Features of bath insulation with aluminum foil insulation

The internal insulation of baths, saunas and hammams has features unique to these objects. In addition to energy saving, “climate” cladding should provide:

- rapid heating of the room;

- thermal inertia (slow cooling after stopping the furnace fire);

- high level of vapor barrier.

Today, foil insulation for a bathhouse is considered necessary, and in some cases, a sufficient element to ensure the above conditions. To understand why this material is a generally accepted standard, it is necessary to consider the physics of heat transfer processes in a steam room.

Do not line the bathhouse with foil: problems and harm of aluminum foil

A good sauna heats up quickly and retains heat for a long time.

To achieve this, many people insulate the ceiling and walls. Usually they choose foil. But as an insulator, this material is useless and even harmful. Foil helps reduce heat loss in a steam room and shorten the heating time. But is it? Why then is the house not covered with foil to save heat?

They usually use a thin layer of foil, which is applied to the insulation or craft paper. The material reflects infra. radiation (up to 97%).

Izolon - pros and cons

Izolon is made on the basis of foamed polyethylene. It has different thicknesses and outer coating. Foil-coated isolon is suitable for baths. The material acts as a waterproofing agent. Additionally, it reflects heat from the walls. The material is not afraid of large temperature changes -85 to +125 °C.

Flexible isolon is easier to install on the walls of a bathhouse with your own hands.

The texture of the material is different and can be flexible or hard, cross-linked (from several layers), homogeneous.

To insulate a bath, you can use any option. Foiled on two or one side will be more effective in a steam room, and unstitched for a rest room or dressing room.

Thanks to its small thickness of 50–100 mm, the insulation will not steal the space of the bathhouse, such as mineral wool or polystyrene foam. But in terms of thermal insulation characteristics, 100 mm thick isolon is equal to a 200 mm layer of mineral wool.

The main advantages of insulating a bathhouse with isola include the following characteristics:

- Heat loss in the steam room is reduced by 90% due to the reflective properties of the foil;

- the area of the steam room is reduced minimally (2–5 cm);

- You can insulate the walls and ceiling with your own hands without additional skills;

- the material is not afraid of moisture;

- not subject to corrosion;

- resistant to sudden temperature changes;

- non-toxic, does not emit harmful substances when heated;

- low price for the material.

Despite the large number of advantages, isolon has a number of disadvantages:

- afraid of mechanical damage;

- The joints must be glued, otherwise cold bridges will appear.

The disadvantages are mainly associated with improper installation of insulation in the bathhouse or the use of low-quality material. To avoid troubles, buy insulation from well-known brands in large shopping centers. Installation should be carried out according to the instructions.

When choosing a material for insulation, it is worth choosing a roll type, although the manufacturer also offers a block type. It is easier to work with a roll in a small room.

Step-by-step instructions on how to insulate a bathhouse with isolon

Before work, it is necessary to calculate the amount of isolon according to the area of the walls and ceiling of the bathhouse. To do this, you need to multiply the length of the wall by the width and multiply between them. The resulting figure is 4. Add the ceiling area to the result and subtract the doorway. The material is laid without overlap, so metallized tape is purchased for a hermetically sealed connection.

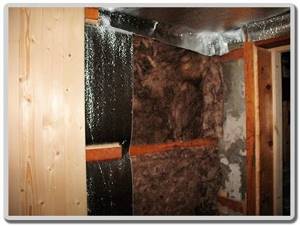

The walls of the bathhouse are sheathed with isolon directly onto the wall. You can first perform insulation with mineral wool.

For work you will need materials and tools:

After everything has been purchased, we proceed to insulating the walls and ceiling.

Installation of insulation on the walls and ceiling of a bathhouse

It is necessary to insulate the walls and ceiling of the bathhouse with isolon between the finishing and the inner wall. A ventilated gap of at least 0.5 cm must be left between them so that moisture can evaporate.

Finishing material is attached to the insulation on top.

The work is carried out in the following stages:

The insulation of the steam room is ready, you can begin finishing. More information about how to insulate a steam room can be seen in the video:

Review of vapor barrier materials ↑

In search of an answer to the question: what vapor barrier to choose for the walls and ceiling of a bathhouse, it is necessary to study the properties of all available materials. They can be divided into the following groups:

- various films;

- membrane materials such as isospan;

- kraft paper;

- insulation with vapor barrier properties;

- coating vapor barrier.

Ordinary polyethylene film ↑

This is the cheapest material. The good thing about the film is that it is sold in sheets ranging from 3 to 6 meters wide. Thanks to this, it is possible to cover the walls and ceiling with a minimum of seams. In a six-meter sheet, the film is sold folded in half, that is, the actual width is three meters. In this folded form, it can be mounted on walls to create a double layer.

However, the film is short-lived. After a few years, it will begin to deteriorate under the influence of high temperatures. Therefore, in modern construction it is used less and less. If you still decide to cover the bathhouse with film, choose the thickest sheet - at least 100 microns thick.

Construction cardboard or kraft paper ↑

In rooms where there is no high humidity, it is quite acceptable to use thick construction cardboard, the so-called kraft paper. In its pure form it is now rarely used; modifications with foil or lavsan coating are more popular.

Plain and foil kraft paper without a polyethylene layer absolutely do not tolerate contact with water, so they are used only for covering a dressing room or rest room. Kraft paper with a lavsan coating or a polyethylene layer is a more durable material, suitable for both dry saunas and steam rooms.

On sale you can find the following vapor barrier for a bathhouse based on kraft paper:

- Izospan FB - cardboard with lavsan coating;

- Megaflex KF - similar material from another manufacturer;

- Alurcraft, Izolar - three-layer vapor barrier consisting of kraft paper, polyethylene film and foil;

- Rufizol S is a foil vapor barrier based on kraft paper.

Foamed polyethylene isolon ↑

This material is widely used for vapor barrier of baths and saunas. In addition to hydro- and vapor barrier properties, it has a warming effect. It is a flexible fabric made of foamed polyethylene.

The most popular is isolon with foil coating. It withstands extreme steam room temperatures well, does not allow moisture to pass through, and retains heat. The thicker the foam layer, the more pronounced the insulating properties. For baths, it is advisable to use foil-coated isolon with a thickness of at least 3 mm.

Foil-coated mineral wool ↑

When deciding which foil is best to choose for a bath, you should take a closer look at such a universal material as foiled mineral wool. This is a modern vapor barrier with excellent insulating properties.

Essentially, it is insulation covered with a heat-reflecting, moisture-resistant layer. This foil vapor barrier is ideal for insulating a bathhouse. It is mounted on the ceiling and walls with the heat-insulating layer on the inside and the foil on the outside.

To cover a bathhouse, you should choose a coating with a thickness of at least 50 mm. Foil-coated mineral wool is sold in rolls. In construction stores you can find mineral wool from the following manufacturers:

- Rockwool Lamella MAT - natural foiled stone wool with a fiber arrangement perpendicular to the coating, which ensures the strength and flexibility of the material;

- Knauf Insulation LMF Alur is a foiled mineral wool that can withstand temperatures up to 600 degrees, but the temperature of the air in contact with the foil should not exceed 100 degrees;

- Isover (Izover) Sauna - a covering made of glass wool and foil, created specifically for baths and saunas;

- URSA M-11 F is another coating designed for insulation and vapor barrier of wet rooms.

Vapor barrier coating “Izospan” ↑

"Izospan" is one of the modern materials. The product line is represented by a wide variety of coatings. However, they all have one thing in common - they are polypropylene films of different thicknesses and strengths, designed to protect against moisture.

Izospan vapor barrier, which can be used on the ceiling and walls of a bathhouse, does not allow not only steam to pass through, but also water. Therefore, steam rooms and shower rooms can be sheathed with materials from this company.

The following brands are best suited for cladding bath rooms:

- foiled "Izospan FS" - polypropylene membrane with a metal coating. Absolutely steam and waterproof. Reflects up to 90% of heat, which contributes to energy saving;

- foil “Izospan FX” on a foam base. A universal product with which you can not only protect walls from moisture, but also insulate them;

- metallized “Izospan FB” with a kraft paper base, it is preferable to use it for the ceiling of a bathhouse. Like other foil products, it reflects most of the thermal energy, keeping it indoors.

Application of foil vapor barrier

Izolon

If you decide to use such material when building a bathhouse on your summer cottage, this does not mean at all that you need to incur significant expenses. You don't need to invest a lot of money to insulate the entire building. The optimal solution is installation exclusively in the steam room and shower room. The foil layer effectively accumulates heat, and the polymer inside reliably protects the structure from moisture and steam. For other rooms, you can simply purchase simpler and cheaper material.

In addition to insulating the walls, foil material must also be installed on the ceiling, under which hot air and steam collect in the steam room. It is advisable not to forget to use it on doors. But it’s not worth laying any foil insulation on the floor, since its construction here usually consists of a concrete screed with a wooden deck on top. The exception here is warm water floors.

The main requirements for materials and raw materials: insulation for a bathhouse on the ceiling, which is better and more reliable

Photo from the site: kak-uteplit.ru

When the entire structure has already been built, and all systems have been well thought out, it is worthwhile to take up insulation, especially if you plan to use the bathhouse throughout the year, regardless of the season. Moreover, in the sultry summer and cold winter, this will be equally useful and simple if all the calculations for insulation are correctly made, especially the ceiling, from where the lion's share of the heat from inside the room can be ventilated. To begin with, before you figure out how you can insulate the ceiling in a bathhouse, you need to understand that this material must meet special requirements, otherwise it’s simply not worth taking it, it will be wasted funds, and now is not the time to risk your own money.

It is worth understanding that, first and foremost, the insulation in a bathhouse on the ceiling, the builders forum is replete with similar statements from real professionals, must be moisture resistant, since all the hot steam first rises. Moreover, you should not hope that vulnerable material that absorbs water can be reliably hidden under a vapor barrier. It will, of course, help a little, but such an insulator can still become unusable and completely lose its properties in just a couple of years, due to the regular appearance of condensation, which is inevitable with temperature changes.

- Also, the insulation for a bathhouse on the ceiling must be completely harmless and not dangerous to human health and life. That is, it should not release toxins, aldehydes, or other dangerous substances, even under the influence of high temperatures that will regularly occur in the bathhouse.

- Fire safety is another important factor that insulation for the ceiling in a bathhouse must have, and which one is better under this criterion, they will help you figure it out, for example, in a store.

- We should not forget about sudden changes in temperature, which the thermal insulation indoors must withstand without much reaction, and over a long period of several years.

- Biological and chemical inertness, as well as resistance to the development of various microorganisms, fungi and other “living creatures” of the material for bath insulation is also extremely important.

Photo from the site: info-potolki.ru

Among other things, I would like to definitely note that the heat-insulating layer must be sufficiently tight and elastic, but such that, for example, it itself will not sag over time. Therefore, in order not to be too tormented by the question of which insulation to choose for the ceiling of a bathhouse, it is worth purchasing one that is relatively inexpensive, but in terms of performance and properties is at its best. Moreover, it is worth understanding that this can be done using natural materials, or you can choose synthetic ones, which also “work” quite well.

How to insulate concrete floors

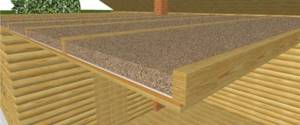

If you are completely confused by the wide range and do not understand what material to use, then take the advice of experienced builders. For example, with concrete floors it is recommended to use expanded clay.

No special preliminary preparation is required. For convenience, timber slats can be attached to the base of the roof. This will make it easier to check the uniformity of expanded clay distribution. Although this condition is advisory in nature.

So, pour expanded clay (30 cm thick) over the entire surface. An ordinary garden rake will help distribute the granules evenly. If the attic space will be used in the future and a floor is provided, then expanded clay is laid level.

If all the backfill is leveled, you need to lay the GIP. Durable polyethylene is quite suitable. It is distributed with an overlap of 10-15 cm. Scotch tape is glued to the joints.

If you want to make a floor, then planks are laid on the beams.

This is a fairly cheap and easy-to-follow method that will help you insulate the ceiling in a bathhouse with your own hands. But because it is cheap, it does not become less effective.

Common mistakes and installation tips

The main mistakes when insulating a wooden ceiling with isolon from the inside are in laying the material with an overlap. There is no air gap between the two layers, so condensation accumulates there, which then flows into the room and leads to damage to the finish. Correctly lay the foil insulator only end-to-end. After this, all joints are insulated with silicone sealant or sealed with tape. Joints should not be left unprotected because moisture can penetrate through the seams.

Reflective insulation is placed on the walls of the room to a height of 150 mm, and is not adjacent to the wall. It is also forbidden to attach electrical wires to the foil layer, because it conducts electricity well. The wiring must be well insulated, for example, using a special corrugated pipe.

When using foil insulation as the only insulation, the type with the greatest thickness is used. In this case, the foil layer should be on both sides. If there is an unheated attic behind the ceiling, then foam polyethylene insulation is used only in combination with another reliable heat insulator.

Forewarned is forearmed

When doing insulation with your own hands, you can make a number of mistakes. What you should pay attention to when insulating a bathhouse with isolon:

- Isolon foiled on both sides is used to insulate the steam room. The material will not only reflect heat inward, but also cold outward.

- The joints and places where the isolon is attached must be sealed with tape. Otherwise, moisture will get under the material and the metal fasteners will become corroded.

- The joints between the ceiling insulation and on the walls are also taped.

- The insulation is applied 5 cm away from the floor, so that moisture from below will not get under the material.

- For a small bathhouse in a country house, insulation with a thickness of 50 mm is suitable, for a constantly used steam room - 100 mm.

- Wooden walls must be coated with antiseptic compounds before insulation; they also come with slats for lathing for finishing.

- You should not leave the isolon open for a long time; it can be easily damaged by any hard, heavy object.

- You should not finish a bathhouse made of wood with natural moisture until it shrinks completely, as the isolon may warp.

It is better to attach a natural, breathable finish on top of the isolon, for example, linden lining.

It is better to carry out work in the warm season, since the tape will not stick well at subzero temperatures.

By following all the rules, you can perform high-quality insulation of your bathhouse with isolon. The correct installation will determine when you will have to carry out repair work, which is not cheap. Save your money and personal time, and let the steam in your sauna be light and warm!

Source of the article: https://banyabest.ru/vnutrennyaya-otdelka-bani/kak-uteplit-banyu-izolonom.html

Features of insulation

Not all products are used for insulation. Plastic products will deform from high temperatures. If you use plywood or fiberboard, then from the hot air they will begin to expand and change shape, accumulating moisture. These products are definitely not suitable. The best way is to finish in several layers:

- The first step is to use an insulating material that prevents water from penetrating.

- Place a second layer of insulation (for example, mineral wool).

- The third level is aluminum foil.

This “multi-layering” holds heat well and does not allow steam to escape for a long time, so heat losses are reduced.

Insulation materials can be divided into the following types:

- fibers;

- plates;

- blocks;

- wall slabs;

- backfill.

And depending on the composition they distinguish:

- Organic such as ecowool.

- Inorganic - mineral wool.

- Expanded polystyrene.

- Other insulation materials are such as technovent and technoblock.

How to insulate a bathhouse with isolon with your own hands

An insufficiently insulated bathhouse will cool down quickly and take a long time to warm up. Especially concerning is the problem of bathhouses, which are used all year round. Heat loss will be reduced several times when using isolon. We’ll tell our readers what kind of material this is and how to insulate a bathhouse with isolon.

Izolon is ideal for insulating a bath; it can withstand high temperatures and does not allow water to pass through.

Ceiling insulation options

There are 2 options for how to insulate the ceiling in a bathhouse with your own hands. It is preferable to arrange the so-called External insulation is both more practical and easier to implement.

But such insulation has one drawback - it will not be possible to move on the ceiling. Internal insulation of the ceiling is practiced in small lean-to bathhouses, where it is not possible to put a layer of insulation on top of the ceiling, or to ensure the ability to move along the ceiling.

The ceiling of the bathhouse, before insulation, must be thoroughly cleaned of dirt. If damage to the ceiling structure is discovered during cleaning, it must be repaired. You also need to additionally treat it with antiseptics and fire retardants, if such treatment was not carried out when installing the ceiling.

Selection of insulation material

The modern construction market offers a fairly wide range of such materials. But how to make the right choice specifically for your bath? Since they are all fairly new, you can get confused about their differences.

By the way, please pay attention to the following point: the polymers that make up the substrate may have different structures. Namely, they can consist of polypropylene foam and polyethylene foam. We will not go into details, but the first option is suitable for high temperatures, the second is relevant for less aggressive environments.

Here are some technical characteristics that I hope will help you choose the right one from the most popular materials at the moment.

- Penotherm is distinguished by a base made of foamed propylene foam and a wide operating temperature range - from -40°C to +150°C. Certificates confirm its moderate flammability and low-hazard toxicity class. There is virtually no thermal shrinkage during operation. The NPPLE model can be used when installing heated floors. Great for a steam room.

- Izospan FB is intended directly for creating a vapor barrier in baths and saunas. It can be safely used at high temperatures. You can read more about the many labels and uses of isospan in this article.

- Alufom has a base made of polyethylene foam and one-sided coating with aluminum foil. The temperature range is from -60°C to +100°C. In addition to the functions of hydro, sound, steam and thermal insulation, it includes protection against radon. Can be used for insulation of floors and roofs. The special “wrinkled” texture of the surface makes it possible during the installation process to bend around curved elements of small radii without tearing the foil coating.

- Tepofol has a polyethylene foam base and may have a reflective layer on one or both sides in different models. Withstands temperatures from -60°C to +100°C. Can be used for thermal insulation of roofs, walls, air ducts, and installation of “warm floors”. Available on the market in various variations.

- Izolon is an environmentally friendly and safe material. The base is also foamed polyethylene foam. It is a durable, vapor-tight, soft and flexible foil insulator.

Principles of thermal insulation of bath ceilings

Based on the design features of the roof, bathhouses made of logs or timber can be divided into two types: buildings with and without attic space. In the path of warm air flowing out of bathhouses with attics, there will be a much more powerful ceiling, into the layer cake of which thermal insulation material is usually laid during the construction process.

The under-roof space itself, filled with an air mass, also inhibits the leakage of thermal energy, and the insulation of the roof structure also slightly moderates the agility of the “escaping” heat.

However, this does not mean that insulation of the ceiling in a bathhouse with an attic or attic is not necessary. Increasing the thermal insulation characteristics in it is no less necessary than in a building without an attic, where the heat leaking out encounters few and too weak barriers in its path.

Specifics of the vapor barrier device

In both cases, regardless of the roof structure, a vapor barrier is laid on the bathhouse ceiling before laying the heat-insulating layer. To equip a building without an attic space, you can use aluminum foil, compacted cardboard, generously impregnated with drying oil, or wax paper as a vapor barrier layer.

In bathhouses with an attic, the same materials are used, but most often the ceiling boards on the roof side are coated with a two-centimeter layer of clay.

Of the options offered by the industry, the following are used:

- standard polyethylene film (as for greenhouses 0.4 mm with variations) - a type of vapor barrier that is not very popular due to the greenhouse effect;

Note. The use of polyethylene film as insulation requires leaving a gap necessary for condensation to evaporate.

- a special vapor barrier film made of polyethylene with fibers to retain condensation;

- membrane type vapor barrier material.

Vapor barrier is necessary to prevent the transit of wet vapors and their settling in the insulation. After all, water accumulated in the thermal insulation material will shorten its service life, increase the weight of the multilayer ceiling system and, if we return to the physics course, reduce its insulating qualities.

Three functions of bath ceiling insulation

The hotter the room temperature is required, the more difficult it is to build a barrier to retain heat. To solve this difficult problem, those who want to know how to insulate the ceiling of a bathhouse should familiarize themselves with the three main leak patterns:

- movement of heated air through the cracks in the ceiling;

- gradual transition of heat from heated objects to cold ones;

- intersection of homogeneous barriers by thermal waves.

Laying thermal insulation material in a multi-layer roofing system prevents all types of thermal leaks. Properly done insulation will adequately perform all the work assigned to it. Due to poor thermal insulation, condensation will settle on the ceiling, it will take much longer to warm up the room, and more fuel resources will be spent.

Selection of materials for insulation

Before deciding how to insulate the ceiling in a bathhouse, you need to consider all options for suitable thermal insulation materials.

- “Classic” mineral wool is used most often. In its chaotic interweaving of fibers melted from basalt there are billions of air-filled voids, each of which works responsibly to retain heat. Disadvantage: loss of insulating properties when wet.

Note. When using mineral wool to insulate the ceiling in bath buildings, it is recommended to lay a waterproofing layer on top of the insulation if the roof is not sufficiently protected from atmospheric water leaks. A thermal insulation gap must be created between the waterproofing layer and the insulation.

- Super-light polypropylene foam - penotherm - is also often installed on the ceiling of a bathhouse. The foil-laminated material was developed specifically for arranging bath buildings and saunas. In addition to its intended function of insulation, its foil side reflects the flow of thermal energy. Working on the mirror principle, penotherm allows you to reduce the heating time of the steam room by 2-3 times.

- Expanded clay is suitable for large-sized bath structures. The layer sufficient to insulate the ceiling should be 30 cm. Although the material is relatively lightweight, it will inevitably increase the weight of the building. Its porous granules, like mineral wool, are susceptible to moisture. Waterproofing is also necessary.

- "People's" heat insulator. The first element is a 2 cm layer of crumpled clay. Instead, a mix of black soil and peat, wood shavings filled with cement mortar, a mixture of clay, sand or sawdust are suitable. A “carpet” of dry sawdust or leaves (preferably oak) is laid on top of the laid layer, and the insulation is completed by laying a layer of dry earth 15 cm thick.

- Growing aerated concrete, for pouring which a simple formwork is arranged. The video will clearly depict how this insulation of the bathhouse ceiling is carried out: the video demonstrates the simple technology in detail.

It is difficult to recommend the thickness of the insulation layer offhand, without knowing the actual size of heat loss and the technical parameters of the structure. The figures are approximate throughout, variations are allowed. Much depends on the climate zone, because the ceiling insulation in a bathhouse is not only a barrier to heat, but also protection from external temperature factors. If the ceiling freezes from the outside, moisture will certainly condense on the ceiling. In such cases, the thermal insulation layer is simply increased.

Effective shiny insulation of bath walls

High-quality thermal insulation, resistance to penetration of hot steam, high temperatures, resistance to moisture and external influences - this is foil insulation.

A thin aluminum layer reflects heat, keeping it inside the building. Such characteristics allow it to be used for installing insulation on the walls of baths and saunas.

Bath or sauna buildings require insulation and isolation from external influences. Internal insulation of walls from increased moisture, steam and high temperatures is also required.

A material is selected that is not susceptible to such influences - this is foil insulation for a bathhouse. Construction experts recommend this type of insulation.

Why do you need a foil layer?

Bath insulation with foil is called two-layer. It consists of an outer covering of a layer of aluminum foil, which is perfectly polished.

The metal coating reflects heat into the building, retaining over 95% of it indoors. This coating repels moisture and steam. The foil layer can withstand air heating up to +150°. The temperature inside the room increases by 2-4°.

The insulation base consists of foamed air bubbles, which prevents the conduction and absorption of heat.

Criteria for choosing foil for a bath

From the presented insulating insulation materials, a coating with foil paper is selected. The positive characteristics of bath foil are also taken into account.

To do this you will need a product that:

- protects against ultraviolet radiation;

- has additional moisture-proof and vapor-protective properties;

- thermal insulation;

- soundproofing;

- use on a variety of surfaces, including wood, concrete, brick;

- has dimensional characteristics.

Taking into account the building material from which the room is built, the thickness of the thermal insulation is selected. When choosing, they are guided by studying the number of positive reviews, checking quality indicators and certificates.

Attention is also paid to the condition of the packaging and its tightness.

Types of foil and coating features

The walls of the bathhouse or sauna are insulated with aluminum-coated material, which retains internal heat. For this purpose, some types of protective layer are selected.

Folgoizol

Foamed polyethylene is the basis for a protective layer called folgoizol. Its thickness can be manufactured according to customer requirements from 100 microns to 200 microns.

The material can be rolled into soft rolls or presented in hard plates. The thickness of the insulated sheet is from 2 to 11 cm, length 25, 30 m with a width of 1 or 1.2 m.

Based on polystyrene, rigid plates have a thickness of 2 to 10 cm, size 60x120 cm. This type of insulation is used for application to the wooden walls of a log bathhouse, or to walls lined with clapboard.

The material is non-flammable and does not emit toxins at high temperatures. Environmental indicators allow the use of folgoizol in the food industry.

Protective aluminum layer, resistant to corrosion. Withstands temperatures up to +150 °. The operating period in comfortable conditions is more than 20 years.

Kraft foil

This type of insulation consists of three layers: a paper base (kraft paper), aluminum foil, and polyethylene in between. It functions as an additional water-repellent component and serves as an adhesive connector.

This material ideally protects the insulation from steam and moisture. Used to insulate the internal surfaces of baths and saunas. Without releasing toxins under the influence of high temperatures up to +120°. The joints are connected with aluminum tape.

Kraft aluminum coated foil is available in two sizes:

- 25 m long and 1.2 m wide;

- canvas 15 m of the same width.

Foil on a paper base for a bath is not subject to fire, reflects ultraviolet radiation well, and maintains the tightness of the surface.

Folar

Aluminum layer, fiberglass mesh and polyolefin film, glued together using polyurethane glue. A three-layer thick insulator is a folar.

The fiberglass mesh does not allow it to deform under the influence of high temperatures up to +150°, but retains high quality characteristics. The material is also environmentally friendly.

Foil mineral wool in soft rolls

A popular thermal insulation product on the Russian market is rolled mineral wool with a foil coating. Thermal insulation protects wooden bathhouse structures from the influence of steam and increased moisture.

High thermal insulation rates retain heat by 95%. Thanks to the protective base, the insulation belongs to the group of low-flammable materials.

The length of the canvas in a roll is 12.5 m, width 1.2 m with a thickness of 50 mm. The insulation is resistant to infection by mold fungi and damage by insect pests.

Performs the function of sound insulation. The lightweight material is used in any frame structures.

Foil-coated mineral wool in the form of hard mats

Foiled layers of polystyrene foam are used in the form of hard mats. Used to cover water heated floors.

The polished surface screen reflects heat upward from the heating pipes. The applied markings help in the installation of the heating network.

Foil in rolls

Sauna foil on a soft base is used to maintain the thermal conditions of the room and is secured under the lining.

The joints are connected with special tape. The length of the canvas in a roll is 31 m ± 0.25 m, width 1.25 m, with foil 7 microns thick, cardboard density 50 g/cm³.

The thickness of the layer has high thermal conductivity. It is used as an insulated layer in steam rooms, applied on top of the insulation.

Correct installation

Thick foil insulates the walls of the room from the increased influence of moisture and high temperatures.

For work you will need:

- foil insulation;

- stapler;

- hammer, nails with wide heads;

- metal adhesive tape.

The main mistake in attaching the material is the incorrect location of the reflection layer. The shiny surface of the sheet is directed into the building, with the paper facing the wall. The joints are never overlapped; they are glued together with aluminum tape. The canvases are fixed using a construction stapler.

To fix the insulator, which has an adhesive base, additionally glue it pointwise with rubber glue. After laying and gluing the sheets, the coating is fixed with wooden lathing.

Ventilation of bath rooms

Before insulating the steam room, a ventilation system is designed. For room ventilation, natural or forced systems are used.

- Ventilation is arranged with one lower hole, opposite the flue stove mounted on the wall. The heated steam rises and cools. It is mixed with the incoming fresh flow from the inlet window and drawn out by the stove's blower system.

- The heating furnace can be installed below the level of the floor covering, so that the blower system is located in the gap between the floor and the insulation. The entrance windows are located at the top of the basement and in the flooring of the bathhouse. The air passes through the underground passage, into the steam room and is drawn into the stove's ash system.

- The supply window is mounted at the bottom of the steam room next to the heating system. To prevent a draft from forming, an exhaust window is installed at the top behind the partition. The natural system is equipped with a device that regulates air flow.

- The use of such ventilation does not deliver the expected effect because the air quickly heats up when entering, rises up and is drawn out. For additional fresh air, the doors are opened, which is unacceptable when taking the procedure.

- You can install ventilation on one end wall, opposite the heating system. The incoming air flow is further enhanced by a fan, this type of ventilation is called forced ventilation.

- For efficient ventilation, windows are placed in opposite lower planes. The exhaust ventilation window is additionally equipped with a fan. After entering the room, heated air rises to the ceiling, cools and is drawn out by a fan.

There are three holes for air flow for efficient air exchange:

- one window downstairs, near the stove;

- another window in the floor, where there is a gap between the floor of the room and the insulation;

- the third hole is on the opposite wall from the stove in the upper part.

A device for forced ventilation is installed in the upper window. The window area is calculated based on the area of the bathhouse: per 1 m² - volume 24 cm².

Only properly installed room ventilation will extend the life of the sauna room.

Thickness of walls and insulation used

The insulating effect is obtained by using paper-based foil correctly, taking into account its thickness. This table is used to determine:

| Wall composition | Wall thickness, mm | Material thickness, mm |

| Concrete | 350-370 | 80-100 |

| Brick | 250-350 | 100-150 |

| Wooden log house | 100-150 | 60-80 |

| Wooden log house | 150-200 | 40-60 |

| Wooden log house | From 200 | up to 40 |

This calculation involves the development of insulation for the walls of baths and saunas. The reflective layer of aluminum is mounted only indoors.

Insulation of walls using foil insulation

Thermal insulation must be resistant to hot air with an average temperature of +100°. The environmental friendliness of the coating under the influence of thermal loads is taken into account. Hot steam permeability is below 0.02 g/m².

The building material used in the construction of the walls of the bathhouse affects the choice of reinforced fabric, installation of insulation and the thickness of the covering layer.

Insulation of a bathhouse from a wooden frame

Before finishing work, the building must shrink. The walls of the log house are carefully caulked on both sides before insulation.

The covering is laid and secured with staples over the entire surface of the wall without gaps or gaps. Damage should be sealed with aluminum tape. The joints of the insulation are also glued to achieve tightness.

Slats 30x50 mm thick are fixed on top of the foil paper. The board trim is fixed on them. The thickness of the slats creates the effect of ventilation underneath.

Insulation of a bathhouse made of brick and concrete

Walls made of brick, concrete or foam blocks differ in the order of installation work.

- The first step is marking and calculating the sheathing on the walls. The bars are selected according to the thickness of the insulating layer, since it is inserted flush. The distance between the beams is equal to the size of the insulation sheet. Ventilation windows are lathed for easy installation of foil. The bars are mounted in a vertical position.

- Aluminum foil for the bath is fixed to the surface. The joints are sealed with metallized tape and additionally secured with staples. The foil is carefully fixed to the ventilation windows.

- The insulating material with foil is secured with horizontal bars. Sheathing is placed on top of the beams. The clearance created by the thickness of the beams will serve as ventilation for air and steam. The foil also protects the insulation and sheathing from moisture.

Reliability and long-term use of foil insulating materials are important qualities. Before purchasing, please read the warranty periods.

Also ask for information on the operation of this insulation, according to customer reviews. Only such an analysis provides the opportunity to select a worthy insulating material.

Source: https://teplota.guru/teploizolyatsiya/folga-dlya-bani.html

Which method to choose for insulation inside and outside the room?

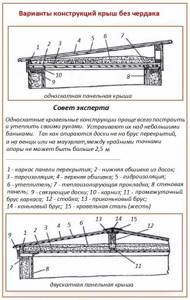

The choice of insulation method is influenced by what is located above the ceiling - a cold attic, a residential attic or a flat roof with a low slope, which leaves minimal attic space. In total, there are only three methods for arranging the ceiling:

- grazing;

- hemmed;

- panel.

Flat ceiling insulated with expanded clay, clay and sawdust

For those who have an attic, but do not want to turn it into a warm warehouse or recreation room, the design of a flat ceiling is suitable. It is considered the simplest, since you are not supposed to walk in the attic, which means there is no need even for floor beams. The rough ceiling is placed on the frame of the building, that is, directly on the walls.

Important! There are limitations associated with this. The boards will withstand a layer of insulation if their length is no more than 2.5 m with a board thickness of 4–5 cm.

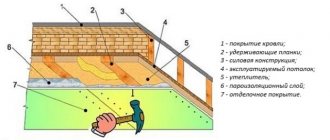

Different materials can be used, but the structure of the “pie” is the same in any case. It consists of layers (from top to bottom):

- insulation;

- wax paper;

- boards;

- vapor barriers;

- finished ceiling.

The layout of a flat ceiling with insulation is very simple

The vapor barrier material must not only be hydrophobic, but also withstand high temperatures, so its choice is limited. Most often, foil is used as a vapor barrier. The last layer is made of expanded clay (slag) or clay with straw.

In the first case, expanded clay is poured in a layer of 20 to 30 cm onto a layer of waxed paper (so that it does not spill through the cracks). This thickness is enough for the thermal insulation properties of this material to manifest themselves. Expanded clay fractions should be taken different so that the small ones fill the voids between the large ones.

Often, before filling, divider boards are placed on the rough ceiling from the attic side.

The appearance of a flat ceiling insulated with clay is no worse than when using modern materials

Advantages of modern materials over traditional ones

In a bathhouse, especially in a steam room, due to the extremely high humidity and temperature in the room, the structures are strongly exposed to the aggressive effects of these factors, which significantly increases the risk of their premature destruction. To protect walls and ceilings from wear and tear due to excess moisture and steam, it is necessary to install layers that protect the insulation in them from the penetration of water vapor.

Everyone has probably been in bathhouses, where for this purpose, in the old fashioned way, cardboard, roofing felt or roofing felt soaked in drying oil is used, covered with a layer of clay on top and hemmed with boards. Not only do these materials begin to emit an unpleasant odor when the air warms up well, but these fumes are also harmful to health.

Vapor barrier with foil does not have this drawback - it is completely safe for people. Due to the presence of a reflective coating, the use of such materials reduces energy costs for heating the steam room by 25-30%. Accordingly, it allows you to use less powerful electric heaters or save solid fuel. At the same time, a “thermos effect” is created in the room, which prevents rapid cooling. The reason for this is that foil vapor barriers can reflect back up to 98% of radiant heat.

This is a composite material that consists of a base made of foamed polymer and a coating of reflective foil. Thanks to its water resistance, there is no threat of mold and all kinds of fungi. The technical characteristics of reflective foil vapor barrier enable it to effectively also perform the functions of insulation and reliable waterproofing. The material is able to withstand temperature changes on average from -40°C to +100°C, which is important for saunas and baths.

Bathhouse layout

A good bathhouse has several functional rooms, usually three. This is a dressing room, a wash room and a steam room. The different functions of these rooms require different designs. In the dressing room they undress and dress, you can sit with friends and relax. There is normal room temperature, normal air.

In the wash room the main washing is done. It is much warmer there and has high humidity. And in the steam room the temperature is high, and the humidity is determined by the type of steam room. The steam room of a Russian bath is filled with hot steam and the humidity is high. If this is a Finnish sauna, then the air is hot but dry. Temperature and humidity are set by users as desired. Heat sources for each type of steam room are specialized.

Expert advice

We went through popular YouTube channels, where they talk about baths authoritatively, knowledgeably, by people whose opinions we ourselves listen to. But the only problem is that they talk about a lot of things, but for some reason the problem of insulating ceilings, as well as the choice of materials, does not attract everyone’s attention.

Therefore, don’t blame me, the example of expert advice on ceiling insulation will be the video below, made - we simply couldn’t find anything more significant.

https://www.youtube.com/watch?v=xCCC_y1f810

But what’s interesting is that you won’t hear standard descriptions in it. On the contrary, the authors of the video turn to the experience of previous generations and offer the most budget-friendly, simplest option for organizing both the ceiling itself and its insulation - this is a completely simple floor ceiling, insulated... with sawdust and clay. It couldn't be simpler.

You don’t even need to bother with the lining - you can make the flooring boards into a finished ceiling if you plan and sand them first.

Of course, any opinion will be controversial, and you have the right to question it or not consider it an expert.

Now that it is already clear why a ceiling without insulation is a waste of heat, all that remains is to wish every owner that in any weather his bathhouse will warm up properly and keep warm for the second day.

Ceiling insulation with foil-isolon

Sheets of foil-isolon should be spread over the surface of the ceiling so that the foil “looks” into the room. After this, the insulation must be pressed with a clamp strip. The foil layer serves to reflect thermal radiation, which can be used as an additional advantage if foil isolon is used together with penoplex or polystyrene foam. In this case, the foil material will act as a vapor barrier.

vote

Article rating

What can you use?

Before the advent of modern insulation, owners used various natural materials. Sawdust, clay, moss and straw were used. Some baths are still insulated this way.

Its greatest disadvantage is the susceptibility of natural materials to rotting and other biological effects. And clay is also distinguished by its considerable weight. To use it on ceilings, you need to build a fairly massive and durable structure.

All modern insulation materials do not have such a huge disadvantage as heavy weight. They are also distinguished by good resistance to external influences and a long service life.

The most popular and modern ceiling insulation materials include mineral wool, expanded clay and ecowool. Foam and other materials based on plastics cannot be used due to the risk of fire.

When choosing building materials, special attention is paid to:

- resistance to open fire;

- ease of installation;

- environmental cleanliness and safety;

- light weight.

To save space (ceilings in bathhouses are already low), it is preferable to place thermal insulation material in the attic, if there is one. The simplest option is to spread mineral wool and protect it from high humidity with a vapor barrier film.

You can do the insulation work yourself. If you use natural material (for example, sawdust), the entire insulation process will be completely free for the owners.

In case of various difficulties in the installation and use of modern building materials, you will have to turn to professional builders. Payment for their labor is made on a per square meter basis. For example, laying basalt wool costs from 150 rubles per square meter, and glass wool from 90 rubles.

Working with certain types of insulation is quite a difficult task.