The small size of suburban land plots, as well as the desire of their owners to make maximum use of fertile soil, forces them to expand the usable area of buildings not in the horizontal direction, but in the vertical direction. In addition, it is much easier to arrange an attic floor than to add another room to the house. However, it makes sense to begin such a conversion if there is a sufficient area of under-roof space with a height of at least 2.5 meters and, in addition, it is possible to safely walk on the upper plane of the ceiling. If these conditions are met, you can create an excellent living space in the attic, but first you need to insulate it.

Since this room is part of the roof of the house, the energy saving of not only the attic floor, but also the entire building, largely depends on how high-quality thermal insulation is installed there.

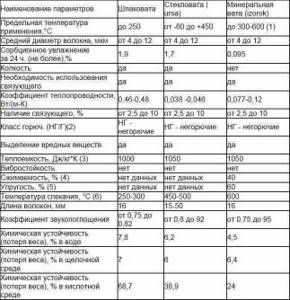

Cotton wool is different: choosing insulation

Plates, mats and rolled materials made of basalt fibers, used to insulate the attic from the inside, attract developers and builders with three important properties:

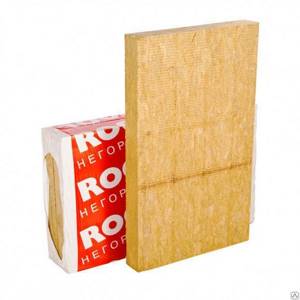

Mineral wool is an effective and popular insulation material in Russia

- Fire safety. All brands of mineral wool belong to the NG category.

- Vapor permeability. Due to its ability to absorb condensation and evaporate it when the temperature rises, mineral wool works well in contact with wooden rafters. It protects them from waterlogging, which causes the development of fungus and wood rotting.

- Good noise-absorbing characteristics. Randomly oriented fibers most effectively reduce the level of high-frequency noise, which is especially intrusive and irritating in the rain.

Rolled mineral wool for attic insulation

The described characteristics, to a much greater extent than the cost, influence the choice of this type of insulation for attic insulation. However, different brands of basalt thermal insulation differ significantly from each other in a number of other parameters. Insulating an attic from the inside of a room with your own hands requires some experience in working with mineral wool and imposes additional restrictions on the properties of the material: this becomes clear from the video posted in the “Self-installation algorithm” section.

Among these additional qualities are:

- Material format. For laying between rafter beams, the width of the thermal insulation should be 600 - 610 mm.

- Density. When working alone, the less the slab or section of it weighs, the better.

- Elasticity and fairly high rigidity. This quality greatly simplifies the insulation of the attic with mineral wool.

- Availability of large thicknesses - 100, 150, 200 mm.

It is a common misconception that the high density of basalt insulation indicates its increased energy efficiency, and the low density indicates low rigidity and inability to hold its shape. However, there is no direct relationship between thermal conductivity and stiffness and density. The length and thickness of the fibers, as well as the type of their orientation, are of decisive importance.

Mineral wool in the form of slabs is convenient for insulating the attic alone

We compared the actual parameters of mineral wool brands recommended by leading manufacturers for roof insulation. All four stated requirements are met by only three names: Rockmin and Rockmin plus (Rockwool brand), as well as Rocklight TechnoNIKOL slabs. Plates of these brands (formats 1000×600 mm and 1200×600 mm) with a thickness of 100 mm weigh respectively 1.6 kg; 2.1 kg and 2.9 kg. At the same time, they are elastic and hold their shape well.

There are many types of mineral wool insulation that exceed those we recommend in terms of thermal resistance or stiffness. But they are all of the wrong format, or very heavy or not flexible enough, and therefore inconvenient for working alone.

What is the difficulty of insulating an attic?

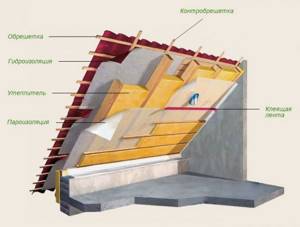

The attic floor has difficulties with insulation. This is due, first of all, to the unique geometry of space inherent in attic design. Most of the attic surface is sloped. In addition, insulating the attic involves creating an air cushion for the roof, a layer of vapor barrier on the surface, good waterproofing and the formation of a windproof membrane. That is why, in order to insulate the attic, you need to have the knowledge to do it correctly and ensure long-term thermal protection of the room.

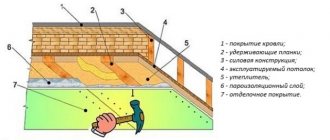

Roofing pie composition

Insulating a residential attic with mineral wool requires mandatory compensation for the weaknesses of this material: the ability to absorb moisture coming from the room, as well as high airflow and low resistance to precipitation. Therefore, in the roofing pie, provided that fiber insulation is used, two and sometimes three membranes are introduced. In the direction from the room to the outside, the layers are arranged in the following order:

Scheme of attic insulation with mineral wool

- Finishing ceiling cladding. The warmest material for this layer is drywall and a layer of putty (taken into account separately in the thermal calculation).

- The air gap formed by the sheathing for attaching the finishing cladding. Equal to the thickness of the slats (or galvanized profiles) of the sheathing. This gap is not necessary for the operation of the heat-insulating system.

- Vapor barrier film. Protects the insulation from steam rising from the room.

- Basic insulation (2 - 3 layers of mineral wool).

- High diffusion membrane (waterproofing). Its peculiarity is the one-way passage of water. Moisture coming from below (evaporated by mineral wool) should freely penetrate through the membrane, and water coming from above (precipitation and condensation) should flow under the roofing down to the street. Films of this type combine the functions of a water barrier and wind protection. In domestic practice, three-layer isospan membranes have proven themselves well. It is better to use Izospan AQ proff for the attic, which is characterized by high strength and good steam transmission (1000 g/m2 per day). There is no need for a gap between isospan and mineral wool.

- Ventilation gap between the membrane and the roof deck. It is formed by sheathing strips located perpendicular to the rafters in plan. The thickness of the lathing is usually 4 - 6 cm.

- Roofing flooring.

Advice from professionals

To avoid mistakes when insulating an attic with mineral wool from the inside, you must follow some advice from experts:

- Use thermal insulation materials in accordance with climatic conditions.

- Choose insulation only from trusted manufacturers.

- Lay only completely dry material on the wall, roof and floor - mineral wool is not able to dry.

- All wooden elements must be treated with protective impregnation against mold and fungi.

- The use of a vapor barrier film should not be ignored; it will prevent the heat insulator from becoming moist. To insulate the attic from the inside with mineral wool, roofing material, plastic film, and glassine are perfect.

- Good results are obtained by using a foil film panel. This material can significantly reduce heat loss, only it must be laid with the metallized side inside the room.

- It is recommended to work with mineral wool indoors wearing special clothing, glasses, a respirator, and gloves.

- Lining, MDF boards, plasterboard sheets, OSB are suitable as finishing materials.

- If there is no wind protection, then it is necessary to install a special membrane and fiberboard sheets on the bottom side.

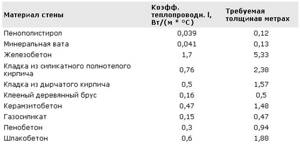

Sufficient insulation thickness

To determine the required thickness of mineral wool, you should choose one of the independent online thermal calculators (not owned by any insulation material manufacturer). In the filters, you must specify the region and all components of the roofing pie, indicating materials and thicknesses. Each air gap is also a significant insulation layer.

The thickness of the insulation for the attic must be accurately calculated

After this, the calculation will show the final indoor temperature. Using the method of successive approximations, you can find the value of all thermal insulation parameters that provide the required level of comfort in the attic.

In most regions of the European part of the Russian Federation, the required thickness of mineral wool for internal insulation of an attic is 280 - 300 mm.

Often, developers are content with values of 200 - 250 mm, for the reason that “this corresponds to the geometry of the rafters” and “this has been tested in practice.” They simply ignore the fact that heat in the attic is compensated by heating systems located on the ground floor. The money saved on attic insulation results in significant annual energy waste.

Table: comparative characteristics of various insulation materials and the required thickness depending on thermal conductivity

How to prepare an attic for insulation with mineral wool

Correctly carried out preparatory measures will help to avoid poor-quality thermal insulation in the room:

- Inspect the roof truss system to identify rotten or cracked elements. If there are any, then it is recommended to completely replace them with new ones. There should be no damp, rotten or moldy elements.

- Treat the wooden structure with an antiseptic compound and prime it. Such simple techniques will reliably protect wood not only from the harmful effects of moisture, but also from pathogenic microorganisms. After this, all wooden elements must be thoroughly dried. If you follow the manufacturer's instructions, there will be no difficulties with the use of protective impregnation.

- If the thickness of the rafters is insufficient, an “extension” should be performed. This implies additional beams and boards nailed to them. The thickness of the rafters should correspond to the thickness of the selected heat insulator - this is convenient during installation, and also more reliable for the stability of the entire system.

Advice! The formation of cold bridges will be eliminated by installing sheathing that is installed under the rafters.

Technology for self-installation of mineral wool

First, you need to make sure that the outer elements of the roofing pie (or at least the waterproofing layer) have already been installed. This is necessary to protect the mineral wool from atmospheric moisture before installing the outer membrane.

Place mineral wool tightly between floor beams or posts

Next, the width of the openings between the rafter beams is checked. If the size ranges between 550 mm and 600 mm, then you will not have to cut the insulation (you can use the factory width of the slabs 600 - 610 mm). If the distance between the rafters is more than 600 mm, it will be necessary to cut fragments of the required width from mineral wool slabs based on the installation compression of 20 - 30 mm. For example, if the rafter niche has a width of 720 mm, then sections of 700x600 mm are cut out of 1200x600 mm slabs. Residues 500×600 are accumulated for use in insulating various contours (for attic walls, around window openings, for laying crossbars on top, etc.)

The second method involves cutting rectangular slabs diagonally and relative displacement of the halves along this diagonal. When shifted, the overall width increases, ensuring that the ends of the wool rest against the vertical edges of the rafters. However, in this case, for a tight connection, the following slabs will have to be cut curvilinearly from the outside.

Installation of mineral wool and further operations are carried out alone using the following techniques:

Fastening mineral wool with nylon thread

- If there are no significant differences in width in the openings between the rafters, you can install mineral wool slabs without preparatory work. Pressing the material by 20 - 30 mm allows you to lay out all the insulation elements from the inside of the room into the roof slope. Otherwise, to support the wool, a temporary (removable) sheathing of planks, boards, or nylon thread (non-removable) is used, stretched along the lower edges of the rafters in a zigzag using a stapler. Layers of mineral wool are laid out in a checkerboard pattern to cover the joints.

- A vapor barrier film is stapled from below to the ends of the rafters. It must be joined with an overlap, gluing the joints with special tape.

- The lathing is installed to install the final ceiling cladding.

Step-by-step photo instructions for installing thermal insulation

Video: how to insulate an attic roof with mineral wool (Isover Pro 100 mm and Ursa Pure One 50 mm)

The total thickness of the insulation was 250 mm. The insulation is fixed using a 50×40mm beam. To eliminate sagging mineral wool, the author of the video additionally uses twine, which is stapled to the block.

How to properly insulate an attic with mineral wool

Anyone can preserve heat indoors with the help of effective thermal insulators with their own hands, if you follow a certain sequence of actions and treat each stage with full responsibility.

How to insulate an attic roof from the inside with mineral wool

Here the essence comes down to fixing the insulation between the rafter system and the cladding with facing materials. The algorithm for performing work on insulating an attic with mineral wool from the inside comes down to the following:

- Waterproofing. In accordance with building codes, insulation cannot be laid close to the waterproofing material, which is provided at the stage of roof installation. To ensure the required gap, you need to either nail it to the slats or pull the threads in a zigzag pattern between pre-installed nails. In this way, it will be possible to prevent the mineral wool from being moistened by condensate, otherwise its thermal insulation characteristics will not only deteriorate, but also its service life will be reduced.

- Fixing the vapor barrier film. This stage is often ignored, but, as practice shows, thanks to the rough surface, moisture is not retained, but evaporates. It is convenient to mount the material on the rafters using a construction stapler. It is better to lay the sheets with an overlap (5-10 cm); it is recommended to seal the joining places with reinforced tape. When laying, it is important that the smooth surface of the membrane is directed towards the insulation.

- Laying mineral wool. The insulation blocks must be adjacent to both the rafters and each other.

- Installation of another layer of vapor barrier. It is made according to the method described above.

- Lathing for plasterboard sheets. It can be placed both vertically and horizontally, everything will depend on the type of cladding. Mount it to the frame, on the rafters.

- At this stage, the roof insulation is completely completed.

The do-it-yourself scheme for insulating an attic from the inside with mineral wool is as follows:

If you insulate the attic in compliance with all technological requirements, you can save a large percentage of heat

Insulation of attic walls with mineral wool

To protect the walls of the attic, it is necessary to equip a timber frame, lay a heat insulator, and arrange everything decoratively. Step-by-step instructions for insulating attic walls:

- Prepare the surface. The walls must be smooth, without signs of mold or moss. If there are cracks, they must be eliminated using sealant.

- Lay waterproofing film. The material must be secured with a construction stapler over the entire surface.

- Make a vertical frame. For these purposes, bars are used. Its pitch should correspond to the thickness of the blocks or rolls of mineral wool. Installation is carried out using dowels. The space between the heat insulator and the timber should be minimal.

- Laying mineral wool in cells.

- Fixation of vapor barrier material. The membrane is secured using a stapler without sagging.

- Sheathing with clapboard or OSB boards. They are mounted on a frame made of wooden blocks.

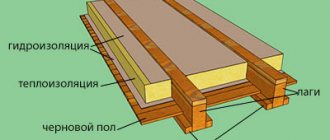

Insulating the attic floor with mineral wool

You can arrange the floor according to the following principle:

- Prepare the surface by freeing it from the old coating. Make sure that the joists are intact and undamaged.

- Laying vapor barrier material using a construction stapler.

- Laying insulation between wooden joists.

- Laying another layer of vapor barrier.

- Covering with facing material.

Video of the technology for insulating an attic from the inside with mineral wool:

Insulation of mauerlat and walls

The insulation of the attic walls should form a closed loop with the insulation of the roof slopes. Thermal calculations for walls are carried out separately. In most cases, it shows the required insulation thickness 1.5 times less than for the roof.

Insulation of the attic mauerlat

Mauerlat is a log or beam that serves to transmit and average pressure from the rafter beams to the upper end of the wall. It is recommended to insulate the Mauerlat before installing the hydrobarrier. The Mauerlat is insulated from above and from the street side. Then the membrane is installed.

Video to help: why moisture forms on the roof of an attic insulated with mineral wool

Poll: what is the best insulation for the attic?

What would you choose from insulation for the attic or would you recommend purchasing?

Hotrock Smart

5.95 % ( 5 )

Rockwool

17.86 % ( 15 )

Ursa Geo

5.95 % ( 5 )

Isover Warm House

13.10 % ( 11 )

Knauf Therm House

5.95 % ( 5 )

PSB S 15-O

5.95 % ( 5 )

TechnoNikol XPS Technoplex

1.19 % ( 1 )

Penoplex Comfort

34.52 % ( 29 )

Shelter EcoStroy ShES standard

1.19 % ( 1 )

Which mineral wool is best for the attic

According to experts in the field of private housing construction, mineral wool is considered the best thermal insulation material.

In order to verify this, we will perform a comparative analysis of cotton insulation on different bases.

Slag wool was popular in the former USSR more than 30 years ago. Its disadvantage is its high hygroscopicity. This quality is unacceptable in insulation for rooms with high humidity. Modern builders prefer modern glass and basalt products.

Comparison of mineral wool on different basis

*

On the Russian market we can distinguish the TOP of 7 manufacturers whose high quality products best correspond to the price:

Rockwool basalt wool

The leader is the Danish company Rockwool, which produces basalt-based thermal insulation. According to reviews from builders, it maintains a high standard of 10 points out of 10 possible, and ensures maximum quality without unnecessary unjustified overpayments.

Paroc basalt wool

Three companies occupy second place. Their performance is 9.9 out of 10:

- Paroc is a manufacturer of basalt mineral wool from Finland. His rating is 9.9 out of 10.

Mineral wool ISOVER

- The French concern Saint-Gobain is an international concern. He began producing his own thermal insulation materials 80 years ago. Products are manufactured based on glass and basalt rocks.

The German group of companies Knauf produces insulation from glass and stone fibers.

Glass wool URSA

An international company from Spain, URSA, was formed relatively recently, after the URALITA Group concern acquired the German company Pfleiderer, or rather, its insulation business. Mineral wool is made from glass. Factories are scattered throughout Europe, and there is a representative office in Russia. The company's rating is 9.8 out of 10.

TechnoNIKOL basalt wool

The TOP is completed by two companies TechnoNIKOL from Russia and Beltep from Belarus. Their products are made from volcanic rocks and are of high quality and reasonable prices. Rating indicators 9.5 out of 10.

Beltep basalt wool

Having become familiar with the best mineral wool manufacturers, the builder makes his own choice. There is no consensus which of the listed brands is the best. When choosing, take into account the structural features of the roof, the climatic conditions of the region and the price.

Features of thermal insulation of the attic floor

The technology for insulating a mineral wool attic from the inside involves creating an obstacle to the outflow of heat and reducing air exchange with the cold street. This is a feature of the isolation process. As a result, warm, moist steam remains inside the room. In such conditions, it is necessary to reliably protect the cotton wool from moisture, otherwise it will quickly get wet and lose its properties.

Another problem is the dew point shift. If you insulate an attic roof from the outside, the dew point will be on its outer side. In this case, the resulting condensate will evaporate into the atmosphere. But if the insulator is laid from the inside, this does not happen. Therefore, it is very important to leave an air gap of 50-100 mm between the roof and the insulator. It is necessary for the evaporation of condensate.

For effective insulation you need a roofing pie of five layers. If you look from the roof, they are located in the following sequence.

TechnoNIKOL Rocklight stone wool

Layers of roofing cake

- Ventilation gap 50-100 mm.

- Vapor-permeable membrane, moisture and wind insulation.

- The insulating layer is laid between the rafters.

- Vapor barrier film or membrane.

- Attic ceiling.

For vapor barrier, it is best to choose special membranes. On one side they are rough, the other side is smooth. Thanks to this feature, condensation does not form on them. If there is no membrane, lay a film of polypropylene or polyethylene, glassine. For moisture and wind protection, other membranes are chosen: double-layer film, porous and superdiffusion. The last option is considered the best.

How to choose mineral wool for insulating an attic roof

Almost any type of mineral fiber is suitable for laying thermal insulation from the inside of the attic, the main thing is that the material is certified and meets all the requirements for stone wool. If you have the opportunity to choose, it is best to use mineral wool of the middle and upper price segment, such as Rockmin Rockwool, Izover Ursa, TechnoNIKOL Rocklight.

The advantages of such brands of insulation include:

- Minimal release of pili and phenol;

- The presence of surface impregnation, which gives the sheets good flexibility and elasticity.

Such a mat made of mineral wool can be laid in a cell of the sheathing and not worry that the material will settle from inside the wall, and thus a window or a cold bridge will be formed in the attic wall. Mineral wool generates less dust, but still, when laying it from the inside of the attic, you must use protective clothing, gloves and a respirator.

Technological process

Insulating the ceiling in the attic begins with drawing up a work project. Measurements of the main geometric parameters are carried out:

- total length and width of the ceiling;

- the size of the gaps between the beams;

- niche depths.

All this serves as the initial data for calculating material requirements . The need for mineral wool and polyurethane foam is calculated by the specific volume of the substance, in roll and sheet materials - by the number of layers and area with a correction factor that takes into account trimming to the required shapes (it is usually equal to 1.1...1.4).

The next stage is preparing the necessary materials and tools, performing preliminary work, which includes marking and surface treatment, for example, applying antiseptic to wooden structural elements. After this, they proceed directly to installation.

The molded sheet materials are placed in the openings, leaving a gap of 2-5 cm to the waterproofing layer to ensure ventilation. It is extremely important to ensure tight fit and minimize the size of mounting cracks and gaps. To do this, during preliminary cutting, a small reserve of material is left, and the excess, if necessary, is trimmed directly during installation with a stationery knife.

In the case of using roll, cotton, or aerosol substances, you will need to install an inner film layer , which will serve as a mounting base. To do this, a thick film is attached with a construction stapler to the upper part of the side surface of the beams.

When the main insulation is installed in the openings, it is covered with a vapor barrier . This is usually a membrane, foil or perforated film. The layers are placed across the rafter system, gradually unwinding the roll.

Advice. It is more convenient to do the work together - otherwise it will be difficult to manage the bulky roll and distribute the material evenly.

The vapor barrier is attached to the ceilings with an overlap, with a margin of 10-15 cm , using a construction stapler. The material should not be too tight; even slight sagging is allowed. All joints should be additionally taped with special tape.

Then the vapor barrier layer is hidden under any type of decorative coating . This can be plasterboard, plywood, chipboard, fiberboard, lining and other materials. It is possible to install them directly to the beams through the vapor barrier, however, in order to avoid ruptures of the latter and to improve ventilation, it is recommended to install an internal sheathing of slats 1.5-2 cm thick. As a result, the design of the “pie” of the ceiling and roof should resemble the one shown below.

We hope we helped you understand how to insulate an attic ceiling and decide on the choice of technology and material. Let your attic always be warm and cozy!

Features of insulation

Before starting work on laying thermal insulation material, pay attention to the following important features of insulation:

- The attic will be a living space, and therefore will require more thorough thermal insulation than roof insulation.

- The rafter system and floors are not designed for great forces, so the insulation should have a small mass. Taking into account the specific gravity, mineral wool is ideal.

- Heat leaves the attic not only through the roof, but also through the walls and floor; they also require careful insulation.

- Warm air, due to its physical characteristics, promotes the formation of dew drops, so the thermal insulation layer should be covered with a vapor-proof film.

Why shouldn't you choose mineral wool?

Although mats made from cotton wool insulation are very light, mineral wool and ecowool are too dependent on environmental influences. A mineral wool board is compressed wool with the addition of binding components. But, as you know, wool perfectly absorbs moisture, so it is very difficult to protect mineral wool insulation from water and steam. Condensation formed in roof structures settles in the insulation and practically does not disappear from there. The more moisture in the insulation, the lower its heat-protective properties. In fact, wet mineral wool ceases to function as insulation. But that's not all - it turns into a favorable environment for the growth of mold, rot and bacteria.