Mineral wool is a large class of insulation materials that have different parameters, which makes them easy to work with. Rolled ones are suitable for walls. For the floor, in sheets. The sizes of mineral wool in slabs vary, depending on the density and type. In order to achieve high efficiency, you can use only the material that is suitable in size and density.

Dimensions are affected by density

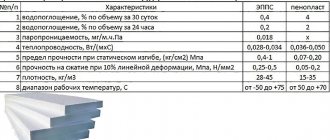

Brief characteristics of the material

Insulation for walls, ceilings and floors under the general name mineral wool is several different types - stone, basalt, glass wool. They all have common positive characteristics, including:

- Naturalness. Regardless of the type, such insulation is made from environmentally friendly materials.

- Low thermal conductivity coefficient.

- Possibility of operation in different temperature ranges.

- Fire safety - the insulation does not burn, but smolders.

- Soundproofing properties.

Important! Modifications of stone wool sizes include rolls, slabs, and cylinders. They differ in density, footage and rigidity.

Buyers' opinion

Here are some reviews from people who used mineral wool in the construction of their houses

I needed to insulate my country house. I spent a long time choosing between mineral wool and polystyrene foam. Friends helped - having given many arguments in favor of the first one, I decided to insulate the facade with basalt wool for further plastering. Among the advantages, I would like to note the high vapor permeability and non-flammability. The house is practically not heated in winter, so it is important that the walls breathe and fungus does not develop. Well, in the heat, in the summer, I’m a little calmer than my neighbors if dead wood suddenly catches fire. There are also disadvantages. Alkaline plasters are not compatible with this type of insulation. It is also possible to relatively easily damage the slab during installation. Overall I'm happy with my choice!

This product is currently on discount.

Lightweight hydrophobized mineral wool slabs based on basalt rocks. Intended for use as a non-load-bearing thermal insulation layer in partitions, interfloor ceilings, walls of low-rise buildings, including vertical and inclined walls in attics, as well as as the first (inner) layer in curtain wall systems with an air gap with two-layer insulation. The slabs should not be subjected to significant loads.

Composition: rocks of the basalt group, binders and water-repellent components.

Quantity per package: 12 slabs.

Packaging volume: 0.288 m³.

Quantity per pallet: 18 or 24 packages.

Manufacturer: Russia.

Gross weight: 10.66 kg.

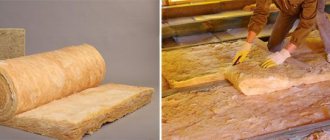

Rolls

Rolls of stone and any mineral wool are among the most popular among consumers. This insulation has a low density, as it can be compressed 3-5 times. But it has low vapor and moisture permeability. In order to further protect it from moisture, a foil coating is applied to it on one side. Another protective coating is metal film; such insulation options are successfully used in bathhouses. The use of such material allows you to save on moisture barriers.

Just don’t focus on the packaging dimensions

Each manufacturer offers its own dimensions, but they are more or less standardized. So its thickness is within 5 cm, it is rare, but you can find options with 10 cm thickness. If this is not enough, then laying is carried out in several layers. The convenience of such insulation lies in its lightness and practicality; one person can easily cope with its installation.

This mineral wool is soft, so it does not withstand loads very well - it shrinks and loses its insulating properties. The dimensions of mineral (stone) wool in rolls may also vary depending on the manufacturer.

Plates

Stone wool slabs are convenient to mount on walls and ceilings. They are often denser, which makes working with it more comfortable – cutting, fixing, plastering. With it, the joints are of better quality. Due to their increased density, the slabs are more resistant to loads and absorb less moisture. The sizes of slabs (sheets, mats) are very diverse, so before buying, you need to carefully measure the dimensions of the area to be insulated. You should also pay attention not only to the dimensions of the slabs, but also to the structural features - some of them have a tongue-and-groove system, which greatly facilitates the installation process. In this design, the heat insulator can be used for insulation:

- Ventilated facades.

- Polov.

- Stan.

- Frame structures.

- As a sound insulator in any room.

Since the slabs are packed in a sealed shrink film, you should not focus only on the volume of the packaging; you should pay attention specifically to the dimensions of the individual mat. The average width/length is 1/2 m. If necessary, sometimes manufacturers accept orders for the production of non-standard sizes, but not all of them.

Mineral wool in rolls

Mineral wool in a roll

Such dense stone wool can be cut and trimmed to the required parameters. Some dimensional characteristics of well-known manufacturers involved in mineral wool:

- Knauf - slab length - 1.25 m, width 60 cm, thickness 5 cm.

- Isover – 1.17 m/56.5 cm/5-10 cm.

- Technique – 1.2m/60cm/10cm.

- Rockwool and Ursa have standard lengths of 1 and 1.25 m, but the width and thickness are different.