Cats don't sleep on cold radiators.

The efficiency of the entire heating system directly depends on the performance of the boiler. Malfunctions of the main heating equipment negatively affect the efficiency of the home heating circuit and lead to excessive energy consumption. That is why any breakdowns, even the most insignificant ones, are given special attention. People’s experiences are understandable if the boiler is working and the radiators are cold. After all, this not only reduces the level of comfort in the house, but also entails expensive repairs. To properly solve a problem, you need to understand its essence. Only a specialist can correctly determine the reasons why the boiler does not heat the batteries. Also read: “Why do radiators heat poorly?“.

Boiler malfunctions

Typical problems with the operation of heating equipment:

- malfunction of the built-in pump;

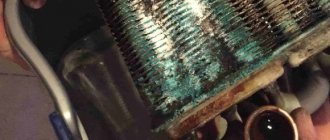

- the heat exchanger is clogged;

- The three-way valve does not work.

If the boiler is working and the radiators are cold, experts recommend, first of all, assessing the technical condition of the main heating element. More specifically, determine whether the circulation pump built into the device is working. This part is an invariable attribute of modern equipment and is designed to increase the efficiency of its operation. Very often, after a long period of inactivity in the summer, the pump can become clogged or become covered with a layer of limescale. As a result, it does not remove the heated coolant from the heat exchanger in a timely manner. The boiler is boiling, but the radiators are cold.

It is strictly prohibited to independently repair such complex equipment as a boiler. In this case, either a specialist from the service center or a repairman with the appropriate certificate or permit is called to your home.

Experts do not recommend using ordinary tap water as a coolant, as it is hard. When the coolant temperature increases, dissolved salts settle on the heat exchanger. As a result, the following problem arises: the boiler is working, but the radiators are barely warm. Scale reduces the thermal conductivity of the heat exchanger, so the water in the circuit does not heat up, although the heating element constantly works with excessive energy consumption. You can fix the problem by changing the coolant and cleaning the heat exchanger. This video will help you understand how to clean the heat exchanger correctly:

A double-circuit boiler heats water, but does not heat the radiators. Here you need to pay attention to the serviceability of the three-way electric valve. It is responsible for switching the bypass from heating circuit maintenance mode to DHW and CO mode.

Before making a heating register with your own hands, familiarize yourself with the technical base.

Why can't antifreeze be used for radiators? The answer is here.

Operating principle of the boiler

To understand the causes of the breakdown, you need to understand how the boiler works. Double-circuit devices “Ariston”, “Baksi” and other models have several blocks. In the gas unit, ignition and combustion take place, the water unit is responsible for the water supply and pressure in the line. The smoke exhaust unit removes combustion products to the street.

As soon as you start the boiler, the pump is activated, which pumps water into the system. The gas valve opens. The liquid circulates through the tubes of the heat exchanger, and the burner evenly heats its body. Sensors control the heating process. As soon as the temperature reaches the set temperature, the gas supply is turned off and heating stops.

When the temperature begins to decrease, the sensors will send a signal to the control module - the heating cycle will start again.

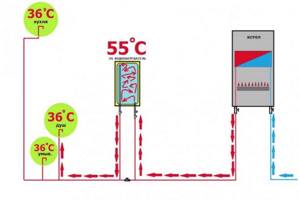

When the mixer is opened, the flow sensor is activated. It signals the board to switch the three-way valve to DHW heating. When the mixer closes, the valve switches to the heating system. Some models are equipped with a “quick start” mode. Then the valve periodically switches, heating both the first and second heat exchangers.

Problems with the heating circuit

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Any of the above problems must be resolved before the start of the heating season. Otherwise, the room may be left without heat for several days, since the repair involves completely draining the coolant.

So, why doesn’t the boiler heat the batteries if everything worked fine over the previous years? The reason is a dirt plug that has formed on the heating circuit filter and completely blocks the coolant flow. It can be solved simply - the water is drained from the pipes or its circulation is blocked using bypasses, and the filter is cleaned. To prevent a recurrence of such a situation, it is necessary to completely replace the coolant with parallel flushing of the entire circuit.

In a gravity system, the slope of the pipes is key.

The second reason why the boiler works but the radiators are cold is the insufficient power of the circulation pump. The performance of the device is not enough to pump the entire volume of coolant in a timely and efficient manner. Or the heating system in the house has branches that are located at a significant distance from the pump. As a result, the circulation pump overheats, the heating equipment operates with excessive energy consumption, and the radiators remain cold. The solution is to change the coolant pumping device to a more powerful one.

If the house has a two-pipe heating circuit with natural circulation of water, and during the heating season it is often noticed that the boiler is on and the radiators are cold, then the reason lies in non-compliance with the slope of the main line. According to regulatory documentation, only a pipe slope of 10 mm per linear meter in a heating system with natural circulation will ensure normal coolant movement. The result is uniform heating of the batteries throughout the house. If there is no slope, the coolant stagnates, which negatively affects the temperature of the radiators. The problem can be solved by completely redoing the wiring.

Is it possible to heat a garage using antifreeze for cars?

Which liquid to clean heating systems should you choose? The selection criteria are described here.

The main problems are why the boiler does not heat water

More often, boiler problems are detected during the heating season, when both circuits of the device are operating. There are two main problems that owners of wall-mounted gas boilers such as Ariston face:

- all boiler systems are working, the device turns on, but heats the water poorly or does not heat at all;

- the boiler does not start and, as a result, no hot water is supplied.

Each of these problems has its own causes and solutions. To troubleshoot problems, you need to figure out what caused them and what caused them.

Before finding out the reasons for the malfunction of the unit, you should look at the operating manual, read the instructions and check that the settings and connections of the device are correct.

Note! Modern gas boilers are equipped with a diagnostic system that detects faults and displays an error code on the display. The instructions for the unit will help you decipher the codes.

If all requirements and conditions are met, the most common causes of malfunctions should be considered:

- Blockage. Experts say that using unfiltered working fluid increases the risk of clogging the heat exchanger pipes. The resulting scale reduces its thermal conductivity, which causes the unit to operate with excessive energy consumption. In this case, the optimal temperature regime is not achieved even with continuous operation of the device. Due to limescale deposited inside the heat exchanger pipes, the metal is subject to corrosive changes, which can lead to its rupture.

- Faulty pump. The circulation of the coolant may be stopped due to the accumulation of air, the so-called air lock in the pump. The second cause of a pump malfunction may be a rotor that is jammed. A circulation pump that stops functioning can lead to overheating of the gas boiler.

- The flow sensor is stuck. Inside the boiler there is a sensor in the form of a turbine, resembling a small fan. When the turbine rotates inside the sensor, an electrical pulse is generated due to the fluid flow, which is supplied to the control unit. This way the electrical system understands that it needs to warm up the coolant.

- The three-way valve is stuck. Such a malfunction will not allow you to switch the water supply from heating to DHW. Valve stoppage can occur due to blockage, either in the part itself or in the gas hose or filter.

- Insufficient pressure. If the volume of liquid in the system does not create the required pressure, the water supply valve does not open, which leads to burner ignition failure.

Why are the radiators cold when the boiler is running?

Low efficiency of the heating system can be the result of malfunctions of both the circuit itself and the main heating element. In the case of a heating device, it is necessary to pay attention to the three-way valve, the functionality of the pump and the technical condition of the heat exchanger. Typical problems for heating wiring are a clogged filter, insufficient power of the circulation pump and lack of slope of the pipes of the circuit with natural water circulation.

During the operation of a double-circuit gas boiler, each user will encounter certain problems associated with the operation of the hot water supply circuit. These problems are inevitable. They always appear, regardless of the manufacturer of the boiler and its heat exchanger, or the design features of the boiler; it does not matter whether the boiler is wall-mounted or floor-standing. Often the boiler begins to heat hot water poorly or not heat it at all. Especially when you use several points at the same time. In this article we will talk about how to get rid of this problem forever.

Troubleshooting: why does a gas boiler not heat hot water well?

If a gas boiler does not heat hot water well due to a clogged or ruptured tube in the heat exchanger, repairs are necessary. It is performed by replacing a failed unit. In this case, threaded connections are not used, so disassembling and subsequent installation yourself will be difficult. To create a high-quality connection by soldering, it is better to invite an experienced craftsman. A qualified specialist will ensure the required level of quality and provide written guarantees.

Finding out about the problem in advance is not easy. The scale layer grows slowly, so it will not be possible to register a clear decrease in power. Extraneous noise can be caused by the passage of sand and other mechanical impurities through the pipes. Technological openings are too small for visual inspection. To complete this, dismantling is required.

The information provided explains why emergencies of this type occur unexpectedly. To prevent them from developing into a more complex problem, you can equip your boiler equipment with a modern remote monitoring system. Some manufacturers offer ready-made solutions in the form of an additional electronic unit and specialized software.

The corresponding application is downloaded to the smartphone. The advantage is the ability to remotely change settings and check temperature sensor readings. If the Navien gas boiler does not heat hot water due to scale, replacing the heat exchanger is not enough. These same contaminants reduce the internal diameter of pipes and narrow the ducts in radiators. A complete cleaning of the system is necessary.

This procedure is performed according to the following method:

- Pour the water into the drain.

- Rinse all circuits sequentially or simultaneously with a special solution.

- It is also used to clean the heat exchanger if it is only clogged and can be used further.

- After assembly, the functionality of the system is checked under pressure.

- Eliminate identified defects (cracks, loose connections).

To remove calcium solutions, magnetic water converters mws or aggressive chemical compounds are used. The duration of the standard procedure for one household object is several hours. Appropriate corrections are made taking into account the actual state of the system. Strong acids can damage metal parts and solder joints of an Ariston double-circuit boiler. For this reason, experienced teams take repair tools to complete orders.

It is possible to carry out such procedures independently. But for many ordinary users it is not advisable for several reasons:

- You have to purchase expensive equipment for pumping liquids that will be used.

- Independent selection of the optimal composition of the solution will cause difficulties.

- During this procedure, there are no mechanisms for operational control of processes within the pipeline system. This increases the likelihood of breakdowns.

- When performing transactions in person, you will not receive official guarantees from a third party. Any problems that arise in the future will have to be resolved at your own expense.

Additionally, it should be noted that careless handling of aggressive chemical compounds can cause harm to health.

Preventive actions

Specialists from companies offering flushing recommend doing this every heating season. It is combined with a general inspection of the equipment. The frequency is adjusted taking into account the level of rigidity, the intensity of operation of Baxi gas double-circuit boilers, and other significant factors.

Tips like this are really helpful. Regular cleaning will prevent more complex procedures. Simultaneous testing will help identify problems at an early stage. However, it is necessary to emphasize the main disadvantage of this technology - it itself can damage the equipment. It is especially unpleasant if defects appear during the heating season. It will be quite difficult to prove the guilt of the workers who did the cleaning.

Instead of using potentially dangerous techniques, effective protective measures are used. They are based on modern water treatment technologies.

To prevent scale from forming in a Navien or Ariston heating boiler, install a water filter to prevent scale from forming in front of it. They dissolve when a stream of water passes, creating dense shells around microscopic scale particles (in the first stages of growth). After such a “modification”, harmful impurities are not able to attach to the walls and to each other. They pass freely along the circuit and are removed into the sewer system.

The second method is to replace harmful compounds with sodium ions. This procedure is carried out using special resins. They are poured into two large containers, which work alternately. As contaminants accumulate, washing is performed using an inexpensive regeneration solution made from table salt. Such equipment is used for general protection of apartments, cottages, and other real estate objects.

The next reason why a gas boiler does not heat hot water and its solution is a protective technology that appeared recently, although it has been known for more than a hundred years. The fact is that previously only permanent magnets were used for descaling treatment. They lose their beneficial properties over time. Moreover, a “habituation” effect was experimentally discovered when calcium and sodium compounds stop responding to the corresponding influences.

Nowadays the technique has been improved! Today, electromagnetic converters with high-frequency oscillation generators are used. With minimal energy consumption (5-20 W per hour), they operate at a distance of up to 2 km along the length of the pipeline from the installation site of the Baxi or Proterm heating boiler. This technique maintains its initial efficiency throughout its entire service life.

Ultrasound can grind scale particles and remove old formations. But this technology is rarely used. Like acids, it can destroy the structural components of the water supply system. It should also be noted the likelihood of harmonic vibrations occurring in the audio range.

Membrane technologies provide a high level of purification from various impurities, including hardness salts. But standard household installations process no more than 200 liters. liquids per day. This is not enough for the needs of the Vailant heating boiler and hot water supply.

Features of different boiler cleaning technologies and conclusions

If a gas boiler stops heating water, it has to be repaired. To extend the life of the Buderus or Ferroli heating boiler and prevent accidents, various techniques are used. To choose the appropriate option, you need to pay attention to the following details:

- Flushing with aggressive chemical compounds does not eliminate the problem, but eliminates scale that has already formed.

- Polyphosphates pollute water, so this protection is used only for the heating circuit.

- Sodium compounds are harmless (this is ordinary, well-refined table salt). However, after appropriate treatment, the water will acquire a distinct taste.

- Ion exchange fillers are sensitive to temperature, humidity, and various impurities. You should clarify the requirements that are set out in the official instructions of the manufacturer of the Navien double-circuit boiler.

- To connect electromagnetic converters, you need a current source of appropriate power. To ensure its continuous operation in difficult conditions, autonomous emergency power supply circuits are used.

When determining the reason why the Navien gas boiler does not heat or does not heat hot water well, this is limescale and there are 3 methods of protection that must be taken into account: water hardness, architectural characteristics of the property.

What happens when hot water is turned on at one point of intake

The double-circuit boiler is set to maintain a certain temperature in the hot water supply circuit. When you turn on hot water at one of the points:

- For some time, cold water continues to flow from the tap, which was standing in the pipe before it was opened,

- the boiler heats up, and a certain time is required for it to reach the set temperature,

- after a few seconds, the heated water enters the pipe and begins to move to the intake point,

- a few more seconds are needed for the hot water to reach the point of intake,

- an additional few seconds are necessary due to the fact that the incoming water seems too hot to the consumer, and he adjusts the water supply with the mixer.

Thus, at least a few seconds pass from the moment the hot water tap opens until the water supply starts at a comfortable temperature. The further the water intake point is from the boiler, the longer this period of time.

All this time, the user cannot fully use the water and it will be that the boiler does not heat hot water normally. He waits until water arrives at a comfortable temperature. Meanwhile, water at a temperature that is not comfortable for the user simply goes down the drain.

Unproductive water consumption can range from several liters to tens of liters, depending on how far the water intake point is from the boiler.

DHW does not heat up - causes and troubleshooting.

The most common reason why DHW does not heat up is severe scale formation inside the heat exchanger. Scale not only narrows the water flow in the heat exchanger, it significantly reduces the water temperature.

The reason for this is that the thermal conductivity of scale salts is many times less than the thermal conductivity of the metal from which the heat exchanger is made. The unit does not produce (does not supply) hot water or it flows poorly if a piece of plaque has broken off and blocked the flow of liquid.

Hot water does not flow into the tap when the flow sensor does not work. It is a fan that works when water flows through it. in this case, the signal from it is sent to the control board, which gives a command to heat the water. The sensor may become clogged; it can be cleaned without dismantling it.

The sensor is a cylinder located near the circulation pump. To clean, simply open and close the tap in front of the device. If this procedure does not produce results, you will have to dismantle it, clean it and put it in its original place. If the sensor is not working, you will have to replace it.

If the three-way valve is faulty, the unit will not produce hot water. The purpose of the three-way valve is to shut off the heating system when the hot water tap opens. When the valve does not switch, the boiler continues to heat water for heating.

The cause of a valve malfunction may be a simple blockage, for example, a piece of rust. If the problem is more serious, replace the valve with a new one. In addition, one of the simple reasons why hot water does not flow from the tap may be a clogged gas hose or gas filter.

Sectional view of a three-way valve

With heating this will not be so noticeable, but at the temperature of the water from the tap it will be more noticeable. Clean the hose and filters. Some of the points listed above may also be the causes of problems with heating and hot water in wood, electric and solid fuel (ST) boilers, provided the design details are similar.

What happens when hot water is turned on simultaneously at two points of intake

The scheme becomes more complicated if, while using hot water at one point of intake, it becomes necessary to turn it on at another point, for example: when the shower is turned on in the bathroom, it becomes necessary to wash your hands in the toilet washbasin. In this case:

- the rate of hot water use increases sharply, its consumption increases,

- weak pressure of hot water appears;

- the flow of cold water into the boiler increases,

- a drop in the temperature of the boiler heat exchanger leads to the fact that the water temperature at the first intake point ceases to be comfortable,

- a few seconds are required to turn on the boiler automation for heating,

- a few more seconds for both users at two points of collection to be able to use water at a comfortable temperature.

All this time, both users cannot fully use hot water. It arrives intermittently. The unproductive consumption of water, which goes uselessly into the sewer system, increases sharply.

What if one of the users turned off the water? In this case, the consumption of hot water drops sharply. A temperature jump occurs on the heater of a double-circuit gas boiler. As a result, the temperature of hot water increases sharply at the point of intake that continues to operate. The user cannot fully use the water; it goes down the drain until the automation on the boiler is activated and water at the required temperature begins to flow to the user in a stable manner.

Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed.

The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a fault on the board, the boiler can spontaneously reboot or turn off when it reaches maximum power, which in most cases is required precisely in the hot water preparation mode. It is also possible that boards may be configured incorrectly as errors. But this only applies to those cases where problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Good evening everyone! After 4 months of operating the Baxi double-circuit gas boiler, it stopped heating hot water. Why? What is the reason? I assume that the boiler runs on untreated water and is possibly “overgrown” with scale or rust. What do you advise Lord?

NURLAN_DRAGON 2015.06.21 06:21

User Answers:

None. I don’t communicate closely with them))))) Oh, I remembered - when Dolph Lungren, Van Damme, ... If other problems in connection with the move do not bother you, go calmly! ... Happy holiday, Irina! Beautiful photo. How I love mimosas! I didn’t have to choose, my hand reached out to

The most common cause of boiler breakdowns is scale. Most likely, your boiler heat exchanger is clogged with scale and that’s why it’s not heating. Solution - install special. filters. For example, magnetic or electromagnetic. They are placed in front of boilers and work for many years without requiring maintenance. See manufacturers Kema (Moscow) or Aquashield (Ufa). Good luck!

Yes, most likely your double-circuit boiler is covered with scale. That's why it stopped heating hot water! Why? Hard water! What to do? Install a filter. For example, ion exchange or electromagnetic.

OBAPATEH 2015.06.21 12:26

User Answers:

Chakapuli, chashushuli…. and many more dishes of Georgian cuisine... also fried potatoes with wild mushrooms.... I’m listening to biology now... I can’t even imagine this. It would be boring for me alone, to get involved with all sorts of dubious companies

Vaillant and Baxi boilers are particularly reliable and safe. Breakdowns of such complex equipment must be repaired by a specialist. But, minor faults can be removed yourself if you have a basic level of knowledge about the design of heating and heating gas double-circuit boilers Baxi, Aristan or Naien. Most faults are indicated on the display of the Baxi double-circuit gas boiler. Having deciphered the errors, you can figure out the reason for the boiler’s failure to heat water. Where to start the search if the heating of water in a double-circuit gas boiler Baksi or Vaillant does not work, and the indicator does not show an error or it can be interpreted differently? The gas boiler does not heat hot water. Why? Cause? Double-circuit boiler Baxi (baxi). If the Vailant, Baksi, Aristan or Navien double-circuit gas boiler does not heat hot water, you should check the secondary heat exchanger. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled. What is the reason? Why is this happening?

Water heaters are used as the main or additional source of hot water supply in apartments and country houses. A complex device can fail for various reasons; breakdowns cause a lot of everyday inconvenience and require urgent repair. Let's take a closer look at why cold water does not flow into the water heater, why the pressure may decrease, and why difficulties arise with heating.

Water heater

Ways to solve the problem

The problem can be solved in ways that require significant investment, for example:

- using an indirect heating boiler together with a boiler,

- purchasing a new boiler with a built-in boiler.

However, there is a less expensive, but very productive method - inserting an electric storage heater into the hot water supply circuit. Moreover, for this purpose, any standard heater with a volume of 30 liters is quite suitable, regardless of the manufacturer.

Use a water heater

A water heater embedded in the hot water supply circuit acts as a buffer tank. Its purpose is to equalize the temperature of hot water and smooth out possible temperature surges. The storage water heater and the gas boiler heater are set to the same operating temperature.

Even if the hot water taps are turned on simultaneously at different points of its intake, all users will initially receive water from the storage tank. The time spent waiting for a comfortable water temperature is reduced. Unproductive water consumption is reduced.

Turning the hot water supply on and off at any point of intake causes a temperature difference in the water leaving the gas boiler. However, this water enters the lower part of the water heater, and when it leaves the upper part, the temperature jump is completely smoothed out.

Connecting the water heater through a ball valve allows you to switch to a conventional gas boiler operating system at any time, which can ensure uninterrupted hot water supply in the event of a water heater failure.

Using a bypass jumper with a tap in close proximity to the boiler allows you to exclude the boiler from the hot water supply system. If the boiler is under maintenance, using the existing water heater will ensure uninterrupted operation of the hot water supply system.

Use an expansion tank

In winter, when the boiler's heating circuit is activated, any activation of hot water results in the heating circuit being turned off so that the hot water supply circuit can turn on. In the summer, when the boiler's heating circuit is not activated, each turn on of the hot water leads to the gas boiler turning on.

Often the user opens the hot water tap to simply rinse his hands. The boiler turns on or switches, hot water flows through the pipes. But the user may simply not wait for it, washing his hands with cold water.

Meanwhile, frequent and useless turning on and switching of the boiler “eats up” its operating life. A possible solution is to install a small expansion tank. It is installed in front of the water heater. If there is such a tank, for the first time after turning on the tap, hot water enters the pipe exclusively from the water heater due to the increase in pressure in the tank. Thus, in case of short-term use of hot water, there is no need to turn on and switch the boiler.

It is recommended to use a tank designed for hot water supply. Using a tank intended for heating will cause an odor because its membrane is made of rubber.

Why there is no hot water coming from the boiler - a description of the reasons

The most common reasons why hot water does not come from the boiler:

- The coarse filter at the boiler inlet is clogged. If you have old pipes or the water is too dirty, the strainer will become clogged over time. You need to disassemble it and clean it or replace it with a new one. To do this, remove the plug from the flask using a key and remove the mesh. Installing an additional filter also solves the problem.

- The check valve is stuck. This can happen due to debris getting into it. You need to disassemble it and move the stem. Since it is connected directly without shut-off devices, all liquid is drained before this.

- Cold water does not flow from the tap. Even if the device is completely filled with liquid, if there is no pressure in the water supply, warm water will not flow out, since it is taken from above the tank and moves due to pressure. To check, open the cold tap and, if necessary, call the utility services.

- The pressure reducer is broken or incorrectly adjusted. The storage water heater produces the same pressure as it receives at the inlet. If there is pressure in the tap, but warm water flows poorly, check the pressure reducer and, if necessary, adjust it or replace it with a new one. Household pressure reducer

- A lot of scale has accumulated in the tank. If the water heater is equipped with an open heating element, for example Termex ER 80 H, then it must be cleaned regularly. If this is not done at least once a year, then salt deposits can block the hole through which cold water flows. You need to remove the protective cover, disconnect the wires, and pull out the heating element. Clean it by soaking it in a solution with citric acid and rinse the tank from the inside. To make scale easier to clean, magnesium anodes are installed inside.

- One of the input or output valves from the device is broken and does not open.

- The pipes are clogged. Poor quality water can clog water pipes. This happens especially often in places where they are folded. It is recommended to replace all old pipes with polypropylene ones.

- The mesh on the faucet spout may become dirty. In this case, the pressure will be weak for both cold and hot water. It is removed and cleaned or replaced with a new one.

Before carrying out repair work yourself, you should turn off the water supply valve to the room and disconnect the device from the network. If you cannot eliminate the cause of the breakdown yourself, contact a specialist.

Use a recirculation pump

The best option is that the water heater is located in close proximity to the hot water intake points. The closer it is, the faster the hot water enters the tap, the more efficiently it is used. If this option for installing a water heater is not possible, then it is recommended to install a recirculation pump.

The pump is installed in the section between the water heater and the hot water intake points, ensuring the slow movement of hot water through the pipes. In addition, if you install a heated towel rail in this section, it will perform its direct function at any time of the year, regardless of the operation of the heating circuit of the boiler.

Vaillant boiler does not heat hot water due to blockages

This is one of the most common problems. Most often, the reason is poor water quality - scale appears, units, filters and pipes become clogged.

If the flame does not light up in the boiler, start checking with the flow sensor. Finding this cylindrical device is quite simple. The flow sensor is located near the pump; the wires go to it. There are two sensors installed near the pump:

- Pressure sensor in the heating system.

- Flow sensor.

The flow sensor looks like a small fan; it begins to rotate as water moves through the pipes. If the flow sensor detects the movement of water, the automation receives a signal to turn on the gas and heat the water. If the flow sensor is clogged, water will flow but the fan will not move. Accordingly, the signal to turn on the heating is not received. There are two ways to solve the problem:

- Don’t rush to disassemble the boiler and try to “blow out” the system first. Turn off the main water supply valve to the house. Open the hot water tap and drain the system. Now the percentage of air in the pipes has increased. Start sharply opening and closing the water tap immediately in front of the boiler. These simple manipulations will help create pressure and clear the flow sensor fan of debris.

- If “blowing” does not solve the problem, you need to open the boiler, unscrew the flow sensor and clean it manually.

If the Vaillant boiler does not heat hot water

, the secondary heat exchanger should be checked. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled.

A clogged three-way valve can also cause the boiler to fail to heat water. And you can remove this unit yourself, clean it and install it back.

Having purchased a Vailant boiler, be sure to check with the seller

information about the places where filters are installed. You can clean and change these components yourself.

Faulty pump

Heating of water in a Vailant boiler largely depends on the operation of the pump. To repair or replace this unit, you must call a specialist. But, you can check for yourself whether this is the reason for the boiler’s failure to work.

Set the water temperature on the boiler to 0 °C and turn on the water heating mode. During this time, monitor the operation of the pump. If after 20 minutes of operation it does not heat up, then the problem is with the pump.

The reason for the boiler’s failure to heat water may also be due to a simple loosening of the bolts at the connection areas. Carefully examine the boiler diagram and check that all connections fit tightly. Perhaps simply tightening the bolts will solve your problem.

When problems arise with preparing hot water in a double-circuit boiler, you must first determine how the boiler operates in DHW mode. There are two options: bithermic heat exchanger and secondary heat exchanger.

In the first case, the heating circuit and the hot water circuit are combined in one heat exchanger - the primary one. When it is necessary to prepare water, the heating circulation pump stops working and all the boiler power is transferred to the flowing tap water.

In another case, the boiler is equipped with an additional (second) plate heat exchanger and a switch (three-way valve). When it becomes necessary to prepare water, the coolant from the heating circuit is directed to a second heat exchanger, through which the heat is transferred to the flowing tap water. At the same time, the pump continues to work - pumping the coolant in a small circle.

Therefore, hot water problems must be diagnosed differently for different circuits.

Most frequently encountered problems:

Baxi boiler does not heat hot water well

Baxi boiler does not heat water (hot water does not turn on)

Efficiency of the proposed method

At a relatively low cost, installing a water heater, expander and pump allows you to:

- save up to 25 thousand liters of water per year if a family of four lives in an apartment,

- use water at a comfortable temperature even if several water intake points are operating simultaneously,

- reduce gas and electricity consumption,

- extend the service life of a double-circuit boiler.

One of the best in terms of price-quality ratio are Korean gas boilers Navien. These units have a lot of advantages, are quite reliable and inexpensive. However, during the operation of Navien gas boilers, malfunctions also occur. Let's look at what they are connected with and how to eliminate them without resorting to the help of specialists.

Design features of the gas boiler Baxi (baxi), Navien, Ariston

In any case, it will be useful to become familiar with the equipment of this class and the features of modern models. This knowledge will help you choose the right equipment and avoid making mistakes during operation.

In household boilers Baxi (baxi), Navien and Ariston, gas, diesel and solid fuel are burned to heat water, and electric heating elements are used. To more fully utilize the potential of energy resources, heat exchangers are being improved. They make long ducts of complex shapes to ensure that the liquid remains in the working area for a long time.

The current trend is compactness. Manufacturers offer gas boilers with square bodies of relatively small thickness. Some models, due to their aesthetic characteristics, deserve to be placed in a prominent place.

The next feature is the introduction of automated control systems. They control the combustion process, change operating modes taking into account the readings of temperature sensors on the street and in individual rooms. If the equipment overheats, it turns off without user intervention.

It is necessary to carefully consider situations when the Baxi gas boiler does not heat the water. This happens, for example, when the supply of energy resources is cut off. It is not difficult to carry out an appropriate check even without special professional training.

Circulation pumps, valves, and other typical components and assemblies rarely fail. Their designs are designed for many years of operation without mandatory maintenance. Electronic circuits have no moving parts at all. Their breakdowns occur due to defects. Subject to the rules established by the manufacturer, the service life of modern gas heating boilers is more than 10 years.

Voltage surges in the power supply network can damage the electrical part of the equipment. To eliminate such influences, an external stabilizer is installed. It will be useful to check the grounding system. This completes the set of preventive measures for this group of problems.

It is much more difficult to provide protection against the most common cause of breakdowns of gas boilers - scale.

It is this that will be studied in detail in this article. When heated, calcium and magnesium salts are converted to a solid state. It is these impurities that clog narrow technological openings in heat exchangers. They also form a porous structure on the surface of electric heating elements. If normal heat dissipation is significantly disrupted, their housings are damaged.

Filters (scale converters) such as AquaShield or MWS do not use chemical reagents or replaceable cartridges in their operation. Once you install such a device in front of the boiler, you will forget about the problem of scale for many years!

What kind of breakdowns can occur in a Navien gas boiler?

Most often, consumers choose a Navien double-circuit gas boiler; its faults are displayed on the display. Many users on the forums are interested in what error codes mean and how to fix problems.

As practice shows, the occurrence of malfunctions is mainly associated with improper installation and operation of units, as well as with voltage surges and the use of low-quality coolant.

Navien floor-standing gas boilers - pros, cons and model range

Floor-standing single-circuit gas heating boilers - what is important to pay attention to

The manufacturer has provided the following fault codes for Navien gas boilers:

- 01E – system overheating;

- 02E – lack of coolant or the flow sensor circuit is broken;

- 03E – no flame signal;

- 04E – short circuit of the flame sensor circuit or false message about the presence of fire;

- 05E – temperature sensor circuit connection failure;

- 06E – temperature sensor circuit short circuit;

- 07E – connection failure of the DHW temperature sensor;

- 08E – short circuit of the DHW sensor;

- 09E – malfunction of the coaxial chimney fan;

- 10E – failures in the combustion product removal system;

- 13E – short circuit of the heating system flow sensor;

- 27E – malfunction of the APS sensor circuit;

- 15E – malfunction of the control board.

If some error codes appear, only a service center specialist will help solve the problem. However, you can try to fix certain problems yourself without involving a technician.

The principle of operation of a double-circuit heating boiler

Using a gas unit as an example, let’s look at the operating principle of a double-circuit boiler. The design of the unit is a system of blocks, the operation of which is interconnected and controlled by a security system, which includes various sensors. The main blocks are a gas block, where ignition and combustion occurs, a hydraulic block, which regulates the flow and pressure of liquid, and a smoke removal block, which removes gas combustion products.

When the boiler is turned on, the circulation pump is initially started, then gas is supplied using the gas valve. Automatic ignition ignites the gas, and as the gas burns, the heat exchanger heats up, heating the coolant passing through it. In this mode, the unit will work for some time until the parameters that are regulated by sensors change.

Sensors monitor the temperature in the room, in the return flow, gas pressure, system pressure, draft flow, and the presence of flame. Temperature sensors can regulate the temperature at the inlet or outlet of the heating circuit. If there is a sensor on the return, when the set temperature is reached, the thermostat sends a signal to the electronic board, which, after processing it, turns off the gas supply.

In this case, the circulation pump will run for some time to cool the heat exchanger. This is done so that the remaining heat in the heat exchanger does not bring the coolant to a boil. After the water in the system has cooled to the set temperature, the electronic board will start the pump, the gas valve will open the gas and the entire cycle of operation of the double-circuit boiler will be repeated.

When a hot water tap is opened, the flow sensor is activated and the control board switches the three-way valve to heat the secondary heat exchanger. Heating hot water in the system is a priority, i.e. immediately after you open the hot water tap, the entire system will only work to heat this water.

When the tap closes, the reverse process occurs - the board transmits a signal to the three-way valve, it closes the DHW system and the unit again starts working on the heating circuit. Please remember that it will take some time for the unit to produce hot water from your tap.

Some devices are equipped with a “quick start” or “comfort” function. This function allows the boiler to periodically switch the three-way valve and heat the water in the secondary coolant.