Everyone knows: in the professional kitchen of a cafe, restaurant or even an ordinary dining room, the chef is the king, God and simply the leader and organizer of the entire process. And his tasks include preparing a wide variety of dishes in parallel with each other. And what to do with the fact that fish soup is being prepared nearby and pork is being fried, honey wings are simmering and the pie is finishing baking? After all, during the mixing process, odors can spoil the next dish, undoing all the efforts of the cooks.

In addition, grease and burning particles rising into the air can settle on the walls, contaminate the tiles, spoil the ideal picture of a beautiful, clean and tidy kitchen, and also significantly complicate the life of the cleaners.

There is another important reason why it is simply necessary to install an exhaust hood in the kitchen. And it lies in the need to maintain the cleanliness of the ventilation duct. Believe me, cleaning it when it is dirty and does not remove air from the kitchen well is much more difficult than purchasing such cleaning equipment once.

In fact, the solution to the problem is very simple: HICOLD exhaust hoods are used to solve all these problems.

Classification by materials

Air ducts for exhaust system equipment are made from various materials. To determine which one is best to choose for a particular case, you need to study the characteristics of all units on the market.

Plastic structures

Today, plastic air ducts for kitchen hoods are considered the most popular. They come in round and rectangular shapes. The latter look quite aesthetically pleasing and neat. In turn, the installation of round products is easier and faster (in such situations it is not necessary to use adapters to connect the air duct to the hood). The main advantages of plastic products:

- rust resistance;

- ease of assembly;

- low cost;

- smooth inner surface minimizes the risk of accumulation of fat and other contaminants;

- light weight, which makes installation much easier;

- absence of noise during operation of the hood.

Steel and aluminum units

Aluminum products take second place in the popularity ranking. This material is also used to make structures for ventilation system equipment. Main advantages:

- aluminum is a simple and versatile material;

- products are cheap;

- quick and easy installation;

- designs are resistant to high temperatures.

However, aluminum air ducts, like any other product, have a number of disadvantages. Some of them:

- The material has high thermal conductivity. In a room where an aluminum air duct is installed, condensation often accumulates.

- Unpresentable appearance. Often, such units are hidden in kitchen cabinets or disguised using special boxes.

- Aluminum is not very durable and can be subject to deformation due to mechanical stress.

It is not uncommon to see steel air ducts. In most cases, galvanization or stainless steel is used for the manufacture of such structures. If we talk about home use, galvanized products have performed well here.

However, it is important to note that such units are no longer as popular as they used to be. Every year, steel air ducts become less in demand

The main advantages of such models:

- Relatively cheap.

- A flat base that does not interfere with the passage of air flow. In addition, dust deposits and soot do not accumulate in smooth products.

- Steel products are not subject to deformation under high temperature exposure. In addition, no harmful substances are released into the environment.

Some cons:

- for mounting on walls, the most stable and reliable fixing elements are required;

- to assemble a non-standard air duct, you will need to additionally cut metal pipes;

- heavy weight (especially compared to plastic structures), so it will not be possible to carry out installation yourself;

- To seal the channels, the use of special means will be required;

- During operation there is a lot of noise.

Materials for making a kitchen hood

Two types of steel are used to make a kitchen dome:

- stainless;

- galvanized.

The thickness of the material varies from 0.5 to 1 mm.

Both types of material are hygienic and resistant to aggressive environments. At the same time, galvanized steel will cost the buyer a little less than stainless steel. The anti-corrosion properties of a galvanized steel exhaust ventilation hood are imparted by a thin layer of zinc on top. In addition, such elements can be painted in any color.

Stainless steel equipment has improved performance characteristics:

- not afraid of deformation;

- has no cracks or metal pores, and is not prone to the growth of bacteria on the internal walls.

To make stainless steel umbrellas, two types of steel are used:

- AISI 430. This is ferritic steel that is resistant to temperature changes. Umbrellas made of this material can have a matte, mirror or polished surface.

- AISI 304. Low carbon steel. Resistant to aggressive environments (acids, alkalis) and extremely high temperatures. Often withstands up to +900 degrees. Therefore, stainless steel ventilation umbrellas are more often used in the food industry, catering establishments and chemical laboratories.

Both types of material are not subject to corrosion.

Forced ventilation

The principle of forced ventilation in a private house is used in those rooms where natural ventilation is not able to fully ensure the flow of fresh air. Such rooms are in constant contact with a large amount of moisture, where fungus and mold can form - these are the kitchen, bathroom, basement and boiler room. Such ventilation is installed to remove unpleasant odors and excess moisture from rooms using fans and forced exhaust hoods.

You can regulate the flow of fresh air using a special device called a supply valve. In addition to the main function, it has the following advantages:

- Minimizes noise from the surrounding world;

- Provides air filtration;

- Provides thermal insulation of the housing, which reduces the likelihood of freezing and condensation;

- The ability to regulate the operation of the device with your own hands.

Each ventilation duct for a home will require additional installation of this device. In extreme cases, you can get by with just one valve, provided there is centralized ventilation.

The functioning of the valve depends on the temperature difference between the room and the outside world. During the operation of forced exhaust, adjustment is carried out manually.

To install a forced ventilation system with your own hands you will need:

- Calculate the required air exchange. The air exchange rate is taken at the rate of 10 m³ per hour per person;

- Determine the installation location of the equipment (dry utility room);

- Mark the location of the holes for air inlet and outlet.

For air ducts, flexible, usually plastic, pipes are used, but aluminum ones are also suitable. Using fasteners, channels are routed throughout the rooms of the entire house above suspended ceilings. And the outlet of the air duct pipes is covered with ventilation grilles.

Openings for air supply and exhaust are located in opposite corners of the room. A pipe is inserted inside the hole and covered from the outside with gratings. A check valve is installed from the inside. The supply and exhaust unit is fixed in the selected location, and ventilation ducts are connected to it using metal clamps.

If a supply and exhaust ventilation system is used in a private house, its performance can be improved by installing a recuperator. Recuperation systems immediately, through one hole in the wall, remove exhaust air and supply fresh air. This is an ideal solution if you have taken care of ventilation after renovation or if you need to solve the problem only in some rooms. The main thing is that these rooms have at least one wall facing the street.

The most suitable ventilation system for a private home is considered to be supply and exhaust ventilation.

Where the supply and removal of air is forced. A house with an effective ventilation system will ensure long-term operation of the housing structure and maintain a healthy microclimate for the whole family

Therefore, it is important to make the correct calculation of the project and select reliable materials.

For more than 10 years, it has been supplying high-quality building materials and rolled metal products at competitive prices and with the possibility of delivery throughout the Irkutsk region, Buryatia and the Trans-Baikal Territory. Rolled metal and building materials from UralSibMet will guarantee the reliability of your home.

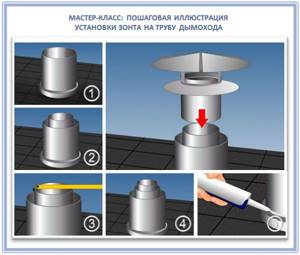

Installation

To install a ventilation umbrella, you can use 4 methods:

- to Wall. In this case, you need to screw anchor bolts into the wall and hang the umbrella on them. Be sure to make sure the fastenings are secure;

- to the ceiling. Anchor bolts are also used here. In this case, the exhaust structure itself is placed directly at the ceiling;

- on a chain. This method of placing an umbrella is used if you need to install an exhaust device closer to the working equipment. However, it does not make it possible to make a stable structure;

- on a metal frame. A support is made from a metal corner and pipes, which is fixed to the floor. An umbrella is attached to it.

Only a specialist can choose the right ventilation system and understand sales racks and other equipment. Therefore, be sure to consult with the seller before purchasing.

Kinds

All existing kitchen umbrellas differ in several ways:

| Purpose | Can be domestic or industrial |

| Installation method | There are wall and island types. |

| Shape | Can be rectangular, square or round. |

| Device | As mentioned above, different models may have some design differences. |

Next, we will take a closer look at the features of each type of these devices.

Household ventilation round umbrella

Household and industrial hoods

An industrial exhaust hood for ventilation is in many ways similar to household hoods.

The difference is only in a few points, such as:

- Size – industrial devices have much larger dimensions, since they cover the area of industrial furnaces.

- Fan power is significantly higher.

- Filters - industrial hoods have special grease traps, from which the settled impurities flow into a special glass. Such a drive must be periodically emptied and washed with soapy water. Household devices, as a rule, have paper and fiber disposable filters.

It must be said that the differences between industrial and household hoods are sometimes not very pronounced. For example, in cottages they often install devices whose characteristics are very similar to industrial hoods.

Wall design

Installation methods

As mentioned above, there are two types of hoods according to the installation method:

- Island ventilation umbrellas - suspended from the ceiling. Often installed above kitchen stoves located in the middle of the room. As a rule, such devices contain several rows of filters.

- Wall-mounted – as you can easily guess from the name, they are mounted to the wall. Such structures are often installed above kitchen stoves located near the wall. Installing such a hood with your own hands is quite simple.

These are, perhaps, all the main differences between local exhaust systems, knowing which, you can choose the most suitable device for a given case.

How to make it yourself

Making an exhaust hood for a pipe is a simple and simple process. Before you start work, you should choose a diagram and take the dimensions of the pipe itself.

Schemes and sizes

On the Internet you can find a huge selection of schemes for installing a roof ventilation hood. Before you begin, be sure to read the size chart used in the diagrams.

Before you begin, we recommend making a paper model and checking the dimensions for consistency.

We bring to your attention one of the simplest umbrellas, which consists of a cylindrical base, a cone-shaped roof and three holder legs.

Preparation of material

An important element of any job is preparation. To make it you will need:

- galvanized steel sheet,

- sheet of cardboard,

- pencil,

- ruler,

- compass,

- metal scissors,

- bolts and nuts or rivets.

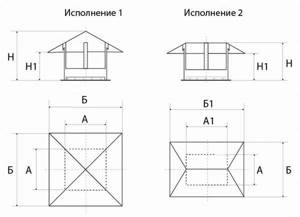

Design selection

We propose the two simplest designs, and show them in the figure (Fig. 1). The difference between these schemes is the shape of the roof that will be made. Depending on the chosen pattern, use the following dimensions:

Execution 1.

| A | B | N | H1 |

| 25 | 45 | 24 | 15 |

| 50 | 90 | 40 | 25 |

| 100 | 180 | 81,1 | 53,8 |

Execution 2.

| A | B | B1 | B2 | N | H1 |

| 25 | 45 | 40 | 72 | 40 | 25 |

| 50 | 90 | 80 | 144 | 93 | 63,8 |

| 80 | 144 | 100 | 180 | 99,5 | 63,8 |

You select the size based on your pipe, we give you the main dimensions, if you could not find a suitable one, use another diagram (you can easily find it on the Internet).

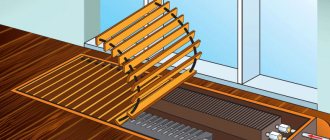

Design and installation features

According to the type of design, exhaust hoods can be wall-mounted or island-mounted. Wall-mounted models are mounted directly on the wall, directly above the work surface. Island ones have a more complex design, as they are attached to the ceiling and hang over the equipment located near the center of the room, away from the walls. The wall dome has one row of filters, and the island dome has two.

If the wall-mounted umbrella has significant weight and dimensions, additional pendants, brackets and chains are used to assist in fixing the device. To give the structure rigidity and stability, its shape is given a trapezoidal profile. This allows you to increase the maximum permissible area of the dome for hanging over large equipment.

Island-type ventilation units provide air circulation in a much larger volume than wall units. Therefore, they are excellent not only for forced air ventilation in the center, above objects distant from the walls, but also for ventilating the entire volume of the room as a whole.

The quality and stability of the ventilation dome operation depends not only on the choice of its type and modification, but also on the correct installation of the unit above the work area. The exhaust structure must be suspended exactly above the location of active kitchen, industrial or laboratory equipment that pollutes the air: cookers, deep fryers, fryers, burners, containers with chemicals, etc. It is necessary to ensure that the centers of the umbrella and the active surface coincide.

For ordinary kitchen appliances, a couple of centimeters of difference is enough, but for larger installations, standards require increasing the dome size by 10 cm or more. The height of the structure’s suspension above the working surface should be from 70 to 110 cm.

https://youtube.com/watch?v=XQ6_C_YpyWc

Advantages and disadvantages

Stainless and galvanized exhaust hoods have a number of advantages:

- resistance to wet environments and corrosion;

- inertness to temperature changes;

- resistance to mechanical stress, no deformation even despite the small thickness of the sheet;

- heat resistance;

- relatively light weight without the risk of weighing down the ceiling or wall.

- inertness to aggressive media (acids, alkalis, etc.).

A relative disadvantage is the need to regularly replace grease traps. But without them, the ventilation system will not work fully.

Why do you need a deflector?

For a better understanding of the issue, we present data from reference literature. The magnitude of local resistance to air flow in ventilation systems is characterized by the dimensionless coefficient ξ. The greater its value, the stronger the shaped element - umbrella, elbow, gate - slows down the movement of gases through the pipeline.

In relation to our cases, the coefficient is:

- at the exit of the air flow from an open pipe of any diameter ξ = 1;

- if the channel is covered with a classic cap, ξ = 1.3–1.5;

- a Grigorovich umbrella with a diffuser (section expansion) is installed on the pipe, ξ = 0.8;

- Volper nozzle is cylindrical or star-shaped “Shenard”, ξ = 1;

- TsAGI type deflector, ξ = 0.6.

So, a deflector is a nozzle that, under the influence of wind, creates a vacuum at the outlet of the vertical ventilation duct and thus reduces the aerodynamic resistance to the flow. That is, it acts as a traction amplifier.

In addition, the exhaust device solves the following problems:

- protects the air duct from precipitation;

- does not allow the wind to blow inside the pipe;

- prevents the occurrence of reverse thrust (overturning).

The operating principle of any deflector is based on two effects: vacuum from the wind load and ejection (entrainment) of a slow gas flow by a faster one. Although some foreign manufacturers implement mechanical incentives - they simply equip the umbrella with an electric fan. Let us consider the structure of each design separately.

From this angle it is clearly visible that the cross-section of the lower nozzle pipe does not decrease, which means that the speed and pressure of the gases does not change

How to choose an umbrella

When choosing an umbrella, you should consider the size of the equipment over which it will be installed. There is a rule that the hood should overlap the hob by at least 10 cm.

The standard width of hoods is 50, 60, 70, 90 and 120 cm. Umbrellas of other sizes can be made to order.

The second point that you should pay attention to is the noise level of the exhaust equipment. The greater the power of the hood, the more noise it produces, and for humans a noise level of up to 40 dB is considered acceptable. Sound-absorbing devices, which manufacturers equip some models with, help cope with the problem.

Hoods are often equipped with lighting and act as a source of additional lighting for the kitchen.

If the hood is installed high, it requires a remote control. The price of this equipment will be higher, but the ease of use compensates for the financial costs.

When choosing an umbrella for a chimney pipe, you should take into account the size of the pipe itself, because the head must overlap its edges. The umbrella itself can have any shape. It is also necessary to pay attention to the equipment with additional structural elements (drip cap, fixing parts and protective mesh).

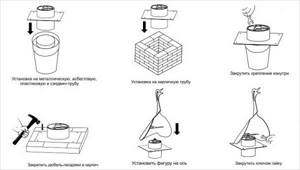

Basic installation rules

The installation of a smoke hood directly depends on the design features of the additional element and chimney pipe, as well as the material used in manufacturing. Based on standard rectangular sheet steel, the easiest way to create a tetrahedral pyramidal umbrella is by bending the sheet of material a couple of times in a diagonal direction.

This option is traditional for arranging chimney pipes on hipped roofs, but to attach racks and further installation it is necessary to use additional elements in the form of corners, as well as drill holes.

Wind vane installation

Simple vaulted umbrellas with a minimum number of folds and cuts have a less complex design. Fixing such a smoke umbrella on an oval chimney pipe is carried out due to the presence of racks bent from sheet steel of sufficient thickness or made using standard metal corners.

Regardless of the manufacturing method, racks can be fixed in several ways:

- on metal and asbestos chimneys, you can use a metal clamp or make a regular wire frame yourself;

- the wire for the frame base should be as strong and reliable as possible;

- mounting holes are drilled in the racks;

- the outlet parts of the twisted wire frame are passed through the mounting holes on the racks and twisted until the smoke umbrella is completely fixed.

On brick chimneys, even standard galvanized nails of sufficient length, implanted directly into the masonry, can be used to fix the umbrella. However, as practice shows, it is best to drill holes in the brickwork using pre-drilled holes in the umbrella posts, and then secure the cap to the chimney pipe with steel pins or galvanized screws.

Umbrella installation

In this case, if necessary, you can quickly and with minimal effort dismantle the umbrella yourself for cleaning or replacement.

CAREFULLY!

It should be remembered that when using a gas system as an autonomous heating system, it is strictly not recommended to install an umbrella on the chimney pipe.

What is the difference between an umbrella and a weather vane, cap, head and chimney?

There are several types of products that are installed on the pipe. They differ in their structure and operating principle. The main ones can be distinguished: umbrella, weather vane, cap, head and chimney. We have already discussed what an umbrella is, now let’s define the remaining concepts.

A weather vane is often a decorative element, in the form of a bird or a dragon. The weather vane is designed in such a way that it has a rotating element, that is, it rotates from the wind currents. Its main purpose is to enhance the removal of air from the chimney, that is, to increase draft.

A chimney is, in common parlance, any device that decorates a pipe.

A cap is a device that is customarily used to decorate and protect the neck of the pipe, that is, it is a kind of continuation of the chimney. Attached to the outside of the pipe using brackets.

Head - this device is the most complex in its design. Because the cap is not just the top of the pipe, it is a complex of absolutely all elements designed to protect the chimney. The headband is quite difficult to make on your own, but you can find a large selection of designs in a specialized store.

As you and I see, each device has its own purpose and functions. Additionally, they differ from each other in appearance and cost.

Varieties based on operating principle

The difference between modern exhaust devices can be traced in the very principle of their operation. Despite their multifunctionality, hoods are used for strictly defined purposes.

For example, a snail hood is an excellent option for cleaning rooms in country houses with no ventilation system. Such models are also used for industrial purposes, when the question arises of cleaning large areas with a high degree of pollution.

In the kitchen it is better to use forced exhaust, but even here it is important to understand that the optimal cleaning method is determined taking into account the nature of the equipment used

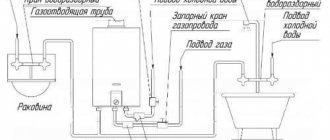

Attention! In addition to exhaust hoods for gas and electric stoves, hoods for gas water heaters are also widely available, solving the issue of air ventilation in isolated rooms.

Standard types of kitchen hoods, depending on the method of air purification, include three models.

- recirculation hood;

- flow type hood;

- mixed exhaust model.

The first option is suitable for those who do not need to install a high-power hood, since cleaning when using such equipment occurs by passing air through external and internal filters built into the housing.

An external filter is designed to clean the air from grease elements: as a rule, grease filters are made of durable metals so that you can clean their surface from contaminants yourself.

Internal filters can have different compositions, but most often they have a carbon structure, which contributes not only to thorough air purification, but also to the elimination of foreign odors in the room. That is why hoods with circulation mode are often called coal hoods for the kitchen.

Internal filters cannot be cleaned of contaminants, so they must be periodically replaced with new ones to ensure high-quality operation of exhaust devices.

During the purchasing process, make sure that the required filters are freely available, since it is not always possible to find a suitable option in a timely manner.

Advice: if you do not have the opportunity to install a large hood of this type, pay attention to telescopic hoods with a retractable panel. As a rule, such models have higher performance compared to other hoods operating in recirculation mode. Flow hoods cannot purify the air on their own: they are designed to effectively remove contaminants from the room

To do this, the hood is connected to the ventilation shaft using a durable air outlet pipe (most often made of corrugated material)

Flow hoods cannot purify the air on their own: they are designed to effectively remove contaminants from the room. To do this, the hood is connected to the ventilation shaft using a durable air outlet pipe (most often made of corrugated material).

Experts recommend additionally installing anti-return valves to prevent contaminants from flowing back into the kitchen.

It is important to remember that connecting any system to general ventilation requires a preliminary study of its operation. Flow type hoods can be connected in this way only if your apartment has an individual ventilation duct.

Otherwise, ensure that the contaminated air exits directly to the street.

Mixed models are the most powerful and highly efficient, but they can occupy large areas. However, it is this version of exhaust devices that is most popular and is available in a wide price range (starting from 3.5 thousand rubles).

When installing hoods with exhaust and circulation, first consult with specialists about all the pros and cons of such an installation, taking into account the specific placement of your kitchen.

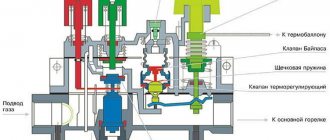

What is it and how does it work

The design of the umbrellas is quite simple. For example, a rectangular umbrella includes a main body, a tray for collecting grease and filters that perform a grease-collecting function. The tilt angle of the filters is 45°.

The ventilation hood for the chimney can also be equipped with additional elements: lamps, fans, connection lugs, etc.

Design and principle of operation: hot air, formed above the thermal surfaces and having a lower density, rises up, is drawn into the hood and enters the pipe, where there are special grease-removing labyrinth filters. Fats from contaminated air masses condense and flow through special drain channels into the bath, and the purified air enters the air duct, which has a round or rectangular shape, through which it is discharged outside (in recirculation mode, the purified air is returned back to the room).

What are umbrellas made of?

The umbrellas are made of stainless steel with a high nickel content, which guarantees their long service life and the necessary strength. There are hoods made of aluminum and glass.

Specifications

When choosing an umbrella for the kitchen, you need to familiarize yourself with its technical characteristics. First of all, we are talking about its overall dimensions. The material from which it is made, its thickness and the mass of the hood also matter.

All necessary characteristics, incl. the effectiveness of air purification from aerosols is indicated in the passport.

Units for local exhaust system

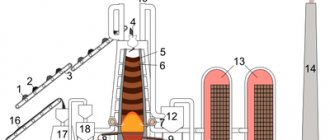

Existing shelters that are equipped with exhaust ventilation systems are divided into several specialized categories:

- units installed at the source of pollution;

- solutions that cover the source of pollution;

- blowing products.

In practice, units are very popular, with the help of which the source of the spread of hazardous substances is localized in a certain area. However, such solutions are not always convenient and advisable to apply. They have been replaced by more modern hoods with ventilation outlets:

- metal and polycarbonate umbrellas with exhaust function;

- local suction units;

- powerful fume hoods;

- encapsulated solutions;

- removal of secretions from the body of machines and working units;

- display, shaped and on-board solutions.

Exhaust hoods are the most popular and widespread suction designs. They equip small work areas (tables for soldering, cooking). Hazardous impurities are quickly collected and redirected upward, after which they are removed. Exhaust ventilation operates both through natural draft and forced draft.

Specialized suctions – extract unwanted and potentially dangerous substances with minimal oxygen consumption. Industrial exhaust ventilation is often represented by several local units. Their main feature is that they do not interfere with work.

Fume hoods are one of the most effective solutions for the forced removal of harmful fumes and substances, while creating a minimum level of air exchange. There are several types of such cabinets on sale:

- with a top exhaust device, through which hot and humid air is removed;

- with the removal of contaminated flows from the side structure - we are talking about some analogue of a “snail” for collecting residual products;

- with combined type outlet solutions located at the bottom of the unit.

A fan located in the air exchange system creates a turbulence in the flow so that the dust is localized in a small area and does not spread throughout the room. An example of such an installation is a welding station, where forced exhaust ventilation is represented by a small cabinet. The suction in them is located at the top of the structure.

If we are talking about the removal of non-hazardous substances, then the speed of movement is allowed within the following limits:

- 0.5 – 0.7 m/s;

- 1.1 – 1.6 m/s – for those cases when toxic impurities and metal fumes are removed from the room.

General and local (local) ventilation

Experts divide all exhaust ventilation systems, taking into account the area of their design cleaning - local (local) and general.

A general ventilation hood is capable of quickly removing polluted air from all rooms in the building. A striking example is exhaust ventilation in an apartment. Its grilles are traditionally located in the bathroom and kitchen (in the upper part of the room), through which polluted air, small particles of soot and fat are removed.

General exchange systems are actively used in health institutions, warehouse complexes, storage facilities, residential buildings, shopping centers and shops. A characteristic feature of these objects is that the concentration of unwanted contaminants is minimal; they are evenly distributed throughout the volume of the room.

It is recommended to install general-exchange exhaust ventilation in a number of cases:

- the presence in the space of leaky mechanisms and machines that produce hazardous emulsions and substances;

- insufficient power of local solutions;

- absence of outlets for contaminated oxygen and unsafe substances.

General exchange ventilation hoods eliminate the concentration of hazardous particles and impurities in the room to the optimal values stipulated by regulations.

Local exhaust ventilation is used to eliminate point releases of hazardous and harmful substances.

Due to their directional impact, they guarantee normal working conditions at the local site. The basis of the structures are exhaust pipes for ventilation, with the help of which smoke, air, dust, and unsafe fumes are removed, thereby preventing their spread.

The best clear example of such a device is mechanical kitchen hoods. The cost of equipment for a local system is an order of magnitude cheaper than a general exchange system. From an economic point of view, they are much more affordable. If the pollution is spread over the entire area of the room, the described solutions are ineffective.

Calculation of local hood parameters

To absorb emissions and vapors hazardous to human health, suction units made in the form of umbrellas are installed. If they are difficult to purchase, you can always make them by preparing the appropriate drawing.

At the first stage, the following data and parameters are determined:

- area of release of harmful substances – a * b, as well as the diameter of the umbrella – d;

- air movement speed at the work site - VB;

- calculation of local exhaust ventilation is carried out taking into account the suction speed into the umbrella - Vз

- the height of the installation of the structure above the source of hazardous pollutants is designated Z.

One of the key parameters that determines the efficiency of absorption of harmful substances is the installation height of the exhaust hood. Engineers recommend hanging it as low as possible to the work area so that all fumes and emissions are effectively absorbed and removed.

The installation of exhaust ventilation is carried out based on the following dimensions of the umbrella:

D = 0.8×Z+d, taking into account other parameters – A = 0.8×Z+a, while B = 0.8×Z+b.

The optimal level of umbrella opening is 60 degrees. With this value, the danger of the formation of stagnant zones is eliminated. If we are talking about a very low room, it is better to increase the opening angle to 90 degrees. As for the height of the lower edge, it ranges from 180 cm. The hood is connected to the ventilation in such a way that there is access to the folding curtains from 3 sides.

For rooms where the speed of movement of air masses is from 0.4 m/s, it is better to supplement the umbrella with special folding curtains. The presented calculation data will help you more accurately determine the cost of the finished product, as well as determine the appropriate equipment. However, before connecting the hood to the ventilation, it is better to consult with a specialist who can carry out the appropriate calculations and recommend specific models of devices.

Grease cassettes

Cassette grease filters are one of the types of grease traps that are in high demand when using exhaust hoods. The products are mounted inside the hood directly above the stove. Their mesh design allows air to pass freely inside the ventilation system, while particles of fat settle on the filter and do not pollute the air duct.

The design of the cassette is quite simple, it consists of:

- frames - most often stainless steel or galvanized metal is used;

- mesh filter.

Household filter meshes can be made of paper or fabric, while products for restaurants, cafes and canteens are equipped with a metal mesh. In this case, galvanized steel or stainless steel is also used. The advantages of metal cassettes are that they can be reused. If fabric filters have to be constantly changed, then metal grease cassettes can be cleaned. To do this, just place them in a container with water and detergents. The advantage of stainless steel is its immunity to aggressive chemicals and water.