Analysis of the causes of noise in the apartment

Planning soundproofing in an apartment/house begins with the causes of discomfort, as well as your own needs. The usual soundproofing of the floor in the apartment will help against noisy neighbors below, but the roar from playing a powerful audio system will have to be “hidden” under comprehensive sound insulation.

There is no way to completely get rid of extraneous sounds in an apartment; you will still hear them. It is impossible to get rid of the impact noise of the neighbor's hammer drill using floor sound insulation; it can only be reduced.

Selecting sound insulation according to the flooring material

Finishing materials made of wood are excellent sound conductors. Isoplat or Texound underlay is laid under laminate, parquet or plank flooring. In the latter case, “floating floor” technology is also considered.

A screed is made in front of the tiles or porcelain tiles. Insulation made of fiberglass or with a basalt base is installed below the leveling solution.

Linoleum is a soft coating, so fiberglass with a porous-fibrous structure is laid underneath it.

Types of sound insulators and installation methods

Not all types of sound insulation are suitable for a particular apartment. Thus, a noise-absorbing system made using wooden lathing requires high ceilings in the room. Its level is 5 cm, plus the thickness of the plywood on top. As a result, the ceiling will become lower and the parameters of the room will decrease. In this case, modern materials are chosen for soundproofing floors in an apartment with a small thickness but good sound insulation.

The market is overflowing with soundproofing raw materials, and choosing the right one is not easy. However, there is a list of the most popular types of noise absorbers:

- expanded clay;

- stone wool;

- soundproofing;

- cork insulation;

- shumoplast;

- eco-panels;

- Isoplat;

- makes noise;

- expanded polystyrene.

Expanded clay noise insulation refers to frame insulation; it is quite in demand, since the raw material has a lot of advantages:

- very durable;

- does not ignite;

- environmentally friendly;

- resistant to attacks by mold, fungi, and pests;

- not afraid of moisture.

Cons: not used in rooms with low ceilings, causes installation difficulties.

Frameless soundproofing in apartments is not popular, as it can only absorb light noise: loud conversations, background from the TV. But its design is thinner - only 2-3 cm. The frameless version is easy to install and does not eat up space due to its location on the surface.

Mineral wool

Three types of mineral wool act as insulation and sound insulators - slag wool, glass wool and stone wool. You can buy them in slabs or rolls. All types have different densities, thermal conductivities and load effects. They also differ in their heat and moisture resistant characteristics.

Slag

Slag wool is not used in rooms with high humidity. The product is made from various blast furnace slags. It is laid between the lags of the sheathing, but it is still not recommended for residential premises.

Glass wool

Glass wool is always used in tandem with the sheathing. Its main purpose is sound and heat insulation of non-residential buildings: workshops, warehouses, storerooms. Cotton wool absorbs moisture and is therefore unsuitable for use in damp areas. It is not suitable for exterior finishing work for the same reason.

Stone wool

This wool can withstand temperatures up to +550°C and is based on molten rocks. For example, MaxForte EKOplit 110 are basalt acoustic elements held together with safe PVA glue. The material does not contain formaldehyde resins, is considered high-density, and is used without lathing. Copes well with impact noise.

Floating floor

This type of floor has nothing to do with interaction with water; it received its name due to the absence of decorative finishing compounds on the surface. When laying flooring or parquet boards on joists, do not use nails, glue, or screws. Despite this, such a floor is an excellent sound insulator.

We recommend: Instructions for self-soundproofing the ceiling in the house

Cork sound insulation

Cork is an excellent decorative sound insulator; it is laid using laminate technology. It is used to make a substrate - a flooring for any floor covering. Cork perfectly absorbs noise and reflects extraneous sounds from the outside. For example, a 2 cm thick cork material protects against loud sounds in the same way as a 10 cm thick concrete wall.

Cork is sold in the form of slabs, rolls, and panels. It can be used with or without a cork backing. The material has a lot of advantages:

- keeps the room warm;

- environmentally friendly;

- "breathes";

- easy to install;

- eliminates noise at low thickness.

Cons: ignites quickly, is affected by pests, has a high price.

1 sq. m of cork insulation with a layer of 1 cm costs approximately 650 rubles. The price of laying the coating starts from 100 rubles. per square.

Other materials

Less popular sound insulators are soundproofing, expanded polystyrene, shumoplast, shumane.

- Sound insulation is a product made from two-layer bitumen-polymer raw materials, sold in rolls. Easy to install, has excellent hydro- and sound-proofing properties, and can be laid under all types of floor coverings. Minus – high price: 1 sq. m costs 570 rubles.

- Expanded polystyrene is resistant to moisture, weighs little, is cheap, and easy to install. Disadvantages - fragile, quickly flares up from fire. 1 sq. m of extruded polystyrene foam 5 cm thick costs 260 rubles.

- Shumoplast - polymer granules for soundproofing concrete floors. Based on rubber, polystyrene foam, acrylic compounds. For complete sound insulation, a layer of 2 cm is enough. Cons: long wait for complete polymerization - about 2 days, more suitable for floors with floating screed.

- Schumanet is a mineral acoustic slab. It has high density and thermal conductivity, is non-flammable, and is used in damp rooms. Price per 1 sq. m — 260 rub.

Cork sound insulation

Cork is a natural material that has a lot of advantages in its arsenal. One of them is good sound absorption, which is why cork coverings are often used to protect an apartment from extraneous noise.

If we are talking about cork, then you need to understand that it can be not only the top layer of the floor covering, but also a substrate that can be installed under any material. In any case, the natural properties of cork will provide good protection against sounds coming from the lower floors. To understand how well cork absorbs sound, you can consider the comparative characteristics of different materials used in construction.

A small example will suffice: a two-centimeter layer of cork is superior in sound absorption to a monolithic layer of concrete ten centimeters thick. A comparison between cork and wood will end in an unconditional victory for the former: the degree of sound protection on average will be approximately 2.5 times higher.

Installing cork flooring on a bare floor will reduce the noise by half. To achieve maximum effect, you can use cork in combination with other soundproofing material - the presence of layers of different densities in the structure will ensure high-quality noise absorption.

If you use cork as a finishing coating, the quality of the soundproofing cushion will be quite high, and if you also install a balsa wood backing before this, the result will be maximum.

Both the decorative coating and the cork backing have their own positive qualities, for the full implementation of which you need to approach the installation of the selected material competently and responsibly.

Sound insulation by base type

When choosing sound insulation, you should take into account not only the final floor covering, but also the type of base on which the insulation will be laid. This affects the flooring design and future use of the floor.

Wooden logs

Wooden logs serve as a kind of frame for laying sheet, roll and tile coverings. In addition to them, the design uses hydro- and vapor barrier, plywood and finishing. The logs, under which there are a couple of layers of acoustic “cushion”, are attached to the walls using vibration-damping supports. The perimeter of the room is fixed with damper tape.

The plywood sheets placed on top of the joists are secured with acoustic sealant. The seams of the second layer should be placed so that they are offset relative to the joints of the first. Then the finishing is done. Pros of the scheme:

- quick installation;

- replacement of individual elements if necessary;

- flat final base.

Unfortunately, this option is not suitable for heated floors.

Concrete wet or semi-dry screed

Wet screed is the process of filling the base with a cement composition. Usually this is a sand-concrete composition used in almost all areas of construction. Wet screed has many advantages:

- used for wet areas;

- high strength;

- used as a finishing coating for coatings.

Flaws:

- long-term shrinkage - about a month;

- tendency to cracking;

- load on the base due to heavy weight;

- the need for further leveling using special mixtures;

- preliminary laying of reinforcing mesh.

Semi-dry screed is a loose mixture of sand and cement, including additives and plasticizers. It is mixed and supplied to the room using special pneumatic blowers. The finished area is treated with a trowel-grinding device. After grouting, to avoid cracking, holes are made across the entire surface of the floor to a depth of 1/3 of the total thickness of the screed layer.

Before decorative finishing, these seams are masked with sealant. They can be reinforced with metal corners - this will allow the floor to withstand heavy loads and not crack.

You can use the floor, as well as lay a decorative covering on it, or make sound insulation 12 hours after installation.

Dry screed

Drywall, OSB, gypsum fiber sheets, and plywood are used as dry screeds. The raw materials are laid in 2 layers, each secured with special glue. The joints are carefully fixed, which significantly reduces the penetration of sounds. If necessary, the resulting area is puttied and covered with waterproofing mastic. Then the finishing coating is applied.

We recommend: Sound insulation of sewer pipes

Sound insulation materials

The most common soundproofing quality flooring materials are all types of mineral building wool. Construction wool is part of the group of porous materials. Good sound insulation is achieved by a material whose porosity is not lower than 80% and whose pore diameter does not exceed 1 mm. This group also includes aerated concrete and fiberboards.

Soundproofing materials

Despite the many advantages of mineral wool, its main disadvantage is the large thickness of the slabs (from 25 mm). They take up a significant part of the space in the room. To maintain the height of the room, thin foamed synthetic materials are used, containing a large number of small air bubbles in the structure, which serve as good sound insulators.

Membrane soundproofing materials are common: plywood, thick cardboard, special fabric. The membrane is a reliable barrier through which sound waves lose energy.

How to estimate the cost of work

The cost of sound insulation depends on its type, the area covered, and the insulation manufacturer.

| Type | Brand | Characteristics | average price |

| Membrane | Texound-70 | Width – 1.22 m, length – 5 m, thickness – 3.7 mm | 1450 rub. |

| MAXFORT-SOUNDPRO | Width – 1.4 m, length – 5 m, thickness – 12 mm | 1100 rub. | |

| Rolled | MAXFORTE SHUMOISOL | Width – 1 m, length – 10 m, thickness – 4 mm | 300 rub. |

| Vibration stack-V300 | Width – 1 m, length – up to 450 m, thickness – 3 mm | 300 rub. | |

| Slab | SCHUMANET | Width – 60 cm, length – 1.25 m, thickness – 5 cm | 260 rub. |

How much the cheapest sound insulation costs can be seen from the table. Inexpensive products include slabs and roll samples.

The budget option is Zvukoizol-M, its cost with a length of 15 m and a width of 1 m is only 190 rubles.

Installation of the KNAUF Superpol system

- Beacons are installed on the interfloor ceiling to determine the height and horizontal level of the backfill. The thickness of the layer of fine-grained expanded clay is selected taking into account the presence and size of existing irregularities, as well as the need to cover utility lines (if they are hidden), but not less than 40 mm.

- The layer of fine-grained expanded clay is backfilled, leveled and compacted.

- Beacons are removed.

- Vibration decoupling is done around the perimeter of the room, as when using prefabricated screed technology.

- The backfill is covered with GVLV sheets, on which sound insulation will be placed before installing a massive floor screed slab.

- A noise-absorbing layer of mineral fiber material with a density of at least 70 kg/m3 is laid. There should be no gaps or cavities between the mineral wool slabs.

- A massive screed slab is formed from KNAUF Superpol panels, which are two glued GVLV sheets located offset relative to each other. Panel protrusions are used to securely connect parts. On the side of the walls, the protruding parts are cut off to fit tightly into the vibration decoupler. The joints of the panels are glued and fixed with self-tapping screws for GVLV.

- The seams of the solid slab are sealed with gypsum putty.

- Another layer of GVLV is mounted on top of the KNAUF Superpol panels, which is attached to the massive slab with self-tapping screws.

- The flooring is being laid.

- The protruding parts of the vibration isolation around the perimeter of the room are trimmed.

Materials for floating screed using KNAUF Superpol technology

| Floor elements | Thickness, mm | Price per m2 |

| Backfill Knauf 20 | 20 | 200 ₽ |

| GVLV floor | 10 | 200 ₽ |

| Rockwool Floor (first layer and side) | 25 | 200 ₽ |

| Knauf superfloor 20 mm | 20 | 510 ₽ |

| GVLV floor | 10 | 200 ₽ |

| Consumables (glue, edges, screws, etc.) | — | 250 ₽ |

Preparatory work and step-by-step actions

Before installing soundproofing, inspect the walls for cracks, potholes and other defects. Repairing such damage with gypsum plaster can significantly reduce the penetration of sounds into the room.

Let's also consider how to soundproof the floor in an apartment if there are no cracks or putty does not help. In this case, a frame is built on the wall, which is covered with sound insulation and finished with plasterboard. The structure is secured using rubber layers. The sheets are not pressed tightly against the wall - they leave a gap of 4-5 mm, which is subsequently filled with silicone sealant.

Step-by-step instructions for soundproofing the floor in an apartment:

- Soundproof the ceiling and walls - sounds pass through these parts of the room, so insulating the floor alone is not enough.

- Level the floor, sweep well and wash.

- Seal the perimeter of the room with vibration-isolating pads, attaching them to “liquid nails.” The final height of the spacers should not exceed the height of the screed.

- Set the beacons according to the level.

- Lay sound insulation tightly and cover with polyethylene.

- Seal the top with a dry sand-cement screed, proportions 3 to 1.

- After filling a few centimeters of the base with the composition, place a reinforcing mesh.

- Pour another 2 cm of screed onto the mesh, then lay a layer of waterproofing.

- Level the surface along the beacons, then remove them.

- Sand the floor.

In this way, they soundproof a bathroom in an apartment; they work with floors made of wood and concrete; however, there are slight differences in the layout of their installation.

Installation of cork sound insulation on the floor

As a rule, when it comes to choosing cork as a soundproofing material, it means using both the floor covering and the underlay. That is why the process of plug installation will be considered comprehensively.

The work algorithm will look like this:

- Having prepared the base layer, removed all debris and leveled the surface, you can begin installing the cork backing. It must be laid on pre-laid sheets of foamed polyethylene, extending onto the walls by about 5-10 cm and secured with construction tape.

- A backing is laid on top of the polyethylene. All actions must be carried out carefully and confidently, constantly checking the algorithm. If the substrate was originally in the form of a roll, then after laying it you should wait a little for the material to level out and straighten out.

- Plywood sheets are laid on top of the substrate, which must be attached to the floor surface. The floor covering will subsequently lie on these sheets.

Nuances by type of apartment building

The method of insulating floors in an apartment depends on what type of noise bothers residents. This could be a child crying, playing a musical instrument, or structural noise spreading throughout the structure of the building.

Let's look at how to start soundproofing the floor in a panel house with your own hands:

- The old flooring is dismantled, cracks, holes and other defects are cleaned.

- The interior is often finished with mineral wool, filling all the cracks, cracks, and potholes.

- Cover the floor with polyethylene, install wooden logs, and lay a sound insulator between them.

- The top is filled with a concrete screed and covered with plywood or fiberboard.

- Lay a decorative layer.

To soundproof a wooden floor in an apartment, cellular, fibrous and granular materials are used. The most popular fiber option is the most environmentally friendly and has excellent sound-absorbing properties. Boards made from fiber from coniferous trees are highly valued, as they do not contain synthetic compounds.

Floor installation looks like this: mineral wool or glass wool is placed on wooden beams, then logs are placed. Boards or sheets of chipboard are laid on top, and on them there is a finishing coating of the residents’ choice.

Before purchasing soundproofing materials, it doesn’t hurt to check their quality. Often there are low-quality products that do not cope with the functions assigned to them.

Leading manufacturers of soundproofing for floors

On the domestic market of building materials in the segment of soundproofing products, products of foreign and Russian companies are sold, the most popular among users are:

- "MaxForte", "TechnoNikol", "TechnoSonus" and "AcousticGroup" (Russia);

- "WolfBavaria (Germany);

- "Texdecor" (France);

- "Rockwool" (Denmark);

- "Mappy" (Italy);

- "IsoverEcophon" (Sweden - Finland);

There is always the opportunity to choose the right material in the right price range and in accordance with the purpose and nature of use

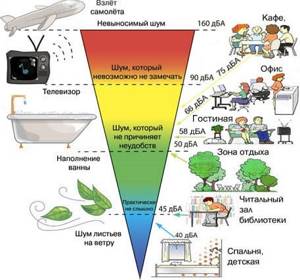

Types of noise

In the fight against noise, there is no one universal recipe, just as there are no universal soundproofing materials. To successfully deal with the problem, you need to know the nature of sounds, how they spread and where they appear.

Depending on the location where the noise occurs:

- external, appears outside a residential building (car noise, construction work, etc.);

- intra-house, when the source of sounds is inside a residential building (elevator operation, loud music from neighbors, etc.);

- intra-apartment - appears as a result of the operation of sanitary equipment, household appliances, people talking, etc.

The path for internal noise to pass through to neighbors below.

According to the medium of propagation of sound waves, noises are:

- Airborne. A sound wave travels through the air. It enters apartments through windows. Installing modern double-glazed windows mostly solves the problem;

- Drums. They arise from falling heavy objects, stomping, hitting with a hammer, etc. Distributed over building elements: walls and floor slabs;

- Structural. The most unpleasant type of noise, since the propagation of sound is helped by the mechanical impact on the wall or floor of a hammer drill, drill, operating electrical equipment, etc., which causes vibration of building elements. The combination of a vibration wave with a sound wave amplifies the latter and carries it throughout the building structure over much greater distances than it could propagate on its own.

Sound intensity from various sources.

Here you need to know one more very important point (from school physics): the wall is a medium for sound transfer, and the ceiling is a repeater of it into the surrounding space. The explanation lies in the different thicknesses of building elements. Once inside the wall, the sound wave cannot escape beyond its boundaries, since its length is less than the thickness of the wall.

Spreading over concrete or brick, at the border with air it ricochets back into the wall, since the conductivity of building materials is several times higher than that of the air space. This effect is well demonstrated by a bullet. Where there is little resistance, there it flies. When it encounters an obstacle, it bounces away from it.

The thickness of the floor slab is less than the sound wavelength. Therefore, she freely breaks into the apartment. From the above, the most important conclusion follows - the fight against noise in a residential area should begin with soundproofing the floor.