The main purpose of any bathhouse is to create and maintain a constant high temperature inside it and (if it is a so-called Russian bathhouse and its analogues) the formation of water vapor in the air, which has a beneficial effect on human health, helps cleanse the body, remove toxins - and simply gives great pleasure .

If the bathhouse is built from foam blocks, then it must be insulated - this is the most important part of the measures for its proper functioning.

Let's talk about how to properly insulate a bathhouse made of foam blocks

The main purpose of any bathhouse is to create and maintain a constant high temperature inside it and (if it is a so-called Russian bathhouse and its analogues) the formation of water vapor in the air, which has a beneficial effect on human health, helps cleanse the body, remove toxins - and simply gives great pleasure .

If the bathhouse is built from foam blocks, then it must be insulated - this is the most important part of the measures for its proper functioning.

About foam blocks

Recently, foam block baths have become especially popular, because a foam block is a material obtained by foaming an aqueous concrete or cement mortar mixed with sand and a special protein substance. It is thanks to the protein that a foam solution is formed, when it hardens, a mass is formed with a uniform distribution of tiny air bubbles inside it.

A bathhouse made of foam blocks is much more accessible to the general population due to the low cost of the material. It is quite possible for even an inexperienced person to build it. Foam blocks are light, durable, fireproof and moisture resistant, but still a bathhouse built from them must be insulated - even despite the high strength qualities of this material.

Useful video

Below is a video that describes in detail the insulation process of a block bath. Before you begin installation yourself, you should carefully read both theoretical materials and video broadcasts on this topic. This video will also answer questions about how to insulate a foam block bathhouse and how to insulate a cinder block bathhouse.

With a responsible approach to insulating a bath structure, you can provide yourself with a real health resort on the territory of your summer cottage.

Materials for wall insulation

Let's take a closer look at insulating materials.

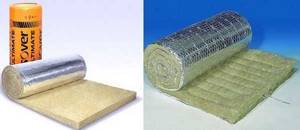

Minvata

Mineral (basalt) wool is very popular and is most often used for external and internal insulation of bathhouse walls. Excellent heat retention, very durable and noise-reducing properties. This absolutely non-flammable material can withstand heating up to 1000 degrees Celsius.

Mineral wool is harmless and biologically neutral, i.e. resistant to the formation of mold and fungi.

Glass wool

Glass wool is inferior to basalt wool in thermal conductivity. Internal insulation of bathhouse walls is impossible with it, because... glass wool cannot withstand heating above 400 degrees. In addition, when this material wears out, it begins to emit an unpleasant odor, which is completely unacceptable for a bathhouse.

Felt

Jute felt is of organic origin and is very good for insulating walls both inside and outside. It retains heat perfectly, is durable, resistant to mold, and has the ability to remove excess moisture from the room.

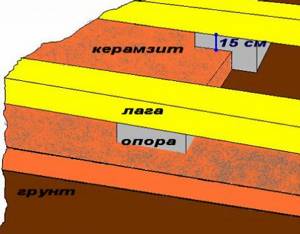

Expanded clay

Expanded clay is a dry heat-insulating substance consisting of light, tiny balls of baked fusible clay. Used for filling horizontal elements of a bath structure - for example, a ceiling or floor.

Styrofoam

Expanded polystyrene (foam plastic) - ideal for external insulation of bathhouse walls made of foam blocks. Typically, external walls are covered with polystyrene foam, fixed with glue and fasteners, and then plastered (or other decorative material is used).

Rationale for using foam blocks to insulate a bathhouse from the inside

Foam concrete blocks belong to a group of materials that retain internal heat, but freeze at subzero temperatures, so bathhouse visitors feel discomfort. The material is hygroscopic and absorbs moisture. It is necessary to insulate a bathhouse from a block inside using technology, since the process has its own characteristics.

Comprehensive thermal insulation includes protection against moisture and steam. The protective layer is installed inside and outside, preventing the foam concrete from getting wet. Foam blocks are chosen grade M25, the density of the material should be D700.

Vapor barrier of bath walls

The most important nuance when insulating the walls of a bath structure made of foam blocks is the correct use of a vapor barrier layer indoors, especially in the steam room. Foiled polystyrene foam is used as a vapor barrier.

When laying heat-reflecting and vapor barrier layers between the interior wall finishing and the insulation, an air gap must be left. The internal finishing material is attached to a wooden sheathing - a special frame that is fixed on top of the heat reflector.

Vapor barrier polystyrene foam is applied to the wall in two layers, while its sheets are combined with each other end-to-end or overlapping, without tensioning the material. Additional sealing is provided using metal (mirror) tape.

A layer of mineral wool can be laid on top of the foil insulating layer on the internal walls of the bathhouse, which is separated from the internal decorative upholstery by a layer of waterproofing. The resulting air gap can be equipped with a ventilation pipe, which will prevent the accumulation of moisture in the thickness of the wall of the bath structure.

Insulation of a steam room made of foam blocks

A bathhouse is a place with high humidity, under the influence of which even the most reliable material can rot and collapse. That is why it is recommended to carry out exterior finishing using ventilated facade technology. For such a system, more suitable materials are such as polystyrene foam, basalt wool in slabs of standard sizes and jute fiber.

Among this variety, I would like to note basalt insulation. It is good in everything: it holds heat better than other materials, despite its small thickness, it does not burn, it is durable and environmentally friendly and safe, and in addition it performs noise-insulating functions.

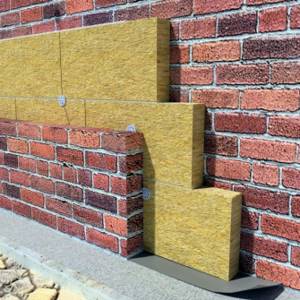

The installation of insulation on a ventilated facade system occurs in several stages:

- In order to properly secure the insulating material, first of all you need to install the grooves on which it will be mounted; they can be made from ordinary angles. The distance between them should be equal to the width of the insulation.

- After fixing the material, all joints are properly waterproofed, and if there is a need for this, it is additionally secured to the wall with dowels. The exception is basalt insulation; it is so elastic that it holds its shape perfectly without auxiliary materials.

- After that, a roll waterproofing material is laid around the entire perimeter. It can be secured using slats.

- On top of this entire structure, guides are placed for the installation of facing materials.

To carry out insulation work inside a bathhouse, you can use the following materials: expanded clay, mineral (including basalt) wool and jute felt.

On top of the insulation, the walls of the steam room can be finished with any environmentally friendly material that does not emit any harmful substances when heated and has good resistance to moisture and elevated temperatures.

The most popular finishing is made from hardwood lining - linden, cedar, larch.

You can also use tile finishing, which is laid on GVLV sheets (for example, Knauf supersheet with a straight (PC) or folded (FC) edge). To glue tiles in a steam room, it is recommended to use:

- Plitonite “super fireplace” is heat-resistant, reinforced, for tiling walls in the area where the stove is installed and the chimney is laid.

- Knauf tile standard for gluing tiles to the shelf level.

- Knauf reinforced fixation “elastic” (“Flex”) for all other areas.

Completion of work

When building a bathhouse from foam blocks, it is extremely important to insulate the floor. Usually the foundation itself is laid with mineral fiber mats. An air gap is also created here between the blocks, from which a ventilation pipe comes out.

From the inside, the floor of the bath structure is insulated with mineral wool or expanded polystyrene and must be equipped with a heat reflector - foil film or polystyrene foam.

The gaps between the blocks are filled with expanded clay, which allows for even more insulation of the floor and at the same time has an air gap necessary for additional ventilation.

Insulation of the walls, ceiling, roof and floor of the bathhouse is carried out according to the general principles of thermal insulation. All seams, joints, and cracks in the insulating material must be sealed. Window openings and doors are small in size, and the windows are given a horizontally elongated shape. All this allows you to maintain as much as possible a constant high temperature and (if desired) humidity inside the bath.

Source of the article: https://x-teplo.ru/uteplenie/bania/uteplenie-bani-iz-penoblokov.html

The process of insulating such a bathhouse is quite simple and even a novice builder can do it. Foam block walls do not require leveling after construction; their surface is almost perfect. Thanks to this, almost any finishing and insulation method can be applied to foam blocks. Moreover, foam concrete blocks, due to their thickness and material characteristics, themselves are excellent thermal insulation. Therefore, insulating a bathhouse from such blocks will require minimal effort. Finishing the walls inside a bathhouse made of foam blocks means protecting the foam blocks from regular exposure to moisture, in order to prevent deterioration of their characteristics, destruction and increase their service life. Before insulation, the walls must be treated with special impregnations with water-repellent properties, after which a special film insulation is made. But more about everything...

Contents 1. What needs to be done to insulate a bathhouse 2. Insulation for buildings made of foam concrete 3. Insulation of walls 4. Insulation of the ceiling 5. Insulation of the floor 6. Conclusion

What needs to be done to insulate a bathhouse

Let's consider thermal insulation options. This is done to ensure that the bathhouse is warm at any time of the year and that you feel comfortable and get maximum pleasure from taking bath procedures. If, for some reason, the bathhouse cannot be insulated, then the heat will escape as quickly as possible. Accordingly, it will lead to financial losses, since the bathhouse will have to be repaired in the near future. For a real bath, the temperature must be maintained.

Work on installing insulation for a bathhouse made of blocks is carried out in parallel with construction work . It all starts with insulating the foundation . It uses a material that is resistant to moisture, biological and temperature influences. The ideal option would be foam . Installation of insulation is carried out after the concrete has hardened and the foundation formwork has been removed. The outside of the building is covered with a layer of waterproofing, after which it is covered with insulation sheets. The thickness of the insulation must be at least 5 centimeters. The best option would be to lay two layers of insulation 5 cm each in a checkerboard pattern. After this, the surface of the foundation is plastered, preferably with “warm” plaster.

- The foundation in the bathhouse is insulated using mineral mats. A layer of expanded clay and slag is laid under the floor. To prevent the accumulation of moisture from inside the foundation, a ventilation hole is removed.

- Vapor barrier of walls . High-quality insulation of a bathhouse made of foam blocks is impossible without effective vapor barrier of the walls. The best material for this would be foil. It is laid on top of the insulation in vertical overlapping strips, without tension. Since foil is a rather thin material, it can be laid in two layers. The seams between the strips are sealed with reflective tape. The vapor barrier is installed in such a way that there is a small gap between it and the subsequent finishing of the bathhouse.

- A huge part of the heat escapes through window openings . Therefore, cracks that appear are sealed with any material that is less susceptible to burning. To eliminate fogging of glass, it is necessary to check how tightly the window frames fit to the frames. It will be very good if the windows have at least two glasses, and preferably three. But when insulating, it is worth noting that the shape of the windows must also be taken into account. The most optimal window shape is a rectangle that is elongated horizontally.

- To better retain heat, a small doorway . Doors and windows are required to be airtight.

- If in any place the thermal insulation is not done well or is simply not enough, this will have a significant impact on the heating of the bath.

Insulation for buildings made of foam concrete

It is usually recommended to use natural materials as insulation for bathhouse walls due to their environmental characteristics. For interior decoration, this requirement is justified. But synthetic insulation materials are also suitable for exterior decoration and insulation of baths. What materials are most often used for insulation?

Mineral wool is a popular material with good thermal insulation properties. It is resistant to high temperatures, withstands heating up to 1000 degrees, which allows it to be used not only for exterior, but also for interior decoration. Mineral wool is durable, resistant to biological influences, and is not susceptible to rotting or fungus formation.

Glass wool - has slightly lower thermal conductivity than mineral wool. For such a purpose as insulating a bathhouse made of blocks from the inside, it is not suitable due to its poor reaction to high temperatures. When worn out, glass wool emits an unpleasant odor, which also makes it unsuitable for interior decoration.

Jute felt is a natural insulation material of organic origin. Ideal for insulating bathhouse walls made of blocks inside and outside. It retains heat perfectly, is resistant to mold and mildew, has high strength and the ability to remove excess moisture from the room.

Expanded clay is a dry granular substance consisting of small balls of baked clay. Used for insulation of horizontal surfaces - floors, ceilings of bathhouses.

Polystyrene foam - usually used to insulate the outside of a bathhouse. They cover the facade with it, fixing it with glue or fasteners, and finish it with any chosen material - plaster, siding, panels.

Wall insulation

In order to insulate a bathhouse made of foam blocks, expanded clay or slag blocks, first of all, you need to choose insulation. Let’s say right away that the most environmentally friendly product in this situation will be felt, but since it is not available for sale on the construction market, we will have to choose from what is available.

Foiled mineral wool

Based on the above data, we can come to the conclusion that in order to insulate a bathhouse made of expanded clay concrete blocks, of all the listed materials, mineral wool will be the most suitable (this includes stone wool, glass wool and slag wool). Its price is not very high, and you can choose the required thickness (from 20 to 200 mm) depending on the climate of your region. But in any case, you will need foil for waterproofing .

Foil polyethylene foam

If the mineral wool does not have a foil layer, then it needs to be added, and foil polyethylene foam, which you see in the photo above, is excellent for this. The thickness of such material varies from 2 to 20 mm, and by covering a layer of mineral wool with this, you significantly increase the effectiveness of thermal insulation.

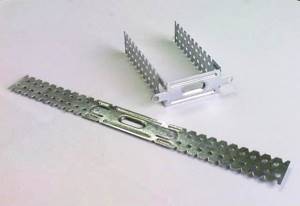

U-shaped belt suspension brackets (pawns)

For wooden lining, that is, for cladding a steam room, you need a sheathing that will be attached to brackets, or it will be thick bars, between which insulation for the bath will be installed. The second option is simpler, but installing timber on a block wall is not so easy, even if it is plastered. The fact is that if the thickness of the sheathing is 100 mm, then anchor bolts will be needed to fasten it, which is not entirely acceptable for a wall made of such material.

Mineral wool is inserted through the consoles

We continue to consider how to insulate a cinder block bathhouse from the inside and will install the sheathing. Place some kind of waterproofing material on the wall, under the brackets, and then attach the consoles themselves with bod profiles. Mineral wool is threaded directly through the pawns, and then carefully covered with foil polyethylene foam, trying to ensure that no holes remain.

Advice! If you are interested in insulating plastic windows, then I can disappoint you - they are not insulated. Just so that they transmit less heat, you can use two-chamber or three-chamber double-glazed windows, as well as a thick, five-chamber plastic profile.

Ceiling insulation

Insulation of the ceiling in the bathhouse

The method of insulating the ceiling in a bathhouse made of foam blocks depends on the design of the roof.

If there is no plan to install a “working” attic , use an open type of ceiling insulation. In this case, the ceiling sheathing is covered with a layer of waterproofing, on top of which a layer of insulation is poured. expanded clay is most often used for these purposes , covering it with a layer of at least 25 centimeters. But you can use the old-fashioned method - sprinkle the surface with sawdust and earth . A layer of waterproofing is again laid on top of the insulation - roofing felt, polyethylene film, etc.

With a closed type of insulation, layers of insulation and waterproofing are covered on top with the attic floor. In this case, mineral wool is most often used as insulation. It provides the necessary thermal insulation with a thinner layer thickness than bulk insulation. Installation of insulation occurs according to the same scheme as the insulation of bathhouse walls - vapor barrier, insulation, waterproofing layer. When thermally insulating and waterproofing a ceiling, only the installation plane changes. Considering that there cannot be foam blocks on the ceiling, but, for example, a wooden floor or a concrete slab, timber can be successfully used as a sheathing.

Advice! To make it easier to install mineral wool on the ceiling so that it does not fall, use nylon thread. From beam to beam, a constriction is made in the form of a mesh, fixing the material.

Floor insulation

Bathroom floor insulation

The method of insulating a bathhouse floor depends on its design. If you are installing a “cold” leaky floor that has gaps between the boards to allow water to drain out, you will not be able to insulate it.

Insulation work can only be carried out with a “solid” non-leaking type floor. Such a floor is installed with a slight slope and equipment in the underground catchment area. To insulate a “deaf” floor, use mineral wool or expanded clay chips . The insulation is placed between the rough and finishing layers of the floor covering.

On the ground side, the insulation is protected with waterproofing; on the room side, a vapor barrier material is installed to protect the insulation from moisture. If a concrete floor is planned for the bathhouse, it is insulated by placing insulation in the screed. In the washing compartment you can install a “warm floor” system to provide additional comfort.

Conclusion

We looked at how to insulate a bathhouse made of foam blocks, and what material is most suitable for this.

Wood is an excellent insulation material, which means that the thickest wooden lining can be used (10-14 mm). The use of wooden lining as a finishing material for a foam concrete bathhouse is a very popular solution, firstly due to the significantly lower price, and secondly due to its pleasant appearance and real aroma of wood, without which the bathhouse would not be the bathhouse that everyone knows. It is advisable to make the floor in the bathhouse wooden or make a warm floor under the tiles on the floor. Sufficient care must be taken to seal all seams on doors and windows.

As you can see, building a bathhouse from foam blocks is not so difficult and you can probably do it. We hope that a bathhouse made of foam blocks will serve you for many years and delight you, giving you warmth and steam!

Features of insulating a bathhouse made of foam blocks from the inside

The need for additional thermal insulation measures is obvious. Despite the fact that foam blocks are a material that retains heat quite well, it can freeze in severe frosts and not provide the room with the necessary comfortable temperature. And for a bathhouse, maintaining heat inside is a very important point.

Insulation of walls in a bathhouse made of foam blocks from the inside has its own characteristics. This is primarily due to the fact that this material has a porous structure into which moisture can easily penetrate. Lingering inside, it can not only significantly reduce the ability of thermal insulation, but also affect the durability of the structure itself.

Advice. In addition to insulation, use waterproofing materials. This applies to both auxiliary premises and the steam room itself.

The most popular waterproofing material is membrane film or isospan.

As for insulation materials for insulating walls from the inside, the following most popular types can be noted:

- Mineral wool - the material is excellent due to its resistance to high temperatures, withstands heating up to 1000 degrees. That is why it is popular for insulating walls directly in the steam room. Mineral wool is durable and not susceptible to rotting and the formation of mold and fungi.

- Jute felt is great for insulating the walls of a bathhouse from the inside. This natural material has high thermal conductivity and is also able to remove excess moisture from the room. Not susceptible to fungi and mold. Also suitable for insulating a steam room from the inside.

- Foil insulation is a specially developed material for insulating walls and ceilings in saunas and baths. It is great for insulating a steam room. Its main advantage is the possibility of installation without battens.

Glass wool and foam insulation are not suitable for insulating the walls of a bathhouse from the inside, since these materials are not able to withstand high temperatures, and can also release toxic substances when heated, which will in no way help maintain a healthy microclimate.

Features of external work

A special feature of the design of bath walls is the requirement for their thermal characteristics in combination with resistance to moisture, and in a steam room also resistance to elevated temperatures.

Moreover, unlike a country house, where at different times of the year a comfortable air temperature must be ensured with the least energy consumption, in a bathhouse the walls should retain heat only for the duration of its use, that is, periodically from time to time. This allows you to reduce the amount of construction work by reducing the thickness of the wall and installing a stove of sufficient power that quickly warms up the premises.

It is believed that in a steam room the walls should be especially carefully waterproofed so that moisture from the room is not absorbed into the porous foam blocks. This is partly true; the porous structure of foam blocks reduces their frost resistance, and if they get wet and subsequently freeze, such blocks can crack quite quickly.

At the same time, when visiting a bathhouse, the amount of water used in the steam room can be only 2-3 ladles of water, which, you see, is not the amount of moisture that can wet the walls enough to cause them to freeze.

A properly selected stove provides good draft, quickly “pumping” moist air outside the bathhouse. And in order to expel humid air from the interior of the bathhouse to the street, after the bath procedures it is enough not to immediately put out the stove, but leave it to burn for another 15-20 minutes, throwing in 2-3 logs.

When designing the cladding structure and selecting thermal insulation, it is necessary to take into account the properties of the bathhouse caused by the material used for its construction.

Foam blocks

The specificity of the resource is its porous structure, since the production technology involves foaming a concrete mixture with protein additives and sand. Therefore, during insulation, the foaminess of the raw material leads to the fact that the blocks need to be protected from moisture as best as possible. Otherwise, excessive dampness will lead to a decrease in the thermal insulation parameters of the structure and its service life. You should not use polyethylene here; membrane films are more appropriate.

When insulating with foam blocks, you need to use membrane films

Expanded clay concrete

In the process of insulating a bathhouse made of expanded clay concrete blocks from the inside, the porous contents of the workpieces are also taken into account; they are made on a vibropress. This is an environmentally friendly and easy-to-build material; it absorbs moisture abundantly. When arranging the “pie,” you need to provide waterproofing from kraft paper and a foil screen.

Cinder blocks

The budget resource can have different standard sizes, and the low price is explained by the use of waste from the coal and metallurgical industries as raw materials. Products vary in size, weight, and thermal conductivity.

As in the case of expanded clay concrete blocks, a ventilated gap should be maintained during the assembly of internal insulation. For cladding, you can use wood in the form of a block house or lining; it must be impregnated with compounds intended for use in hot, humid microclimates. The boards should be sewn horizontally so that as the lower segment wears out, local replacement can be made.

Gas silicate

The insulation of a bath made of gas silicate blocks is carried out in accordance with the type of base material. If this is a category from D800, it means that the structures are characterized by insufficient thermal insulation and high strength. The gap between D500-D800 is characterized by average parameters in both respects, while blocks of grades below D500 have excellent insulating properties and low strength.

When insulated, aerated concrete products need to protect air cells from moisture penetration and contact with high temperatures, otherwise the raw material will lose durability and strength.

Initially, it is advisable to prepare and plaster the facade in order to achieve acceptable evenness of the walls and fill existing cracks and crevices. Most often, the facade of aerated concrete baths is sheathed with mineral wool or expanded polystyrene. In the first case, the walls are first covered with rolled materials to protect the insulation from moisture.

If polystyrene foam boards are a priority, they can be fixed on external surfaces without worrying about laying guides in advance; This is where special glue or polyurethane foam comes in handy. Next, the panels are additionally fixed with dowels, the joints and seams are filled with foam. A sheathing for installation of siding is stuffed on top: this sheathing will help protect the insulation from mechanical damage and exposure to ultraviolet radiation.

Features of different materials for insulation

Bathhouse premises are divided into types depending on the internal microclimate. The washing room, steam room and combustion chamber have high humidity and temperature, and the rest room and dressing room have normal conditions.

The following insulation is used for bathhouse premises:

- jute felt;

- mineral wool;

- expanded clay;

- Styrofoam.

The materials are intended for different rooms, because... differ in properties and characteristics. When choosing, the hydrophobicity of the insulation and the ability to release harmful substances when heated are important.

Jute felt

Natural fiber from the plant of the same name is used in production. Natural resins protect the threads from rotting; the material is durable, environmentally friendly, and has a uniform density throughout the mass. Polyester fibers are used for bonding, which impart elasticity.

The peculiarity of jute is that when it is hot, it does not release toxic substances into the surrounding space. Requires film vapor and waterproofing, since the fibers get wet when in contact with moisture.

Mineral wool

Mineral wool

Types and characteristics of vapor barrier materials

There are quite a few of them; we will focus only on a few of the most frequently used ones. Let's start again with a little “educational education”. Some amateur builders do not fully understand the difference between vapor barrier and waterproofing materials. After all, steam is the same as water. Why should some materials be used for vapor barrier and others for waterproofing?

Vapor barrier and waterproofing. Differences and Similarities

The fact is that water molecules and steam molecules have different sizes. Based on these characteristics, manufacturers produce materials with different micropore diameters. Some do not allow steam molecules to pass through (vapor barrier), while others do not allow water molecules to pass through. This means that vapor barrier materials can also be used as waterproofing, but the latter cannot be used in the same way. Recently, the production of vapor-waterproofing fabrics has begun; they consist of two layers with different micropore diameters. When installing such materials, you need to monitor the location of these sides so as not to install “exactly the opposite.”

Anti-condensation multilayer vapor barrier “Brane D Super”

Tyvek Solid is a single-layer waterproofing material with high vapor permeability that protects against precipitation and wind

ISOSPAN FX reflective heat-hydro-vapor barrier

Izospan RS

Izospan fx

Prices for Izospan

Izospan

What vapor barrier materials are produced?

| Material | Description |

| Ordinary polyethylene film. | The cheapest, but pretty good option. It has another significant advantage. The films are produced in sleeves with double walls, the sleeve width is up to three meters. By cutting the sleeve in half, you get a sheet of continuous film more than five meters wide - quite enough to cover the wall of a bathhouse with a continuous material without overlays. |

| Glassine, roofing felt and other bituminous materials. | They are rarely used in baths due to the likelihood of unpleasant odors. |

| Pure aluminum foil and aluminum coated multi-component materials. | Used most often, multi-component materials have a small layer of thermal protection or special fibers to prevent condensation from draining. |

| Liquid rubber. | An excellent vapor barrier material that can be applied to surfaces of any complexity and configuration. |

| Liquid polyurethane foam insulation. | In addition to their main tasks of insulation, they have a sealed outer surface that does not allow steam to pass through. Universally applicable, characterized by high performance characteristics. |

How to insulate a bathhouse from the inside

The technologies for insulating a log house and a brick bathhouse are very similar. Most craftsmen do not consider it necessary to insulate the walls of the bathhouse from the inside, paying attention only to the roof, ceiling and foundation. So let's find out the reasons why you should insulate a bathhouse from the inside and what technologies exist for this.

Insulation of the steam room - photo

Why do you need to insulate a bathhouse from the inside?

The diameter of the wooden crown in a log bathhouse is most often 20 centimeters. If the caulking was done efficiently, then there will be no need to insulate your bathhouse from the inside. But there are still reasons why this is necessary:

- it may happen that the diameter of the crown in the log house is small, which in the future will lead to poor thermal insulation;

- The bathhouse must be insulated from the inside if the foundation has not been insulated. Or it was insulated, but very poorly;

- Due to bad weather conditions, the insulation of the bathhouse from the outside is insufficient.

The masters are confident that if the bathhouse is insulated well enough, then heating it will take 3 times less energy, and it will be possible to use a weaker stove.

Insulating the walls will allow you to save on fuel in the future

The structure of the walls of an insulated bathhouse is very similar to a thermos (sometimes this is called an insulation “pie”). After all, those who are going to really insulate a bathhouse with high quality will need steam and waterproofing.

The walls of an insulated bathhouse have the following structure: a pre-prepared wall, a mandatory layer of waterproofing, thermal insulation, vapor barrier and, of course, decorative finishing.

If you choose the right quality material, you can independently cope with the insulation of the bathhouse from the inside very quickly. To insulate a bath you will need material that will:

- high quality, with high thermal insulation properties;

- not prone to rotting and will not be damaged by a variety of insects;

- most importantly, the insulation must be fire-resistant, because the temperature in the bathhouse can be above 100 degrees.

Since not all materials are suitable in quality and properties for internal insulation of a bathhouse, experts most often use basalt wool. In addition to the fact that it has a very reasonable price, basalt wool is also suitable in other respects. In addition, it is recommended to choose special synthetic boards that have a soft structure.

Insulating a steam room from the inside: recommendations

Note. When insulating the floor in a bathhouse, it is recommended to use an expanded clay layer, and polystyrene foam boards are ideal for the roof in a bathhouse.

It should be remembered that when insulating walls, you should perform hydro- and vapor barrier in parallel with thermal insulation, because these processes are closely related.

First of all, you should prepare the surface of the walls.

If you see any cracks or seams, you should fill them with plaster. Experts also recommend using sealant for these purposes. Once you have finished, you should move on to the next stage - waterproofing.

Note. If your bathhouse was made from a log house, then waterproofing it immediately after construction is strictly prohibited. First, you should wait until the shrinkage finishes, often this takes more than a year.

Insulation schemes for log walls

How is hydro- and thermal insulation produced?

First of all, you should protect the walls, floor and ceiling of the bathhouse from moisture. It is best to use polyethylene film or special foil.

The insulation technology itself using foil is simple. You should do the following:

- First of all, you should vertically attach wooden blocks (4*4 centimeters) to the wall of your bathhouse. It is to them that the foil will be attached. Make sure that all the bars are in the same plane; when working, use a laser level or pull a guide cord for convenience. If necessary, place thin wedges between the wall and the bars. Fasten the bars with long self-tapping screws, first drilling holes for them in the wall and the bars themselves;

Frame for insulation

Next, you should place the insulation between the bars (it should be no thicker than the bars themselves);

Laying insulation between the sheathing bars

- foil is attached to the bars, which is carefully stretched and secured using a special stapler;

- all kinds of joints must be insulated with aluminum construction tape;

- on top of the foil, which has been carefully fixed, you need to stuff wooden blocks in a vertical direction;

- and lastly, the facing board (lining) should be attached to the beams.

The photo shows the insulation, the sheathing for the lining and the facing panels themselves

Note. All bars must be lubricated with a special antiseptic in advance.

Insulation for buildings made of foam concrete

It is usually recommended to use natural materials as insulation for bathhouse walls due to their environmental characteristics. For interior decoration, this requirement is justified. But synthetic insulation materials are also suitable for exterior decoration and insulation of baths. What materials are most often used for insulation?

- Mineral wool is a popular material with good thermal insulation properties. It is resistant to high temperatures, withstands heating up to 1000 degrees, which allows it to be used not only for exterior, but also for interior decoration. Mineral wool is durable, resistant to biological influences, and is not susceptible to rotting or fungus formation.

- Glass wool - has slightly lower thermal conductivity than mineral wool. For such a purpose as insulating a bathhouse made of blocks from the inside, it is not suitable due to its poor reaction to high temperatures. When worn out, glass wool emits an unpleasant odor, which also makes it unsuitable for interior decoration.

- Jute felt is a natural insulation material of organic origin. Ideal for insulating bathhouse walls made of blocks inside and outside. It retains heat perfectly, is resistant to mold and mildew, has high strength and the ability to remove excess moisture from the room.

- Expanded clay is a dry granular substance consisting of small balls of baked clay. Used for insulation of horizontal surfaces - floors, ceilings of bathhouses.

- Polystyrene foam - usually used to insulate the outside of a bathhouse. They cover the facade with it, fixing it with glue or fasteners, and finish it with any chosen material - plaster, siding, panels.

Expanded clay concrete blocks are a rather controversial material that has significant advantages and the same disadvantages.

One of the most obvious is its hygroscopicity, which is completely inappropriate in a room with high humidity. This is explained by the fact that in severe frosts, blocks of expanded clay concrete saturated with moisture will freeze and collapse.

If we take into account the fact that in winter, after heating the bathhouse to very high temperatures, it remains to cool, then in one or two years the frost resistance limit will be completely exhausted.

That is why insulating a bathhouse made of expanded clay concrete blocks from the inside is simply necessary in order to avoid premature destruction of structures.

Expanded clay concrete has many more advantages:

- It is one of the most environmentally friendly materials because it is absolutely non-toxic;

- Light weight;

- Good thermal insulation properties.

Bath insulation technology

To properly insulate a bathhouse made of foam blocks, it is necessary to cover all surfaces: floor, ceiling and walls with thermal insulation materials.

Floor insulation

You need to think about floor insulation even at the stage of building a bathhouse. To increase the protection of walls from groundwater, a layer of waterproofing should be laid between the foundation and the foam block masonry. Most often, ordinary roofing felt or similar materials are used for this.

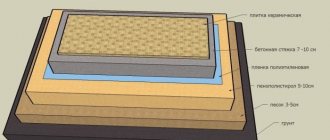

Having erected the walls, you can proceed directly to the equipment and insulation of the floor. All work in this direction is as follows:

- The earthen base is leveled and covered with thick polyethylene in several layers. This is done to prevent moisture from seeping into the insulation layer.

- Then a layer of expanded clay, at least 10–15 cm, is poured in and compacted thoroughly.

- You need to make a cement screed on top of the expanded clay. In this case, you should use a reinforcing mesh, which can be placed directly on the expanded clay or buried in the thickness of the mortar during the process of pouring the floor.

- The top layer of the screed must be carefully leveled using a long rule.

Vapor-tight or vapor-permeable finish?

The choice is quite complex and should depend on the conditions in which the foam block building will be erected. For example, if a house made of foam blocks is built in a rather humid area (high humidity and frequent rain), then the best option is a vapor-tight finish. But, you need to take into account in advance that the foam block must dry well before finishing.

- If a foam block building is erected in a drier area, then a vapor-permeable finish is better suited. It, as already mentioned, will create an optimal microclimate indoors and allow the insulation and foam blocks to “breathe”.

- As for bathhouses, their vapor barrier is mandatory. It will increase the temperature and reliability of the building. The same rule can be applied to bathrooms that have foam block walls.

- The main danger posed by high indoor humidity is the appearance of fungi and mold, which can harm human health and are quite difficult to get rid of.

- The foam block does not contain organic substances, so the appearance of fungus in it is excluded, but if the vapor barrier is not properly organized, microorganisms may appear on finishing materials - wallpaper, drywall, etc. Unfortunately, not a single building material that exists today and is used for the construction of walls is immune from such phenomena.

Tests carried out under different conditions allow us to assert that, with proper finishing, the foam block can last for decades without any problems such as mold and mildew on the walls, condensation, increased dampness in the premises, etc. It is enough just to properly organize the ventilation inside the room, waterproof the foundation in case of high groundwater levels and prevent the walls from completely freezing with sudden heating - it is temperature changes that, more than other factors, act destructively.

That is why it is strongly recommended that even at the stage of designing a house, you discuss this point with the builders and contact only professionals in their field who will competently and clearly answer your questions.

07.12.2016

Contrary to the claims of manufacturers that such foam and aerated concrete blocks do not need additional insulation, in practice it turned out that in the Russian climate a layer of thermal insulation is not superfluous for them. First, let's figure out how these materials differ.

Wooden floors

Wooden floors are insulated in a different way than concrete floors. For these purposes, more suitable polystyrene foam boards and foamed polymers are ecowool or Icing foam.

Insulation of wooden floors includes the following steps:

- The bars are ground to the very bottom edge of the main beams; they will be indispensable for constructing a subfloor.

- Pre-cut boards are laid between the beams on bars; the dimensions of these boards should be slightly smaller than the distance between adjacent beams. It is better to use low-grade wood for the construction of the cranial floor.

- A waterproofing membrane with a vapor-protective film is laid over the resulting layer; it should cover the entire area of the wooden floor structure. Expensive film can be replaced with sheets of roofing material with seams taped with bitumen mastic.

- Insulation is laid on this layer, on top of which the finishing floor boards are mounted and baseboards are installed.

An important point is that there should be a gap of 4 cm between the top boards and the layer underneath; it is necessary for drying the boards.

Concrete floors

If you decide to pour a concrete floor, then the bottom slabs or subfloor on the ground are thoroughly protected from the harmful effects of moisture. For these purposes, you can use rolled material in 1 layer or coating mastic in 3-4 layers. An alternative is to combine these types of waterproofing materials, after which the selected insulation is installed. If it is expanded clay, then it can also be mixed into the concrete screed. By the way, you can also insulate it with a layer of 25 cm of foam concrete of lower density. A reinforcing mesh is mounted on the installed insulating layer, this is done to prevent destruction of the concrete coating. After strengthening the floor, a concrete screed is laid on the reinforcement frame. The finishing coating depends on the wishes of the owner of the future bathhouse.

Ceiling insulation

Without reliable thermal insulation of the ceiling, it is impossible to properly insulate the bathhouse from the inside. More than 90% of thermal energy rises to the ceiling and evaporates. There are two methods for insulating the ceiling:

- The first method requires the use of foil, which is placed on the ceiling of the bathhouse from the attic side. Then the foil is covered with a layer of waterproofing and the entire space between the rafters is filled with fine expanded clay. Then the expanded clay is covered with another layer of plastic film on top and the roof can be installed.

- The second method is more suitable for a bathhouse with an attic. In this case, instead of expanded clay, you can fill the ceiling with clay mixed with sawdust. The effective layer of such coating is 20–25 cm.

Wall insulation

In order to properly insulate the walls of a bathhouse from the inside, it is necessary to use frame technology:

- Wooden sheathing is mounted on foam block walls.

- A layer of waterproofing material is installed.

- Insulation is being installed.

- Then you need to install another layer of vapor barrier.

Advice! To increase thermal insulation properties, it is best to choose a vapor barrier material based on foil. This will shield thermal energy, thereby reducing heat loss.

Based on the above material, it is quite easy to insulate a bathhouse. A distinctive feature of such work for a structure made of foam blocks is the use of a large amount of waterproofing material. A properly insulated sauna will last a long time and bring a lot of positive emotions.

Attic insulation

To insulate the attic, you can use mineral wool.

If the bathhouse is built with a technical upper floor, it is insulated along the covering, walls and slopes.

Materials used for the horizontal layer:

Insulation of walls and ceilings in the attic is done according to the insulation scheme for similar surfaces in the bathhouse.

Materials

For a steam room, the best vapor barrier materials are foil materials. They simultaneously do not allow steam to pass through and reduce heat loss by reflecting heat waves back into the room. Some believe that this is a sales trick, but in fact the foil does not affect anything except the cost of finishing. But in practice, they prefer to use foil or foil-coated materials.

Simple thin foil is difficult to use: it breaks easily. Paper-based construction foil is much more convenient. Here are some materials:

- RufIzol S. Foil mounted on waterproof kraft paper. Operating temperature range from -60°C to 120°C.

This is what materials look like on kraft paper - Alucraft. This material consists of three layers: a layer of polyethylene film is placed between kraft paper and polished aluminum foil.

- Izospan FB. This is kraft paper with metallized lavsan. This means that it is not metal. Therefore, using it in a sauna steam room raises questions (in other rooms - easily). Although the manufacturer says that it can be used up to 140°C.

- MEGAFLEX KF. This is also metallized lavsan on kraft paper.

- YUTAFOL N170 AL (Czech Republic) is a four-layer vapor barrier membrane with a foil coating. Can be used for baths and saunas.

There is also foil based on fiberglass. It is more durable, also less flammable, but more expensive. According to the manufacturers, this material can withstand temperatures up to 450°C (peak load up to 600°. This is more than enough for use even near chimneys. This material, along with steam protection, has thermal insulation properties. This does not mean that without thermal insulation you can get by, but using a smaller layer is easy.

According to the manufacturers, it can be used in baths: it does not emit harmful substances. Price: approximately 3 times higher than on kraft paper.

By brand: almost all materials are nameless. There are only a few with the name:

- Thermofol ALST - temperature range up to 400°C;

- Folgoizol is a heat-resistant vapor barrier;

- ARMOFOL - can withstand up to 150°C, there are different types, even with a self-adhesive base.

If you want to see the description and characteristics of the “nameless” ones, search for “foil on fiberglass.” And then choose

In addition to vapor barrier, they also have quite significant thermal insulation properties. There is also a combination of a heat insulator covered with foil. It is laid like a regular heat insulator - spaced between the beams of the sheathing, and the joints are taped with foil tape. When using such material, installation time is saved. If this is important to you, you can use this material. Despite the fact that the material appeared relatively recently, there are more proposals here:

- Isover Sauna;

- Ursa (Ursa) foil;

- SAUNA BUTTS from ROCKWOOL.

These are heat insulators covered with foil.

There is one important nuance: when choosing a material, pay attention to its flammability. It is advisable to choose either non-flammable or low-flammable materials. After all, a bathhouse is a fire-hazardous building and it’s better to play it safe.

Insulation of washroom and rest room walls made of foam blocks

Insulation of other rooms of a bathhouse made of gas blocks can also be done with basalt wool or expanded polystyrene 100 mm thick.

Unlike a steam room, these rooms do not require resistance to high temperatures, so polystyrene foam may be a good choice.

The advantages of insulation made from this material include:

- resistance to getting wet;

- resistance to the spread of mold and fungi;

- high thermal characteristics.

Expanded polystyrene is laid between bars having a thickness equal to the thickness of the insulation, from which a frame is made on the inside of the walls made of foam blocks, on top of which a foil hydro-vapor barrier is spread, the joints of which are carefully sealed with metallized tape.

Some general tips for laying vapor barrier materials in a bathhouse

You can find advice from “experts” who encourage making small holes in vapor barrier materials through which air will pass, and the structure supposedly will not suffer from high humidity. There is nothing to say, it is better to remain silent. When installing a vapor barrier, the main condition for effectiveness is the complete absence of gaps ; overlapping materials must be sealed with ordinary tape (cheaper option) or special metallized tape (more expensive option). The presence of any cracks nullifies all activities.

Laying the material strictly without gaps

The fewer holes the material has during fixation, the better the protection. If possible, try to use double-sided tape or silicone glue. Of course, the choice of adhesive composition must correspond to the physical characteristics of the vapor barrier material. Now we will consider two options for performing the work: for a bathhouse with brick walls and for a ceiling.

Wall vapor barrier Izospan V is laid on the inside of the insulation with the smooth side facing it

Izospan SL - special tape for fixing steam and waterproof membranes

Connection of canvases

Finishing the bath from the outside

Due to the fact that we already have the necessary wooden frame, all we have to do is find high-quality material for the exterior decoration of the bathhouse. Only after this the insulation of the bathhouse can be completed. Most often, wooden lining is used for the external cladding of bathhouses in Russia.

Example of façade cladding with clapboard

In conclusion, to all of the above, it would not be superfluous to pay attention to interesting and useful advice from experts.

Tips and tricks

- First of all, do not forget that heated air masses can exit the bathhouse through the windows. And for this reason, you should give preference to small windows. What is also important, experts recommend, if possible, installing frames with more than one double-glazed window. And it is best to have 2 or 3 double-glazed windows (the more, the better, because this will prevent the rapid evaporation of warm air from the bathhouse).

Small window in the bathhouse - photo

Doors and thresholds have an important influence on the thermal insulation in your bathhouse. Quite often, specialists are contacted with the problem of rapid evaporation of air from the bathhouse. And the reason for this in 90% is the gap between the threshold and the door, due to which all the heat evaporates. To be sure that you will not encounter a similar problem, it is best to install low doors with a high threshold.

It is recommended to install small doors with a high threshold

Due attention should be paid to the heater. After all, the intensity of heating the bath and how long the warm air will be retained in it will directly depend on the heat capacity of the stones.