Private house selection and installation of heating circuits

A private house can be small, one-story or two-story, and recently three-story houses have appeared. Both a cottage and a wooden log house are considered a private house. It is impossible to install a heating system in a private house without a project developed by specialists, without a well-written estimate and a professional team of craftsmen who will bring the planned project to life.

If for small private houses or cottages it is permissible to independently create heating systems, then for two-story, and even more so three-story houses, one cannot do without a well-designed project. After all, you need to provide a reserve for heating, heated floors, installation of automation systems and many other subtleties that only professionals know about. The price for installing heating in a private home can vary widely.

The price depends on the region, the size of the house and the number of floors, the number of heating appliances and other factors that are reflected in the investor’s estimate. In Moscow, for example, the price list for installing heating in a private house is slightly different from prices in other cities of the country. In Moscow, installing a heating radiator costs 2,500 rubles, the price in Voronezh is 2,000 rubles.

The price for installing heating in a private house depends to a large extent on the contractor, who can make changes and additions to the estimate, which in such cases is called a contract estimate. It reflects the actual installation costs. It should be noted that prices for heating installation in a private home may change due to inflation and the dollar exchange rate.

How many heating circuits should there be in a country house?

Of course, everyone decides for himself how many heating circuits to install in a country house, but a heating system is not a one-day purchase and reasonable savings are more popular in 99% of cases (the only exception is the case when it is urgently necessary to install heating, and there is very little money ).

The specialists of the Mosvodostroy company have been installing heating systems in Moscow and the Moscow region for many years and will help you create individual heating in your home with high quality and quickly. To receive an individual price for a turnkey heating system, simply fill out an application.

Heating system in an apartment building connection diagram and features

To meet the heating needs of residents of high-rise buildings, centralized heating systems are well suited.

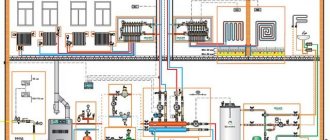

Centralized heat supply involves the transfer of heated coolant from the boiler room through a network of insulated pipes connected to a multi-story building. Centralized boiler houses have sufficient efficiency and make it possible to combine low operating costs and acceptable efficiency indicators for heat supply to multi-storey buildings. But in order for the efficiency of the central heating supply to be at the proper level, the heating scheme in an apartment building is drawn up by professionals in their field - heating engineers. The fundamental principles by which a home heating scheme is designed are to achieve maximum heating efficiency with minimal resource consumption.

Contractors and builders are interested in providing apartment owners with a reliable and productive heat supply system, therefore the heating scheme of a multi-storey building is developed taking into account the current cost of heat resources, the thermal output of heating devices, their energy efficiency and the optimal sequence of connection to the circuit.

Fixing the boiler

Installation of a wall-mounted boiler in a house is carried out as follows:

- They study the manufacturer’s recommendations and select the optimal place in terms of safety and convenience.

- Fix the mount on the wall. supplied with the boiler. To install it in the house correctly, you should use a level and slope. Very often the fastening consists of long dowels and hooks with threads on the longer end.

- In the place where the chimney should cross the wall. make a hole for it.

- Fix the chimney in the boiler. This process is carried out very carefully, since the chimney is coaxial (not only carbon monoxide is released through it, but also fresh air is supplied). This means that if a mistake is made, air and carbon monoxide will not be able to circulate correctly, which will certainly lead to bad consequences.

- Hang the boiler on the fastenings fixed in the wall.

In the case of a floor-standing boiler, installation is simpler, because you just need to make a solid base on the floor with your own hands and place the device against the wall.

Rules for installation on a wall or floor

The gas unit must be placed inside a separate room. which meets the following requirements:

- There is a window that can be opened at any time.

- Availability of functioning ventilation.

- Availability of gas and water pipes.

- The presence of an outlet to ensure the operation of the circulation pump and electronics. Of course, it should be the end of a separate branch that extends from the electrical panel. This cable must be connected to a separate circuit breaker. In addition, grounding is mandatory.

There are also requirements regarding the correct placement of the boiler in the house. They are:

- The distance between the main element of the heating system and other gas appliances must exceed 20 cm.

- There should be no window nearby.

- The distance between the boiler and the socket should be at least 0.5 m (at least, such recommendations are given by manufacturers). In general, the further the outlet is from the boiler, the better. It is worth adding that some models have a power cable without a plug. This means that you need to connect the wire yourself directly to the circuit breaker located in the electrical panel.

- The space between the side walls of the boiler and adjacent walls or objects must be greater than 15 cm.

- The wall on which or near which the boiler is installed must be strong and covered with non-flammable substances. If the wall is such that it can catch fire, it should be covered with at least 3 mm of non-combustible material. This is often noted in various videos.

What does the heating control system calculate?

Modern control systems calculate the required water temperature in the boiler (flow temperature) depending on the outside temperature. The relationship between the outside temperature and the flow temperature is shown on the graph as a heating curve. The lower the outside temperature, the higher the supply line temperature should be. There are three types of regulation of the heating system:

settings:

- regulation based on outside temperature

- room temperature regulation

- regulation based on outside temperature, taking into account factors influencing indoor temperature

Illustration No. 2 Graphic characteristic of the heating circuit (example) X - Outside temperature Y - Flow temperature

How two-pipe heating systems are implemented

Depending on the number of floors of the house, the design of the attic and basement spaces, two-pipe heating systems may have a different design. In this case, the choice must be made based on calculation.

For one-story houses, the following methods of implementing a two-pipe heating scheme are used:

- If the building is equipped with a gable roof, that is, the attic space allows the installation of system elements in it, then preference should be given to overhead wiring with vertical risers. In this case, the coolant is supplied to the attic through one pipeline of the appropriate diameter. Wiring for each individual room is installed in the attic, the coolant is supplied to each individual battery (sometimes risers are used for twin radiators). The return line is installed indoors in the form of a common circuit to which the outputs from all batteries are connected.

- When installing such a two-pipe circuit, it is necessary to provide for the installation of an expansion tank at the highest point of the system. Such a device will help get rid of most of the air pockets that can form in heating pipelines. The air will be forced into such a tank with the flow of coolant.

- If the boiler equipment is stopped in the basement and the building has a normal attic space, a lower wiring diagram can be used. The main requirement is that the boiler must be located below the distribution lines (supply and return). In this case, all these lines are installed in the basement or basement, and two outlets are made to each individual battery through the floor structures.

- Even when installing a heating system with bottom wiring, it is necessary to provide for the possibility of removing air from the system. In the simplest cases, so-called Mayevsky valves are mounted on radiators, allowing air to be released in places where it accumulates, but if possible, it would not be superfluous to install a special air collector that provides automatic or manual air release.

For multi-story buildings, the same wiring diagrams can be used. It should be taken into account that the upper distribution ensures a reduction in the hydraulic resistance of the system, since the coolant is supplied to the upper point through one pipe. Well, the bed diagrams of a two-pipe heating system are simpler and more convenient to use, since the main pipes (supply and return) are laid side by side (in parallel).

In multi-storey buildings, a collector method of connecting pipes to batteries is also used. To do this, a special collector unit is installed at each level, from which a pair of heating pipelines (in the form of rays) are routed to each heating device.

But when choosing this installation method, it is necessary to take into account that the cost of the system in this case will increase by about a quarter due to the larger volume of pipes being laid.

Features of installation of single-pipe wiring

There are many nuances that should be observed during installation work, but it is quite important to follow the order of work, as well as the preliminary creation of a project that clearly regulates the location points of individual system elements. Note that with natural circulation, special attention should be paid to the creation of a single-circuit heating system project - without accurate hydrodynamic calculations, the system simply will not work.

The installation procedure for a single-pipe heating system is usually as follows:

- Installation of a heating boiler in the selected location (remember that when installing electric heating in a country house with a power of up to 15 kW, no additional installation permits are required, unlike gas heating, for which you need to contact the relevant authorities).

- Pipeline installation - the technology for installing pipes depends on the type of material, as well as the manufacturer’s recommendations, however, special attention should be paid to the connection points of individual sections, as well as the connection points of radiators and other elements of the heating system. If natural circulation of the coolant is necessary, the slopes of the pipeline must be observed.

- Installation of a circulation pump - we have already written about the intricacies of choosing and the features of installing a circulation pump.

- Installation of an expansion tank (in this case, an open one is always mounted at the highest point of the system, and a closed one - in any area, but more often directly next to the boiler).

- Installation of heating radiators on brackets; the technology for installing radiators may differ depending on the type of connection (top, bottom, diagonal).

- Installation of shut-off valves, Mayevsky valves (for bleeding air), as well as thermostats on radiators, if the radiator is installed on bypass.

- Pressure testing of the system.

Note that crimp testing is necessary when installing any heating system, as it allows you to identify leaky areas, as well as theoretically problematic elements, even at the installation stage. Agree, it is better to eliminate defects immediately than to encounter them during the heating season.

Strapping scheme

Before considering it, it is worth paying attention to the fact that all gas boilers with two circuits have four pipes for connecting to water pipes. Two of them are designed to supply hot water

Through one, water flows to the heating radiators installed in the house. Through the other - to the indirect boiler, which is part of the hot water supply (DHW). The other two pipes are designed to return water from the radiators and the indirect boiler.

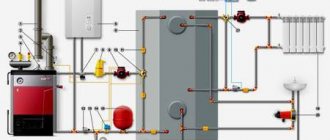

The connection diagram for a double-circuit gas boiler is as follows:

- Boiler.

- Ball valves on four pipes.

- Safety group on the pipe supplying hot water to the heating system. Consists of a pressure gauge, safety valve and automatic air vent. These devices are in demand for floor-standing boilers. As for most wall-mounted models, they already have them.

- Heating radiators.

- An expansion tank on a pipe extending from the batteries installed in the house. In many cases it is part of a system with a floor standing boiler. It can also be added to a wall-mounted harness. This may be necessary in cases where the expansion tank built into the housing is too small.

- Coarse water filter on the same pipe. It protects the boiler heat exchanger from clogging by all sorts of elements. which carries water from heating radiators.

- Ball valves on both sides of the filter.

- DHW pipeline.

- Return pipe from DHW. A water pipe is also connected to it.

- Coarse filter.

- Magnetic filter. Allows you to get rid of rust and scale coming from the water supply.

- Ball valves at both ends of these two filters.

Weaknesses of a single-pipe system

The disadvantages of this scheme usually include:

- Difficulty in calculating thermal and hydraulic parameters.

- A difficult procedure for correcting errors in the calculations of heating devices.

- The influence of all nodes and elements of the system on each other. This is one of the main factors that distinguishes a single-pipe heating system from a two-pipe one.

- Very high level of hydrodynamic resistance.

- One riser can supply a limited number of radiators.

- There is no way to control the heating level of batteries and radiators.

In cases where a vertical riser supplies 10 or more heating devices, the difference in heating temperature of the first and last radiator in a series circuit will reach almost 50 degrees. This fact often becomes decisive when determining which heating is better - single-pipe or two-pipe.

—

CONDITION 1

RESULTS ÑбÑаÑого Ñеплооб¼ÐµÐ½Ð½Ð¸ÐºÐ° плоÑадÑÑ 2 2 м2 ( Ñа registry 0 6 м3, ваÑÐµÐ»Ñ , ASSURANCE. â

RESULTS SYSTEM 2 2 2 ( - 0 6 3, ²Ð°ÑелÑ, ASSURANCE. â

RESULTS ÑбÑаÑого Ñеплооб¼ÐµÐ½Ð½Ð¸ÐºÐ° плоÑадÑÑ 2 2 м2 ( Ñа registry 0 6 м3, ваÑÐµÐ»Ñ , ASSURANCE. â

RESULTS ÑÑ Ð¸Ð· бака-ÑеплообменникР° urn ´Ð¾Ð½Ð°Ð³ÑеваÑеле. › › › registry Ñовод а. â

RESULTS ² Ñом ÑлÑÑае, еÑли ÑеплоноÑиÑели ÑиÑÑÐµÐ¼Ñ Ð¾ÑоР¿Ð»ÐµÐ½Ð ? registry ¾ÑÑи), доп CONTENTS в RESULTS боÑÑ. RESULTS RESULTS RESULTS " оÑнабжениÑ. â

RESULTS, RESEARCH иÑ. $25 ROOM единеннÑÑ Ð±Ð °ÐºÐ¾Ð¼-Ñеплообменником. RESULTS 10 rubles RESEARCH ¸ this ROOM µÐºÑоÑÑ Ð¾Ð±Ñей плоÑадÑÑ 57 6 м2, ÑÑÑбÑаÑÑй Ñеп¿»Ð¾Ð¾Ð±Ð¼Ð µÐ½Ð½Ð¸Ðº Ð 25 June 2, 2019 regurgitation вÐ" RESULTS онÑÑÑе. â

| OPTIONAL CONDITIONS ¬ дома в ÑоÑеÑании Ñ ÑезеÑвнÑми. â |

RESULTS, RESEARCH иÑ. 25. the ÑединеннÑÑ Ð± аком-Ñеплообменником. RESULTS 10 rubles RESEARCH ¸ this ROOM µÐºÑоÑÑ Ð¾Ð±Ñей плоÑадÑÑ 57 6 м2, ÑÑÑбÑаÑÑй Ñеп¿»Ð¾Ð¾Ð±Ð¼Ð µÐ½Ð½Ð¸Ðº Ð 25 June 2, 2019 regurgitation вÐ" RESULTS онÑÑÑе. â

The final stage of work

At the last stage, the radiators are connected, and their internal diameter and volume of sections are calculated taking into account the type of supply and cooling rate of the coolant.

Since central heating is a complex system of interconnected components, it is quite difficult to replace radiators or repair jumpers in a particular apartment, because dismantling any element can cause interruptions in the heating supply of the entire house. Therefore, apartment owners who use central heating for heating are not recommended to independently carry out any manipulations with radiators and the piping system, since the slightest intervention can turn into a serious problem. In general, a well-designed, efficient heating scheme for a residential apartment building allows one to achieve good performance in matters of heat supply and heating.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

Three-way valve for heating: types and features Why do we need heat meters for heating? How to correctly calculate heating in an apartment? Heating registers - their types and features

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts

How does the heating system work in an apartment building?

Due to the high cost of centralized heating, many people increasingly prefer autonomous heating, completely switching to individual heating devices. But many do not realize that an autonomous heating unit in an apartment building is calculated and installed according to the same principle as the installation of a centralized heating main.

- From what date is the heating turned on?

- What is a high-rise building heating system?

- What is return used for?

- Why are batteries often barely warm?

- Purpose of the elevator unit

- The principle of piping the heating main

Overview of a dual-circuit heating system

Double-circuit heating systems require separate lines for the heated coolant and return. Such a system can significantly increase the efficiency of the heating system, as well as more accurately regulate the consumption of heat sources. If, with a single-circuit system, the last radiator in the chain receives a sufficiently cooled coolant and in order to heat the room in which it is located, it is necessary to increase the operating temperature of the boiler (which naturally significantly increases the temperature in the rooms located closer to the boiler), then with a double-circuit system, almost all radiators on the branch have the same temperature. This effect is due to the fact that in two-pipe systems the return flow (cooled coolant in the radiator) does not mix with the hot coolant entering subsequent radiators.

It would seem that this is the best heating system for private houses, however, it also has disadvantages - let's look at all the pros and cons of double-circuit heating in order to objectively evaluate such a solution.

Scheme with an indirect heating boiler

It is relevant for a single-circuit gas boiler. Such a scheme can be implemented according to different rules. Most often the boiler is connected in parallel. A three-way valve is used for this. It is installed on a flexible pipe that connects the boiler supply pipe and heating radiators. Thanks to it, the coolant can both circulate through the indirect heating boiler and move around it. According to this scheme, a flexible pipe extending from the boiler is connected to the return line.

This element can also be included in the diagram with a hydraulic arrow, often depicted in various photos. According to the rules, this option is in demand for systems with a large number of circuits. But in order to implement it, one requirement must be met: install a safety group and a circulation pump on the circuit with the boiler. Some schemes provide for serial connection of the boiler.

All these schemes are suitable for single-circuit and double-circuit boilers. True, the situation with a dual-circuit unit has a slight exception: the DHW system must be connected to the second circuit. Thanks to this, there is no need to use an indirect heating boiler. Although there is a nuance here. A double-circuit boiler is ideal for homes where residents consume a small amount of hot water. However, when the volumes of consumption of such water are very large, the standard second circuit will not have time to heat it. The situation can be mitigated by devices with a storage tank or layer-by-layer heating boiler.

If you plan to use a simple unit with two circuits, then to provide the house with a large amount of hot water you need to use an indirect heating boiler.

As for connecting the boiler to the gas pipeline using a flexible hose or tube, this work must be entrusted to gas service specialists.

Connecting a solid fuel boiler and a gas boiler into one system Two boilers in one heating system Connection diagram for heating radiators Installing a gas boiler with two circuits

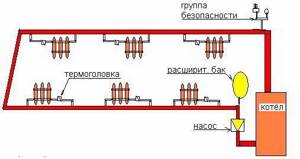

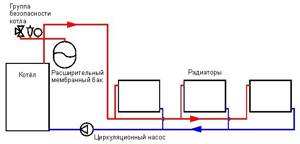

Forced circulation circuit

It is the simplest system, because the circuit contains a minimum number of elements.

Equipment composition in a forced scheme:

- Boiler.

- Measuring instruments.

- Radiators.

- Pipeline.

- Safety valve.

- Circulation pump.

- Expansion tank.

. System operating principle:

- The prepared coolant with operating parameters is supplied by a pump to the top point of the system.

- Due to gravity, the liquid moves through the pipelines and fills the radiators sequentially (as in the developed diagram).

- Through the return circuit, the water is returned to the boiler by a circulation pump for further cycles.

- The minimum number of nodes in the circuit.

- Relatively high efficiency factor.

- Uniform heating of radiators.

- Low cost of construction and installation work and equipment.

- Possibility of operation in natural circulation mode - when the pump is disconnected from the power supply, the water in the system circulates by gravity.

- Low efficiency of the system in houses with a large area.

Types of gas burners

Double-circuit wall-mounted boilers are available with an open type of gas burner and with a closed one. An open gas burner in a boiler requires the supply of the required amount of air for combustion of gas from the room where the gas boiler is installed. For example, the usual diagram of a typical gas water heater for heating water.

A device with a closed burner has an isolated space for gas combustion from the room. Air intake for the combustion process is taken from outside the building. Most often, such devices are connected using a coaxial chimney opening onto the outer wall of the building. It consists of two pipes located one inside the other. Combustion air is taken in through the outer pipe, and combustion products are removed through the inner pipe.

It is possible to connect with the release of combustion products into the provided chimney of the building and air intake with a lateral pipeline supply. Boilers with a closed burner are called turbocharged, as they have a built-in electric turbine-type air blower. The advantage of such gas appliances is their operational safety. Their work does not require constant monitoring of the air supply, ventilation of the room, and the entry of combustion products into the apartment or house is excluded. Due to excess draft, more efficient combustion occurs and water warms up faster.

Installation of a wall-mounted gas boiler.

Double-circuit gas appliances can be connected in boiler mode. This mode of operation involves heating water and its subsequent accumulation in the boiler, and from it the water flows to the water intake points.

Condensing gas heaters are distinguished by the fact that their design allows the water vapor contained in the gas combustion products to condense. During the condensation process, additional heat is released, which is used either for the heating circuit or for the DHW circuit. The scheme may involve the formation of condensation on a specially shaped primary heat exchanger or on an additional device that is located above the primary heat exchanger.

All double-circuit type gas boilers necessarily include an automation unit and control sensors for proper and safe operation. The automation monitors the specified water heating parameters in the circuits and can be used in conjunction with remote indoor air temperature sensors. Draft sensors and control of emergency shutdown of gas supply allow you to operate the boiler in the safest way.

For long-term use of a gas appliance, proper installation must be carried out, including power calculation, installation in accordance with safety standards, and high-quality commissioning operations.

Work on the installation of gas equipment should be carried out only by special gas services that have a certificate for its implementation.

Radiators for heating systems of high-rise buildings

Cast iron radiators, which have previously been used for decades, are familiar to many residents of multi-storey buildings. If it is necessary to replace such a heating battery, it is dismantled and a similar one is installed, which is required by the heating system in an apartment building. Such radiators for centralized heating systems are considered the best solution, since they can withstand fairly high pressure without problems. The passport for a cast iron battery indicates two numbers: the first of them indicates the operating pressure, and the second indicates the test (pressure) load. Typically these values are 6/15 or 8/15.

The higher the residential building, the greater the operating pressure. In nine-story buildings it reaches 6 atmospheres, so cast iron radiators are suitable for them. But when it is a 22-story building, then for the working functioning of centralized heating systems, 15 atmospheres will be required. In this case, steel or bimetallic heating devices are needed.

Experts do not recommend using aluminum radiators for central heating - they are not able to withstand the operating condition of the water circuit. Also, professionals advise property owners, when carrying out major renovations in apartments and replacing batteries, to change the coolant distribution pipes to ½ or ¾ inches. Usually they are in poor condition and it is advisable to install ecoplast products instead. Some types of radiators (steel and bimetallic) have narrower water flows than cast iron products, so they become clogged and subsequently lose power. Therefore, at the point where the coolant is supplied to the battery, a filter should be installed, which is usually mounted in front of the water meter.

Single-circuit and double-circuit heating systems

The main difference between single-circuit and double-circuit heating systems is in the movement of the coolant - in the first case, it moves sequentially and throughout the entire heating line, the return mixes with the hot coolant, which leads to a decrease in its temperature in each subsequent radiator. In the second case, there is a separate pipe for the return, that is, the coolant enters each subsequent radiator at almost the original temperature, which ensures more efficient use of thermal energy.

When choosing a particular system, you should carefully evaluate all the advantages and disadvantages, and also find out what difficulties you may encounter during operation or installation. Note that a one-pipe system will in any case be cheaper at the time of installation, and a two-pipe system will be cheaper during operation, so everyone can choose for themselves - momentary savings or long-term rational expenditure of funds.

What is a contour definition of different meanings

Most often, the word “contour” is used in its geometric meaning, which means the boundary of a flat figure. There are other meanings of this word.

What is an electrical circuit

From an electrical engineering point of view, a circuit is a simple closed circuit consisting of one or more branches connected in series. That is, a closed loop can be called any closed path that passes through the branches of the chain.

What is an information security loop?

CIB - information security loop - is a special software package that is used to control the leakage of corporate information and help detect attempts of unauthorized access to it. This complex was developed in Russia. It operates within the corporation's computer network, controlling its internal information space, as well as a wide range of communication channels.

What is a cartographic contour

In cartography, a contour is a line on a map that connects points of equal height. If the contours are located at a short distance from each other, this means that the slopes of the hill are very steep. Contours at a great distance indicate slightly hilly areas of the earth's surface, and the absence of such contours on the map means that this area is flat.

What is a ground loop

The ground loop is usually installed around the building along the perimeter of the walls. If you look at the ground electrode from above, you will notice that it is mounted along the contour of the object: that is why it is called a ground loop. In fact, it is a group of vertical electrodes that are connected by a horizontal conductor. Such electrodes are mounted near the object at a short distance from each other. The grounding element in such a device is usually either a steel corner or reinforcement (3 meters long). A steel strip measuring 4x40 mm is used as a connecting conductor. It is placed in a pre-prepared ditch half a meter deep. The conductor is connected to the ground electrode using electric or gas welding - gas welding.

What is a DHW circuit?

The DHW circuit is a closed piping system. The main element of such a system is a water-to-water heat exchanger. One of its circuits is used to circulate the heating system coolant (hot water), and the other circuit supplies cold tap water.

Naturally, the concept of “contour” can be found in other sciences, but having a general idea of what a contour is, you can guess their meaning on your own.

What is a home heating circuit?

The thermal circuit of a house made of laminated veneer lumber must be installed taking into account all the features of the difficult Russian climate - dampness, cold winter, wind. Every builder, if he is a professional, will say that the thermal circuit must be given great importance. If technology was not followed or material of dubious quality was used, no matter how good the walls were, such a structure will bring you many problems.

Agree that you don’t want your log house to be drafty and cold; no one wants high humidity at home. Of course, when you contact us, you don’t have to worry about this. Our wooden houses are not afraid of such problems.

What is actually included in the thermal circuit?

Firstly, this is the foundation, including the ground floor.

Secondly, these are the walls. Glued laminated timber is one of the best building materials; the walls of houses made from it do not crack or blow out.

Thirdly, these are windows. Windows can be either wooden or plastic. The most important thing is that the windows are reliable. It should also be noted that laminated timber has an important mission here. After all, laminated veneer lumber is subject to minimal shrinkage. Deformation of windows in houses made of laminated veneer lumber does not occur. They retain heat reliably and are an important part of the thermal circuit.

Fourthly, these are doors. As with windows, doors can be installed as tightly and correctly as possible.

The final component is the roof, as well as interfloor ceilings and internal partitions.

The concept of a thermal circuit does not include a terrace, veranda, garage, porch, carport and balcony.

Remember that the thermal circuit is the basis of the entire timber house.

Construction and cost of a warm circuit

Construction of the warm contour of the house is the main stage of construction. At the end of this stage, you already have a House in the generally accepted concept of this word. It has a roof, walls, windows, a door - a sealed outline of the house . Why is it called warm? Because now the building retains heat, it can be heated. Before proceeding to this stage, you need to clearly understand that you cannot leave the construction of a warm circuit unfinished. Therefore, you must correctly calculate your finances and agree in advance on the supply of necessary materials. So, at the input we have a project for the future house and the foundation. We begin the construction of walls.

Walls

But first the wall kit needs to be produced. The wall kit is prepared by the manufacturer within approximately 1-2 months. To begin production, it is necessary to conclude an agreement and make an advance payment. The walls of wooden houses can be made of the following materials: laminated veneer lumber, simple timber, dry profiled timber, chopped and rounded logs. Detailed information about each type of material is available at these links on our website. There is also information about methods for assembling walls of each material. About their pros and cons.

Roof of a wooden house

After assembling the walls of the house, it's time to start making the roof . This must be done without delay, so you need to take care of the materials in advance. You will need lumber with a thickness of 50 mm, 25 mm; waterproofing, vapor barrier, insulation, fasteners, roofing material, etc. All this will be in your estimate of materials. the roofing and roofing pie still be done by experienced professionals, because there are many nuances, pitfalls and tricks in this matter. The choice of roof type and insulation type depends on you.

Windows and doors

Windows and external doors can be installed immediately after roofing work is completed. It is clear that you need to order them in advance. There are some nuances to installing windows and doors in a wooden house. A competent installer must take into account the process of wall shrinkage. For a wooden house, both wooden and plastic windows are suitable

Floors

The ceilings between the first and second floors in a wooden house are also made of wood. For logs, lumber is usually used with a height of 150-200 mm and a thickness of 50-200 mm, depending on the span of the premises.

The ceiling

Is it possible to install a heating register in an existing furnace?

It would be more correct, of course, to build the furnace around the manufactured register. But, if the stove is already standing, you can still build a water circuit into it. True, you will have to try hard - they are of considerable size and must somehow hold on. So the task is not an easy one. In addition, do not forget that you will have to make two more conclusions - to connect the supply and return pipelines.

The best option is to make a water jacket under the shape of the stove (this one is for a metal stove with burners)

Finding a place to locate the register is also not very easy. Its direct contact with fire is very undesirable, but it should be in an environment of hot gases. In this case, you can hope that the heat exchanger will last a long time.

Main aspects

There are three main aspects that require special control during construction. This:

- Construction of load-bearing structures.

- Organization of the thermal circuit.

- Organization of roofing and gutters.

All other parts of the building can be modernized and remodeled during operation.

The thermal circuit is the basis of the internal climate of the room. To put it simply, a thermal circuit is a sealed box made of materials with low or zero thermal conductivity.

That is, along the entire perimeter of the walls, ceiling, floor and openings, holes in the insulation or the absence of a heat-resistant insert are excluded. And installed doors with windows tend to retain heat.

Only fibrous materials will be considered. The so-called "glass wool". These insulation materials have several types of density: soft, medium and hard. The material must be laid with overlapping seams of the previous layer.

For insulation, steam and wind insulation is used.

A special film that allows moisture to pass through in one direction and retains it in the other. The film also saves the cotton wool from being blown away by the wind.

The walls are insulated from the outside or from the inside. Inside, it is customary to use softer insulation from the middle density segment. The vapor barrier is attached on top and inside, respectively, with the moisture-resistant side facing out.

Special attention must be paid to the corners and junctions with the openings of windows and doors where the insulation in a full layer is brought close to the opening and connected to the door or window frame.

External insulation is made with denser medium-density insulation. The vapor barrier is placed only on top, the moisture-resistant side facing out. The situation is similar for windows and doors.

The ceiling can be insulated both from the inside and from the attic. The insulation here is soft and two layers of vapor barrier with the membrane facing out. The guide beams, depending on the material of manufacture, are wrapped only in film (wood), a thinner layer of insulation (concrete) and the same layer as the entire ceiling (iron).

The floor is insulated with dense grades of glass wool. The joists are wrapped or partially wrapped depending on the material. And the film is laid on top, with the moisture-resistant side facing out.

The most important aspect! Always ensure tightness! Along the entire perimeter and openings, the insulation is connected to the thickness of the entire blanket!

Building foundation (ground floor)

Heat loss through the foundation can reach 20% of the total heat loss, so its insulation is of great importance. By using thermal insulation, you can protect walls from freezing, prevent the formation of condensation, and reduce the influence of frost heaving forces.

And most importantly, it is possible to ensure a positive temperature inside the basement premises in winter, even in the absence of heating there.

House walls

The thickness of the walls is determined on the basis of thermal engineering calculations, which take into account the material, climatic conditions, integrity of the walls, the required humidity inside the room, the purpose of the building and the features of its design (number of floors, type of floors, etc.);

Doors

For this element, the quality of installation is of paramount importance; there should be no large gaps or cracks between the box and the canvas. And the gaps between the frame and the walls must be insulated. The door material is selected based on safety considerations, climatic conditions and aesthetic requirements.

Interfloor ceilings and internal partitions

Interfloor ceilings and internal partitions create additional thermal insulation between warm and cool rooms, retaining heat.

Roof

When constructing a roof, the “pie” principle must be observed, i.e. The following layers must be present: roofing material, counter-lattice, waterproofing, insulation, vapor barrier.

Window

Modern technologies using double-glazed windows can significantly reduce heat loss through these components of the thermal circuit of the house. True, this does not negate the use of traditional wooden windows with ordinary glass; in this case, you just need to pay decent attention to their quality and insulation in the cold season.

Vulnerable unfinished

To begin with, we note: the term “thermal circuit” is not fixed in regulatory documentation; it is a concept from construction practice. But the concept is very comprehensive, which is why experienced builders of individual houses use it.

In the initial stages of construction, the foundation of the building is constructed and load-bearing walls are erected, forming the basis of the so-called thermal loop, which then needs to be “closed” to preserve what has already been built. Any unfinished building is vulnerable to external influences: a freshly built wall can begin to rot, crumble, absorb moisture and ultimately lose its properties. And the foundation may gradually lose its load-bearing capacity, and in this case it is unsafe to live in the house.

The biggest threat to an unfinished house is our unkind climate. In summer (if you're lucky with

weather), the box can still stand without much damage, but in the fall or winter such a standstill entails a number of negative consequences. And all wall materials behave differently. Trees are more afraid than others of atmospheric moisture, under the influence of which they can rot and lose strength. Brickwork and concrete monolith are more resistant to rain and snow, but aerated concrete also does not like moisture. An unprotected wall made of aerated concrete absorbs it intensively and is partially destroyed and loses some of its mechanical properties when water freezes in the pores.

However, any building should not remain open to all weather conditions during the autumn-winter period. It should be protected - a set of works should be performed to close the circuit.

Complex of works

To protect from rain and snow you need a reliable roof. That is why, after erecting the walls, you should, without delay, install a rafter system, and lay the selected roofing material on it. Moreover, it is necessary not only to lay the roof, but also to close all technological holes in it.

Many engineering systems, without which a modern house cannot be imagined, require chimneys, ventilation risers, antennas, etc. to be brought to the roof. When a riser or chimney is installed, the sealing of the roof outlet is ensured by the installation technology itself - what if the house is unfinished? In this case, at the stage of closing the circuit, it is necessary to carefully seal the technological holes in the roof, since both moisture and cold wind easily penetrate through them.

Uncontrolled flows of water on the roof are also not the best option. And if the roof is already installed, then it is advisable to install a drainage system. In this case, prolonged autumn rains, which are not uncommon in our region, will not harm the building.

It is also better to install door and window units before the onset of slush and cold weather. If double-glazed windows are not inserted, then reliable sealing of the openings is necessary. For this, thick plywood, OSB boards or other materials are used. Sometimes protective roller shutters are also installed, but they are not included in the mandatory list.

Plastering, painting and tiling work on the facade requires a separate discussion. Here the need for one or another is dictated by the choice of building material. For example, it is advisable to cover the facade of a box made of aerated concrete before the building is mothballed. In extreme cases, the surface can be treated with a hydrophobic solution to protect it from moisture.

If it is possible to protect a brick wall with plaster, it is worth doing this before the onset of cold weather. Although the brick, we note, survives the cold months without much damage. Wooden wall materials with natural humidity also tolerate winter well. Moreover, log houses made of such materials even have to stand for several months for the shrinkage processes to complete. During this period, wood can be treated with antiseptics and water repellents.

The thermal circuit includes a finished foundation and walls, installed windows and doors and an airtight roof. Some builders include internal walls and partitions in it, others believe that the filling of the house is arranged at the next stage of construction. The same can be said about insulation. Some people believe that closing the thermal circuit involves insulating the external walls, while others are postponing this operation.

Thermal contours of houses made of different materials may differ. For example, in a house made of chopped logs, when closing the thermal circuit, you will have to lay a rough wooden floor. But for a brick or aerated concrete box this is not necessary. One of the subtleties is that you should not completely seal the building (oddly enough) for the winter. Ventilation of the internal space must be organized to prevent the accumulation of moisture and the formation of ice with its subsequent melting. Such ventilation should not be spontaneous so that the winds can flow freely inside, but air exchange with the environment must be established.

When the contour is closed correctly and the interior space of an unfinished house is reliably protected from atmospheric influences, the building will stand until the next season with virtually no damage. The main goal of these measures is to eliminate or at least minimize damage to the load-bearing structures of the house.

Separately about communications

At the stage of general construction work, internal communications, as a rule, are not installed. Only external communications are provided and, in some cases, brought inside the building. However, it is necessary to take into account the presence of utility networks in the house, including during circuit closure.

The outlets of chimneys and ventilation risers to the roof have already been mentioned. However, there is also running water and sewerage. In an unfinished box, these communications do not function, but the entries of external pipelines are usually already made. A main water supply pipe can be inserted and temporarily plugged, as well as a sewer pipe laid to the septic tank on the site. And all these inputs should be carefully sealed. The septic tank also needs to be protected from external influences. Then in the new season the installation of water supply and sewerage systems will take place without problems.