The presence of an attic in the house provides the owner with expanded opportunities for using its usable space. There are at least two reasons for this. First of all, the appearance of the building becomes more interesting. In addition, you can significantly increase the living area. The attic can become a full-fledged floor suitable for year-round use. The insulation of the attic floor deserves special attention. The ceiling must be sufficiently reliable and strong. In order to comply with all the requirements, you must strictly follow a set of special rules when installing the floor in the attic.

Expert opinion

Konstantin Alexandrovich

To properly insulate the floor, you need to carefully study the key features of the attic area. Thermal insulation of this floor inside a given room can take a lot of effort and time. In addition to the insulation material itself, it will be necessary to install layers of insulation against water and steam in the under-roof space. Details are described below.

Peculiarities

A residential attic has long been no longer a rare occurrence when constructing a private house on two floors. More and more attention is being paid to the functional qualities of every centimeter of attic space

Therefore, it is important to renovate or design a house in such a way that, if necessary, you can use individual rooms, make them functional and more suitable for living. In order to feel warm and cozy under the roof at any time of the year, insulation work is carried out taking into account the characteristics of the attic

For example, special insulation is important when the roof is already covered.

There are certain standards for carrying out such work from the inside in the attic under the finished roof. It is worth considering that the attic as such is not equivalent to the attic space. The attic always has a characteristic slope, and the highest point of height is usually at a level of 2.5 m. To insulate such a room, different materials can be used. The most common ones include mineral wool and polystyrene foam. When carrying out work on insulating the attic, it is necessary to take into account what the room will look like in appearance and whether it will lose “extra” meters.

For high-quality insulation of the attic from the inside, if the roof is already covered, the right technology is important. So, when insulating walls and ceilings, one or another method of performing the work is used. For example, to insulate an attic roof, a multi-layer structure is used (for example, 5 layers of screed with foam glue).

All work on the interior decoration of the attic for the purpose of insulation is carried out in five stages.

The roof is insulated and the rafter system is treated. Rafters made of wooden beams can be seen under the roofs of houses built using old construction technologies. Typically, the roof of such houses is covered with tiles or slate. The materials have very high thermal conductivity. In such cases, they say that the roof is simply protected from wind and external weather influences.

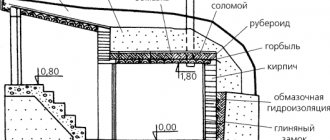

- The quality of waterproofing is another important criterion for ensuring the reliability of the roofing structure as a whole. Waterproofing is simply necessary in the attic space. For this purpose, membrane films are usually used, which can allow steam to pass through, but do not allow moisture to pass through. In old houses, instead of a special film, you can often see a simple roofing material with similar properties. The main feature of insulating materials is optimal protection of the roof at the joints, preventing moisture from entering the heat-insulating material. Waterproofing coatings today are characterized by vapor conductivity.

- Insulation materials. Among modern means, those characterized by low thermal conductivity are used. Insulation parameters between 0.03-0.04 Vi/μ are comparable in quality and durability to reinforced foam. Mineral wool or extruded polystyrene foam (penoplex, penoizol) are also actively used to insulate the attic from the inside. In terms of efficiency, penoplex is rated higher than others, but is more expensive. The selected materials must meet the main requirements - ensure heat exchange in winter, protect against overheating in summer.

- Vapor barrier materials. Usually we are talking about a membrane film that will help preserve the original properties of the insulation. The material should not provoke the formation of condensation, which is a disaster for thermal insulation materials.

- Decorative properties. An insulated attic must meet the design requirements of the room and comply with the overall design concept of the house. That's why so much attention is paid to cladding. Drywall, OSB boards or other types of materials that can be laid on the ceiling, walls, and floor of the attic are often used as decorative finishing.

Features of the attic room

Here is a list of the key nuances of an attic space:

- The geometry of the attic can vary significantly in each specific case and depend, among other things, on the type of roof covering. The design can be symmetrical, asymmetrical or broken. The location of the space under the roof area can be elongated or located on one side of the longitudinal axis. The roof most often has several slopes.

- An attic space can occupy either a significant part of the area of a residential building or a small one. When the projection area is limited, the cantilever roofing technique is used to place the floor.

- When discussing and outlining the project, it will be necessary to take into account some nuances. The main one will be the architectural design of a private house and its load-bearing qualities. Professionals recommend using lightweight materials for construction when constructing an attic floor.

- The area of the attic is usually significant, which leads to the need to minimize heat loss. Despite the fact that the floor does not come into contact with the external environment, its insulation must be approached correctly.

The main rule

Even if you have already decided which insulation is best for you, it is too early to start the work itself. First, you need to understand the sequence of these works, and for this you need to get a general idea of the structure of the insulated roof. Or, as the professionals put it, a roofing “pie”.

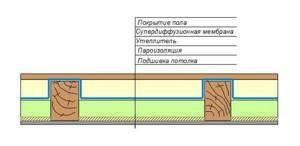

From top to bottom, the components of the pie are:

- the roof itself (corrugated sheeting, tiles, slate);

- sheathing;

- counter-lattice;

- waterproofing material;

- thermal insulation;

- vapor barrier;

- ceiling finishing.

That is, when installing thermal insulation, the main rule should be taken into account first of all - the insulation must be protected both from external (atmospheric) moisture and from internal moisture rising from the room. Otherwise, condensation will inevitably accumulate, which will ultimately lead to the most disastrous consequences not only for the roof space, but also for the entire house.

If you decide to insulate a finished attic roof from the inside, then, as can be seen from the list above, you already have all the layers of the “pie”, up to and including waterproofing. All that remains is to lay the insulation, cover it with a vapor barrier membrane - and you can finish the ceiling. It would seem that everything is simple. But here you need to strictly follow the established rules, otherwise all your work will be in vain.

Technology for arranging the attic floor, main stages

Any construction process consists of several stages and flooring is no exception. To obtain a quality foundation, it is necessary to think through the process in advance and draw up a project containing a drawing and calculations for the purchase of building materials.

The process can be further divided into the following stages.

Laying floor beams

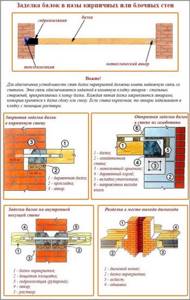

In most cases, beams are laid in specially prepared wall grooves. This option is used at the stage of building a house. In this case, installation in this order:

- The wood is treated with special antiseptic agents that reduce the risk of frame rotting and protect the wood from damage by bark beetles and mold.

- After complete drying, trim the crossbars at an angle of 60 degrees. The edges are painted with bitumen mastic and wrapped with two layers of roofing material for waterproofing purposes.

- Installation should begin with laying the outer two crossbars. The distance from the wall should be no more than 5 cm.

Important! The logs are inserted into the grooves on average 10 cm, leaving a gap of no more than 3 cm.

- To control the horizontality of the crossbars, an even block is laid on top of the beams, on which a level is placed on top.

- To level the beams according to the bubble level, special blades are used, which are placed in the grooves under the beam. They must be treated with bitumen paint.

- To eliminate the creaking of the crossbars and eliminate the passage of air, the gap is filled with tow or insulating wool.

- Having leveled the horizontal level of the base using a control bar and a level, the remaining beams are laid relative to it. The technology for laying in the grooves is the same as for the outer two.

- Every 5th crossbar must be attached to the wall using anchors.

If the house is already ready, the floor beams can be secured in another way.

- First of all, the logs are treated with antiseptic substances.

- Markings are made on the walls for the location of the crossbars.

- At the marked places, supports are fixed in the role of clamps or corners.

- Fastening with self-tapping screws.

- Having laid the logs on the supports, they are fixed using the same self-tapping screws.

- Having finished crossbars, you can move on to arranging the floor.