

Products under the Hydrosta brand are manufactured in South Korea. Hydrosta pipeline is a new generation material for installing heating and water supply systems in residential and industrial premises. Hydrosta products have a diameter from 16 to 50 mm, so it is possible to select the required cross-section for any engineering system.

Hydrosta pipeline design

The main advantages of Hydrosta products are:

- Possibility of installation inside or outside the building, depending on need;

- High strength;

- Lack of oxygen diffusion.

Developers are always interested in how many additional connecting elements will be needed during installation, because the cost of the work directly depends on this. When using Hydrosta piping, a minimum number of fittings will be required. After all, the material is flexible and bendable.

Areas of use

Metal-plastic pipelines are used in the construction industry, industrial and agricultural sectors, transport systems, etc.

Read more: TOP 10 best microwave ovens of 2021

Products are needed for:

- heating and plumbing systems;

- organization of transportation of liquids and gaseous compounds;

- when transporting compressed air mass;

- arrangement of air conditioning and ventilation devices;

- installation of sewerage system structures;

- installation of a protective element for power cables;

- repair of internal pipelines of residential and industrial buildings;

- installation of high voltage electrical networks.

The products can be used when replacing old water supply systems in buildings without displacing residents. Work is carried out in different weather conditions (winter, autumn, etc.).

It is necessary to take into account some restrictions on the use of the type of pipe. The products are not recommended for central heating systems with elevator units. Metal-plastic products are not suitable for premises belonging to category “G” to maintain a sufficient level of fire safety.

https://www.youtube.com/watch?v=PUUiF3ZnWR0

Do not install products near heating devices reaching temperatures of 150°C. This type is not recommended for small diameter pipelines with high pressure (from 10 bar).