Achievements of Russian railway technology

Greetings, our dear reader! Today we will have an unusual article, the topic of which is a diagram of the water supply system of a passenger carriage. For most of you, this information will be, so to speak, for general development, but we guarantee its accuracy and reliability, so it can also be useful to students.

The purpose of the water supply system, its main components

Water supply in passenger cars: diagram for car 61-4179

Sanitary equipment, which is the water supply system for carriages, helps to ensure the necessary conditions of hygiene and nutrition for people during long trips.

Each carriage is equipped with such systems, so passengers are provided with drinking water and water for other household needs. The system is periodically refueled when the train stops.

- Each carriage is equipped with heating and cooling devices. Water is supplied to the toilets, washbasins and dishwashers, which are located in the service area.

- The volume of the entire system in liters is 1200, based on the calculation that no more than 20 liters per day should be consumed per passenger, despite the fact that the system is replenished every 12 hours.

- The plumbing system is gravity-fed, which applies to both hot and cold water.

Passenger reserved seat carriage

Despite the fact that the cars often have different dimensions and structure, the water supply system in them is fundamentally no different.

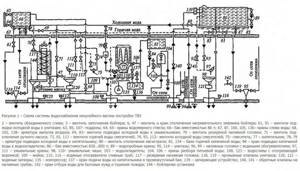

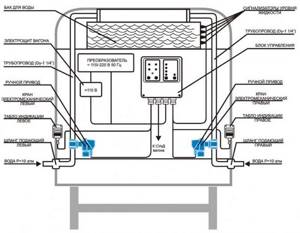

Water supply for TV3 car

We will consider the water supply system for passenger cars using the example of a non-compartment car TV3.

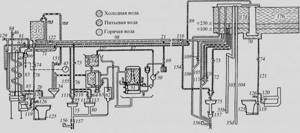

Above is a diagram in which we see:

- Small and large water storage tanks (66 and 86, respectively) - provide the system with cold water. They are spaced on different sides of the car for uniform distribution of liquid. To ensure pressure in the system, the tanks are located under the roof of the car.

- 96 and 99 are filling pipes and filling heads through which containers are filled.

- A network of pipes runs through the entire car , through which cold and hot water circulates.

- The system also contains trays (63, 85, 107) designed to collect condensate and water.

Water supply for passenger cars: boiler for heating water

- Sink (109), boiler (77) and device for cooling cooling water (103);

Car bathroom

- Water disinfectant , a tail pipe, fittings for releasing air from the system and many tap valves.

Now let's talk about all this equipment in more detail.

So:

- A large tank with a capacity of 850 liters is located behind the ceiling of the toilet and corridor at the non-boiler end of the car.

- A small tank with a capacity of 80 liters is above the toilet on the opposite side.

- Two welded pipes approach the body of the large tank, through which the system is filled. These pipes are equipped with shut-off valves to prevent water from splashing while the train is moving.

- There is also a pilot pipe located there, which serves as an overflow when refueling the system, that is, it prevents the tanks from overflowing.

Car water supply diagram: rear view

- The small tank is equipped with a pipe for air outlet, as well as a water meter glass, which allows you to control the level of filling of the tanks.

- Drain valves are installed on the tanks. The drainage occurs into trays through which the liquid goes under the car.

- The large tank is additionally equipped with a tap, which is also located behind the ceiling. It allows you to completely block the highway.

Filling the system

Cold water supply system for passenger cars: water is supplied to the system under a pressure of 10 atmospheres

The tanks are filled with water from the bottom of the car. The supply hoses are connected to the filling heads, which can be seen in the photo above.

Interesting to know! In winter, the heads can freeze, so they are preheated with hot water from the car's heating system.

- Pouring water into a cooled car at an ambient temperature below zero is carried out only after it has been kept in a closed heated room for 24 hours, or after starting the heating system of the car and warming up the air in it to +12 degrees.

- When filling the system, the following taps and valves must be opened: 61,91,69,83 - installed on the water connections to the toilets and washbasins; 68 – valve for air release; 64.65 – taps on water meter glass; 71 – valve for connecting to a hand pump; 78,79 – valves on pipes leading to the boiler; 80 – valve that turns off the main line; 3 – valve for filling the boiler; 140 and 141 valves installed on the filler pipes.

Train at the station

- Even before approaching the station where the system will be refueled, information is taken from the TEM (train electric mechanic) about whether the alarm system that monitors the end of filling is connected.

- If everything is functioning properly, the switch located on the control panel in the service compartment is switched to the “on” position.

- Filling of water will stop when the signal lamp, which is located next to the filling heads, lights up (only on cars equipped with an alarm), or when water appears from the leading pipe and the second filling pipe.

- To prevent water from spilling onto the railway track, a locking device 139 is used. On the side of the filling pipe, the leakage is controlled by filling valves.

Operating trains in winter always presents unforeseen difficulties

In cases of icing of the filling heads or failure of the heater, the system can be filled through a spare filling head (117). It is located in the boiler room near the reserve tank, which means it cannot freeze. With this filling method, an inventory hose is used, which is about 4 meters long.

If such refueling is carried out, the following measures are taken:

- The reserve head valve (70) closes;

- The inventory hose, one side is connected to the reserve head, and the other is led outside through the door and connected to the hose from the water stand located on the tracks.

- Afterwards, it is necessary to open the shut-off valve 70, and the water supply begins, during which you need to ensure that there are no leaks at the junction of the hose with the head.

- As soon as the large tank is completely filled, valve 70 closes, after which the flow of water through the column stops. The hose is disconnected and valve 68 is opened.

The position of the remaining taps and valves is similar to filling through the main filling pipes.

Draining

The cold water supply system of a carriage in a simplified form

To completely drain the water from the system, it is necessary to open all valves and taps. Its instruction manual explains how to drain liquid from a boiler.

- If it is necessary to empty the tanks, hoses are connected to them, which are stretched to the toilets, through which the flush occurs.

- For partial drainage of water, the following are used: mixer (75), toilets (95 and 114), taps (97 and 111).

- If the heating boiler stops operating (at sub-zero temperatures), the water from the water supply system must be drained before draining the water from the heating system.

Water supply systems for passenger cars.

Rice. 1 reserved seat carriage

| Large tank on the non-working side, volume 850 liters |

| Small tank on the working side of the car, volume 80 liters |

pipeline connecting tanks

| water meter glass |

| air outlet pipe |

| drain valve |

| wash basin | toilet | boiler | washing | boiler | boiler |

| filling pipes |

| control pipe |

| drain valve |

Note:

· Under the tanks there are trays for collecting condensation from the tanks.

· The water meter glass is designed to check the level of filling of the car's water supply system with water.

· The drain valve is designed to drain water from the system.

· With the help of filling (filling) pipes, the water supply system is refueled, and water splashing out of the tank is prevented while driving.

· The boiler unit, located in the boiler room, serves to produce hot water for the washbasin and sink.

Rice. 2 Compartment carriage

| 1. Large tank on the non-working side, volume 500 liters |

| 2. Large tank on the non-working side, volume 500 liters |

| Small tank on the working side of the car, volume 50 liters |

pipeline connecting tanks

| water meter glass |

| air outlet pipe |

| drain valve |

| wash basin | toilet | boiler | washing | boiler | boiler |

| filling pipes |

| control pipe |

| drain valve |

| water testing tap “ 250 liters ” |

| water test tap " 100 liters " |

| toilet | wash basin |

Note:

On the non-working side of the compartment car there are water testing taps: 250 and 100 liters, which are designed to determine the water level in the water supply system of the compartment car. If when opening the tap “ 250 liters

“water does not flow, this means that there are less than 250 liters of water left in the car’s water supply system.

It’s the same with the “ 100 liter

” tap.

Filling the water supply system with water.

Produced at formation and turnover stations, as well as at stations equipped with water filling stations. The system is filled from below, from under the car, through the filling heads of the filling pipes (the water filler connects the filling hoses from the water dispensers to the car). The conductor controls the filling of the system through the water meter glass of a small tank (for reserved seat cars), or through the opposite filling pipe of a large tank (water is poured out between tracks). When the large tank is filled from the non-working side of the car, water flows into the small tank through a pipe connecting the tanks, and then to consumers.

Draining water from the water supply system.

It is produced through mixer taps of washbasins, toilets, sink taps or drain taps of small and large tanks.

4. Main consumers of the water supply system:

– Washing in the service department.

Consumer faults and ways to eliminate them:

1. Water leaking through the toilet flush valve

– spring break or subsidence, valve seal wear

– absence of a gap of 2..3 mm between the valve stem and the pusher rod associated with the toilet flush pedal

2. The toilet does not flush; when the lever is pressed, it does not go down

– malfunction of levers, parts of the flushing mechanism

3. Water leaking from the ceilings of toilets and corridors

How does a hot water supply system work?

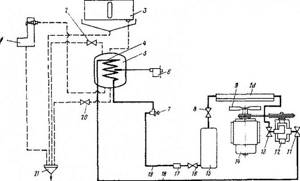

Diagrams of car water supply systems: drawing of a boiler installed in passenger cars

Hot water supply in compartment cars is a system consisting of a boiler (boiler) 144 installed in the boiler room and a pipeline through which water is supplied to water collection points.

- The boiler unit itself is intended not only for heating water, but also for cooking, therefore it is equipped with a stove and a spare tank.

- The system can operate in two modes (winter and summer). In winter, the water in the boiler is heated by water circulating in the heating system. It enters the coil from the boiler, and valves 47 and 6 open.

Boiler and his wonderful operator

- The stove is heated by solid fuel (wood, coal).

- In the warm season, when the boiler is turned off, the water is heated by the heat generated by burning fuel in the stove, and valves 47 and 6 are closed.

- When heated, water enters the boiler from the water supply system through taps 79, 78 and 105 (the latter is a three-way valve).

- The heated water is dispensed through tap 106.

- Through the tank 81 with boiled water, the liquid flows into the cooler, which is also equipped with a tank from which a drain valve (100) and an air release valve (102) lead.

- Cooled water is dispensed through a tap (104), which is installed in a niche in the corridor, on the boiler side.

Cold and hot water also flows to the wash bowls and sink. Cold water is also supplied to the toilets through valves 118 and 119.

Filling the water supply system of a passenger car with water and draining water from it

It is carried out outside the car through filling pipes with connecting heads.

The conductor is obliged to determine the amount of water in the system 5-10 minutes before arriving at the water filling station and turn on the water filling alarm on the remote control. When the train stops at a station, warn the outfitter of the need to refuel. Check the filling process. When draining water from the system, you need to open all valves and taps and drain the water from the boiler. Check the presence of water in the system in our carriage in the toilet on the working side, look at the water meter glass of the small tank. In German from the non-working side

The principle of operation and design of the hot water supply system of a passenger car

The hot water supply system consists of a boiler unit located in the boiler room and a hot water piping system. A boiler installation designed for heating water and cooking food consists of a boiler, a stove and a reserve tank.

The hot water supply system operates in two modes - winter and summer. In winter mode, when the heating system boiler is operating, the water in the boiler is heated by the hot water of the heating system entering the coil directly from the boiler. In this case, the valves must be open.

In summer mode, when the heating system boiler is not working, the water in the boiler is heated by the heat generated by burning fuel in the firebox of the stove. In this case, the valves must be closed. The stove is fueled by wood or charcoal.

Wash bowls are supplied with cold and hot water respectively through taps and 93, 92, and washing through taps. Cold water flows to the toilets through flush valves. The combined flush valve and the boiler fill valve are involved in the operation of the heating system.

Design and principle of operation of a combined boiler

Boiler structure : body

, at the bottom of which there is

a firebox

with a door and

an ash pan

with a door.

Inside the firebox there are grate bars

and

a flame arrester

.

two flasks inside the boiler

: for raw water (9 l) and for boiled water (17 l);

with a water measuring glass

, through which the boiling of boiled water is observed. There are two marks on it - 15 l and 17 l. The water gauge glasses have valves at the bottom to shut off the water gauge glasses in case they break.

Installed on the body of the boiler: a collapsible titanium tap

;

alcohol thermometer

;

three-way valve

- for draining raw water from the boiler, has three positions: raw water;

closed; boiled water; a filter with a settling tank

for purifying raw water from mechanical impurities;

raw water supply regulator

(inside of which there is

a float

(metal), on the float there is a lower needle that goes into the tube and an upper needle with a valve attached to it - to block the access of raw water to the boiler).

According to sanitary standards, it is required to rinse the raw water flask once every 5-6 days - fill and drain at least 2 times. If boiled water has stood unused for more than 12 hours, it is not recommended to use it for drinking - drain it.

Source

Possible faults

The more devices there are, the more often repairs to the water supply system of passenger cars are required.

Malfunctions of the water supply system of a passenger car are not such a rare thing, and they occur mainly due to the constant vibration of the car while moving. The tightness of all connections is disrupted and, over time, cracks appear in the boiler, tanks, and pipes, despite the absence of strong pressure.

- In addition, rubbing parts such as valves, plugs and valves constantly wear out. There is no escape from corrosion either. As a result, leaks appear in different places in the system.

- Other malfunctions include: sticking of the toilet flush pedal, malfunction of shut-off valves, boiler, cooler, wash bowls and other things.

- All breakdowns are identified during car maintenance.

- Troubleshooting is carried out by special teams during scheduled repairs (depot and overhaul) and uncoupling repairs.

- Repair and maintenance are reduced to restoring the integrity of damaged parts and sealing joints.

During scheduled activities, the system is additionally flushed with drinking water.