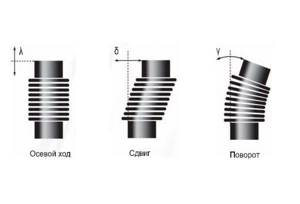

Compensators for pipelines. Pipeline expansion joints help maintain water supply networks in working order.

In difficult climatic conditions, pipes are subject to a large load during the heating season; at high temperatures, pipes are subject to expansion, which can cause accidents on heating mains. To prevent emergencies, special devices are used.

What is a membrane water hammer compensator and how does it work?

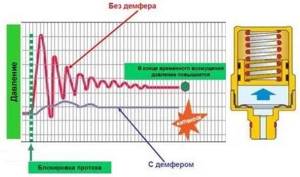

Pressure, as one of the parameters of the heating and water supply system, plays a key role. It is due to the pressure difference that the fluid flow is formed. Modern heating systems use hydraulic pumps. The pressure indicator determines the flow speed, pressure and volume. In open-type systems, which were widely used in the past, the fluid pressure was equal to atmospheric pressure, so an increase in the temperature of the medium was accompanied by a flow of fluid into the expansion tank.

The disadvantage of such a system was the gradual evaporation of the liquid, the inability to increase the boiling point, and vulnerability to hydraulic shocks.

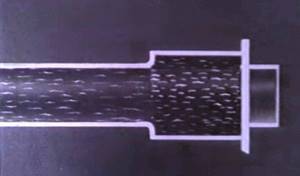

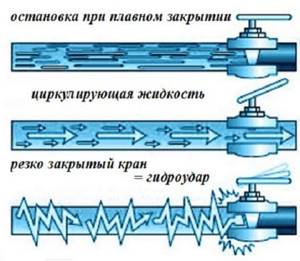

The liquid is practically not compressible. When layers are compressed, large elastic forces arise, which can be transmitted at high speed in the medium. A sharp change in pressure in one part of the residential pipeline could lead to the destruction of pipeline elements in another part.

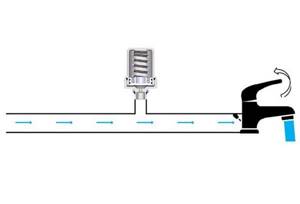

A water hammer can be triggered by opening a tap or any valve. A striking example is the destruction of a newly laid pipeline during its first start-up, when the water supply is opened with the mixer valves closed.

Installation rules

If previously certain installation requirements were imposed on the expansion tank, then in a closed system the compensator can be installed anywhere. However, this is only a theoretical assumption. The requirements for location at the highest point are no longer relevant, since according to Pascal’s law, the pressure is the same everywhere.

The compensator is mounted where there are plumbing units, inputs or junctions.

- On the one hand, this is due to the fact that units are a common cause of water hammer, so it is more advisable to install a device that dampens excess pressure in close proximity to taps and valves.

- On the other hand, aesthetics play a significant role here. Against the background of straight pipes neatly laid around the perimeter of the room, the cylinder will not look good.

An important installation condition is the absence of a long or curved outlet to the cylinder. Since water does not circulate in the outlet, this can lead to stagnation and, as a result, to the proliferation of microbes. Bends should be short and straight.

Based on these considerations, it is worth choosing the location of the compensator.

What is a water hammer compensator: types, design, principle of operation

There are two types of water hammer compensator: membrane and with a spring-loaded valve. They perform the same function: they accept excess liquid, thereby reducing the load on other elements of the system. Since these devices are small in size, they protect those devices that are located in close proximity.

The water hammer compensator is a small device, but it changes the picture significantly

How a membrane compensator works and works

A membrane water hammer compensator is a container that is divided into two parts by an elastic membrane. One of the parts is filled with air, the second is empty in its normal state. Air in the filled part is pumped under a certain pressure. To check/pump up pressure, there is a spool valve (nipple) in this part of the body. Products are supplied from the factory with an initial pressure of 3 bar. This is the “standard” value for most heating systems in single-story private houses. If the pressure needs to be changed, a pump is connected to the nipple and brought to the required value. This value is 20-30% higher than the working one in a particular system. But it should be significantly lower than the performance limit of the compensator itself.

Diaphragm shock absorber for hydraulic shocks in heating and water supply systems

As long as the pressure in the system does not exceed the pressure in that part of the tank, nothing happens. When a water hammer occurs, under the influence of increased pressure, the membrane stretches, part of the liquid enters the reservoir. As it normalizes, the elastic membrane tends to take its normal state, pushing the fluid back into the system. Thus, the jump is smoothed out.

Features of a spring water hammer damper

The second type of water hammer compensators works on the same principle: liquid is passed into the housing as the pressure increases. But access to the container is blocked by a plastic disk, which is supported by a spring. The pressure at which liquid begins to flow inside depends on the elastic force of the spring. It cannot be adjusted in any way (at least, no adjustable models have come across yet), so you have to select a device with suitable parameters.

Spring/disc type hydraulic shock compensator device

The operating principle of this damper is similar to that described above. While the pressure in the system is normal, the spring presses the disk against the body. When a water hammer occurs, it contracts and water enters the housing. As the pressure decreases, it becomes less than the elastic force of the spring. It gradually unclenches, returning the liquid to the pipeline.

As you can see, both devices work on a similar principle. Spring models are considered more reliable, since the working elements in them are less subject to wear (metal spring and durable plastic). But membranes are also made from materials that do not lose their elasticity for a long time. An additional plus is the ability to set the pressure at which the membrane begins to stretch. But the downside is the need to regularly check the pressure and, if necessary, pump it up.

Unpleasant consequences and methods of protection against water hammer

A barrier that suddenly appears in the path of liquid flow creates pressure, which, theoretically, can increase indefinitely. In this case, the rigid elements of the system experience severe loads and gradually or abruptly collapse.

The consequences of water hammer can be disastrous, especially for old pipelines

Accidents caused by water hammer in the heating system are accompanied by a number of characteristic troubles:

- destruction of pipelines and equipment of heating networks;

- rupture of heating devices;

- burn injuries;

- long-term interruption of heat and water supply;

- flooding of the home and damage to property.

Long pipelines, for example, heated floors, are most vulnerable to water hammer. To protect the “underground” system, it is equipped with a thermostatic valve, the installation of which must be entrusted to good specialists, otherwise another risk factor will appear in the system.

Proper protection of heating or water supply systems from water hammer is aimed at reducing their intensity and neutralizing the effects of excess pressure.

No sudden movements

The easiest way to protect yourself from water hammer is to smoothly turn on and off the shut-off valves. This nuance is clearly stated in the standards for the operation of centralized water supply facilities and heating networks. The rule can be extended to autonomous networks without any reservations.

Other ways to combat water hammer

One of the possible options for neutralizing water hammer has already been voiced - close the taps smoothly. But this is not a panacea, and it is inconvenient in our fast-paced times. And there are also household appliances, you can’t teach them. Although, some manufacturers take this point into account, and the latest models are made with a valve that smoothly shuts off the water. This is why compensators and neutralizers are becoming so popular.

You can combat water hammer using other methods:

- When installing or reconstructing water supply or heating systems, insert a piece of elastic pipe in front of the source of water hammer. This is reinforced heat-resistant rubber or PPS plastic. The length of the elastic insert is 20-40 cm. The longer the pipe, the longer the insert.

- Purchase of household appliances and shut-off and control valves with smooth valve movement. If we talk about heating, problems with warm water floors are often observed. Not all servos operate smoothly when closing the flow. The solution is to install thermostats/thermostats with a smooth piston stroke.

- Use pumps with soft start and stop.

Water hammer is a truly dangerous thing for a closed system. He breaks radiators and bursts pipes. To avoid problems, it is better to think through control measures in advance. If everything is already working, but problems arise, the smartest and easiest way is to install compensators. Yes, they are not cheap, but repairs will cost more.

Features of installation of compensating devices

The heating system and water supply systems in residential buildings are equipped with compensators according to the design. Compensators are secured to the main structure by welding.

The devices are installed when the pipeline system is not working, when there is no pressure and no transported liquid. During installation, ensure that the pipe and compensator are aligned in order to prevent radial loads on the system during operation.

The presence of this type of load entails jamming and further breakdown of the moving elements of the product.

The heating system is equipped with compensators on straight sections of the pipeline, and when all sections are attached to fixed supports. Along with fixed supports, it is necessary to install sliding ones so as not to deform the pipeline during warm expansion. It is necessary to take into account the amount of friction at installation locations when calculating the maximum size of the pipeline area with a built-in expansion joint.

Attention! In the area where the bellows expansion joint is installed, supports or suspended structures cannot be mounted.

Protection measures

To avoid ruptures, special devices are installed on all risers in basements, and in apartments on hot ones, which prevent vibrations from destroying the pipes.

Locking devices, their pros and cons

Shock-absorbing pipes are wave, loop or U-shaped pipes made of ordinary or special material, for example, reinforced plastic or rubber, 20-40 cm long, the simplest and cheapest option.

Shock-absorbing connections are cheap, and at the same time they can withstand the water hammer that plastic communications in an apartment have to experience in practice; they do not require special maintenance or periodic replacement of parts.

A bellows shock absorber is a corrugated pipe made of ductile metal that can compensate for linear expansion, elongation, or both phenomena at once; simpler ones are single-layer; more advanced ones are enclosed in a casing that provides additional shock absorption.

Bellows shock absorbers in a casing are also unpretentious, while being more aesthetically pleasing than the previous version.

It is important that shock absorbers (especially loop bends) and bellows are designed to compensate for the elongation of the riser; this is their main function, and the damping of water hammer is, rather, secondary. For plastic pipes, especially not of very high quality material, they are as important as expansion joints.

Shunts are metal tubes that are inserted into the pipe together through the main valve in the direction of water flow and bleed off the excess volume of water behind the valve; they are ineffective in old pipes clogged with rust; they are more suitable for plastic communications.

Shunts are easy to install and do not require opening the pipe, but they lose effectiveness in proportion to the clogging of the pipe, and in a domestic circuit this figure can be quite high.

Membrane compensators (the most common are Valtec) are devices that resemble a ball or tank and are a cavity with an elastic membrane, which is pressed in with a sharp increase in water pressure, and then gradually expands, returning the water to the current, but without impact force.

Diaphragm compensators hold up to 30 bar, and this is a pretty good indicator. Their weak point is an elastic membrane, which over time becomes deformed, breaks or hardens due to salts and additives in the water.

Piston, or spring (the most popular today - FAR) - devices similar to a cap and working on the same principle as membrane ones, with the difference that the membrane is replaced by a spring: with an increase in volume, water pushes a plastic disk into the cavity and thereby compresses spring, then the mechanism returns to its original position, returning water to the circuit.

Piston compensators can withstand surges of up to 50 bar and have ways to protect against real, not weak, water hammer. In addition, they are more resistant to wear than membrane ones, however, they are not immune to leaks at the seal or connection points with the pipe, so they need to be periodically checked and replaced.

Control valves are systems that are usually included in complex protection against water hammer and are installed on controllers of external and general house circuits.

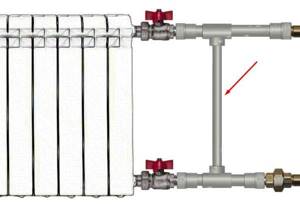

The bypass system is a jumper pipe that allows you to redirect the flow of coolant water in order to avoid water hammer and ruptures in the batteries.

Experts' opinion Old-school locksmiths consider the installation of indoor extinguishers to be a waste of effort and money. According to them, a strong water hammer threatens the water treatment channels in the basement, and that’s all. Other craftsmen note that in earlier times all taps were closed slowly, using a valve, but now they are mostly lever (ball) taps, and household appliances (washing machines, dishwashers) and toilet tanks also shut off the flow of water quite abruptly. Therefore, ideally, the damper should be located in front of each such consumer.

Comprehensive preventive measures:

- smooth closing of taps and valves;

- pump power regulator, which slows it down at the first revolutions and prevents it from provoking a shock wave.

Actually, water hammer absorbers have always included “coils” - a wave-like bend of a hot water riser, led into the bathroom from the toilet. Housewives used it as a heated towel rail. In essence, the pipe slowed down the flow of water and eliminated vibrations, reducing the risk of water hammer. However, leaks appeared quite often at the junction of the apartments, especially over the years.

Metal ages faster than high-quality plastic, the installation of ball valves significantly increased the load on the structure, and the difference in materials, when plastic was placed on top and metal was left below, or vice versa, makes itself felt. Because of this, the “coils” do not work.

Protection of pressure gauges from high and low temperatures

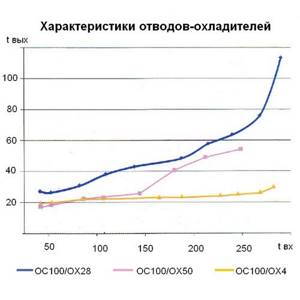

When using mechanical pressure gauges to measure the pressure of high-temperature media, irreversible qualitative changes often occur in the elastic sensitive elements (manometric tubes). As a result of these changes, the inaccuracy and nonlinearity of the measurement critically increases and such pressure gauges, as a rule, subsequently do not pass verification and are rejected. The traditional way to protect pressure gauges from overheating is to install additional auxiliary devices. As a rule, these are siphon tubes of various geometric configurations and metal content and so-called “refrigerators” - short vertical bends with fins.

The design of a simple “refrigerator” involves passing the measured medium through direct flow and cooling it due to plates located at a certain distance from each other on the outside of the device. An example of such a “refrigerator” is the outlet-cooler model OC100/OX28. The temperature of the measured medium at the outlet of this cooler outlet is 2-3 times lower than the temperature of the medium at its inlet.

More efficient are cooler outlets with an internal loop water seal (model OS100/OX50) and an external tubular water seal (OS100/OX4) from NPO YUMAS. The temperature of the measured medium at the outlet of these cooler taps is 5-10 times lower than the temperature of the medium at its inlet.

An integral condition for the effective operation of cooling siphon tubes and cooler outlets is the complete tightness of the connection “cooler outlet - pressure gauge inlet (fitting)”. There should be no leaks at the cooler outlet.

To prevent failure of pressure gauges due to exposure to low temperatures, forced heating of pressure taps in front of the pressure gauge and the housings of the pressure gauges themselves are used. Most often, heating is carried out using a heating electric cable. To increase heating efficiency, pressure gauges are placed in insulating thermal covers or covered with heat-insulating material.

The nature of water hammer

First, let's figure out what water hammer is. It's simple: this is a sharp jump in water pressure in the pipes in one direction or another.

- When the pressure rises sharply when the pump is turned on or the tap is turned off, a positive hydraulic shock first occurs, since the water, by inertia, continues to flow at the same speed, but encounters a sudden obstacle in its path. In this case, in the area directly near the obstacle (for example, shut-off valves (see Valves for water supply: types, purpose, selection nuances)), excess pressure is formed on the walls of the pipe. The water has nowhere to go; it compresses poorly, so the walls of the pipe stretch.

Pipe expansion due to water hammer

- When faced with an obstacle, the water stream is thrown back and collides with a wave that is still flowing towards it. Again, this puts pressure on the walls of the sealed pipeline.

- With a sharp outflow of water mass from the obstacle, an area of low pressure is formed next to it, in which the walls of the pipe are now compressed. This is negative water hammer.

Flow movement under different conditions

The shock wave does not subside immediately; it rolls in and retreats several times with decreasing strength and amplitude. All this happens in a fraction of a second, during which the pipes alternately experience positive and negative loads.

There are other reasons that cause water hammer. These are air pockets in the pipeline, sharp turns or connections of pipes of different diameters, sudden pump starts. Any obstacle to the high-speed flow of liquid changes its volume and, as a result, pressure.

What is water hammer in a pipeline, its causes

Water hammer is a sharp increase in pressure in systems transporting fluid, which occurs when there is a sharp change in the speed of fluid movement. A pressure surge can cause destruction of some elements of the system. Failures occur when the tensile strength of a connection or material is exceeded.

If we talk about our houses and apartments, water hammer occurs in heating and water supply systems. In heating systems of private houses - when starting or stopping the circulation pump. Yes, it does not create pressure by itself. But a sharp acceleration or stop of the coolant is the load that acts on the walls of the pipes and nearby devices. Closed heating systems have an expansion tank. It compensates for water hammer if the pump is nearby. In this case, additional devices may not be needed. You can check the need to install a compensator using a pressure gauge. If the needle does not move or moves barely noticeably, everything is fine.

The most common cause of water hammer is abruptly closing the tap.

In centralized heating systems, water hammer occurs when the damper is suddenly closed when the taps are quickly opened to fill the system after repair/prevention. According to the rules, this should be done slowly and gradually, but in practice it happens differently...

In water supply, water hammer occurs even when a tap or other shut-off valve is suddenly closed. More pronounced “effects” are obtained in air-filled systems. As water moves, it hits air pockets, which creates additional shock loads. We may hear clicking or crackling sounds. And if the water supply is routed with plastic pipes, during operation you can notice how these pipes shake. This is how they react to water hammer. You've probably noticed how the metal braided hose twitches. The reason is the same - pressure surges. Sooner or later, they will lead to either the pipe bursting at its weakest point, or the connection leaking (which is more likely and more common).

Water hammer can cause serious damage

Why was this phenomenon not noted before? Because now most taps have a ball valve and the flow closes/opens very abruptly. Previously, the taps were of the valve type and the valve was lowered slowly and gradually.

How to deal with water hammer in heating and water supply? You can, of course, train the inhabitants of an apartment or house not to turn on the taps sharply. But you can’t teach a washing machine or dishwasher to be careful with pipes. And the circulation pump cannot be slowed down during the start and stop process. Therefore, water hammer compensators are added to the heating or water supply system. They are also called dampers, shock absorbers.

Hydraulic compensator device

In total, there are 2 types of hydraulic compensators, each of which is divided into 2 more subtypes: hydraulic pusher (regular or roller), hydraulic support (regular or for installation in a lever or rocker arm). The design will depend on which timing gear the part will work in tandem with: DOHC or SOHC. In general, a hydraulic compensator is a hydraulic plunger system in a non-separable metal housing. The main elements of such a system are:

- Plunger pair (plunger and bushing);

- Plunger spring;

- Check valve (usually a spring-loaded ball);

- Frame.

The installation location of hydraulic compensators depends on the type of timing belt. In the case of DOHC these are the valve head wells, and in SOHC these are the rocker arm housings. An ideally functioning compensator prevents the occurrence of gaps throughout the entire timing cycle. The prefix “hydro” is placed in the name for a reason, since the operation of the device depends on changes in engine oil pressure. It is not entirely correct to compare a hydraulic compensator with a spring, but this analogy makes sense. We suggest you familiarize yourself with the two main phases of the device’s operation:

- The timing valve is closed. Since the camshaft cam does not act on the compensator, the spring inside its housing is completely relaxed and lifts the plunger as much as possible, pressing it against the cam. In this case, the sub-plunger space is completely filled with engine oil and the lubricant pressure inside the compensator is equalized with the pressure in the oil system;

- The timing valve is open. The camshaft cam is turned towards the compensator and has maximum impact on it. The spring of the device is selected so that its force is sufficient to open the timing valve. Excess oil is then pushed back into the lubrication system.

Thanks to the presence of a correctly selected spring, the hydraulic compensator prevents the occurrence of gaps both in both of these phases, and during the transition from one phase to another, when, for example, the valve just begins to open or close. More importantly, the compensator continues to work normally even when the cams wear out and their cast length becomes shorter than normal. Simply put, the device “selects” the gap based not only on thermal expansion, but also on the wear of the timing elements.

Signs of knocking hydraulic compensators when hot

It is very important for a car enthusiast to know how to understand that one or more hydraulic compensators are knocking. After all, its knocking can easily be confused with other sounds due to problems with the piston pin, crankshaft liners, camshaft or other parts inside the engine.

The knocking of hydraulic compensators when hot can be diagnosed by opening the hood. The sounds will start coming from under the valve cover. The tonality of the sound is specific, characteristic of metal parts hitting each other. Some compare it to the sound of a chirping grasshopper. What is typical is that knocking from faulty compensators occurs twice as often as the engine speed. Accordingly, when the engine speed increases or decreases, the knocking sound from the hydraulics will behave accordingly. When you release the gas, you will hear sounds as if your valves are not adjusted.