Famous brands

Valtec is an Italian manufacturer of a line of products for constructing water supply systems.

A full range of products for metal-plastic, polypropylene water supply and stainless steel systems is always on sale. In Russia, representative offices are located in 6 cities, including Moscow, St. Petersburg, and Krasnodar. Rehau is a German manufacturer with a history dating back to 1948. Products undergo multi-stage quality control.

Far (FAR) is another Italian company. In addition to shut-off and distribution valves, the line includes metal-plastic, polypropylene, copper and steel pipes.

Why is this necessary?

Why and when do you need a water supply comb?

Collector water distribution is necessary in two cases:

- If you need to ensure the disconnection of several plumbing fixtures or their groups from one point (manifold cabinet). This feature is very useful in a mini-hotel or hostel;

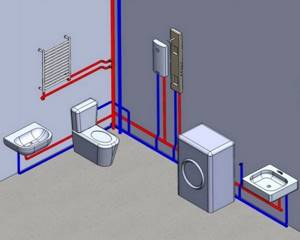

All plumbing is disconnected from one manifold cabinet

- If you need to ensure constant water pressure on all devices at any ratio of water consumption between them.

The second point probably requires some clarification.

Remember the cute communal scene: one of your family members is taking a shower in the bathroom, the other is trying to wash up the dishes in the kitchen. As soon as he opens the cold water tap further, an angry roar from the scalded body can be heard from the bathroom.

Why is this happening?

Because an increase in cold water flow with a constant hydraulic resistance of the water supply leads to a drop in pressure at all water collection points.

Open the tap on one mixer and the pressure on another will drop sharply

This is a common problem with so-called tee (or series) connections.

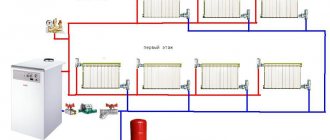

Tee (sequential) water distribution

It is worth providing each plumbing fixture with its own supply connected to a common collector - and the problem of pressure drop will be solved: regardless of the water flow in the kitchen, the pressure in the bathroom will remain unchanged.

Scheme of collector wiring in a house with a boiler

Selection of pipes for the heating system

When creating a manifold wiring diagram for heating a low-rise residential building or other private building, it is necessary to take into account the method of laying pipes throughout the house. If the piping will run under the floor, in a concrete screed, then it is recommended to buy heating pipes in coils so as not to make connections in the floor, as mentioned above.

Plastic pipes must have sufficient flexibility, the pipe material must not be subject to corrosion and the influence of aggressive environments, must not be destroyed at low or too high temperatures, and the service life of the pipes must be extremely high.

The requirements for temperature resistance and tensile strength of pipes are determined by the performance characteristics of the installed heating system in a house or apartment. For individual development, the pressure in the pipes should not exceed 1.5 atm, and the maximum temperature regime should be in the range of 500C -750C. If the house has a “warm floor” system, then the temperature of the coolant in the pipes should not rise above 300C -400C.

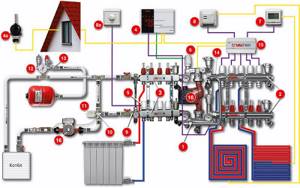

Manifold for combined heating

When installing a manifold heating circuit in an apartment building, the pressure in the pipes will always be high, and the pipe material must withstand ≥ 10-15 atm. at a coolant temperature of up to 110-1200C. Therefore, when laying heating pipes in an apartment building, it is recommended to use corrugated pipes made of stainless steel, rather than metal-plastic or PVC products. As a working example, we can cite the Kofulso brand of pipes, which can withstand pressures of more than 15 atm. at coolant temperature ≥ 1100C. The pressure force that causes the destruction of this material is 215 kgf/cm², which is an excellent indicator.

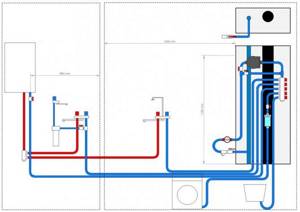

Collector wiring in the apartment

The bending radius of such stainless pipes is equal to their diameter, which allows them to be laid in almost any place and with any bend, without fear that the pipe will leak at the bend. Connections in such piping are made using special fittings, and the twist points are fixed with a lock nut, which ensures the tightness of the connection of corrugated pipes with silicone seals.

But stainless steel is not the cheapest material, and when installing manifold pipes in a two- or three-story building, such a project will be quite expensive. Therefore, it makes sense to use pipes made of cross-linked polyethylene, for example, PE-X brand. These pipes, like other PVC products, are sold in coils, the length of one pipe is 200 meters, the material is able to withstand pressure up to 10 kgf/cm² at a coolant temperature in the system up to 950C. A short-term increase in temperature up to 1100C is allowed.

Corrugated stainless steel pipes

Water pipes made of cross-linked polyethylene are also connected to each other using special fittings in the form of plastic or metal (bronze, brass, copper) fittings with a locking ring, which fits tightly onto the pipe and seals it tightly. The advantage of such pipes is that cross-linked polyethylene has a mechanical memory, that is, assembly is carried out according to the following scheme: the pipe is stretched with a special extender so that a fitting can be inserted, and after some time (up to a minute) the pipe takes on the original diameter and tightly presses the fitting. Additionally, tightness is ensured by a locking ring.

Functions of the heating distribution comb

The heating system must work well. Modern devices require the use of more complex wiring diagrams. The heating system can be optimized and made efficient through the use of a comb.

The main task of the comb is to ensure a comfortable temperature throughout the entire area of the room.

The main requirements for combs are their safety during operation, as well as maximum repairability. If these conditions are met, then some problems can be solved quite simply and quickly. For example, if the radiator in the house is sweating, the comb will allow you not to turn off the entire heating system.

Comb functions:

- Water distribution. It is a centralized unit that allows the coolant to reach all destinations evenly.

- Regulatory. The comb distributes water along the water supply line and also monitors the heating temperature.

Each comb has a locking mechanism. This may be a shut-off and control valve. Thanks to the shut-off valve, it is always possible to shut off an individual circuit of the distribution system. Regulating taps allow you to reduce or increase the volume of water supplied to the circuits.

DIY distribution comb for heating

Welding steel manifold

Considering the high cost of collectors, the pressing question remains - how to make a heating comb yourself. Knowing the principle of operation of the collector, it may seem that it will not be difficult to manufacture it; the main problem arises when selecting components. Square and round steel pipes are considered one of the best materials. However, it is not always possible to work with them at home - this will require a welding machine.

An alternative way is to make a comb for heating systems from polypropylene pipes. This will require tee connections and a welding tool to join them. It is recommended to choose the largest diameter of the inlet pipes, taking into account the principle of calculating the heating comb. Those. if the diameter of the pipes in the circuits is 20 mm, this parameter for the main body of the collector should be at least 3 times larger.

To make a heating comb with your own hands, you will need to perform the following steps:

- Measure the distance between the inlet and outlet pipes of the circuits.

- The size of the collector body should be 10-15 cm larger than the measured distance.

- Cut the pipe according to the dimensions obtained and install pipes on it to connect the circuits.

- Check the tightness of the resulting structure.

Polypropylene comb

It should be noted that before making a heating comb, you need to check the possibility of installing it for a specific system. The problem may lie in thermal conditions - polypropylene connecting fittings do not have reinforcement. Therefore, if the temperature is exceeded, their partial depressurization is possible.

It is important that the throughput of the structure is no less than that of the pipe leading from the boiler. An alternative to making the stroke yourself is to purchase a ready-made body

Its cost depends on the number of inlet pipes and can vary from 1400 to 1950 rubles

An alternative to making a paddle yourself is to purchase a ready-made casing. Its cost depends on the number of inlet pipes and can vary from 1400 to 1950 rubles.

Why do you need a heating comb: 3 functions

A high-quality heating comb will ensure uninterrupted operation of the water supply system. The serviceability of the water supply system is very important, since the breakdown of even the most seemingly insignificant part can lead to the entire water supply system ceasing to function. The heating comb is an important detail on which the uniform distribution of water throughout the water supply depends. The comb is also used to equip heated floors: it promotes the uniform distribution of thermal energy.

Reservoir classification

Switchgears differ in the material of the housing and parts and methods of fastening

This is important to consider when selecting, because... not all products are suitable for plastic pipes

The following types of collectors exist:

- Steel (made of stainless steel). Resistant to fire and high temperatures. The products are distinguished by their neat appearance and light weight; the collector is easily mounted on the wall.

- Brass (sometimes nickel-plated). They have a high cost, but are durable. Do not rust or deteriorate from high temperatures.

- Polypropylene. They are lightweight and resistant to corrosion.

According to the method of fixation, devices are classified as follows:

- with eurocone;

- threaded;

- with compression fittings that allow you to firmly connect plastic or metal-plastic pipes;

- with fittings for plastic pipes for soldering;

- combined.

The collectors are also available in 2 color options for installation on hot and cold water. Devices are divided by the number of outlets.

Manufacturers of distributor combs

The installation of the comb must be thought out to the smallest detail. When buying a comb, it is important to look not at its external characteristics, or even at the material it is made of. The first step is to find out as much as possible about its throughput: the device must cope with a uniform flow to all currents.

Before purchasing, it is very important to study the functions of different models of heating combs, paying special attention to well-known manufacturers

It is important to choose a comb that will match the pressure in the system.

Before installing the comb, it is important to calculate how much energy it will consume at each connection point. The comb must be able to expand if additional nodes are suddenly needed. Choosing a comb on your own can be very difficult, so it is better to do it with the help of a professional.

Leading comb manufacturers:

- Rehao Rautitan . The comb has excellent value for money. The comb regulates the coolant to several circuits at once. The device provides for the connection of cold water that passes through pipes, heated floors and other heating devices.

- Distribution manifold Rehau Rautitan HLV . Collectors operate on the comb principle, but they can be connected to a larger number of media. They are installed separately for hot and cold water.

Modern manufacturers daily replenish the markets with new products that are equipped with new elements that improve the functioning of devices. Each species has its own characteristics and has positive and, less often, negative qualities. To make the right choice, before purchasing, you must first familiarize yourself with the types of devices and their functional purpose.

Selecting a location

First of all, the water distributor must be installed in such a way as to maximize the length of each pipeline to the consumer. If this rule is neglected, then over longer sections the fluid pressure will differ significantly.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor.

There are two ways to install a water comb:

- In the wall of the building.

- In the distribution cabinet.

The first installation option is used when the usable area of the room is limited, or the open installation of pipes and distribution boxes will significantly change the design of the room. In this case, a niche is built in the wall, which is closed with a valve, and if necessary, it will be possible to gain access to the control of the device.

If it is possible to install the distribution device in a utility room, then in this case a special box is installed, inside which the comb and all the pipes leading to this device are fixed.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor

Price

General Fittings Cold Water Manifold - The manifold is designed for use in a cold water system only. The material from which the device is made – nickel-plated brass – does not interact chemically with impurities in water, thereby allowing the device to be used for at least 10 years.

The comb is equipped with valves that are located on the main distributor pipe. The number of pins of this device is 4 pcs., but if necessary, a block of an unlimited number of pins can be assembled from separate sections.

Installation of distribution comb

Installation of the comb does not bode well for easy work. As a rule, it takes a lot of time and requires the hands of a specialist who knows a lot about this matter. But, despite all the installation difficulties, they try to install this particular wiring in modern houses and apartments, since it is very effective and easy to use. New models of combs are produced taking into account the complexity of installation, this greatly facilitates the work of the master during installation. You can mount it not only in a mounting cabinet, but also to the wall; for this purpose, the kit includes mounting clamps for greater stability of the device, and its high resistance to corrosion allows the comb to serve for many years.

In order to clearly understand what a distribution comb is, you need to know about it all the information necessary for a person who does not understand anything about this matter. For a complete overview, it is worth presenting several types of different combs.

Manufacturing materials can be polymer, steel, brass or copper.

Configuration:

Simple ones lack an important quality - control of coolant flows. Such combs divide the total flow of water by the number of nodes present in the house; they supply a uniform flow to the bathroom, kitchen, toilet and other places where water flows

The design of the comb is the simplest - a coupler with special connections on both sides and branches in the amount of 2, 3 or 4 pieces.

Complex - have many useful additional elements: pipeline fittings; control and accounting sensor; automation. Temperature sensors, or as they are also called, thermal sensors, are installed in combs with an electronic or mechanical system. They completely control the flow and supply of water through the pipes, especially convenient when the coolant is connected.

What is a heating comb (video)

A water comb is needed to promote uniform distribution of water along the water supply line. The boiler design is simple, so you can assemble the comb yourself. To do this, you should first read the instructions and decide on the functional load that the comb will perform. Some types of combs can be connected to two taps at once: hot and cold water. Installing the comb will be quite difficult if you have no experience in this matter. In such cases, it is better to take the help of a specialist.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Types of combs

Water combs differ in:

- degree of sophistication;

- material;

- number of taps,

- center distance of bends (36 – 100 mm).

Thus, combs for far water supply can be made from:

The design of an elementary distribution comb for water supply is simple: it is a pipe with several outlets. The number of outlets can be from 2 to 4. This collector is designed only for distributing water flows and is easy to assemble yourself.

There are complex models of combs for far water supply with ball valves and with shut-off control valves required for each outlet. The taps operate only in two positions: on and off, and shut-off equipment allows you to change the flow intensity. According to consumers, the second option is more convenient. The most sophisticated models are equipped with mechanical or electronic sensors and are designed to work in heating and hot water supply systems.

If there are more than 4 plumbing fixtures in the house, several collectors are connected together. The great convenience of using such wiring is the ability to install a hidden water supply system. The comb stabilizes the water flow, reducing the likelihood of a water pipe break.

Project implementation

In order not to become a victim of the situation described earlier, you need to connect a manifold with the correctly selected pipe diameter. You can make a pipe from a half-inch product for the shower and tank. At the same time, the entrance to the collector should be several times larger.

But you shouldn’t be overzealous either. There is no need to install a doubled entrance. A slight increase in the input channel compared to smaller outputs will already give a positive result.

These materials are easy to work with. There is no point in repeating the benefits of using plastic.

It turns out that the work may be difficult, but the result is worth it. Manifold wiring allows you to save money on the purchase of tees. And if metal-plastic pipes are installed, then the tees for them are very expensive. But still, there are no special restrictions here. The owner himself makes the decision.

It should be noted that every owner can independently perform collector wiring. But before starting work, you need to draw up a diagram on paper, which can then be implemented in practice. The collector system for distributing water pipes requires careful operation.

As you might guess, the system will have many connections of pipes, adapters, shut-off valves and other elements

Therefore, it is very important to pay special attention to every detail, so that later you don’t have to redo all the work, which will add even more hassle.

Today you can buy metal-plastic pipes, copper pipes, stainless steel pipes and polypropylene pipes in any construction or specialized store. There are also all kinds of connections, adapters, taps.

That is why it is necessary to have a work plan in advance. It will allow you to purchase the required amount of building materials for the system.

DIY collector

Assembling the comb yourself is an opportunity to save money. The device is simple, but for proper functioning it is necessary to comply with a number of parameters and to approach the manufacture thoroughly.

Plumbing manifold

Making a polypropylene manifold with your own hands is the easiest way. You will need welding, tees, pipes of different diameters, scissors for cutting polypropylene pipes. In extreme cases, you can cut it off with a fine-toothed hacksaw. The number of tees is equal to the number of pipes extending from the manifold.

- The diameter of the pipe is equal to or greater than the total diameter of all branches combined, and at the same time equal to the diameter of the supply pipe. If this is not taken into account, the pressure in the system will become uneven.

- The pipe will need to be cut and a tee welded for each branch. Keep in mind that the tee must match the diameter of both the “comb” and the branches.

- After welding and hardening, the system is welded to the supply pipe with an adapter.

- The system is ready, if everything is done correctly, the functions of the collector will be performed in full.

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

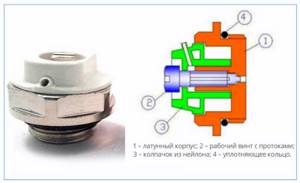

Rice. 2 Air vent for venting air from the heating system - design

Leaders of sells

For an even clearer understanding of what a distribution comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions have been added by manufacturers.

You will be presented with 2 types of distribution comb and distribution manifold, common throughout the world, which have the most modern functions:

- Rehau Rautitan distribution comb for 2 pipes. Combines low price and excellent quality. The manufacturer is the famous company Rehau. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. You can connect to the device both ordinary cold water passing through pipes and a heated floor system, as well as other heating devices. Installation of the comb is facilitated thanks to the sliding sleeves with which it is attached to the pipes. Made of brass, this material is characterized by long service life and high strength.

- Rehau Rautitan HLV distribution manifold for 11 groups. The manifolds have the same functions as the combs, the only difference is in the number of connections - the manifold has many more, connections are made in groups, for cold and hot water separately. Rehau has proven the high quality of its devices. This is evidenced by the numerous purchases by Russians of collectors and combs from their company. The Rehau Rautitan HLV distribution manifold branches out the circuits of radiator distribution systems. All devices have passed mandatory quality checks and necessary tests, including pressure testing in emergency situations. Just like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: eurocone, ball valves, connecting nipples and built-in air valve.

The market of modern technologies is filled with new products every day; distribution combs and manifolds are supplemented with convenient functions for ease of use. They all have their positive, and in rare cases, negative qualities. To choose the right distribution comb or manifold for your home or apartment, you should learn as much as possible about these devices, then it will be difficult to make a mistake in your choice.

Self-production and installation

In order for a self-made device to do its job well, it must not only be manufactured correctly, but also installed

In this case, it is important to take into account the advice of professionals and take into account the recommendations of manufacturers of individual parts. Only in this case can you achieve the desired result and complete the work in the shortest possible period of time

Recommendations from experts

Before you start making a comb, you should read the advice of people who have already done similar work. This will help beginners avoid most mistakes and make a truly high-quality product. Professionals recommend:

- It is advisable to make the distribution comb with a round or square cross-section.

- To avoid problems with coolant movement, it is necessary to install separate circulation pumps for each circuit. In this case, the comb should not synchronize their work.

- If the unit will be located in a separate room, then a protective box may not be installed for it.

- In order to be able to change the volume of coolant, it is necessary to install control valves, balancing flow meters and inlet valves at each inlet and outlet pipe.

- During planning work, a place should be provided for installing a security group.

Distribution and calculation of contours

Before starting the manufacture of the device, it is necessary to calculate the number of required circuits and draw up drawings for their connection

In this case, it is important to provide separate units for some heating structures:

- water-based underfloor heating;

- heating devices for each floor of the house;

- radiators in rooms where the temperature is higher or lower than other rooms.

In addition, it is important to perform all calculations efficiently and provide various geometric parameters. If everything is done correctly, then you can ensure easy access to all components of the structure

This will help simplify repair or maintenance work. Nuances to consider when making calculations:

- intervals between layering should be from 10 to 15 cm;

- the distance between the supply and return manifolds should be set from 20 to 30 cm;

- diameter of pipes for connecting radiators - 0.5 inches;

- collector cross-section is from 1 to 1.5 inches.

- intervals between layering should be from 10 to 15 cm;

- the distance between the supply and return manifolds should be set from 20 to 30 cm;

- diameter of pipes for connecting radiators - 0.5 inches;

- collector cross-section is from 1 to 1.5 inches.

Creating a comb from a profile pipe

To make a comb yourself, you need to purchase a profile pipe and round-section products, the length and size of which must be pre-calculated and repeatedly checked. Procedure:

- According to a pre-prepared diagram, the profile pipe is marked.

- Holes of the required diameter are made in the right places. This work is best done with a gas cutter.

- After this, the pre-threaded pipes are welded.

- Mounting brackets are attached to the resulting structure by welding.

- The surface of the product is cleaned and coated with heat-resistant paint.

- The finished comb is mounted in the selected location of the system.

A heating comb is an important device that helps to simultaneously connect all existing radiators to the heating system. With the right approach to business and following all the recommendations of professionals, you can significantly simplify the work and complete it in a short period of time

One of the methods of connecting heating devices - today it is considered the most modern - involves the presence of an element called a comb.

Below in the article we will talk about how a distribution comb for heating functions and how you can make it yourself.

The nuances of homemade work

The main condition for correct heating operation is the creation of hydraulic balance in the system. The ring collector for heating must have the same throughput capacity of the incoming pipe (the cross-section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 +D3 +D4

When making a heating manifold with your own hands, remember that the distance between the supply and return sections of the pipe should be a value equal to at least six comb diameters.

When installing the device, take into account the following nuances:

- an electric boiler or gas boiler is connected to the upper or lower pipes

- the circulation pump only fits into the end side of the comb

- heating circuits are connected to the top or bottom of the collector.

To heat a house with a large area, circulation pumps are installed on each circuit. In addition, to select the optimal volume of coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and adjustment valves. These devices limit the flow of hot liquid to a single pipe.

In order for the boiler distribution manifold to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible (but not necessary) to additionally equip a mixing unit when manufacturing heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, install a two or three-way valve. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

This entire design allows you to regulate the heating temperature of a particular room or a separate circuit. If too hot water enters the collector in the boiler room, the flow of cold liquid into the system increases.

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of distribution combs.

A manifold for a boiler room, which you make yourself, will ensure normal heating operation only if you accurately select the parameters of the system piping. Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that a comfortable temperature in your home depends on many factors. Only a fully balanced system will ensure correct heating operation.

Design and rules for installing the comb

The heating manifold for a boiler room is a complex structure of two distributors, one of which is directed into the supply line, and the other collects cooled water. Material of manufacture: stainless steel or cast iron. The first is preferable, as it can withstand high temperature changes of the carrier and is resistant to corrosion. Cast iron holds heat well, but is fragile. The price is appropriate. Handicraft structures are made from propylene pipes.

The structural part of the comb contains a certain number of terminals - the number varies according to the presence of radiators available for connection. At any moment, the quantity is increased or decreased - increasing or decreasing the system. The distribution comb is equipped with shut-off valves - taps. They come in two types:

- Cutoffs. Their effect is to completely shut off the supply of coolant to the heating system or to sections of the pipeline.

- Regulatory. With their help, one or another section reduces or increases the incoming volume of hot coolant.

Drain and air valves are an integral part of the heating comb design. Next to them are instrumentation devices - pressure gauges, thermometers. The devices are located nearby; in case of data correction or repair, it is convenient to use the design.

Rules for installing a distribution manifold in a boiler room

There is only one regulation for the location of the comb - an autonomous structure is installed on each floor of a residential building. This causes some difficulties, since a multiple collector is:

- Costs for components. The length of the heating main increases, therefore, there is a need to purchase additional components - pipes, valves, sealing materials.

- To smoothly raise the coolant to the second floor, a circulation pump is required. Accordingly, energy costs will increase.

- The scope of work increases due to the size of the structure and the complexity of installation. If you resort to the services of professionals, your expenses will also increase.

However, the costs will pay off over time. Distribution manifolds with taps are economical designs that are optimized for your own consumption.

manifold mounting

I looked through the entire section and I can’t find how to secure the collector so as not to accidentally collapse

Look at photos of examples of completed work, manufacturers' catalogs. Either specialized fasteners for “steep manifolds” or ordinary plumbing clamps on plumbing studs are used.

If the collector is in a metal collector cabinet, then special fasteners, otherwise - plumbing clamps on plumbing studs.

Please give me some advice: are the collectors attached correctly and can the play of the fasteners in the brick wall affect the operation of the system? (Behind the brick there is one row of emptiness). Thank you.

Right. But everything else is not. Use polypropylene for manifold wiring. bue.

Exclusively metal-plastic? This is polypropylene with fiberglass.

As far as I understand, the choice of material is related to the number of hidden connections from the collector to the consumers? Or something else?

Dmitry - yes. Number of connections and ease of installation.

Here's what's about it

AlexMax wrote: Number of connections and ease of installation.

Well, the installation is almost complete. I hope that the connections are soldered securely, especially in places that will be hidden by tiles.

Interpreter, respected Technician-san, in his review, missed the flexible copper KME Q-tec and flexible corrugated steel. They, too, seem to already exist and are walled up. I don’t mention any joint ventures at all. The statements of Technician-san for MP are true for them.

By the way, information on composite pipes (glass fiber reinforced polypropylene)

Dmitry, that's all bullshit. Press - yes, it gives a gain, but all these PP pipes. When using drill stripping, virtually no time is lost; much more time is gained by proper labor planning and clear phasing in carrying out the planned work. But you can't teach this.

What can you say about the reliability of the system “in general” in this design? Is it worth (and how) to additionally mount the collector where there is a gap from the wall?

Here's the big picture: [

Yes, it's worth it. The collectors, judging by the appearance, are Grandini? If possible, attach it to the console, at least from Hilti. To prevent it from dangling, take a smaller clamp. a half-inch will do. Collectors for 34?

Tiemme manifolds 3/4 (3*16 + 4*16) x 2 pcs. (art. 1866N160404, 1866N160404):

The console also needs to be attached to the brick - and it’s not entirely solid. There are gaps behind the brick where the dowels with spacers fit.

It's worth attaching anyway. Everything has to be tough. and I’m bothered by the pipe coming from the meter from the MP under the press, where does it go?

If you are talking about the white pipe that runs along the wall to the left (from the lower HB meter), this is a temporary “snot” for collecting water and flushing the “repair” toilet.

Greetings! I wanted to create a topic, but here is just a similar one. The question arose: I wanted to attach FAR 3/4 collectors (two in series with 3 and 4 pins, almost like in the photo of the vehicle) to the plumbing wall with 3/4 clamps. However, when I secured the clamps between the outlets, this completely blocked the possibility of connecting pipes to the outlets, since the nut there no longer rotated, and if I attached the clamp at the end, it did not stay there - it fell off. Bends are planned with kofulso pipes, while temporary flexible hoses. So the question is, how to secure them to these clamps so that this does not interfere with the connection of consumers?

Types of distribution combs

Collectors are mounted on hot and cold water supply. For convenience and to prevent confusion, manufacturers produce models in different colors (red and blue).

By type, combs differ in the number of taps, which varies from 2 to 4. For a larger number of connections, it is recommended to use combinations of several distribution devices. For example, the existing 6 points can be equipped with two combs for 3 outputs.

Equipping the heating system with a manifold will be no less useful. Heating will be carried out evenly, which will eliminate differences in the temperature of individual rooms.

The operation of any type of switchgear is safe. The absence of pressure drop will eliminate emergency situations with breakthroughs and flooding.

Purpose of the comb

When laying water pipes in old houses, the main principle was used. The pipes were connected to the main branch one at a time, so residents of the old housing stock still suffer from uneven distribution of pressure and temperature. In water supply systems, tee wiring with threads or welding has traditionally been used. The tee could not provide stable pressure when several points were turned on, which is why a comb is needed in the water supply system.

Wiring using collectors or combs for far water supply is free of such disadvantages. The pipes are connected to the main in parallel. When connecting a cold or hot water comb, even filling the pool will not affect the water supply of neighboring apartments.

The distribution comb for water supply equalizes the pressure in the network, prevents water hammer and sudden changes in pressure. In modern houses, distribution manifolds are installed on hot and cold water supply. Using a comb collector, an independent water supply system is created for each apartment; in addition, you can:

- connect a water pipe to each appliance in the apartment;

- guarantee the independent operation of all plumbing fixtures.

For optimal results, it is recommended to install comb manifolds on both hot and cold water supplies. A tap is installed at the outlet of each pipe, with which you can quickly stop the water supply to any device. This property will come in handy if a faucet or cistern breaks down.