One of the important stages of work in the construction of brick kilns is the correct arrangement of the firebox, since its masonry material will be constantly exposed to open fire. Ordinary stove bricks used when laying a stove, under the influence of very high temperatures that arise when burning solid fuel, will burn and may begin to crumble due to the loss of natural moisture of the material. To avoid this and to extend the duration of trouble-free operation of the heating structure, to ensure the safety of people during constant use of stoves, ordinary ceramic bricks are separated from open fire. This kind of protection is called lining.

Lining a heating furnace - what is it and how to do it yourself

It is also necessary to note that the walls of the fireboxes of metal stoves and solid fuel boilers very often also need protection. Everything is explained by the fact that metal (steel) partitions, even more than brick, are subject to gradual burnout. Therefore, some manufacturers supply the fireboxes of steel heating devices with kaolin or fireclay panels.

So, lining a heating furnace - what is it and how to do it yourself? This question often arises among those stove owners who have already encountered the destructive effects of fire on the material from which the combustion chamber is made. Therefore, information will be provided below on what this process is and how it is performed.

What is a "lining"?

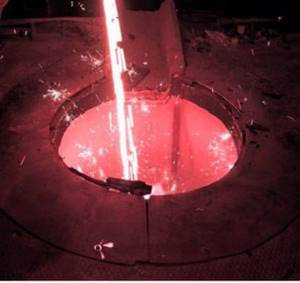

Furnace lining is the installation of a facing layer on the internal planes of the combustion chamber, which are in constant contact with open fire. Its function is to protect external walls from damage of a thermal, mechanical, chemical or physical nature. Lining is performed not only for heating devices for domestic use; this technology is used in the manufacture of metallurgical smelting furnaces, steam boilers, ladles, etc.

In addition to fire protection, heat-resistant material performs a thermal insulation function - reducing heat loss. However, there is some danger here: a lining layer that is too thick will lead to a decrease in the efficiency of the device, since the flow of thermal energy will “fly away” through the chimney to the street, rather than spreading inside the room.

Description of the process and purpose of the lining

Lining is protection against burning out of the internal volume of the furnace; it is made with fireclay bricks

Lining is the lining of the inner walls of chambers in stoves that are constantly in contact with the flame. It is necessary for stove units made of brick, which begins to burn and crumble due to loss of moisture, as well as for metal stoves and solid fuel boilers. Firebox partitions made of steel and other metals are more susceptible to burnout, which is why many manufacturers supplement them with fireclay or kaolin screens.

Lining the furnace firebox with fireclay bricks or other material helps protect the walls from mechanical, chemical, thermal or physical damage. Additional coating helps reduce heat loss, but for this you need to accurately calculate the thickness of the layer, otherwise the walls will not warm up completely. Too dense layers of lining reduce the efficiency of the furnace, since heat flows in such a situation will go outside through the chimney, rather than remaining indoors.

Methods of execution

Furnace bunkers are lined, depending on the building material of the main structure, in several ways:

- installation of a facing layer made of materials with a low thermal conductivity coefficient: fireclay bricks or special panels. This work can be done both during the construction of the stove and after its construction is completed;

Fireclay brick

- installation of protective screens that reflect thermal radiation. It is used for lining metal stoves - heaters, which are used to equip steam rooms in baths. The use of heat-reflecting screens for other designs of heating units is ineffective;

- coating the inside walls of the combustion chamber with a heat-resistant mixture of various types. You can apply the composition to the walls of the firebox at any time - during construction or in a ready-made unit.

Purpose of the furnace lining

There are many methods for producing specific types of furnace lining only. There are no less types of lining materials, and new ones are being developed all the time. However, all this diversity can be divided generally into 4 classes according to the purpose of the lining, the composition of the materials and the characteristics of the work:

- Lining of large industrial furnaces for various purposes;

- Lining of fireboxes and other hot parts of household brick heating and cooking stoves;

- Lining of small metal furnaces, domestic and technological, applicable outside production conditions;

- Lining of induction furnaces, both industrial and small.

Materials used

Refractory materials for lining furnaces, depending on the ingredients included in the raw material composition, are divided into the following classes:

- A - products based on materials of natural origin or a synthetic composition with the addition of an organosilicon binder;

- B - a special type of clay (fireclay) is used as the main ingredient;

- C - other components of refractory substances.

Products and compositions for lining a class B furnace (bricks, blocks, mastics, etc.), the basis of which is fired fireclay clay, are available, inexpensive, and therefore are most popular. To increase heat resistance, portions of quartz sand, sandstone and other types of rocks, the strength of which remains unchanged at any heating temperature, can be introduced into the raw materials during their production.

As additional protection, materials in the form of a roll, plate or sheet are used for fireclay products. They are laid between layers of masonry made of heat-resistant and ceramic products. The list of such materials for furnace lining, which are based on white clay, includes:

- basalt wool;

- dense kaolin;

- mullite - siliceous mats;

- vermiculite and a number of other products.

Dry mixtures are used to make fire-resistant mortar, which is used to coat the surfaces of the combustion bunker and other masonry elements. They fill the cavities of technological clearances and gaps that compensate for the linear expansion of the structural parts of the metal furnace.

Refractory materials for lining furnaces also include heat-resistant aluminosilicate adhesive mass, which is used to glue refractories in sheet or roll form. This glue is also used for fireclay masonry and for coating walls made of bricks with low heat resistance with a thin layer.

Lining: what is it and why?

When fuel burns, the inner walls of the furnace are exposed to high temperatures. If you do not provide additional protection, ceramic or stove bricks will collapse in the first year of operation. The furnace lining was invented precisely in order to extend the service life of the entire structure and increase heat transfer. Another row is laid out inside the fuel chamber; fireclay bricks or fire-resistant panels are used as the material. Fireclay cladding can withstand temperatures up to 1300˚C and is not subject to destruction from alkali, lime or other chemical elements. In addition, the protective material retains heat well, thereby increasing the efficiency of the stove.

Lining methods and their features

Having learned what a lining is, you need to figure out how to create a protective layer for the furnace. Internal lining works are divided into three types:

- Overhead. The refractory lining is laid with fireclay bricks directly during the construction of the fuel chamber itself. Industrial furnaces with increased load are equipped with fire-resistant panels.

- Printed. A clay solution is applied to the inside of the masonry or treated with mastic made from a heat-resistant material. The joints are carefully sealed to reduce heat loss.

- Shotcrete. Concrete solution is supplied from a professional apparatus under high pressure. This method is used for lining chimney pipes and large industrial furnaces.

Is it necessary to soak fireclay bricks before laying?

Even experienced stove makers do not have a clear answer to this question. However, having studied the physical properties of fireclay, you can be convinced that in some cases, before making the furnace lining, it is simply necessary to moisten the masonry material:

- when the masonry is done with used bricks. During previous use, the pores of the material became clogged with particles of dust and masonry mixture, and in order to open the capillaries in its structure, the brick is soaked. After the brick is removed from the container with water, you should wait until all the liquid has drained from it, and only then use it for masonry work;

- when building a heating device in the summer heat, but with high humidity in the fall or spring, it is better not to soak the brick.

Glue and solution

Refractory mortar for laying fireclay bricks

In addition to the quality and characteristics of materials, the effectiveness of the lining procedure is also influenced by their correct installation using special substances.

Solution

Heat-resistant solutions form a monolithic thin layer on the walls of the firebox, protecting the working surface from the effects of flame. Such a monolith may require repairs as it wears out. When working with the solution, you must follow the basic rules:

- Solutions are prepared from dry mixtures of corundum, mullite or fireclay type, which are diluted with water to a creamy consistency. The proportions of the components and the characteristics of the mixtures are usually indicated on the packaging.

- First, the solution layer is fired with a blowtorch or heated in an oven until a hard coating forms during firing.

- If the lining is carried out using fireclay bricks, the joints must be filled to the full height of the masonry.

For 1 m3 of brickwork, at least 100 kg of ready-made mortar from any type of mixture is usually required.

Fireproof glue

Fireproof adhesive for laying out the firebox

Additional lining mixtures

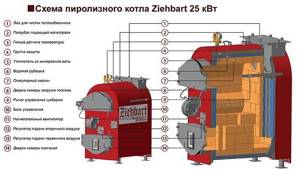

Diagram of a brick kiln.

In recent years, not brick or metal stoves, but stucco stoves of various shapes have become very popular in the construction of baths. They give the bathhouse a unique interior, making it less industrial. To create such ovens, the adobe method is used.

This method consists of making the entire oven from raw clay and giving it the required shape. Subsequently, the inside is burned with wood. After the firebox hardens, the outer part of the furnace is fired using blowtorches. Different firing stages help to avoid cracks.

It is difficult to line such a furnace using fireclay bricks, so special dry mixtures are used:

- corundum;

- fireclay;

- mullite

These compounds are diluted with water right on the spot. Both the firebox and other necessary fire-resistant products are coated with ready-made solutions. Since the lining when using dry mixtures turns out to be monolithic, this affects its quality. It copes with the role of a heat-protective coating better than a layer of fireclay bricks.

Instructions depending on the material

A layer of cardboard between the inner and outer layers of masonry

It is better to entrust the lining of a standard or induction furnace to specialists, but if you have minimal skills, you can carry out this procedure yourself, following the rules.

Brick oven

When lining the combustion chamber of a brick kiln, the thermal expansion of the material is taken into account. Between the internal protective and external standard layer of masonry, you need to leave a gap of 7-10 mm or supplement it with a gasket made of kaolin, basalt or asbestos cardboard.

Metal oven

Lining a metal furnace

The procedure for metal furnaces is carried out in the same way as for brick equipment. It must be taken into account that there must be a gap between the metal wall and the material to compensate for linear expansion. This space can be filled with basalt or kaolin slabs or asbestos sheets.

Solid fuel stove

For solid fuel stoves, it is advisable to carry out lining using one of the three available methods. Heavy lining is carried out for furnaces with weak shielding; with this method, the lining is carried out with masonry in two or three layers. In the case of lightweight lining, the masonry should be single-layer. There is also an option for pipe lining, when the boiler pipes are coated with fire-resistant glue on the outside.

Clay oven

Fireboxes in clay ovens are recommended to be lined with fireclay bricks or coated with plastic refractory materials, for example, mastic or aluminosilicate glue. After hardening, the layer of such material is a dense shell that protects the walls from overheating.

Fireclay brick

Lining with fireclay bricks is carried out by laying out the material in several rows with a slope and an edge with a shift of up to 1/2 of the length towards the block in the bottom row up to the top of the combustion compartment. The upper plane is faced last, laying the bricks flat. It must be remembered that the lining layer and the main masonry of the walls must correspond to each other in the location of the vertical seams.

Independent lining of heating structures and units

Features of facing brick fireboxes

The lining of the walls of the combustion chamber is carried out with mandatory consideration of the thermal expansion of materials under the influence of high temperatures that arise during the operation of the stove, fireplace or boiler. In this regard, an empty gap of 7÷10 mm is left between the inner protective (fireclay) and outer (ordinary ceramic) layers of the masonry, or a spacer is made of basalt, kaolin or asbestos cardboard.

The lining masonry should not be in direct contact with the outer walls of the combustion chamber. Either an empty gap is left, or it is filled with heat-resistant material, for example, kaolin or asbestos sheet

Before starting work, it is necessary to calculate the material. If you plan to make a lining using fireclay bricks, then its linear dimensions are immediately taken into account. Most often, standard bricks with dimensions of 250 × 150 × 65 mm are used.

The variety of fireclay blocks is very wide, so you can choose the optimal material for combustion chambers with complex configurations.

At the same time, the modern range of refractory bricks is very wide. Manufacturers supply fireclay bricks to retail chains with the configuration necessary to create inclined surfaces that frame the grate or are formed on the back wall.

The use of shaped fireclay blocks is convenient in the sense that during the laying process you can try as much as possible to avoid independently undercutting the bricks.

As an example, an illustration is presented - the lining of the fireplace combustion chamber. The slope of the rear wall, which is formed to reflect the heat flow and direct the combustion products, is clearly shown. Pay attention to the gaps left between the outer and inner walls of the oven.

The furnace lining can have different thicknesses, which are determined by the following parameters of the heating device:

- The thickness of the outer layer of the furnace masonry.

- Thickness of the furnace body lining.

- Maximum temperature inside the combustion chamber.

The same parameters must be taken into account when choosing a material for the protective layer, based on the table presented above. It specifically indicates the operating temperatures of the most popular lining materials.

Professional stove makers recommend strengthening fireclay masonry with reinforcement. To do this, steel wire with a diameter of 3÷4 mm is placed in the seams between the rows, in the mortar. Reinforcement is carried out through two rows.

If the lining is carried out during the construction of the furnace, its sequence is described in detail in the order diagram itself, from the first to the last row of lining. When finishing the finished firebox with refractory bricks, work is carried out in the following order:

- First, the brick is laid around the grate. To do this, it is best to use a brick that has a slope towards the grate.

- Then the side and back walls are raised. Due to the fact that it is almost impossible to lay out the back wall of a finished firebox on a slope, it is usually made flat.

Lining the finished firebox with thin refractory blocks. The quality, as you can see, is “not very good”... In addition, there is no gap left between the ceramic and fireclay bricks. So it is better to carry out this operation during the construction of the furnace.

Prices for heating stoves

heating stove

- However, here it is necessary to clarify that if the firebox is very small, and lining needs to be done, then it is better to use panels made of one of the heat-resistant materials or paste-like compositions instead of bricks. Using the latter option, the coating must be done very carefully, without leaving untreated areas. In order to improve the visibility of the interior of the firebox, if possible, it is recommended to remove the cast iron rings from the hob burner and hang a lamp over this hole to illuminate the chamber.

- When making the lining, you need to remember that red heat-resistant and fireclay refractory bricks should not be mixed in it. The fact is that these materials have different densities, and therefore linear expansion, and also differ in thermal conductivity. Therefore, between the outer wall of red brick and the lining, it is recommended to make a gasket of asbestos or basalt cardboard with a thickness of at least 5 mm. With the thermal expansion of bricks made from different materials and in contact with each other, cracks can easily appear in red brick over time.

Video: A clear example of the correct lining of the combustion chamber of a brick kiln

Lining of metal fireboxes

If you need to make a lining for a metal firebox, you should remember that metal and brick generally differ radically in their coefficient of linear expansion when heated to high temperatures. Therefore, a thermal gap should always be left between the metal and the brick, which is filled with basalt or kaolin wool or asbestos.

Combustion chamber of a metal heating furnace after lining with fireclay bricks

In addition, it is necessary to take into account that if a lining is made inside the firebox, then the outside of the metal stove should no longer be lined with bricks. Ceramic brick is characterized by high heat capacity and low thermal conductivity, that is, the heat obtained from burning fuel will not fully warm up the walls, but will “go down the drain.” In this case, the efficiency of the furnace will significantly decrease.

Prices for fireclay bricks

fireclay brick

The cladding is carried out from the bottom up, from the bottom of the combustion chamber to its ceiling. Be sure to leave deformation gaps between fireclay bricks and metal surfaces

The process of lining the combustion chambers of metal furnaces is carried out in the same order as brick ones. That is, first the bottom of the firebox is laid out, and basalt cardboard with a thickness of at least 10 mm is laid between the bottom metal and the brick. To secure the cardboard to the metal, and then the brick on top of this heat-resistant material, the fire-resistant adhesive mentioned above can be used.

Lining of a heating solid fuel boiler

A boiler, unlike a furnace, must transfer the generated energy to the coolant passing through the heat exchange circuit and dissipate it through the outer walls to a minimum. This determines the features of its lining.

When carrying out the lining of steam boilers, three methods of its arrangement are used:

- Heavy lining. This method is used for boilers with weak shielding. During their operation, some areas and parts may reach temperatures in excess of 1250 degrees. This, of course, creates the risk of not only quickly burning out the walls of the device, but also makes servicing the unit extremely unsafe, and can even lead to a fire. Heavy lining consists in the fact that fireclay bricks are laid on a spoon in two or three layers, which reduces the temperature of the outer walls to 60–75 degrees. As a rule, you don’t have to deal with such heavy lining at the household level.

An example of a lightweight lining of a heating boiler operating on the principle of afterburning pyrolysis gases

- Lightweight lining consists of one layer of brickwork. In addition to the internal lining, to increase efficiency and reduce the temperature of the external walls, the external surface of the boiler is often lined with one of the non-combustible materials that can withstand the elevated temperatures characteristic of a particular unit. Well, then sometimes it is additionally sheathed with metal sheets.

- Pipe lining is intended for a kind of thermal insulation of boiler pipes, where due to elevated temperatures it is impossible to use other insulating materials. It is performed directly on the outer surfaces of the pipes. This option can be called the simplest to implement. It is performed using fire-resistant glue or other solution produced in the form of a viscous mass.

The plastic substance is applied to the pipes with a brush in two, and sometimes three or four layers. Once cured, this treatment forms a thick layer that prevents unnecessary heat loss. To avoid through mechanical damage to the protective layer, it is often reinforced with fiberglass mesh. Metal mesh is not used due to its high thermal linear expansion.

Lining of fireboxes for molded clay ovens

Despite the availability on sale of a large number of bricks of different types and qualities, as well as ready-made metal heating units, adobe stoves of various configurations have recently become increasingly popular.

A very ancient heating technology, and now a very fashionable trend: clay stoves with stove beds, which can be given very fancy shapes. The fireboxes of such structures also need to be protected with lining.

It is strongly recommended to strengthen the fireboxes of these furnaces with fireclay bricks. If the walls of the furnace were created from mortar mixed with stone, which acts as “reinforcement,” then it is quite possible to use one of the refractory paste mortars for lining the furnace. For example, the glue already discussed above, or special cement, fireclay, corundum or mullite mixture, is perfect.

Paste-like materials greatly simplify the work - any home craftsman can carry out such lining, even those without experience in such processes. After the refractory materials harden, they form a monolithic layer that will prevent cracking of the main clay walls of the combustion chamber when exposed to high temperatures.

Manufacturing lining and material properties

In production, in metallurgy, the lining of an induction furnace is made using special, pressed fireclay bricks. They are very wear-resistant, do not shrink and withstand thermal shocks well. The use of fireclay bricks made it possible to achieve great cost savings and greatly reduce the cost of the metal production process.

Induction oven

Induction oven

The table shows the properties of some refractory materials

| Material | Density kg/m3 | Maximum operating temperature °C |

| Chamotte | 1800-2000 | 1300 |

| Clay brick | 1600 | 700 |

| Vermiculite | 150-250 | 1100 |

| Basalt wool | 100 | 750 |

| Kaolin is dense | 2400-2500 | 1400 |

Household problems - lining as a solution

In everyday life, people usually have to solve simpler problems. At the very last stage, the burning of the coals, the bottom of the metal stove overheats, sometimes red hot. A man decides to cover the overheating wall from the inside with his own hands.

But even in this case, you have to decide to what level to lining, whether to leave a gap and how to secure the bricks?

Specifically in this situation, the issue can be resolved as follows:

- If the width of the firebox allows, fireclay bricks of a standard size are laid along its perimeter - 250X150X65 mm. In this case, the brick is laid flat against the wall. Can be laid vertically with a height of 250 mm or horizontally with a height of 120 mm.

- In order to securely fix the bricks together, a simple method is used. Using a grinder, a cut is made in part of the joint, and the bricks are held together using an inserted metal spike of a suitable size.

Lining device: temperature and metal

Particular attention should be paid to the fact that the thermal linear expansion of metal is much greater than that of brick. Therefore, all metal parts exposed to heat must have free space for expansion.

Our information: the absence of a gap between the metal wall of the furnace and the lining leads to destruction of the lining.

When installing this lining, the gap is sealed with basalt or kaolin wool, twisted into bundles, cords or in the form of a compressed sheet. Asbestos can be used for this purpose.

Wrong defense. Consequences

This picture occurs very often. The metal stove is lined with bricks using clay mortar, and without any gap. This is motivated by ensuring safety and improving the heating of the furnace.

Brick for lining: chamotte - the ideal solution

Fireclay brick

If external protection in the form of a screen in heating boilers, the use of this method will be very wasteful, since most of the heat will be spent completely in vain. But this method is perfect for installing sauna stoves.

Previously, under the USSR, most private owners were familiar with simple building brick GOST 530-95 . This brick is intended for the construction of industrial and residential buildings and in no way for use in furnaces and heating boilers. By the way, many still use it to build furnaces and boilers.

Many craftsmen at that time managed to get a brick of this GOST, but of a higher grade M - 300 , in the popular expression “kiln”. This brick lined the furnace part of the furnaces to protect against high temperatures.

Later, fireclay bricks GOST 390–96 .

Our information: fireclay materials are made from clay mixed with fired clay powder and then fired at high temperatures.

The use of fireclay is the lining

Due to the fact that all fractions have a homogeneous chemical composition, all fireclay products have a high degree of heat resistance and do not crack when exposed to high temperatures.

Lining the combustion part with fireclay material to protect the heating unit from the effects of high temperature in the combustion part is called lining.

Furnace lining

Furnace lining

Metal lining

The lining of a metal furnace is done only from the inside. Additional external cladding or coating of the stove will speed up its warming up, but, contrary to popular belief, it will have almost no effect on the thermal efficiency of the stove: the rule of insulating rooms “from the cold side” arose because the dew point cannot be allowed into the room; for a lined furnace it is not relevant. But the outer lining/coating of the furnace will greatly increase the thermal stresses in the metal of its body and its sensitivity to chemical influences.

It is best to line a metal stove with vermiculite using ScannMix glue or its analogues: the packaging or specification of the glue should indicate that it glues both metal and/or ceramics to metal (if it glues ceramics to metal, it will also glue slab materials). For good thermal insulation of a muffle furnace, a vermiculite plate 20-30 mm thick is sufficient. If a metal stove is lined with brick, then it must be installed according to the same rules as in the firebox of a brick stove. For example, how a gas forge furnace is lined with fireclay, see video:

Steam boiler lining

According to the type of construction, boiler linings are divided into:

- pipe;

- lightweight;

- heavy.

Pipe lining is made with a special heat-insulating mass applied to boiler pipes in several layers. Reinforcing this mass with a metal mesh will ensure the strength and reliability of the entire structure.

Lightweight lining is made in one layer of fireclay bricks divided into belts. Each belt rests on the boiler frame or intermediate beams. The outer surface of the boiler is sheathed with an iron sheet with heat-insulating plates placed between it and the boiler. This method will increase the efficiency of the boiler while reducing the temperature of the external surface.

Finally, heavy linings are used in boilers where weak shielding is provided. The temperature inside the furnace of such boilers reaches 1300°C, which is very unsafe for external materials. The lining is designed to reduce the temperature of the external surface of the boiler to an acceptable 70-80°C. Heavy lining is made in several layers of fireclay bricks, which are not afraid of exposure to high temperatures.

shotcrete

Shotcrete, which our company offers as a binder, includes better adhesion to the surface, less kickback, quick drying, no cracking due to exposure to high temperatures, shows long-term durability, which is usually twice as long as materials with cement in as a binder.

Conventional shotcrete materials are transported dry under compressed air pressure and mixed with water in a nozzle during unloading. The amount of water (binder) and, as a result, the viscosity of shotcrete completely depends on the skill and skill of the technician using the shotcrete. Low cement content refractories used as shotcrete also contain added water and therefore must be dried and heated before use and are thus susceptible to cracking.

Shotcrete-based materials are prepared as a slurry/slurry using a precisely measured amount of colloidal silica binder (without adding water). The slurry is then pumped into a special nozzle where the technician can add an accelerator during use if needed to optimize adhesion to the target material depending on the ambient temperature and conditions. The unique colloidal silica binder system does not require special drying or heating, unlike cement-based binder products.

When dry, shotcrete-based materials adhere strongly to existing refractory materials as a binder, ensuring long-lasting use. Their inherent resistance to thermal cracking ensures that the profiling lining is fully intact at start-up, providing additional potential for long-term use. Shotcrete binder materials minimize downtime and increase useful time by eliminating long drying periods.

Roll lining

Rolled coatings have a fundamental difference from classic coatings and masonry with a thermal insulation function. Firstly, they are easy to apply. Secondly, the coating takes up a minimum of space, increasing the thickness of the structure by no more than 1 cm. For comparison, heat-resistant concrete in the form of plaster increases the thickness of the walls of a stove structure by 1-2 cm, and brick by this indicator can reach 10 cm. Rolled material presented in several forms, usually on a fire-resistant paper base.

The most widespread in this segment is mullite-silica kaolin wool, which is obtained by melting silicon and oxide in an electric furnace. In practice, it is noted that this material has low thermal conductivity and at the same time increased heat resistance. Also, kaolin thermal insulation materials are not subject to destruction under the influence of chemicals, for which they are valued in industrial production.

Fireproof materials for the protection of boiler and economizer pipes

| Product: | coating of pipes in furnaces with liquid slag removal and waste incineration plants. |

| Type: | pin pipe mass |

| Main raw materials: | silicon urea |

| Type of application: | inorganic/chemical or binding |

| Max operating temperature: | 1750°C for furnaces 1550°C for waste incinerators |

| Material requirement: Bulk density: | 2.65 t/m3 2.58 g/cm3 |

| Max. particle size: Water requirement: | 2 mm 0-0.2 l/100 kg |

| Bond Requirement: Open Porosity: | 5.5 kg/per 100 kg weight 19% |

| Irreversible change in length: Reversible change in length: | — 0.04% / 800° С 0.7 % / 1000° С |

Chemical composition

SICAl2O3SiO2Fe2O3CaONa2O3MgO

| 85,0 | 6,3 | 4,2 | 0,09 | 0,04 | 0,08 | 0,03 |

Physical properties

Cold compressive strength N/mm2 Compressive strength N/mm2 Cold bending strength N/mm2 Pre-drying/firing ° C Thermal conductivity W/mK Temperature ° C

| 35 | 9 | 110 | 8,5 | 400 | |

| 55 | 45 | 12 | 200 | 8,5 | 600 |

| 75 | 55 | 18 | 400 | 8,5 | 800 |

| 85 | 65 | 600 | 8,5 | 1000 | |

| 95 | 75 | 800 |

Storage:

Unlimited in a cool and dry place.

Smallest Deliverable Unit:

disposable pallet.

Package:

PE bag

Flame Furnace Lining (Forge Lining)

Our company offers linings for the forge, linings for the working layer of the walls and the furnace bottom made of refractory concrete, which are excellent for side walls, for the hearth, even if the wear caused by fuel oil is great.

Mechanical strength in a hearth is more important than chemical resistance. Our refractory materials adhere excellently to existing dense bricks, provided the existing lining is dry, clean and free of dust before casting. Even a vacuum cleaner (vacuum machine) was used many times to obtain this.

Replacing the lining of an induction steelmaking furnace

Option 1

We offer a dry ramming mixture in the form of spinel based on fused alumina as a lining.

Areas of use

The lining mixture is neutral and designed for crucible induction furnaces for melting steel and high-alloy non-ferrous metals.

The amount of lining materials required to line one induction furnace is approximately 2500 kg. The durability of the lining is 50-90 melts, subject to the conditions of the melting process.

Characteristics

| Property | Meaning |

| Type | Dry vibration rammed mixture |

| Main raw materials | fused alumina |

| Binder type | ceramics |

| Laying method | vibration |

| Bulk Density | 2800-2950 kg/m3 |

| Temperature class | >1700°C |

| Limitations of use: Continuous operation Short-term operation | 1680°C 1720°C |

Chemical composition:

| Kinds | Weight % |

| Al2O3 | 84.9 |

| MgO | 13.2 |

| SiO2 | 0.5 |

| Fe2O3 | 0.1 |

| CaO | 0.4 |

Grading:

| Size, mm | % |

| -6 +1 | 45 |

| -1 + 0.063 | 29 |

| -0.063 | 24 |

Sintering schedule

The furnace must be filled with charge material, heating occurs at a rate of 200-300°C/h depending on the size of the furnace.

To melt steel, the bath must be heated to 1650-1680°C and kept at this temperature for 30-60 minutes.

Option-2

Magnesia-corundum ramming mass, based on high-quality synthetic magnesia clinkers with the addition of sintered and fused corundum. Bond type: ceramic. The amount of lining required for one induction furnace is approximately 2500 kg. The durability of the lining is 60-90 melts, subject to the conditions of the melting process.

Typical characteristicsTypical indicatorsGuarantor. indicators

| Loss on ignition | 0,18 | … | % |

| Porosity open after firing at 1680°C | 22 | … | % |

| Apparent density after firing at 1680°C | 2,74 | … | g/cm3 |

| Compressive strength after firing at 1680°C | 13 | … | MPa |

| Fire resistance T0.6 after firing at 1680°C | > 1700 | … | °C |

| OTU (OWT) 950°C / water after firing at 1680°C | 10 | … | n |

| Application temperature | 1750 | … | °C |

| Humidity | 0,2 | Max. 0.5 | % |

| Bulk density | 2,2 | … | g/cm3 |

| Granulometry | 0 — 6 | 0 — 6 | mm |

| Fraction content <0.063 mm | 18 | min. 16 | % |

| Fraction content <0.125 mm | 30 | 26 — 32 | % |

| Fraction content <0.5 mm | 46 | 40 — 50 | % |

| Fraction content > 4.0 mm | 10 | min. 8 | % |

CHEMICAL COMPOSITION:

| MgO | 80 | min. 77 | % |

| Al203 | 18 | Max. 20 | % |

| Fe203 | 0,2 | Max. 0.5 | % |

| Si02 | 0,1 | … | % |

Life time

A lined product is a structure with a specific finish that extends the life of the stove and individual parts. A special feature of the barrier is protection from high temperatures and changes. The better the lining was initially carried out, the longer the durability of the structure. A good working life is considered to be 50 years and above. All coatings wear out over time, so it is recommended to check the strength and tightness of the lining 2-3 times a year. If cracks and other damage have formed, the craftsmen reconstruct the lined furnace. Installing a furnace lining is a complex task, so a specialist in this field should design and prepare documentation for it.