Functions

A water heated floor differs from a traditional heating system in that the length of the circuits is significant - up to 120 meters at maximum, and the diameter of the pipes is usually small - 16-20 mm. Each circuit has many turns. Therefore, it becomes clear that for normal heating operation, forced circulation will be required. And it is the pump for the water floor that ensures the speed of movement of the coolant through the pipes sufficient for normal temperatures. Moreover, to maintain a stable temperature, it will be better if the pump has several speeds. Such devices are called adjustable and their operation can be controlled manually or using automation.

Choosing a pump for a heated floor is a rather complex and responsible task.

Calculation of pump parameters

Circulation pumps are installed in heating systems. They do not create excess pressure, but simply push the coolant at a certain speed. Since the need for heat changes depending on weather conditions, the speed of movement of the coolant must also change. Therefore, it is better to install adjustable pumps - three-speed.

Before purchasing, you should decide on two main parameters: performance (flow) and pressure. If the coolant is water, the pump performance is calculated using the following formula:

Q = 0.86*Pn/(trev.t - trev.t)

- Pн — heating circuit power, kW;

- trev.t - temperature of the coolant in the return

- tpr.t — supply temperature.

If there are several circuits, determine the flow rate for each of them and add them up. The sum of the flow rates of all circuits will be the required performance of the unit.

The temperature difference in water heating systems is usually 5 ° C, the power of the circuit most often depends on the heated area, therefore, to simplify the selection of a pump for a water heated floor, you can use the table. But it must be taken into account that the calculations took average figures for central Russia. Therefore, if your house is not well insulated, or you live significantly north or south of the middle zone, you will have to adjust the result (or calculate it yourself). In general, this parameter is taken with a margin of 15-20% in case of abnormal cold weather.

Table for determining pump performance depending on the heated area

The second characteristic by which a pump is selected is the pressure it can create. Pressure is necessary to overcome the hydraulic resistance of pipes, fittings, and other system components. The system resistance depends on the pipe material and its diameter. The value of the hydraulic resistance of the pipe is available in the accompanying documents (averaged data can be used). Also taken into account is the increase in resistance on the valve (1.7), on the fittings and fittings (1.2) and on the mixing unit (required when using a high-temperature boiler and the coefficient for it is 1.3).

H= (П*L + ΣК) /(1000),

- H—pump pressure;

- P is the hydraulic resistance of a linear meter of pipe,

- Pa/m; L is the length of the pipes of the longest circuit, m;

- K is the power reserve factor.

To calculate the required pressure in the circuit, the nameplate hydraulic resistance of a meter of pipe is multiplied by the length of the circuit. The value is obtained in kPa (kilopascals). Convert this value to atmospheres (pump pressure is measured in atmospheres) 100 kPa = 0.1 atm. The found value, depending on the presence of fittings and valves, is multiplied by the corresponding coefficients. After all the operations, you have found the operating point of the pump.

Select a model based on graphic characteristics

But the calculation of the pump for the heated floor is not finished yet. Now you need to select a model. To do this, find the characteristics of the pump in the catalog of the manufacturer you like. It is presented in the form of a graph. Select the model so that the found operating point is in the middle third of the characteristic. If you are installing a three-speed option, then select a model with the second speed - this will ensure an optimal, and not at the limit, operating mode and your pump will last a long time and provide a normal temperature even on cold days.

What data will be needed for calculation

Before you start making your own calculations, you need to determine for what purposes the heating system is intended - for the entire heating of the room or for individual rooms. Then you need to calculate preliminary data to calculate a warm water floor.

Let's consider the most important indicators that affect the efficiency of all heating equipment as a whole, and make a preliminary calculation of them.

Power

To save the family budget on the functioning of the comfortable lower part of the room, it is necessary to correctly calculate the heat loss power of the heating system

To do this, you should pay attention to the following:

- area of the selected room;

- height of doorways;

- location of windows;

- what are the walls made of?

- temperature selection.

You also need to consider whether there is an attic or balcony.

In order to make this calculation, you also need to pay attention to the design of the building where the warm water floor will be calculated. If this is a multi-story building, then in further calculations for power use an average value of 100 watts per square meter

If the system is installed in a private, one-story house, the power is determined depending on the area of the room, thus:

- 120 W/sq. m. - 150 sq. m. area.

- 100 W/sq. m. - from 150 to 300 sq. m. area.

- 90 W/sq. m. - from 300 to 500 sq. m. area.

The calculation of a heated floor is also affected by the length of the contours.

Circuit

The efficiency of heating a room is affected by the volume of the heating system circuit, which is made in the form of a snake or snail. For better coolant circulation, the calculations include a circuit length of no more than 80 meters. If this is not a sufficient value for the area of the room, you can install two or more circuits, and also in this quantity enter them into the program for calculating heated floors.

It is worth noting here that the size of the contours depends on the characteristics of the pipes.

Pipes

There is a large selection of pipes that have different diameters and compositions. But for underfloor heating circuits, experts recommend choosing the following models:

- Metal-plastic with a diameter of 1.6 centimeters. A circuit of such pipes can reach up to 100 meters.

- Plastic with a diameter of 2 centimeters. From such pipes it is possible to construct a circuit of 120 - 125 meters.

- Polyethylene with a diameter of 1.8 centimeters. Of these pipes, the maximum circuit size reaches 120 meters.

Step

When laying out the contours, the average pitch between the pipes depends on the climatic conditions of the region. Thus, if in winter the average temperature is from – 19 to 22 degrees, the step is 15 centimeters. If the temperature is below these indicators, the optimal step is 10 centimeters.

Thus, given the ratio of the pitch and the square meter of the room, it is possible to calculate the length of the pipes for designing the contours.

These data apply to water heated floors only when thermal insulation is installed.

Thermal insulation

The program for calculating underfloor heating depends entirely on heat loss. If you carry out thermal insulation work correctly, you can not only save your budget by 20% in the future, but also achieve the desired results of the floor temperature regime. Thus, the floor in multi-story buildings is insulated with 5 centimeters of polystyrene foam; in single-story buildings, the thickness of the insulation should be at least 10 centimeters.

Heat loss in a residential building (apartment)

Floor temperature

To calculate water heated floors, the following temperature conditions of the floor surface in the room are used:

In a water heating structure, heat is not distributed evenly over the floor surface, since the temperature between the pipes is lower than above them. Therefore, with further calculations, it is possible to determine what temperature the coolant will be if we take 27 degrees from the graph as the maximum value.

Having considered all the data that is needed for the program for calculating a heated floor, you need to find out how it calculates.

Heat loss in a private house

Related Posts

- Optimal temperature for heated floors

- Do-it-yourself connection of a well pump

- We make a water heated floor from a gas boiler

- How to pull a pipe out of a well and how best to get a casing link: we study in general terms

- Mixing unit for heating

- Electric heated floor in a private country house: installation features in a wooden and frame house

- How to choose and install a three-way control valve for underfloor heating

- Aermec nrb

- Installation of an electric heated floor: types, diagrams, do-it-yourself installation

- How to disassemble a submersible pump: popular breakdowns + detailed disassembly instructions

- Hand pump for water from a well

- Installation of a warm water floor

- Calculation of underfloor heating power

- Which pipes for heated floors to choose: characteristics and installation methods

- How to repair a drain pump yourself

- Hydraulic accumulator selection and principle of operation

- Connection diagrams for water heated floors

- Operating principle of vibration pumps

- Hydroarrow: principle of operation, purpose and calculations

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- Do-it-yourself installation of a submersible pump in a well

- Air-to-air heat pump and its prices

- Choosing a manifold for heated floors: types, equipment

- How to choose a circulation pump for heating wilo: instructions, reviews, characteristics

- How to make a heated floor from a stove in a bathhouse

Read with this

- Optimal temperature for heated floors

- Do-it-yourself connection of a well pump

- We make a water heated floor from a gas boiler

- How to pull a pipe out of a well and how best to get a casing link: we study in general terms

- Mixing unit for heating

- Electric heated floor in a private country house: installation features in a wooden and frame house

- How to choose and install a three-way control valve for underfloor heating

- Aermec nrb

- Installation of an electric heated floor: types, diagrams, do-it-yourself installation

- How to disassemble a submersible pump: popular breakdowns + detailed disassembly instructions

Marking and case material

These are two or three numbers like: 25/40, 25/60-130 or 32/80, etc. The first number is the diameters of the inlet/outlet holes in millimeters. That is, in the given markings the connecting dimensions are 25 mm and 32 mm. The second number is the lifting height that this model provides. In the example given, these are 4 meters, 6 meters and 8 meters. If we translate atmospheres, then this is 0.4 atm, 0.6 atm, 0.8 atm. The third number is the installation length, that is, the size of the entire device from one end to the other. In our example it is 130 mm.

Kinds

All circulation pumps that are produced for heated floors are similar to each other. Of course, every manufacturer wants to create a unique product, but no one has yet managed to make a breakthrough in this area. A general classification applies to all models, after studying which it will be easier to select a circulation pump.

With wet rotor

This type of device is mini motors. Their dimensions are reduced due to the close location of the impeller to the rotor. In some models, these two elements are located in the same housing. To prevent water from entering the engine, manufacturers place a reliable oil seal on the drive shaft. It is made from especially durable rubber, which is highly resistant to external factors.

Some models have double water protection . Due to the fact that the motor is small, it can be installed in a heated room. It operates silently, has low power consumption, and is lightweight.

With dry

Devices with a dry rotor have a separate housing for working elements. They have great power, so they are chosen for large rooms.

To install such pumps, a separate technological room is required (most often a boiler room). Installation is carried out on a separate frame.

The weight of these devices is impressive, the operation is accompanied by noise, it is advisable to use them for large areas, therefore they are chosen extremely rarely for private buildings. Glanded rotor pumps are supplied with an additional protection kit for electrical components.

Industrial

For such objects, pumps of the same name are produced. They are secured by connecting flanges with a diameter of more than 50 mm. Such pumps have a dual design , which is convenient in severe frosts and increased load on the system. At the right moment, the second pump is activated, as a result, performance increases, the coolant circulates more actively through the system. If one motor breaks down, you can turn on the second one.

Models are divided by the number of speeds. Single-speed varieties are designed to work with one temperature regime. Multi-speed ones are designed to work in any different-temperature heating system (for heating various objects).

For uniform heat transfer, it is necessary to ensure a stable speed of movement of the coolant.

In what cases is it necessary to install a pump?

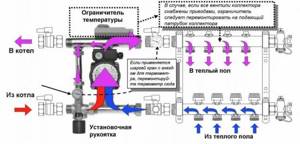

Almost all double-circuit boilers are equipped with circulation pumps that provide a stable supply of coolant at temperatures up to 60 °C. Therefore, with a small floor surface area requiring heating (up to 40-50 m2), an additional pump or group is not needed. For other cases, its installation is required due to the following circumstances:

- Heated floor pipelines often have a much smaller cross-section than the heating system pipes, resulting in heat loss. As a result, the boiler will overheat, and for solid fuel mini-models, more fuel will be consumed.

- A number of heating boilers do not provide for low-temperature operation at all. This is acceptable for wall heaters, but not for heated floors: many coating groups, for example, oak parquet, laminate, etc., do not tolerate high temperatures and are deformed. Therefore, when calculating a heated floor circuit, an additional mixing unit appears, equipped with a thermostatic sensor to regulate the temperature.

- If the walls of a house are built from the same material and, therefore, have the same heat capacity, then the floors can be made of materials with sharply different thermophysical characteristics. For example, in the bathroom the floor can be laid with ceramic tiles, and in the rooms it can be self-leveling. As a result, the required temperature for each heating circuit will be different. When making calculations, you should also take into account how many areas of the house, for example, stairwells of multi-story buildings, cannot be heated by heated floors at all.

The best pumps for heated floors

There are several good pumps for heated floors - decide for yourself which one to choose. An article on the Brigadir-info.ru website and guidelines on the website of the Russian Ministry of Construction will help us understand this issue.

Grundfos

A brand from Denmark that has been producing pumping equipment for more than 70 years. Its circulation devices have good consumer reviews. They are also valued around the world for their optimal price-quality ratio. Currently, models are manufactured not only in Denmark, but also in Serbia, Germany, and China. They are silent, economical, and available in a wide range. Some have a display with a digital indicator that shows energy consumption and power.

Other advantages of the Grundfos pump for underfloor heating:

- overheat protection;

- summer mode – protects against jamming in case of prolonged inactivity;

- three speeds;

- proportional and constant pressure modes;

- AUTO ADAPT function - provides automatic operation, determining what the heating system needs at a given time.

You can control all indicators using a special smartphone application.

Wilo

Wilo brand underfloor heating pumps are valued for their high energy efficiency and durability. The brand has existed for about a century, supplying high-quality pumping equipment for heating systems.

Advantages:

- protection of the housing from corrosion and thermal insulation;

- engine overheat protection;

- wide range of models – there are “wet” and “dry” type devices;

- minimum power consumption – about 3 W;

- ease of maintenance;

- low noise level.

Device design features

By its design, the pump looks like a snail. The small sealed housing has two pipes - inlet and outlet. An electric motor is installed in a sealed housing that rotates a rotor with an impeller. The electric pump operates from a 220V home electrical network.

Structurally, all units used when working with hydraulic systems are divided into two types:

- type of dry rotor equipment;

- wet type equipment.

Before proceeding with the installation of heated floors and the selection of appropriate equipment, you should understand the nuances of both types of pumping equipment.

The first type “with a dry rotor” is a device whose main work is performed by a dry rotor without direct contact with the aqueous environment. In this type, the rotor is in a sealed position and is protected from liquid penetration by an o-ring (oil seal). The main feature of pumps of this type is high efficiency. Some models have efficiency up to 85%. However, dry models are characterized by great noise during operation.

Note: equipment with a dry rotor is significantly larger compared to wet-type models. Such devices are often used to ensure the operation of heating systems in apartment buildings or in production.

For wet type equipment, a distinctive feature is the location of the rotor. The rotating part of the pump is in direct contact with the aqueous medium. Only the stator of the electric motor is insulated.

Here it must be said that upon contact with liquid, natural lubrication of all parts of the rotating group occurs. Due to this, the noise of the running engine is minimized and the service life of the devices is significantly increased.

The efficiency of wet pumps is inferior to their analogues with a dry rotor. Some models have an efficiency of up to 65-70%, and the majority of mechanisms for heated floors have an efficiency even lower. But in this case, the devices also have their advantages. Small size, low noise threshold. Such a pump is convenient for heated floors and is ideal for domestic use, especially since wet units do not require maintenance.

How to choose?

In order not to make a mistake with your choice, you need to study the advice of professionals that we have selected for you:

- The purchase of a pump must be made simultaneously with all structural elements of the future system. This will ensure maximum efficiency of the system and ensure its longevity. Repair work will be expensive, so it’s better to protect yourself right away.

- The choice of pump should be based on the performance of the unit. This parameter can show productivity in liters or cubic meters. It all depends on the amount of coolant that will be in the system. We multiply this value by 3 and obtain the required pump performance.

- The pressure must be selected in accordance with the parameters of the pipes that make up the system (taking into account diameter, length, material).

- A small pump is easier to place indoors, but the size of the unit is directly related to its power. Small pump - limited power.

- The phasing also influences the choice of pump. Typically, single-phase units are chosen for private facilities. But industrial areas require the installation of pumps with a three-phase motor.

- Foreign pumps are not always better than their domestic counterparts. The products of our manufacturers are designed for low water quality and usage characteristics typical for our area.

Where is the pump for heated floors installed?

Before connecting the pump to a warm floor, it is important to determine the optimal location for its installation. There are 2 options for this:

- On the supply side - that is, next to the mixing unit.

- On the return line - that is, in front of the boiler.

In a conventional system, installers always use the second option - it is optimal to place the pump in front of the boiler, from where it will circulate the water, which will ensure its uniform heating. But in the case of heated floors, it is better to choose supply installation. This is done in order to avoid air getting into the system as much as possible.

Important! If the floor pump is too noisy (rotary), it is better to install it under the floor. For medium-sized premises (1-2 floors, up to 300 m2), the equipment can be placed in other places.

Recommendations for selection

To ensure normal circulation of hot water in the system, units should be selected based on the following recommendations:

- The aquatic environment contains oxygen, so you should not install a pump with a cast iron body.

- The aquatic environment has a fairly high content of salts, which can settle on the rotor at temperatures of + 55°C and above. Therefore, a temperature regulator must be provided that will turn off the unit at a certain increase, that is, work as a station.

- If the heating boiler has a standard control panel, then a timer is connected.

How to install a pump on a heated floor

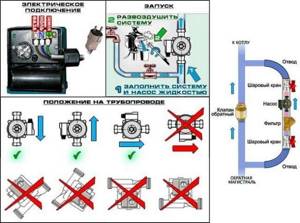

Once the location has been chosen, installation should begin. The algorithm of actions is as follows:

- First, a bypass - a bypass pipe - is installed in the location to be mounted.

- To do this, you need to cut the main pipe.

- Form a thread at its ends.

- Install the ball valve and install the pump.

- Open the tap for water access.

- Open the air bleed screw.

- After installing the circulation pump on a heated floor, you must test the system. First, the work is checked at low speed.

Scheme of correct installation of a pump for a heated floor

Rules for caring for a pump for a warm water floor

The pump for heated floors is durable, provided that it is installed correctly and there are no manufacturing defects. However, it also needs maintenance. During operation you must:

- Periodically (1-2 times a month) bleed air from the circuit using a special tap. If this has to be done too often, there are errors in installation. It is recommended to install additional separators or air valves.

- Lubricate the operating mechanism annually - this is especially necessary for a pump with a dry rotor.

- As for the wet rotor, it is necessary sometimes (for example, once every 2-3 years) to clean it of scale and other deposits.

Important! Do not change pressure or temperature suddenly. If some place is frozen (or after a long break), heating is carried out very slowly so that the water gradually acquires the desired temperature.

Installation and operation

When installing and connecting water circulation pumps, remember the following:

- Installation must be done in such a way that the working shaft is horizontal, otherwise the actual power is reduced by 25-30%.

- For a heated floor system, it is advisable to install the product in the return branch, according to a bypass circuit. Otherwise, a vacuum of coolant may be created at the outlet of the heating boiler with its sudden overheating.

- Before starting the water pump, be sure to bleed the air from the manifold.

The equipment is installed in the following sequence: a bypass is installed, two Mayevsky taps are connected to the line before and after the unit, and in front of the pump, an additional cleaning filter is added.

The most common problem during the operation of the products considered is their restart after a long period of inactivity. The fact is that during operation during the previous heating season, a significant amount of scale is deposited on the moving parts of the water pump. You can turn the impeller manually, but it is better to disassemble the unit, remove the rotor and thoroughly clean the entire internal surface of deposited salts.

Where is the best place to put the pump?

In conventional heating systems, the circulation pump is placed exclusively on the return line, directly in front of the boiler. But in the case of heated floors, this option is far from the best.

The pump connection diagram provides for the installation of pumping equipment on the coolant supply. This is due to the peculiarities of the operation and operation of the water circuit.

Violations of the tightness of threaded connections, the presence of differences in the height of the pipe laid in the floor, malfunctions of the heating system - lead to the appearance of air locks. The pump is set to supply to prevent airing of the system as much as possible and, if necessary, squeeze out air. {banner_downtext} Other options for connecting the pump also exist. But as practice shows, if you start a pump that is supplying coolant, you can achieve better results.

Installing a circulation pump

Here we immediately draw your attention to how to properly install the circulation pump: the shaft must be positioned horizontally and nothing else

Keep in mind that if the shaft is positioned vertically, productivity will drop by up to 30%.

Let's look at the main points of installation in a heating system.

It is advisable to install a filter element in the line before the pump, and taps before and after it. They are necessary in case something happens to it and it needs to be dismantled. In this case, you can calmly turn off the taps and remove the device, without draining the liquid from the system.

The second feature is the following. If the boiler does not have a built-in pump, then it is advisable to install an additional circulation pump before the boiler, i.e. in the return pipeline. With this arrangement, it will pump water into the heating device. In addition, it processes fluid at a lower temperature, which reduces wear.

Another point about installing in front of the boiler is this: air can accumulate in the upper part of the boiler (especially a floor-standing one). When installing the device on an outgoing pipeline, it will begin to draw water out of it, thereby causing a slight vacuum to arise, and this is one of the reasons for boiling. When installing the pump at the inlet, the liquid will be pushed in and the formation of air spaces is excluded.

Why does the pump become airy?

The reasons for airing both the heating system and the pump itself usually lie in violation of the rules for installation and operation of the equipment. Some homeowners have to bleed the air several times during the week.

What can help avoid this?

- Remove air pockets from the water circuit. This must be done before turning on the heating of the coolant for the underfloor heating system.

- Install separators or air valves.

- Carry out station maintenance from time to time. Service is especially necessary if the power consumption of the pump has increased (affected by energy consumption) or unheated zones have appeared.

- It is prohibited to suddenly change the temperature and pressure in the system.

The operating instructions provide a detailed description of how you can independently remove air trapped in the pump housing.

Water heated floors cannot operate normally without circulation equipment, except when the water circuit is connected to an already operating central heating system.

Design and principle of operation

The device includes the following elements:

- frame;

- a motor equipped with an impeller and connected to the housing;

- parts for connecting parts.

Sometimes the pump is equipped with an air vent, but this is rare. More often they use a special nut - if you unscrew it, the air comes out of the system on its own.

The principle of operation of the mechanism is simple: the liquid is directed into the housing, where, thanks to the rotation of the impeller, it is picked up and released further by pressure. Due to this process, forced circulation of water occurs.

Some pumps have 2 motors installed - this way the equipment will continue circulation even at maximum loads. The second engine is connected if necessary and takes on part of the work. The device is also considered more reliable due to the reserve. However, equipment with 2 motors is more expensive and the owner will have to decide for himself whether such a purchase is reasonable.

The pump is installed at any point in the system - usually at the edge of the supply or return circuit. It is recommended to select the location for installation of overclocking equipment individually. There are no special requirements - the operating temperature is not important, but it would be wiser to install the device where it is lower.

Trouble-shooting

The main factor that negatively affects the functioning of the pump is the quality of the water entering the water heating circuit. If the pump operates continuously, salt deposits reduce its performance to a lesser extent than during periods of shutdown.

Connection diagram of the circulation pump to the electrical network

Sometimes, after turning off the heated floor for the summer period, the next time it is turned on, the pump stops pumping water due to the fact that the rotor does not turn. You need to carefully turn the impeller several times using available tools. If the pump does not start to function, professional help will be required.

Pump malfunctions and how to fix them

If a properly selected pump pumps the coolant - tap water, then layers of salt are deposited on the impellers. This problem occurs after stopping while the owners are away or during the summer. When plugged in, the pump makes a strained humming sound, but does not pump water. This means that the deposited salts have “coked” the rotor and do not allow it to move. You can correct the situation yourself, without turning to professionals. You need to take a screwdriver and turn the impeller a couple of times.

Refusal occurs due to airing. Using the valve, air is released to a steady stream of water. Start the pump and repeat the procedure after a minute.