Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

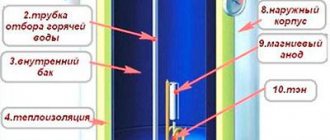

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

What is a bellows eyeliner and what are its advantages?

A bellows gas hose is a corrugated pipe made of stainless steel. Special fittings are installed at the ends of the hose to create a strong and safe connection. The connection to the pipes and equipment is secured using union nuts made of the same material. To increase the level of tightness, metal or plastic sealing rings are installed at the joint.

As a rule, sealing gaskets are included in the flexible hose kit.

Eyeliner kit

The advantages of a bellows hose over other types of flexible hoses designed for connecting gas equipment are:

- strength and rigidity. According to manufacturers' requests, the service life of the bellows is up to 25 years;

- possibility of correct operation at different temperatures;

- not exposed to direct sunlight;

- ability to withstand high pressure;

- possibility of stretching, and when the length increases to 50%, the strength of the liner does not decrease.

The disadvantages include the cost of the equipment, which is 2–3 times higher than the price of rubber analogues.

Bellows connection for gas: characteristics, selection, installation

When installing gas equipment, the user decides how to connect it. For this purpose, you can use steel pipes or a special liner. Unlike pipes, a flexible bellows connection for gas helps simplify the connection process, reduces the money and time spent on work, and also allows you to move equipment without shutting down over a certain distance. Read on to learn how to choose a gas line and install it yourself.

Bellows hoses for connecting gas equipment

Installation of gas supply

Installation of the bellows gas hose is carried out in compliance with the following rules:

- it is unacceptable to hide the liner in the wall, since any leak that is not detected as soon as possible can lead to emergencies, damage to property and loss of life;

- Do not install a hose with a large number of kinks;

- condensation on the equipment will help reduce the service life of the liner.

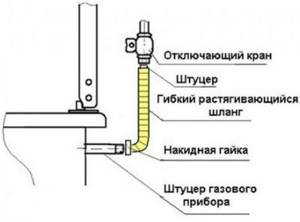

Installation diagram:

- choosing an installation location in accordance with the recommendations given above;

Optimal connection diagram for a gas stove

- turning off the gas supply to the premises. To make a temporary shutdown, you can use the tap installed in the apartment, and if it is missing, you need to contact the management company;

Individual gas shut-off valve

- dismantle the old eyeliner (if any);

- if the supply line and tap are missing, then before connecting the equipment, it is necessary to cut a thread on the pipe and install a tap that allows you to shut off the gas supply directly in the living room. For example, to troubleshoot equipment;

- dielectric installation;

- A flexible hose is connected to the tap. As a rule, in this situation, the “nut” connection method is used;

When connecting the liner, special attention is paid to installing the sealing gasket. A connection without a gasket will not be completely sealed

To increase the tightness, you can additionally use FUM tape or other similar material.

- connecting the supply to gas equipment using an o-ring. All nuts and fittings must be fixed using an open-end wrench without unnecessary effort. Even slight overtightening can lead to damage to the seal and rapid depressurization;

Connecting the liner to the equipment

- examination. To identify a leak, you can use a soap solution and an ordinary brush (sponge). If soap bubbles appear on the surface when applying the solution, then the connection is not airtight.

Leak detection with soap emulsion

How to connect a gas stove yourself, watch the video.

If you cannot install the equipment yourself, it is recommended to contact gas service specialists. Replacing the eyeliner will cost approximately 300 - 500 rubles.

Gas stove connection diagram

Schematically, connecting the stove to gas is as follows: a gas riser passes through the kitchen room, from which a branch pipe with a tap at the end is connected, which is connected to the stove. This piece is also called a drop or tap.

In older houses, a petal type faucet is installed on the slopes. When reconnecting, it is recommended to replace it with a ball one. It takes up less space and is more convenient to use

A rubber-fabric hose is screwed into the faucet, through which gas is supplied. For old houses, it is common to place the slab on a metal pipe. This method is inappropriate to use, because in this case the location of the device will be stationary.

In remote areas of the private sector, where there is no access to a main gas pipeline, gas is used in cylinders. Only a gas service specialist is allowed to connect to such equipment.

Other types of gas hoses for gas stoves: sizes, prices

A gas rubber hose in a metal braid has an internal part made of polymer materials, which is covered with a layer of vulcanized rubber on top. On the outside, the hoses are braided with special steel threads, creating a so-called reinforced layer.

The main disadvantage of using hoses is considered to be the high ability of steel to transmit electricity, as well as the susceptibility of the internal polymer material to destruction, which may not be noticed due to the presence of upper layers. If the stove is not in use, it is recommended to shut off the gas hose during this time, which will increase its service life. The price for a finished product 60 cm long starts from 140 rubles.

When using this type of connection, you additionally need to install dielectric inserts, which are installed at the junction of the hose and the gas pipe. The presence of a dielectric will protect the gas stove and the hose itself from the effects of stray current, which can cause a fire.

A gas rubber hose in a metal braid has a disadvantage - it is the high ability of steel to transmit electricity

Advantages of using rubber reinforced hose:

- affordable price;

- ease of installation;

- operation in a wide temperature range: from -35 to +50 °C;

- wide choice of length and diameter.

Reinforced PVC hose is considered more modern than the options listed above due to the fact that the characteristics of the material do not allow the product to conduct electric current. In addition, polyvinyl chloride does not break down as easily as rubber. Additional strength to the hose is provided by the presence of two layers of PVC. Inside the sleeve there is a black material, and the top layer is most often distinguished by a yellow color. It is used for supplying various types of gas mixtures: acetylene, propane and butane.

The PVC gas hose for a gas stove is designed for operating pressure up to 0.63 MPa, and the temperature at which gas can be operated varies from -20 to +90 °C, which is a significant advantage. Another positive aspect of using PVC products is the wide range of sizes, with the maximum length of a gas hose for a gas stove being 5 meters and the minimum length being 0.4 m. Galvanized steel is used for the manufacture of fittings, and dielectric properties are ensured due to the presence of a paronite gasket. Other advantages of the product:

- does not collapse upon contact with a hot stove;

- affordable cost, price per meter of product starts from 170 rubles;

- not subject to destruction when exposed to hot drops of oil;

- suitable for use under high load conditions;

- long service life: minimum – 12 years, maximum – 20 years.

The PVC gas hose is considered more modern and is used for supplying various types of gas mixtures

Bellows Gas Hose: Best for Gas Stove

If you ask a specialist what type of hose for a gas stove should be, most likely he will suggest purchasing a bellows version for installation. This type of hose is considered the most reliable for connecting the hob to the central gas supply. In addition to gas stoves, it is used to connect water heaters and gas boilers used for individual heating. A bellows is an elastic corrugated shell that protects the inner layer from mechanical and other types of damage.

The great demand for bellows hoses is due to the high technical characteristics and reliability of the devices. The products easily withstand the high pressure created by the gas flow in the pipe. Ease of connection is provided by two fittings designed for connection to a gas pipe and directly to the device. All hose components are made from high-quality stainless steel, which guarantees maximum service life.

Helpful advice! For a safer connection when connecting the hose, a special gasket made of plastic or soft metal is additionally used.

The bellows gas hose is considered the most reliable for connecting the hob to the central gas supply

The price of a gas hose for a gas stove of this type is significantly higher than the cost of other product options, but the service life is at least 10 years longer than the service life of other devices. So, the minimum time during which you can safely use a bellows hose is 25 years, although some companies give a 30-year warranty. The final price is usually influenced by the manufacturer and size of the product.

You can find out how much a gas hose for a gas stove costs (depending on the characteristics) from this table:

| Connector diameter, inch | Length, m | Price, rubles |

| 1/2 | 0,4 | from 250 |

| 0,8 | from 290 | |

| 1 | from 320 | |

| 1,5 | from 400 | |

| 3 | from 780 | |

| 4 | from 950 | |

| 5 | from 1150 | |

| 3/4 | 0,6 | from 350 |

| 1 | from 450 | |

| 2 | from 700 | |

| 2,5 | from 900 | |

| 3 | from 1050 |

Selection rules

Gas connections should be purchased in specialized stores, where the quality of the products can be confirmed by SNIP and GOST certificates, and permission from Rostechnadzor of Russia. Each product must be accompanied by a passport indicating the production date, service life and recommended replacement period. Before purchasing, you should inspect the product for damage. Chinese hoses are not recommended for purchase because they wear out quickly.

The range is represented by products of various lengths: from 30 cm to 7 m. It is necessary to select a hose length so that you do not have to use a second one. Extension of sleeves by connecting to each other is not allowed. If the distance between the gas pipeline and the device does not allow the use of one hose, the supply line is increased using a metal pipe.

The liner should connect the pipeline and the device fairly freely, without tension. The hose shortens slightly after gas is applied due to pressure.

When connecting a gas stove, the length of the line should not exceed 2 m. This is a European standard.

The diameter of the section is given importance. Full gas supply is possible provided the cross-section size is at least 10 mm. The ends of the hoses can be equipped with two nuts or one nut and a fitting. The nut has an internal thread, and the fitting has an external thread. If the output of the device is direct, an angle fitting is used for connection. The nut and fitting are selected exactly to size.

Chinese manufacturers counterfeit well-known European brands, so the purchased product must be carefully checked:

- make sure of the quality by comparing the passport characteristics with the real ones;

- study the quality certificate;

- inspect.

Chinese fakes are short-lived and can release toxic substances into the air. It happened that products were made from metals with radioactive impurities.

Eyeliners from well-known brands, sold at a suspiciously low price, are 100% likely to be counterfeit.

You can opt for a regular rubber-fabric hose, but you must constantly monitor the degree of wear and tear and check whether the smell of gas has appeared. The reinforced hose is the most optimal in terms of price and quality ratio; the bellows type liner has the longest service life and reliability. Moreover, the fitting must be connected to the corrugation by welding or be solid. You should not take a liner where the fitting and corrugation are glued to each other.

The main advantages and disadvantages of using bellows hoses

Simple models of bellows hose are presented in the form of corrugated products, which are distinguished by the presence of a round cross-section. If you choose a more expensive option, then in addition there will be a metal sleeve or polymer coating for protection. The modernized version of the bellows hose has a built-in thermal protection valve, which, when the temperature rises critically, independently shuts off the flow of gas. Of course, this option will also affect how much the hose costs, but the losses that can be incurred in the event of a gas leak will be much higher. Other advantages of bellows hoses:

- easily bend and stretch;

- can withstand loads up to 6 atm;

- are operated in a wide temperature range from -50 to +200 °C;

- are made of high-quality materials that comply with all GOST standards;

- meet the technical requirements for domestic use;

- maximum possible service life - up to 30 years from the date of installation;

- withstand the influence of electric current up to 1.5 kW;

- a large selection of hose lengths for connecting a gas stove - from 0.4 to 5 m;

- compatibility with most types of gas equipment and various accessories;

- the presence of a coating that protects the base of the hose from the effects of various household chemicals used for cleaning and disinfecting the kitchen.

Simple models of bellows hose are presented in the form of corrugated products

Additional safety for the hose is provided by an electrically insulating polymer layer, which protects not only from mechanical stress, but also from high-frequency currents that are created by some household appliances, for example, a microwave oven. Due to the strength of the hose, manufacturers guarantee the integrity of the connection even in the event of natural anomalies, such as an earthquake, when the stability of the building is compromised.

The only relative disadvantages include the price, which is several times higher than the cost of similar products from other groups. However, the presence of a large number of positive characteristics, which include a significant service life, covers this drawback.

Helpful advice! When installing a stove or hob with a built-in electric ignition function, experts recommend additionally installing a dielectric insert between the gas supply tap and the bellows hose to ensure greater safety.

Bellows

The only type of flexible connection that is allowed for connecting gas household appliances in our country. This is a corrugation that is resistant to temperature, mechanical loads, and pressure.

The name comes from the English word Sylphon. The type is single-layer and multi-layer, the material from which it is made is metallic, non-metallic. The outer shell acts as a barrier, making the hose safer to use.

Bellows hoses are made from stainless steel. By type they are divided into models:

- with metal braid without insulation;

- with yellow polymer dielectric coating.

For optimal supply of the gas mixture, you should choose a connection with an internal diameter of at least 10 mm.

Bellows hoses have a service life of up to 30 years. They differ from other types of hoses at a higher price. However, they pay off well due to their positive qualities. Advantages of bellows hoses:

- the sleeve is made in accordance with technical specifications and GOST standards;

- the only type of hose that is allowed to be used;

- PVC coating reliably protects the connection, polymers protect against impacts and aggressive environments;

- high level of resistance to critical loads;

- long service life, more than 25 years;

- protection against electricity of 1000 V or more;

- There are no regulations restricting operation.

When choosing a gas hose, always ask for a government certificate. We strongly recommend choosing bellows gas hoses. But even in this case, beware of cheap Chinese counterfeits. Often they are indistinguishable from a quality product. The danger lies in the thin, low-quality rubber used in their manufacture.

Make sure that the connection is gas - the yellow elements must be included in the braiding. Do not buy excessively long eyeliners, add 20% to your measurements - this length will be enough. The options that are in greatest demand are one- and two-meter ones. Standard household diameters are 1\2 or 3\4 inches. The hose may have two union nuts with female threads, or a nut on one end and a male threaded bushing on the other.

When comparing bellows hoses on our market, and there are plenty of them, you need to pay attention to the different types of connections. Consider the points presented here - and your choice will be optimal

- Material. Buy gas connections made of the same material as the fitting. This way you will benefit from the strength of the hose.

- Compound. The type of connection determines the service life of the product. Glue-based coupling is short-lived, so choose a welded or solid joint.

- Temperature. Optimal indicators for using bellows eyeliner are from -55 to +255 degrees Celsius.

- Pressure. The hose is used with operating pressures up to 6 atmospheres. In our gas systems, a value of no higher than 0.03 atmospheres is allowed. Therefore, we can talk about a huge margin of safety for the sleeve.

- Stretching. Theoretically, a stretch of 2 times the original length is allowed. In reality, the limit value is half the original value, otherwise there will be a loss of rigidity.

- Certification. A quality certificate is required for devices working with explosive substances; gas hoses are no exception.

https://youtube.com/watch?v=5882GeZ2o6s

Main manufacturers of bellows gas line

The market leader in the production of bellows hoses is considered to be the Italian company Emiflex, which has also been certified in Russia. After some research, approval for the use of hoses from this company was given by the state organization Rostest. In addition, the manufacturer received the appropriate permit from Gosgortekhnadzor, which approved the use of products for connecting household gas in residential premises.

The Emiflex gas hose has the following technical characteristics, which make the company a market leader:

- the product is designed to work with natural and liquefied gas;

- the maximum gas pressure for which the product is designed is 7 atm;

- the device can be operated without loss of properties at temperatures from -20 to +100 °C;

- thickness of the metal bellows hose – 2.1 cm;

- it is permissible to stretch the product twice its original length;

- Hoses are available in various cross-sectional diameters - 1, 1/2, 3/4 (in inches);

- Among the types of fastenings, options such as nut-nut and nut-fitting are available;

- The outer coating of the bellows protects the product from exposure to chemical detergents.

The maximum length of the Emiflex gas hose, which is certified in Europe, is 2 meters. For the production of devices, stainless steel is used, marked AISI 316 L. In addition, the hose comes with an aluminum gasket, which is used during installation. The manufacturer draws attention to the fact that lengthening the sleeve is possible only during installation. It is unacceptable to stretch the hose during operation.

Another certified Italian manufacturer in the Russian Federation is Idrosapiens SRL, which also has a European quality certificate confirming the product’s compliance with standards for household use.

The gas hose from Idrosapiens SRL has excellent technical characteristics

Gas hoses from this company guarantee high-quality and safe operation for 15 years. At the same time, longer use is not excluded, but without providing a warranty from the manufacturer. Below is a table indicating the price of gas hoses from Italian manufacturers.

| Size, inch | Length, m | Manufacturer and price, rubles | |

| Emiflex | Indrosapiens | ||

| 1/2 | 0,5 | 1350 | 1300 |

| 0,75 | 1700 | 1500 | |

| 1 | 1850 | 1650 | |

| 2 | 3800 | 3450 | |

| 3/4 | 0,5 | 1700 | 1550 |

| 0,75 | 2000 | 1750 | |

| 1 | 2500 | 2150 | |

What is a dielectric insert for gas: main purpose

The dielectric insert (coupling) is a cut-off fitting that prevents failure of gas equipment, which can be caused by stray current. These currents are formed in the ground due to a violation of the integrity of a household or industrial electrical line. In addition, their source is a railway or tram line. Stray current enters the gas pipeline due to the difference between the resistance of the soil and the metal parts that make up the gas pipeline. It is through the main line that the current enters the household gas pipeline.

Another reason for the occurrence of stray current in the gas system may be poor-quality grounding of household appliances that come into contact with the gas pipe. In general, we can say that there are many reasons for the appearance of stray currents, and the consequences from them will only be negative. To avoid this problem, a dielectric is used for the gas hose, which is inserted between the gas tap and the bellows connection to the gas appliance.

The coupling is installed in order, firstly, to prevent failure of gas equipment, especially if it is modern equipment equipped with a large number of electrical functions. Secondly, the presence of a dielectric prevents the occurrence of a spark, which can cause a fire or even an explosion. For these reasons, according to the rules of the gas service, a dielectric must be used to connect gas equipment, be it a bellows or rubber liner. It comes in two types:

- dielectric couplings - attached between the gas pipeline and the hose that fits the device;

The thread of the fitting can be cut both outside and inside the end part

- dielectric bushings - are non-conducting bushings mounted in the place of dismountable mating of gas pipe elements.

Like bellows hoses, inserts are classified by size, which vary depending on the diameter of the threaded part - 1/2, 3/4 and 1. Therefore, for any type of flexible bellows gas line, you can select a product of the appropriate size. The thread of the insert can be either external or internal. Both bushings and couplings have the same strength characteristics and are designed for a pressure of 6 atmospheres.

Interesting information! The dielectric material used in the production process of the bushing is polyamide, a non-flammable polymer characterized by a significant resistance of approximately 5 million ohms.

Dielectric couplings are special fittings with threaded ends, mounted between the gas pipeline and the fuel-consuming device.

How to properly install the dielectric when making bellows connections

According to the state safety standard, a dielectric insert must be installed between the gas tap and the bellows connection. Basic steps to be taken when installing the bushing:

- Turn off the gas valve. It is important to leave the gas on the stove so that it all burns out.

- Take 2 adjustable wrenches: with one you need to hold the valve body, and with the second, you need to tighten the nut of the bellows connection that connects the pipe to the gas appliance.

- Screw any seal onto the free ends of the coupling (a polymer version is best for this), and then manually screw the dielectric into the gas pipeline.

- Again, using 2 keys, one of which holds the valve, and the second holds the coupling, the product is screwed in until it stops. It is important not to overdo it here, so as not to strip the threads and deform the valve body.

- Screw the nut from the bellows hose onto the other end of the coupling, holding the dielectric with an adjustable wrench, and tighten the connection firmly.

After completing all the steps, you need to check the joint for leaks. To do this, use either a small brush or a shaving brush, which is first lathered generously. A soap solution is applied to all joints and inlets, after which the gas tap is slowly opened. If even small bubbles or foam suddenly appear, the tap should be turned off and the quality of the joints should be additionally checked. You can use a gas appliance only if the soap solution does not bubble. Neither matches nor lighters should be used to check leaks, as in the event of a leak they can cause a tragedy.

Any sealant must be applied to the free ends of the dielectric coupling

Types of gas taps

In old buildings, two types of cranes were usually installed on vacation:

The differences in the designs of these products can be seen in the figure.

When the slab is replaced or the valve fails, it is best to install a new ball valve.

This device is much better, but more expensive. Installation of an Italian faucet will cost $10. You can also install a cheaper domestic faucet, costing $5. They are no worse than their foreign counterparts, but sometimes have defects. Therefore, do not forget to take a receipt with you when purchasing so that you can exchange the defective product for a good one.

How to make a safe gas connection: connection features and safety precautions

Regardless of which hose for the gas stove is chosen: bellows or any other flexible hose option, the connection will be made according to the same pattern. Before connecting the hose, you need to unfold the gas device and inspect the back wall of the product. On some models, the gas pipe is marked “Output”. Depending on the configuration, the product must be placed straight or at a slight angle.

In any case, it is important that the hose does not bend too much. To avoid this, additionally purchase corner adapters that allow you to change the angle of direction of the sleeve. In advance, before carrying out all work, it is necessary to think about the location of the stove and calculate the length of the hose.

Important! Before starting work on installing or replacing a gas hose, you must turn off the gas valve and do not open it until measures have been taken to identify a possible leak.

The riser is most often located in one of the corners of the kitchen, and a pipe extends from it, connected by welding, with a gas tap attached to it, to which a flexible bellows gas supply will be attached. If the faucet has an external thread, then a union nut is used to connect the hose. If there is an internal thread, the sleeve is screwed directly into it.

Before you begin work on installing the gas supply, you must turn off the gas valve.

It is imperative to install a paronite gasket between the entrance to the gas equipment and the hose, which comes complete with the tap. Some experts recommend purchasing a gasket equipped with a metal mesh yourself. If a high-quality faucet has been chosen, then you can be sure of the reliability of the gasket.

After installing the paronite gasket, the bellows hose is screwed to the outlet of the plate, and then all connections are tightened using a wrench. At the last stage, it is necessary to conduct an inspection for the possible presence of leaks, using a soap solution, as in the case of installing a dielectric. If no bubbles appear, the cooker or other device can be used safely.

What you need to know: valuable tips

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, a collapsible box is used, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

If a technician has been called to connect a gas water heater or stove, it is necessary to check that the work is being done correctly: the excess tap from the tap on the lower side must be unscrewed, the flexible line must be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove .

It is also possible to use an adapter. Any additional installations are prohibited.

Installation recommendations

Experts advise following several rules when attaching gas hoses:

- to avoid kinks, tension or twisting, in order to connect the hose to the plate without compromising its integrity, you should select a bending radius of the part equal to three diameters of the hose used;

- the length of the part is selected taking into account the required distance, so that it is possible to move the equipment if necessary, and the type of product that was chosen, with some supply of hose for the gas stove, so that unnecessary stress is not created in the structure;

- the place must be accessible for inspection of parts;

- there should be no extraneous connections on the device;

- the product cannot be painted to prevent surface cracking;

- connections are made using metal tips;

- parts should be protected from condensation causing oxidation.

Regardless of which hose you connect to the gas stove, you should use the electric ignition very carefully.

Installation features

When connecting gas equipment, you need to take into account the nuances of installing the liner:

- Place the hose in an accessible place so that it can be easily replaced if necessary. This is also a safety requirement: this way, wear on the liner can be detected in time.

- Tighten the connections tightly, but do not use excessive force to avoid stripping the threads.

- Connect only suitable metals together: brass with copper, steel with steel. It is unacceptable to combine copper with steel - these metals form a galvanic couple.

- Observe the bending radius: it should not be less than three times the diameter.

- Lay the sleeve without tension, bends, or twisting.

- Protect the metal from condensation, which leads to corrosion and premature failure of the hose.

- It is imperative to install a dielectric gasket between the connection and the tap - it prevents the accumulation of stray currents, which can cause overheating and melting of the rubber.

If you follow all the recommendations, the gas hose will last as long as it is supposed to, and even more.

What to consider for connection security

To safely connect and use the equipment, you should follow some rules:

- whatever the hose is to connect the gas stove, its location must be freely accessible so that it is not blocked by foreign objects;

- You should not replace the hose on a gas stove with your own hands; it is better to invite a gas specialist;

- connecting equipment with a flexible hose must be carried out in strict compliance with safety requirements;

- after connecting, the hose should sag slightly, without tension;

- the element must not be bent or twisted;

- the part cannot be painted;

- It is worth replacing the element a little earlier than the time for which it was designed; you cannot wait until a gas leak begins at the stove and then change the hose.

Replacement of the liner must be carried out by specialists licensed for such activities. They also periodically check the functionality of the equipment.

Safety precautions

Any installation work carried out with gas appliances requires mandatory compliance with all safety requirements. The connected flexible hose must always be in front of your eyes. It is strictly forbidden to close it. It must always be located in a place accessible for visual inspection.

It is prohibited to use a gas hose of non-standard sizes. They must comply with existing regulations.

The hose does not need to be painted, as paint may cause it to crack quickly. If you want to make the appearance of the sleeve more beautiful, you can cover it with self-adhesive paper.

The rubber hose is directly connected to the tap if it is located on the outlet. If the thread has non-standard dimensions, an adapter may be used.

When operating gas equipment, it is very important to comply with safety rules and existing operating standards. The fire safety of gas-fired installations depends on this.

Source

Rules for connecting a stove in a private house

If in a city apartment the duties of gas supply service specialists, with whom the owner has entered into a voluntary-compulsory agreement, include mandatory inspection of gas equipment at least once every six months for the safety of the entire house, then in the private sector the situation is different.

Here the homeowner independently makes a decision on gas supply; he can connect to the central gas pipeline and enter into an agreement with the relevant services, similar to apartments, or use an autonomous gas supply from cylinders and gas holders.

With the latter options, you will most likely have to connect the gas stove yourself or with the help of hired specialists without any guarantees. Therefore, you should approach the matter with full responsibility and carefully study the technologies in order to choose the right components and carry out high-quality installation.

Installation of gas hoses

Rules for connecting a stove in an apartment

When using a stove in an apartment, it is better to entrust its connection to specialists from gas supply services and organizations, with whom you must first conclude an agreement for the supply of natural fuel with the opening of a personal account to pay for services. An agreement is usually necessary when purchasing a new apartment; the list of documents that are generally needed to connect a gas stove in compliance with all standards is as follows:

- Certificate of ownership of the apartment and a certificate confirming state registration of housing.

- Registration certificate for the apartment.

- An old contract for the maintenance of the stove and a subscriber's book, if available.

- Passport for the installed stove and gas meter.

The documents collected by the homeowner are submitted to the gas service, after which its specialists issue forms for filling out a gas supply contract. After filling out the papers and receiving instructions on the operation of gas installations, the contract is signed by both parties with the issuance of permission to connect the equipment.

Pipes for gas stoves and panels

Connection using a pipe

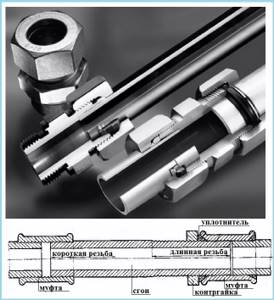

Connecting a gas stove with a metal pipe is used quite rarely in households - this technology is complex, economically unprofitable and obsolete, and it does not allow installing the stove in another place. To connect, it is necessary to manufacture and bend a pipe of a given size, cut threads at its ends and connect it to the main line and equipment using couplings.

- When carrying out work, several options are considered: in the first case, the supply pipe is welded to the main pipeline, and the second end is connected to the slab using a surge coupling with a fixing nut.

- In another option, couplings with lock nuts are installed at the edges on the supply pipe section (threads are pre-cut on both sides), which is then screwed to the main pipeline and the outlet pipe of the slab.

You can do without couplings with nuts to implement a collapsible connection if you have a welding machine - for this, American adapters are welded to the two ends of the pipe.

One of the rather rare connection options is the use of copper pipes - in this case, the workpiece is bent as required with a pipe bender and fittings with union nuts are soldered to its ends.

Connection diagram for a pipe section using couplings

Instructions for self-connection

Paying a gas technician for installation work is not too high, but many home craftsmen prefer to do everything themselves. This is a feasible task that requires the purchase of components and theoretical knowledge.

To connect, you will also need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver for tightening the clamp, if required;

- sealants (Loctite 55 thread, flax, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2′;

- a brush and soap solution, which will be required to control the work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary seal against gas leaks. The narrowed edge of the plug must be adjusted to fit the hole in the supply pipe. If during the extraction process a homemade part gets stuck, you can easily remove it with a corkscrew.

Step #1: Removing the old slab

Shutting off the crane when lowering is a primary task to ensure the safety of the work being performed. Next, you need to unscrew the locknut located on the outlet and remove the coupling. If the old slab has a coupling and locknut that were previously painted, this will significantly complicate the process of dismantling them.

Sometimes it is not possible to complete this procedure, then you will need to cut the eyeliner with a grinder.

The gas stove is dismantled after disconnecting the gas main from the conductor pipe. Difficulties that arise with unscrewing the lock nut on a metal pipe can be solved by cutting off the liner

In the process of unscrewing the squeegee located in the lowering valve, it is necessary to hold the valve itself with a key. It does not have to be removed unless you plan to replace the faucet. When they plan to delay the installation of the slab, an additional plug is installed on the lower side.

Step #2: Replace the faucet

There are situations when the wall is located very close to the tap and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue doing the work.

It is necessary to prepare a piece of rag sufficient to completely block the pipe after dismantling the old tap. The next thing will be to tear it off without completely unwinding it. You will also need to prepare the selected type of seal. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the tap, the outlet from the pipe is tightly fixed with a finger and then with a wet rag. The main actions are aimed at eliminating gas escape from the pipe as much as possible. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the seal, the threads on the lower end must be thoroughly cleaned. Next, its winding is carried out directly. This process ensures a reliable and airtight fixation of the new faucet, which is then tightly screwed on. The last step is to install the previously removed handle on the faucet.

Using soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work was completed correctly, installation of the gas hose can continue.

If gas equipment is connected to the mains for the first time, you will definitely need to call a gas technician. In his presence, the equipment is checked for gas leaks when the valve is open. If the gas service worker does not find any violations, he must enter the established brand of stove into the register.

Step #3: Connecting the Flex Hose to the Stove

The external thread of the hose fitting is wrapped with a sealant. After this, it must be screwed into the tap on the branch pipe. The flexible hose is connected to the manifold at the finishing stage.

Next, the stage of test opening the tap on the lower side is mandatory to check for gas leaks. Using soap foam, the joints are treated with a brush. If foaming occurs when opening the gas tap, the work must be redone.

It is necessary to check the threads located on the manifold of the plate. Quite often it is 3/8′. In this case, you will need to install a 1/2′ adapter with a seal

If the work of replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will produce too much soot, which likes to settle on furniture and dishes in the kitchen.

Safety Rules and Tips

You must adhere not only to the step-by-step instructions, but also to the requirements for a secure connection, which include the following recommendations:

- The connections and flexible hose make them accessible in case of a sudden gas leak.

- The maximum permissible length of 1.5 m cannot be exceeded by a centimeter.

- Twisting, bending, pressing, and contact with hard surfaces is not allowed.

- Normal use is permitted only after inspection by a gas service inspector.

- Before starting work, stop the gas supply and check that the valve is sealed in the closed position.

- During the installation process, only special equipment, fasteners, tools, and seals are used.

- The use of uncertified components and sealing materials is prohibited.

- After depressurization, the pipes are plugged with a damp cloth and released immediately before connection.

- For half-inch pipes, a regular cap from a PET plastic bottle is used as a stopper.

After assembly, each connection is coated with a soapy water solution to detect leaks. Bubbles indicate that the connection needs to be unscrewed, the seal removed, a new one applied and re-twisted. After this, the verification procedure is repeated. At the end of the activities, the tap is turned off, and a master from Gorgaz is called, who must carry out an inspection and make a corresponding note in the log. Even if you have to wait several days for an inspection, do not use the oven as it is unsafe even if everything is done correctly. Only a specialist will identify a defective slab if the manufacturer allowed it.

Connection Security Basics

Any gas equipment, including related ones, must be connected in compliance with safety rules. Gas is an explosive substance, when working with which you should be extremely careful.

This requirement also applies to devices for its connection, which must be of high quality and provide the appropriate level of protection:

- It is not recommended to hide the gas hose; it is important to ensure access to it.

- The product cannot be painted.

- When installing, you should pay attention to the tension of the sleeve - it should sag a little.

- During the installation process, do not bend or twist the eyeliner too much.

- Metal parts of the product must be protected from condensation.

To install a flexible hose, only tools, materials and components designed for working with gas equipment are used. This is worth paying special attention to, because many parts are almost identical to materials for plumbing.

Gas line service life

After installing the hose, you should check its service life and remember the installation date. The product, depending on the type, is designed for a period of 5 to 15 years. It is important not to forget to replace it on time.

Guaranteed service life is indicated in the product passport and in the certificate of conformity.

- rubber hoses (with and without sheath) – 5-year warranty, service life up to 10 years;

- PVC eyeliner – 12-year warranty, lasts up to 20 years;

- bellows gas hose - 15 year warranty, does not require replacement up to 30 years.

How to choose eyeliner

When independently choosing a bellows-type liner for any gas equipment, you must consider:

Types of bellows liners

To connect gas, use:

Types of gas hoses

There are no fundamental differences between the types according to technical data. Hoses with polymer protection are more leak-proof and have a longer period of use (up to 30 years).

Selection of technical parameters

A flexible pipe for gas is selected depending on the following parameters:

Methods for connecting gas supply

Popular manufacturers

In order for the gas supply to last for a long period, it is important to choose the right equipment manufacturer that guarantees the quality of the products. The most popular are:

°C – +100°C and pressure up to 7 atmospheres;

Hose from EMIFLEX

Documentary question

Connecting a gas stove begins not with preparatory work, but with purchasing the stove itself and carefully unpacking it. But even after the most thorough inspection, do not rush to start work. After all, you still need to get a list of documents from the gas service. To do this, you must provide local gas workers with your passport with a certificate of family composition, a title document for housing, a passport for the meter, a maintenance agreement, gas receipts, a subscription book, and a certificate of registration of ownership.

Only after this Gorgaz will issue you a subscription book with notes on instructions on how to behave with gas for you and all members of your family, forms for an agreement on the supply of gas to your home, as well as a contract for this same gas supply.

Advice: after receiving the necessary documentation, try to connect the stove as soon as possible. After all, the warranty period extends from the date of purchase of this household appliance, but not connection. Therefore, if you decide to put your new stove in the garage or pantry for an indefinite period of time, this is not the best idea.