A stove for a cauldron is an essential component of country life. Dishes in a cauldron are prepared according to the same principle as in a Russian oven: the temperature gradually decreases, and the food simmers under the influence of low-intensity heat. This design can be bought or welded (this is a variation on the theme of a tripod over a fire, and it’s not difficult). Building it out of brick is also a solvable task; at FORUMHOUSE, it was successfully completed by people who had never held a mason’s trowel in their hands before. All the details are in our article.

What is a cauldron

A cauldron is a cast iron or aluminum cauldron of a hemispherical shape. This shape allows you to lower the vessel directly into the hearth: this way the heat is evenly distributed throughout the prepared dish.

Cauldrons come in different sizes, but the most common in everyday life are:

- for 2-4 liters;

- for 5-8 liters;

- for 9-25 liters.

The first two types of cauldrons can be placed on a regular gas stove (although a special stand is needed), but for a large container you need a special oven.

The thickness of the walls of the cauldron depends on the material from which it is made. The walls of a cast iron cauldron are on average 2-4 mm, and an aluminum cauldron should be thick-walled, a centimeter or so, then the heat will be retained for a long time and the food will not burn.

Kindling and operation

Laying firewood occurs 1 time. It is impossible to add fuel during the combustion process. Before ignition, you must remove the cover and remove the piston. The logs are placed horizontally and tightly together on the bottom of the oven. Vertical placement is undesirable due to uneven burning of wood and piston misalignment. As a result, smoldering turns into full combustion, which seriously interferes with the proper functioning of the stove. In this mode, fuel is consumed much faster. It is prohibited to block the chimney.

To facilitate ignition, kindling material is poured onto the stacked firewood: sawdust, wood chips or chopped branches. They are covered with rags soaked in kerosene. Place the piston on the bookmark and close the lid. Ignition is carried out through the air duct by throwing burning rags inside through the air pipe. After allowing the wood to burn (about 15-20 minutes), close the air damper, transferring the stove to the main operating mode.

The Bubafonya stove from an old gas cylinder is an interesting heating option that allows you to improve the design almost endlessly. It’s not difficult to do, but if you take into account all the nuances, it will make life at the dacha and the heating process in various outbuildings on the plot of private property easier.

Operating principle of the furnace

The nomads carried a cauldron with them, but they didn’t do any tricks over the hearth: they dug a hole, lined it with clay and stones, made a shallow hole on one side from below for storing firewood, and on the other side from above - a hole through which smoke came out. Such a simple hearth worked flawlessly. A fire was lit at the bottom of the pit, and at the first stage of cooking, the flames only heated the bottom of the cauldron: this was enough to melt the fat and fry the meat. At the same time, the fire heated the stone walls of the hearth, and the rice was cooked in the heat that they slowly released.

A modern stove is the same hearth, only made of metal or brick, on a pedestal, with a chimney and a flat top surface.

Homemade brick device

A brick stove is the device the manufacture of which is associated with the greatest number of difficulties. Before you begin assembling this furnace, you must prepare a sufficient amount of materials and an appropriate list of tools. The material that forms the basis of such a stove is brick. It is recommended to use its fireproof equivalent, although the use of ordinary brick is also acceptable.

A cauldron stove made of this type is stationary and cannot be moved to another place. In some cases, its chimney is equipped as part of the main blast furnace chimney. At the same time, the stove can serve not only as a household appliance, but also as an interior decoration. At the preparation stage, design manipulations are carried out. Drawings are prepared on which the dimensions of all the main parts of the structure are noted: the upper plane of the slab, the firebox, the blower, and the chimney openings.

First, the base of the furnace is prepared - the foundation. The stronger the base, the more stable the future stove will stand , which will prevent it from bending under the pressure of the weight of the cauldron, as well as under the influence of shrinkage processes. The outer walls of the furnace and its inner circular part are laid out simultaneously on the foundation.

The presence of circular masonry is mandatory, since in its absence the weight of the filled boiler will fall solely on the cast-iron surface of the stove, which can lead to its destruction.

The inner diameter of the circular masonry must correspond to the diameter of the hole in the slab. Thanks to this, the weight load will be distributed evenly, and its main part will fall on the brickwork. In the process of laying bricks, it is necessary to follow all the rules of this masonry. It is obligatory to have the elements tied together and the initial construction of the corners (if provided for by the design).

It is important to pay attention to the quality of the seams between the bricks. The factor of heat retention inside the furnace, as well as the degree of their gradual burning, will depend on this. The solution is spread evenly with a margin. Its excess part can be removed by subsequent manipulations.

It is recommended to use refractory mixtures as the base solution, as this will extend the life of the furnace. As an alternative, you can use a clay solution. However, it is necessary to choose the right clay, the quality of which will meet the standards for furnace construction. It should not be too greasy or contain excessive amounts of sand and other impurities. At the stage of laying the outer wall of the furnace, the following elements are laid:

- ash doors;

- grate;

- fire door.

These elements are purchased in specialized stores. They should be made primarily of cast iron. Any other material is not suitable for installation in the oven. This is explained by the fact that elements made from other materials quickly burn out, and a stationary stove device is very problematic to repair.

The firebox of this stove must correspond to the size of the cauldron that will be installed on the stove. Its internal space must be sufficient to load a certain amount of firewood, and the distance between them and the bottom of the boiler must facilitate efficient combustion of the fuel material.

How to choose a stove

All lovers of cooking in a cauldron can be divided into two camps:

- For those who believe that a cauldron demands respect and needs an adult solution - a stove made of fireclay bricks;

- For those who believe that a metal cauldron stove is no worse than a brick one.

BeutifletFORUMHOUSE Member

In my opinion, for simple cooking of “food on coals” it is more advisable to have an iron structure.

Now on sale there are enough not only “barbecues with a stove under a cauldron”, but also quite normal devices. You can buy such an oven if you don’t have any special culinary tasks and plan to do regular outdoor cooking. You can even use a special ring - a stand for a cauldron, which is placed on the grill.

The only thing: if a person likes smoky dishes, not every oven is suitable for him. When preparing such dishes, the smoke should just barely hover above the surface of the pilaf or other food. This effect can only be achieved on the stove:

- cylindrical shape;

- with a plugged pipe;

- with burnout holes in the upper part of the casing nut (this is the name given to the welded rings that make up the stove body).

There are also ready-made metal stoves that allow you to cook the most ambitious dishes in a cauldron. These are no longer a grill with a cauldron stand, they were designed by famous culinary bloggers and are refreshingly expensive.

Laps2 FORUMHOUSE Member

There is either something on sale that you are not happy with, not much different from a ring on a grill for a cauldron, or something that is not at all budget-friendly, so you have to develop and manufacture it “for yourself.”

How to make a stove for a cauldron with your own hands

Many consider the standard of a metal stove to be designed and made according to the ideas of the popularizer of oriental cuisine, Stalik Khankishiev. Its main feature is the ability to control live fire, like a gas burner. Combustion is regulated by a handle that opens and closes the dampers.

Lars2 FORUMHOUSE Member

The convenience of adjusting the combustion intensity is a very necessary option.

This stove has two chimneys: upper and lower (smoke goes into it through the rectangular holes shown in the photo). While it is heating, the smoke goes into the upper chimney, and when it warms up properly, the upper chimney closes. The smoke goes down, gives up all its heat to the cauldron along the way and comes out warm, not hot, through the lower chimney. The walls of the stove are double-layered, so the outside always remains cold.

A stove based on this one was made by FORUMHOUSE member Laps2 for his 18-liter cauldron. The body is bent from sheet metal 5 mm thick and welded with a vertical seam. A sealed, adjustable ash collector acts as an air regulator.

The smoke comes out into the chimney from the back of the stove, so the grate is slightly shifted towards the firebox door for more uniform heating of the cauldron.

FORUMHOUSE participants empirically concluded that the distance from the grate to the bottom of the cauldron should not exceed 30 cm. This is important for proper radiation heating of the cauldron: the wood will burn out, the pilaf will simmer on the coals, and if the distance is more than 30 cm, much more wood will have to be burned.

Lars has a single-wall stove, the original was double-walled. As experience shows, double-walling does not particularly affect the uniform heating of the cauldron, but it increases the efficiency of the stove and reduces the likelihood of getting burned. It is much more difficult to make a double-walled stove (from two pipes of different diameters). A sketch of such a design was developed by our user with the nickname Starodachnik.

StarodachnikForumHouse Member

Flue gases in a two-pipe stove go down, forming a back-up and increasing the sensitivity of the firebox to the opening/closing of the blower and valve.

You can add a very thin and cheap third pipe to the structure and separate it from the second layer of non-combustible insulation.

To implement this design you will need:

- Plate 450x15 mm;

- Pipes 426 and 530 mm with a wall thickness of 10 mm.

- The outer shell is tin or stainless steel, 1 mm (thinner is possible).

- Flat parts made of 10 mm steel.

- Grate 250x87 mm.

- Furnace and blower doors 250x210 mm and 250x140 mm. Chimney sandwich 200 mm, insulation thickness - 50 mm.

An umbrella should be installed on the chimney. The gap between a pipe with a diameter of 530 mm and the outer thin-walled shell must be filled with non-combustible insulation. Install the doors in the frames with a gap of 5 mm on threaded fasteners; also fill the gap with non-combustible insulation. Cleanout doors are needed at the base of the chimney to provide access to the space between the pipes.

Let's look at a few more options for simple cauldron stoves from the craftsmen of our portal.

A 9-10 liter cauldron is ideal for a stove made from a gas cylinder with a diameter of 30 cm.

neznaika-345FORUMHOUSE Member

The damper and blower make adjustment very sensitive, just like on a gas stove. But I did it with a pipe, I like it better with a pipe.

A grate for such a stove can be made in two ways: - cut a round insert from metal, make a rectangular hole in it and insert a magazine grate made of cast iron into it; - just drill holes in the disk.

Starodub welded this stove for a 12-liter cauldron.

Susanin made his own grill for a cauldron from the drum of an old Evrika stove.

It seems that this is too simple, but this approach can be considered authentic: the ancient Turks also made stoves for cauldrons quickly and simply.

Options for stove designs made from gas cylinders

The spherical shape of a natural gas cylinder allows you to create a simply ideal firebox, in which the fuel burns completely, and most of the heat through the walls is distributed throughout the heated room evenly and simultaneously in all directions.

The main thing in a stove made from a gas cylinder is the ease of self-production and low cost of construction

From a gas cylinder you can make with your own hands:

- horizontally and vertically standing potbelly stove;

- heating and cooking stove for a small cottage;

- heater for non-residential and residential premises;

- long-burning pyrolysis furnace;

- summer cooker for the cottage;

- heater for cauldron.

You can use waste, sawdust, peat and, of course, ordinary firewood as fuel for these stoves.

The technology for making a firebox from a gas cylinder is extremely simple. You will need a small set of tools and skills in handling a welding machine. Problems can only arise with the legalization of such homemade products. The requirements of the Ministry of Emergency Situations are strict; it is simply impossible to fully satisfy them when assembling such a structure.

The cylinder can be installed both vertically and horizontally. It is more a question of the availability of space in the room and the intended purpose of the stove. You can heat a dacha, a bathhouse, a garage, a small house, a greenhouse or a barnyard. The stove can also be used as a stove for cooking.

Brick stove for cauldron

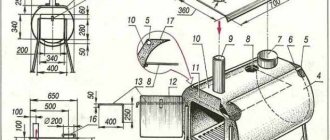

Russian summer residents usually build brick stoves for cauldrons according to the book “Street Hearths” by a member of our portal, Victor Selivan. The task of this design is still the same: to ensure uniform heating of the entire surface of the treasury. Unlike an authentic fireplace, it has a high chimney. And this is a multifunctional design: after two to three hours of heating, it can be used like a tandoor, hanging pieces of meat in the firebox and closing it on top with a damp wooden lid.

The stove is connected to a separate pipe with a horizontal chimney no longer than two meters. The cross-sectional area of the chimneys is at least 300 (one brick).

The firebox must be cylindrical: while the fire is burning in it, the smoke comes out into the vents in its upper part, enters the outlet channel, flows around the cauldron over its entire surface, and only then goes into the chimney.

1 – cauldron; 2 – steel plate 15 – 20 mm; 3 – steel corners; 4 – grate; 5 – combustion door; 6 – blower door; 7 – ash pan; 8 – firebox; 9 – lowering channels (collection) smoke channels; 10 – burnouts; 12 – internal walls of the firebox; 13 – outer walls of the firebox.

Here's the order:

The manufacturing technology of such a stove is described in detail on our forum.

Brick stoves for cauldrons are a big separate topic. Usually they are built in barbecue areas in large areas near Moscow or other large cities, and the stove for the cauldron is part of the complex along with a Russian stove or “pompeika”, barbecue, etc. The photo shows a furnace complex made by Victor Selivan.

A faster option is a tandoor cauldron.

Shader22 did not make a pipe and a fire door; all the smoke goes into the gap between the neck and the cauldron.

Muksipuksi built a multifunctional tandoor made of fireclay bricks. I did masonry for the first time in my life.

Material and tools

To build a fireplace for a barbecue outdoors, you need to have the following tools:

- shovel;

- Bulgarian;

- Master OK;

- mixer;

- welding machine;

- roulette;

- level;

- marker.

Materials needed:

- red brick;

- fireclay brick;

- chimney pipe;

- plate with rings;

- Sheet steel;

- doors for the firebox and blower;

- annealed nichrome wire;

- concrete mixture;

- steel corners;

- fireclay clay.

Working with stone and metal is quite dangerous. It should be performed wearing safety glasses, gloves and a respirator.

conclusions

To cook food in a cauldron according to canonical recipes, you need a special oven. You can buy a ready-made one, but it will either be expensive or pointless, you can weld it yourself “from what you have,” you can lay it out of brick with your own hands - it’s not that difficult.

We offer our article, which tells in detail how to build a universal brick structure with a stove for a cauldron, a barbecue and an analogue of a Russian stove. Read how to make a brick barbecue with a stove for a cauldron. Look at the options for metal cauldron stoves. And in the video there is a street complex with an ancient Aryan oven.

Subscribe to our Telegram channelExclusive posts every week

Shape and size

When planning to make a metal stove for a cauldron with your own hands, you usually choose a simple form:

- Cylinder;

- Square or rectangular prism;

- Rarely, a hexagonal prism with many faces.

So, prism or cylinder?

The prism is easy to bend or assemble from edged pieces, but such a stove will definitely need a top sheet with an even circle under the cauldron.

It is difficult to roll a cylinder without rollers. By simply bending the sheet, you can roll the cylinder, but the surface will be a little uneven, with creases. But the fact that the top sheet with a circle is not necessary for a cylindrical furnace is an undeniable plus. It is important to make the oven the same diameter as the cauldron.

We believe that creating a cylindrical kiln will require less equipment but slightly more effort.

And you also need to decide whether it is necessary to make a chimney or not. The chimney is like a pipe. Usually, a separate chimney is made to reduce smoke around the cauldron. With a tall pipe and good traction it works.