Roof insulation - advanced technologies:

- Expanded polystyrene

- Penoplex

- Minvata

- Polyurethane foam

- Penoizol

- Ecowool

- Sawdust

- Expanded clay

How to insulate different types of roofs:

- Mansard roof

- Cold roof

- Attic

- Flat roof

- Garage

Cost of roof insulation

Insulation of the roof of an enterprise

Air heated in a room is known to rise.

If the roof is not insulated, the heat leaves the house and goes outside.

Therefore, roof insulation is one of the most effective heat-saving measures.

Currently, there are many materials and methods of thermal insulation of roofs.

We invite you to further familiarize yourself with the most advanced and effective technologies.

Insulating the roof of a building - basic methods and materials

The concept of “ roof insulation ” means the creation of a thermal insulation layer that prevents heat from escaping outside, that is, keeps it indoors.

For these purposes, materials with low thermal conductivity are used.

As a rule, they have a cellular or fibrous structure and low density.

As a result, most of their volume is occupied by air, which is one of the best heat insulators.

The exception is polyurethane foam, which we will discuss in more detail below.

All options for insulating roofs of buildings can be divided into two types:

- internal - the most common method, which is most often used for thermal insulation of pitched roofs, but can also be used for flat structures;

- external - used exclusively for flat roofs or pitched roofs during their construction or reconstruction.

All insulation materials are divided into three main types:

- polymer - these include regular, liquid and extruded polystyrene foam, as well as polyurethane foam. All these materials have a cellular structure;

- mineral - their most common types are stone wool, glass wool, expanded clay, etc.;

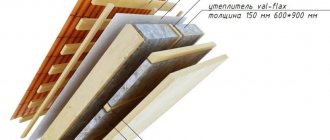

- organic – these include ecowool, sawdust, flax insulation and more.

To make the right choice, consider factors such as:

- thickness and thermal conductivity - selected taking into account climatic conditions in the region;

- service life - modern materials can effectively protect the roof from the cold for decades;

- performance qualities - these include moisture resistance, fire safety, and environmental friendliness.

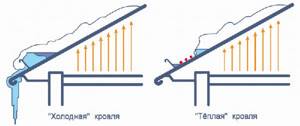

Types of roof according to attic parameters: “cold” and “warm”

Conventionally, roof insulation in the construction world is divided into attic, when the roof slopes are insulated, and attic, when the ceiling is thermally insulated.

Like this? We can say that attics also have their own attic - this is a ventilation gap between the internal insulation and the laid roofing. The fact is that heat, according to all the laws of physics, always rises and seeks its release into the atmosphere. It passes through both the insulation and the vapor barrier, and together with water vapor. And here the external air is pulled in at the eaves plumb, which passes to the ridge and along the way picks up both vapors and excess heat. Through aerators or the same ridge, all this is safely removed and does not cause any problems.

Those. in an ordinary, unused roof, the attic occupies the entire space from the ridge to the attic floor, and in the attic, the attic is just a small space under the slopes between the insulation and the roofing. And in insulating both, the type of roof has its own approach, which we will now study.

Roof insulation with foam plastic (expanded polystyrene)

Polystyrene foam, also known as expanded polystyrene, is a white cellular polymer heat insulator.

It is well known to everyone as a packaging material for fragile products.

Foam insulation is sold in the form of rectangular slabs, which come in various thicknesses.

One of the main differences between this material is its density, which is in the range of 15-50 kg/m3.

In pitched roofs, foam plastic is not subject to any mechanical stress, so it is more advisable to purchase slabs with the lowest density.

Firstly, they are cheaper, and secondly, the lower the density, the lower the thermal conductivity coefficient:

- PSB S15 – 0.037 W/(m K);

- PSB S25 – 0.035 W/(m K);

- PSB S35 – 0.033 W/(m K).

If the roof is flat and the insulation is planned to be done from the outside, you will need a grade no lower than PSB S25-PSB S35.

One of the most important advantages of expanded polystyrene is that even high-density grades have a low thermal conductivity coefficient.

In addition, expanded polystyrene has a number of other advantages:

- light weight;

- affordable price;

- easy to machine;

- not subject to rotting.

However, polystyrene foam also has several serious disadvantages:

- most often burns well - many manufacturers, in order to reduce the cost of their products, save on fire retardants, as a result of which the material ignites from a lit match;

- toxicity – the polystyrene foam itself is safe, but when subjected to strong heating and melting, for example during a fire, it releases toxic substances;

- absorbs moisture - as a result, the thermal insulation properties are reduced, so the insulation needs high-quality vapor barrier.

Roof insulation with extruded polystyrene foam (penoplex)

Popularly, extruded polystyrene foam is often called “Penoplex”.

But this is wrong, since Penoplex is a well-known brand under which this material is produced.

Visually, extruded polystyrene foam is easy to distinguish from regular polystyrene foam.

It is usually painted in bright colors and has a uniform rather than granular structure.

In addition, extruded polystyrene foam has a number of advantages, such as:

- strength and durability;

- thermal conductivity 0.028-0.034 W/(m K);

- does not absorb moisture;

- fire safety - manufacturers add fire retardants to the composition, as a result of which the material does not catch fire or has a self-extinguishing property.

Extruded polystyrene foam

Extruded polystyrene foam also has disadvantages:

- quite high price;

- the material “does not breathe” - this can lead to rotting of the rafters in case of poor-quality vapor barrier or its depressurization;

- toxicity when burning - like polystyrene foam, when heated, it releases toxic substances that can lead to poisoning and death.

Extruded polystyrene foam is excellent for both internal and external roof insulation.

From the outside, it can additionally protect the roof from moisture.

There are special slabs on sale for external insulation that allow for a slight roof slope.

As for internal insulation, as when choosing conventional polystyrene foam, it is advisable to give preference to brands with the lowest density.

Roof insulation with mineral wool

Rock wool, which is made from molten rocks, is currently the most common material for roof insulation.

The material is suitable for these purposes in almost all respects.

Visually it resembles glass wool, but has a higher density.

Most often sold in mat form, but low-density brands can also be found in rolls.

You can touch it with your bare hands with virtually no consequences.

Its fibers are more elastic than glass wool.

Special impregnations make it resistant to moisture - drops of water roll off without penetrating into the mat.

In addition, mineral wool has a number of other advantages:

- environmental friendliness - does not contain harmful substances;

- fire resistance - mats not only do not burn, but are also able to protect a wooden structure from fire;

- high vapor permeability - thanks to this, moisture does not accumulate in the rafters and other wooden parts of the rafter system;

- has an affordable price.

The only disadvantage is that the thermal insulation properties of mineral wool are inferior to polymer materials.

Thermal conductivity is in the range of 0.035 – 0.042 W/(m K).

To compensate for this disadvantage, it is necessary to use a thicker layer of insulation.

In addition, impregnations are not able to fully protect the material from moisture.

Therefore, it is necessary to pay maximum attention to waterproofing.

Tools and equipment for installing an attic roof

Roofing installation cannot be done with bare hands. This will require the use of not only tools, but also special equipment. Depending on the type of roofing material, the appropriate equipment is selected.

When installing rafter system elements, you cannot do without:

- Power saws.

- Electric planer.

- Axe.

- Hammer.

- A set of chisels.

- Screwdriver.

- Electric drills.

When installing bitumen-based roll materials, you will need a gas burner. This device ensures heating of the material to the required temperature, gluing the joints and fixing it on the roof.

A gas burner reliably glues the bitumen base and roofing felt

Using a roofing crane will make the job much easier. This equipment will save energy and time during the construction of an attic roof.

A roofing crane, being a small-sized representative of lifting mechanisms, will greatly facilitate the process of building an attic.

It should be noted that the equipment used in the construction of the attic must comply with the requirements of GOST 12.2.003–74. This standard establishes general safety requirements for the design of production equipment:

- special equipment used for melting bituminous materials must be equipped with thermal sensors and an exhaust pipe;

- equipment intended for drying the base under rolled welded materials must be equipped with a special protective screen;

- the process of refueling the fuel tanks of the equipment used must be mechanized.

To install the roofing pie of an attic roof, the following tools are required:

- Yardstick.

- Hammer.

- Axe.

- Sharp knife.

- Construction stapler with staples.

- Hacksaw.

- Plumb.

- Graphite pencil.

- Cord.

- Metal scissors.

- Wire cutters.

- Drill with drills of different diameters.

- Screwdriver.

- Plane.

- Calculator.

Roof insulation with polyurethane foam

Polyurethane foam is a unique heat insulator that is applied in the form of liquid foam.

By the way, polyurethane foam, known to almost everyone, is polyurethane foam.

True, for insulation it is used in the form of a two-component composition, that is, it is prepared directly during use.

When applied to an insulated surface, the material dries instantly and gains strength.

One of its main features is that it does not absorb moisture at all.

Unlike the materials described above, polyurethane foam does not require the use of a vapor barrier.

Its advantages, of course, are not limited to this.

Additionally, we highlight the following points:

- exceptional thermal conductivity – 0.019 – 0.028 W/(m K);

- provides a continuous thermal insulation layer - thanks to this, cold bridges are eliminated;

- excellent adhesion – sticks to any type of surface;

- high speed of insulation - the roof of a house with an area of 150 square meters can be insulated in a few hours, since fasteners and installation of a vapor barrier are not required;

- fire safety - fire retardants are added to polyurethane foam, which makes it non-flammable.

However, roof insulation with polyurethane foam has a number of disadvantages:

- It is impossible to insulate the roof on your own - this procedure requires sophisticated equipment, as well as extensive work experience and certain knowledge;

- low operator qualifications negatively affect the efficiency and durability of thermal insulation;

- During the polymerization process, polyurethane foam releases toxic substances into the air.

Note that polyurethane foam (PPU) comes in two types:

- closed-cell - the cells of this material are sealed capsules filled with gas, the thermal conductivity of which is even lower than the thermal conductivity of air. Accordingly, this material is the most effective;

- open-cell – has open cells filled with air (spray foam is this type).

Closed cell polyurethane foam has higher performance.

However, it is necessary to take into account that it costs more.

At the same time, gas leaves the cells over time.

As a result, thermal conductivity increases to the level of open-cell polyurethane foam (PPU).

Thermal insulation with foam insulation

Types of roofs and methods of their insulation

It is worth considering the shape of the roof; this affects not only the work itself, but also the choice of certain types of materials. Then it will be easier to understand how the attic space is arranged, gable or other option.

How to insulate a flat roof?

It is better to insulate ventilated roofless roofs using the following materials:

- Mineral wool with a density of 20-35 kg/m2.

- Expanded polystyrene with a density of 12-15 kg/m2.

More solid foundations are needed if a roofless roof is used as an attic. An excellent option is mineral wool with a weight of 120-220 kg/m2 or expanded polystyrene with a minimum weight of 20 kg/m2. 150 mm is the minimum layer thickness, regardless of which type is chosen in a particular case.

The insulation itself is made in two layers to reduce existing risks to a minimum. It does not matter whether the base type is wood or metal.

With the outer layer, it is imperative to take care of the arrangement of each of the stages and components:

- Vapor barrier layer.

- Thermal insulation.

- Waterproofing.

- Roll coating.

- Bulk materials for which a step-by-step algorithm has been developed.

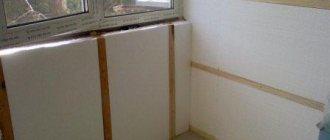

For internal insulation, first, planks are screwed to the ceiling surface every 40 cm. Usually soft rocks are chosen. The first runs along one of the walls, perpendicular to the beams of the supporting structure.

The second is connected to the opposite wall. Next, they begin to glue the slabs of insulation material. The planks and the thermal insulation layer are laid one after the other. At the last stage, do not forget about the plastic film.

Next come the decorative panels, fastened with special nails. It will not be difficult to complete all the work step by step.

How to insulate a pitched roof?

To resolve issues, use one of four available methods:

- Laying insulation between the rafters.

- To the rafters.

- Under the rafters.

- Combined way.

The most popular materials in this case are:

- Polyurethane foam boards.

- Expanded polystyrene analogues.

- Mineral fiber mats.

The main thing is that the base does not shrink and does not sag under the pressure of its own weight. Otherwise, the likelihood of cold bridges appearing increases.

Work begins with the creation of a waterproofing layer. The film is rolled out in a horizontal plane, with an overlap. A special strip marks the places where there is such an overlap. Galvanized nails and a construction stapler are used to fasten materials. Special adhesive tape can be used to provide insulation. Its price is always affordable.

At the next stage, we move on to the insulation materials themselves. The main thing is to ensure that the layer with the “perforation” faces outward. Usually, the manufacturers themselves write on the materials where the outer side is located.

It is necessary to have a film, which protects the structure from condensation. The gluing areas are reinforced with a pressure strip. The insulation and the lower surface of the film should not come into contact with each other. Then the private house will not be damaged.

Cold roof insulation technology

Exterior cladding with thermal insulation materials is a mandatory requirement for all types of fences separating the street and residential premises. It would be more rational to start insulating from the roof side.

There are reasons for this:

- There is no need to redo renovations in an apartment that is almost ready.

- Even after laying thick layers of insulators, the height does not decrease significantly.

- The process is simpler physically. Work outside is done correctly, it is easier to achieve results.

It is necessary to have special bars against which the insulation rests. If necessary, the wood is treated with compounds that provide additional protection. Bituminous waterproofing is cut off between the reinforced belt and the Mauerlat. Be sure to lay out rolls of windproof materials. They are secured before work with insulation begins.

Insulation boards usually have a width of 600 mm. But it is recommended to make the step for the bars smaller, about 90 mm. A small strip of material can be used to seal all cracks. Next, the roll is cut into all the necessary parts.

The insulation is distributed between the joists, not forgetting about the overlap of the layers.

This way the entire area is gradually filled. Be sure to cut and fix the vapor barrier. The joints of the sheets are glued using tape. You cannot do without the use of sealants.

Boards and bars are attached to the vapor barrier layer. The room will then be ready to use the material for arranging the ceilings. You can use penoplex.

Roof insulation with liquid foam insulation

Penoizol, also known as liquid foam, like polyurethane foam, is applied in the form of liquid foam.

It then polymerizes within a short time.

Accordingly, penoizol has the same advantages as the polyurethane foam described above - it is quickly applied and forms a continuous layer of thermal insulation.

Another important advantage is its relatively low cost.

Thermal insulation properties are somewhat inferior to polyurethane foam - in the range of 0.033 - 0.048 W/m K.

Insulation with liquid foam insulation

As for the disadvantages of penoizol, there are several of them:

- absorbs moisture - needs vapor barrier . True, thanks to vapor permeability, it is able to remove accumulated moisture out;

- toxic during application - therefore requires the use of protective equipment;

- has low mechanical strength - like polystyrene foam, it is a fragile material;

- It is impossible to insulate the roof on your own - it requires special, sophisticated equipment.

Thermal insulation of the roof with cellulose insulation

Cellulose insulation, or ecowool, is made from recycled waste paper.

This explains the low cost of this material.

In addition to cellulose, it contains 20% of various additives that prevent combustion, protect the material from biological influences, increase its moisture resistance, and so on.

Please note that there are two types of ecowool:

- dry – is a bulk material, used for insulating horizontal surfaces or frame walls;

- wet-glue – impregnated with glue, which allows you to spray cotton wool on the surface like foam.

It has excellent adhesion, so it can be used to insulate any surface.

Among the advantages of cellulose insulation are:

- environmental friendliness - it’s not for nothing that the material is called “ecowool”, even during the application process it is completely non-toxic;

- the ability to cover surfaces with a continuous layer - as in the case of foam, there are no cold bridges, it is possible to fill any cavities;

- vapor permeability – ecowool removes moisture well;

- does not burn - when exposed to fire, the insulation only smolders and has the property of self-extinguishing;

- practically does not increase the level of thermal conductivity when moisture accumulates.

If mineral insulation, with the accumulation of several percent of moisture, increases thermal conductivity by 10 times, then ecowool can absorb 25% of moisture . At the same time, increase thermal conductivity by no more than 5%.

Roof insulation with ecowool – disadvantages:

- Thermal conductivity is quite low - 0.032-0.042 W/m·K.

- Over time, it decreases in volume - this leads to an increase in thermal conductivity by 20-30 percent. Therefore, it is necessary to use ecowool with an appropriate reserve.

- It takes a long time to dry - when applied using the wet-adhesive method, drying may take several days.

- It is impossible to carry out insulation yourself - special equipment is required to apply wet-adhesive ecowool.

Thermal insulation with sawdust

Thermal insulation with polyurethane foam

The peculiarity of this material is the method of its application. Most often, polyurethane foam is used in liquid form , sprayed or poured with a pre-foamed substance onto the surface. In the first case, foam is formed, which, when hardened, fills all the voids in the space between the rafters, thereby ensuring complete insulation of the roof and the most effective insulation. When pouring, foam is supplied to a pre-localized space through a technological hole. The foam fills the void and crystallizes.

We talked in more detail about roof insulation with polyurethane foam here.

Advantages:

- Easy . Almost the entire volume is air; the solid component accounts for only 2%.

- Waterproof.

- Harmless , does not emit toxic substances.

- It does not mold , insects and rodents do not grow in it.

- Provides reliable sound insulation.

As you can see, this material does not require the cost of waterproofing . The total cost of insulating polyurethane foam is less than half that of other options. In addition, the material does not require preparation; it is applied immediately and fills all the cracks, cracks, etc. Installation time is significantly reduced, the effect is maximum.

The service life of the material is very long, the characteristics do not change over time.

The disadvantages of this method include its price , which is higher than that of foam plastic or mineral wool. But savings on hydro- and vapor protection and on preparatory operations make the final cost of the work much lower than when using other materials.

Roof insulation with sawdust

Sawdust is the cheapest and most environmentally friendly thermal insulation material.

It has fairly low thermal conductivity.

This indicator is at the level of 0.070–0.093 W/mK.

Sawdust is used to insulate horizontal surfaces, for example, floors.

They simply fall asleep between the beams.

If the floor is concrete, you can use logs on which the flooring will subsequently be laid.

You can also use sawdust to insulate the roof slopes from the outside during its installation.

Insulation with sawdust

To do this, it is necessary to secure a vapor barrier from the inside and make a lining from boards or other material.

Please note that only well-dried sawdust is suitable for insulation.

No traces of rot.

Their main disadvantage is flammability and susceptibility to biological influences.

To eliminate this drawback, you can make a mixture consisting of the following components:

- 85% sawdust;

- 10% lime;

- 5% gypsum paste mixture.

Roof insulation with expanded clay

Expanded clay is a bulk material made in the form of granules, so its scope is the same as that of saws.

This material is obtained by firing clay with special additives.

During heat treatment it foams.

Due to its porous structure, it has a thermal conductivity of about 0.16 W/mK.

Among the positive qualities of expanded clay are:

- environmental friendliness - there are no toxic substances in the composition;

- vapor permeability – removes accumulated moisture well;

- low cost - is one of the cheapest bulk thermal insulation materials;

- fire resistance – expanded clay does not burn and is able to protect a wooden structure from fire;

- biostability - the material does not rot and is not affected by fungi.

Thermal insulation of the roof with expanded clay

The main disadvantage of expanded clay is its high or relatively high thermal conductivity.

To achieve the desired result, it must be used in a thick layer.

Insulation of gables can be carried out both from the outside and from the inside.

From the outside they are insulated using the same technology as the facade.

For insulation from the inside, a frame is mounted in the form of racks, between which slabs or mats are laid.

Otherwise, the technology is the same as for insulating slopes.

Features of attic roof insulation

The highest demands are placed on the insulation of the attic roof, since it most often serves as a living space.

Therefore, the main characteristics that a thermal insulation material must have are environmental friendliness and fire safety.

Basalt wool has all these qualities.

Less commonly used for these purposes are materials such as:

- polyurethane foam;

- expanded polystyrene;

- ecowool.

As a rule, the thickness of thermal insulation for a residential attic in central Russia is at least 200 mm.

In regions where winter temperatures often exceed -25 degrees, thicker insulation should be used - 250 mm.

The insulation technology depends on the type of material.

Foam materials or ecowool are sprayed in a continuous layer on all surfaces of the structure.

Board materials and mats are used using the following technology:

- Superdiffuse film is used as roofing waterproofing, allowing moisture to escape to the outside;

- the space between the rafter legs is filled with expanded polystyrene. The gaps in the insulation are filled with adhesive foam;

- A vapor barrier film is attached to the side of the room. The joints are taped with double-sided special tape, which allows you to create an absolutely sealed contour;

- wooden slats are mounted on top of the vapor barrier, to which the sheathing is attached.

Not only the comfort in the room, but also the durability of the rafter system depends on compliance with the technology.

How to do it yourself?

Work on insulating the attic simultaneously affects the thermal insulation qualities of the roof. The attic roof is also the roof of the house, representing the inclined part of the rafters, on which the waterproofing and insulation are installed. All waterproofing runs along the rafters. Thermal insulation is carried out more “economically”, the insulation is laid between the ceiling beams of the attic, the material is hemmed from below.

The work is being carried out in stages.

Insulation of attic floors. The technology for insulating an attic space allows you to start with the floors. The process is similar to installing insulating cladding on wooden floors. In this case, mineral wool mats or polystyrene foam boards are used.

Insulated attic ceiling. For this part of the work, insulating materials such as basalt insulation, polyurethane foam, mineral wool or polystyrene foam are used. Modern roofing insulation is heat-saving layers

It is important here to ensure that during the installation process there are no gaps or cracks between the slabs. You can use a more convenient material - roll insulation

Waterproofing and vapor barrier must be carried out.

Finishing the attic. This stage involves performing a number of works to give the attic a finished look. Typically, plasterboard sheets are used for this purpose. They are mounted on a frame with sheathing. The ceiling and walls of the room are often covered with clapboard. It all depends on personal preference.

Insulation of a cold roof

A cold roof is any pitched roof whose slopes are not insulated.

In this case, the space between the slopes and the ceiling itself serves as thermal insulation.

But, since the temperature in the attic is much lower than in a heated house, heat loss is still at a fairly high level.

To avoid them, you should insulate the cold roof, namely, thermal insulation of the ceiling.

Absolutely any material that we mentioned above is suitable for this.

The technology depends on the type of overlap.

If beams serve as the load-bearing element, thermal insulation is carried out as follows:

- the structure is covered with a layer of vapor barrier, which should form a sealed contour;

- then the space between the beams is filled with any heat insulator;

- A layer of waterproofing film and flooring are laid on top of the insulation and beams.

If the floor is a solid slab, insulation can be done either in the manner described above using logs, or by pouring screed.

The principle is quite simple - polystyrene foam slabs are laid on the ceiling.

A concrete screed is poured on top of them.

As a result, the roof remains cold, but at the same time, virtually no heat leaves the room through the ceiling.

Attic insulation

Combined insulation schemes

It can also be combined. For example, it is permissible to lay insulation both between the rafters and above them. With this method, the main layer stands out sharply; it should be made of glass or mineral wool of medium density. The top layer will need to protect more than retain heat, so it will need to be resistant to compression. The material for the top layer can be wood fiber or basalt slabs

When installing the top slabs, special attention should be paid to the complete overlap of the rafters, which will eliminate the possibility of the appearance of cold bridges. Instead of the top durable insulation, you can use the usual one, but an additional power frame must be attached to it, installed on top of the rafter legs

This frame will take the entire load of the attic from the roof, as well as snow and rain with winds.

Scheme of combined roof insulation

One of the most optimal and common insulation schemes is the use of material between and under the rafters. This option is ideal for country houses or residential buildings with an optimal indoor climate. In this case, it is necessary to completely insulate the rafters with insulation and supplement them with an inner layer. The inner layer should be laid on the rafters. We must not forget about the vapor barrier, because if it is located between the layers, condensation will appear, and to prevent this from happening, the thermal resistance of the inner layer should be no more than 20% of the outer one.

Vapor barrier

A vapor barrier is a necessary layer that serves as a barrier that protects the insulation from vapors reaching it from inside the house. The steam will cause condensation on the insulation, which, in turn, will gradually begin to lose its thermal insulation properties. Films based on polyethylene and polypropylene can be used as vapor barrier materials. When using polyethylene, which is less strong, several layers are applied and reinforced on both sides with strips of the same. Polypropylene is much stronger; it is often a fabric rather than a film. But do not forget that fabric is threads, gaps between which are inevitable. To avoid problems with them, the fabric is also laminated on both sides with a thin film. Finishing the roof with cardboard can also create a vapor barrier.

Attic insulation

Attic insulation involves thermal insulation of slopes, ceilings and gables.

The slopes are insulated from the inside in the same way as an attic roof.

The only thing is that if the procedure is carried out at the stage of roof installation, it can be performed from the outside.

In this case, the insulation technology looks like this:

- on the inside, a vapor barrier and plank sheathing are attached to the rafters;

- on the outside, insulation is placed in the space between the rafters on the filing;

- then the roof is covered with a diffuse film and the roofing material is installed.

The insulation of the floor is carried out according to the scheme described above.

Flat roof insulation

Insulation methods

There are two main ways to insulate a roof:

- Attic (the ceiling is insulated);

- Attic (roof slopes are insulated).

MatildaFORUMHOUSE Consultant

If you want to have a cold attic, insulate the ceiling of the top floor. If you want a room in the attic, insulate its walls and ceiling. If you want sloping walls in a room in the attic, lay insulation between the rafters.

In most cases, roof slopes are insulated using the “between the rafters” method; this is the simplest method, and therefore the most popular. For inter-rafter insulation, thermal insulation materials in rolls or mats are used. The material may not fit tightly to the frame, forming cold bridges, and the effectiveness of this method directly depends on the quality of installation. The tighter the thermal insulation is to the rafters, the better the roof will be insulated.

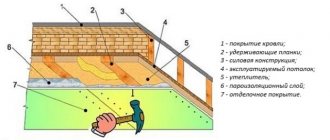

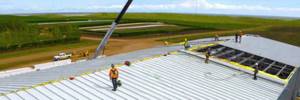

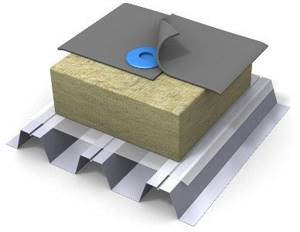

Flat roof insulation

A flat roof is usually insulated from the outside.

For these purposes, polymer slab insulation or mineral mats are used.

The technology looks like this:

- a layer of vapor barrier is laid on a well-dried and cleared of debris flat roof;

- Insulation boards are laid on top. As a rule, they are laid in two layers, overlapping the joints, which eliminates cold bridges;

- A waterproofing film is laid on top of the insulation and a screed is poured, which is also waterproofed.

Instead of a screed, a special roofing membrane can be used, which is laid on top of the insulation.

Her seams are sealed.

A flat roof can also be insulated from the inside.

For example, covering it with polyurethane foam, liquid foam or ecowool.

In order not to involve equipment in the work, thermal insulation can also be made using slab materials.

If, for example, the roof is formed of concrete slabs, the insulation technology looks like this:

- expanded polystyrene or mineral wool is glued to the concrete surface with special glue;

- additionally, the insulation is fixed with disc-shaped dowels;

- A reinforced fiberglass mesh is glued to the insulation and covered with a continuous layer of glue, which acts as rough plaster.

If the roof has a rafter structure, it can be insulated in the same way as a gable or attic roof.

Garage roof insulation

Warm roof insulation technology

The mansard roof is a special design. There is also a cold attic here, only it is very small, because... the insulated attic ceiling is pulled almost flush against it using additional sheathing. In fact, there is only space for ventilation, and nothing more. And ventilation serves to ensure that the heat from the attic does not touch the roofing, on which the snow in winter should remain as a heat insulator and not melt.

Here is a striking example of the most standard situation of improper insulation of an attic: they install the cheapest rafters of 15 cm, put fluffy mineral wool in two layers of 5 cm and cover it all with a roofing covering. Ventilation - only 5 cm, without inflow and outlet, because... There was no specialist nearby to advise. As a result, in the summer there is unbearable heat, from which even air conditioners cannot help, and in the winter there is a generous amount of ice on the roof. And all because in this circuit it is the street air that heats up the most. In other words, that very small attic that we talked about must definitely be there, and far from 5 cm.

And in such a roof you need to think through the vapor barrier especially carefully:

And further. The material used to make rafters is always designed for a certain weight. Thus, a roof under soft tiles can also be built from plasterboard profiles, but it cannot be insulated with heavy basalt wool. Also, the attic roof needs good forced ventilation so that the insulation does not rot or deteriorate. Therefore, carefully read all the points of the master classes we prepared:

Insulation with mineral wool

Follow these simple instructions:

- Step 1. Install hydro and wind protection. If possible, use modern membranes - they are stronger and more durable. In any case, fasten the material with an overlap, and seal all joints with construction tape.

- Step 2. Now measure the distance between adjacent rafters.

- Step 3. Using a regular or stationery knife, easily cut the insulation into the required pieces and insert it between the rafters.

- Step 4. We install additional lathing between the membrane and the inner lining.

For this purpose, we recommend using hard slabs, or even better, basalt slabs.

Please note that you need to attach the vapor barrier membrane with the smooth side to the insulation, and the fleecy side - inside the room.

If the distance between the beams is no more than 60 centimeters, it will be more convenient for you to use square insulation mats:

- Step 1. It is advisable to add rough sheathing inside, under the rafters, so that the insulation has something to rest on. Make the distance between the bars about 20-30 cm. Ordinary uncut wood with medium-sized nails is also quite suitable for this purpose, it is only important that the bars are of the same thickness.

- Step 2. After installing the rough sheathing inside the structure, remove all dust and dirt using a construction vacuum cleaner.

- Step 3. Next, we treat all wood with a special agent against fungus, rot and mold. Just use for this purpose not a spray gun, which is less effective, but a regular paint brush. With its help, you can achieve deep penetration of the product into the wood, and this is important.

- Step 4. Allow the product to completely absorb and dry for two to three days.

As a result, all your sheets should lie tightly - a little tighter than you need at first glance. This is the only way to avoid the presence of cracks and subsequent freezing of the roof.

And one more point: ordinary mineral wool slabs are not particularly suitable for insulating roof slopes, because... They don’t stick well between the rafters, but they can be used to insulate gables.

Glass wool insulation

To insulate roof slopes, purchase the best glass wool from well-known manufacturers. Such glass wool practically does not contain dangerous glass dust, which is what annoys workers the most. Also, even after installation it does not emit harmful substances, which is even confirmed by the Finnish Institute of Health. After all, it’s one thing to throw this “thorn” onto the ceiling of an unused attic, and another thing to cover it with clapboard in a billiard room or private office on the attic floor.

Combined insulation

If desired and appropriate, you can insulate the roof from the inside with two different types of insulation at the same time. But one important point must be taken into account - vapor permeability. The fact is that when selecting different insulation materials for an effective combination, we usually only summarize their heat-insulating properties. But their vapor permeability is completely different!

And, if, for example, you put mineral wool down first when insulating, and foam plastic on top, then the water vapor that gets into the wool will begin to tend to the colder part of the roof and bury itself in the absolutely non-breathable foam plastic. As a result, all the insulation will simply suffocate and “delight” with mold. But on the contrary, it is possible: first we put foam plastic on the bottom of the rafters, and then mineral wool on it. If some steam passes through the vapor barrier and the cracks between the foam boards, it will easily overcome the mineral wool and enter the ventilation duct. Therefore, there is such a rule: the top layer of insulation should always have high vapor permeability and thermal conductivity.

And finally, if the warm roof will be used as a sauna or an additional bathroom, insulation and roofing in it need to be thought out especially carefully.

Garage roof insulation

The process of insulating a garage roof does not differ in any special ways.

It all depends on the type of its design.

If the roof is gable, you can only insulate the ceiling using one of the methods described above.

Thermal insulation of a flat roof can be done both outside and inside according to the standard scheme.

Materials for attic insulation

Let's take a closer look at glass and mineral wool. Glass wool fibers are produced from molten glass, and mineral wool fibers are obtained from molten basalt rocks. Cotton wool fibers are bonded together with a special binder - phenol-formaldehyde resins. According to the structure of the fibers, they are able to retain motionless air inside themselves, which simply retains heat perfectly.

It is worth discussing a number of differences between glass and mineral wool. To install glass wool you will need a respirator and a pair of gloves, but for mineral wool board you do not need to use any self-protection devices. It is worth noting that mineral wool holds up better in the space between the rafters; its main disadvantage is its high cost, but if you want your attic to keep the cold out for more than ten years, then you should pay attention to basalt wool.

Mineral wool is considered the best material for insulation, as it is easy to install, holds better in the space between the rafters and lasts a long time.

The thermal insulation properties of expanded polystyrene (foam) are superior to the two previous types. Its features include zero water absorption, high rigidity and strength. With the help of special additives, polystyrene foam is resistant to fire, but if it does catch fire, it will begin to release substances hazardous to human health. Despite all the advantages, polystyrene foam is not particularly popular. If you still use slabs made of this material, you need to protect it from rodents.

For work we will need:

- insulation - the amount depends on the size of the attic roof;

- several wooden blocks;

- hammer;

- mallet;

- chisel;

- polypropylene film.

Roof insulation - price

The cost of roof insulation depends on the type of material chosen.

Below are the prices current for 2018-2019:

- mineral wool – from 100 rub./m2;

- liquid foam - from 2200 rub./m3;

- ecowool - from 160 rub./m2;

- expanded clay - from 1950 rub./m3;

- polyurethane foam - from 400 rub./m3;

- polystyrene foam - from 150 rub./m2.

Manufacturers of thermal insulation materials

The effectiveness of thermal insulation depends not only on compliance with the technology, but also on the quality of the insulation.

When choosing insulation, it is advisable to give preference to products from well-known brands, such as:

Penoplex

Penoplex

Penoplex is a Russian manufacturer that has been producing extruded polystyrene foam since 1998.

Currently it is one of the largest domestic companies.

The products are of high quality, environmental friendliness and durability.

TechnoNIKOL

TechnoNIKOL

TechnoNIKOL is another Russian company that produces high-quality extruded polystyrene foam, mineral wool, hydro-vapor barrier and other insulation materials.

The brand is known not only in Russia, but also far beyond its borders.

In particular, we have our own production sites in Italy, Great Britain, the Czech Republic and many other countries in Europe and the CIS.

Paroc

Paroc

Paroc is one of the largest mineral wool producers in Europe.

The office is located in Finland, but the products are sold in markets of more than 40 countries.

The history of the company goes back more than 80 years.

During this time, the Paroc brand has become synonymous with high quality.

Isover

Isover

Isover is a famous French brand that produces mineral wool known throughout the world.

The Saint-Gobain company, which owns the Parok brand, was founded 350 years ago. Currently, it has representative offices in more than 60 countries around the world.

The products are famous for their high quality and the most modern technologies used in their production.

Knauf

Knauf

Knauf is a German company founded in 1932 that needs no introduction.

It produces a huge amount of building materials.

In particular, thermal insulation materials are also available on the market - polystyrene foam for insulating walls, floors and other surfaces.

Rockwool

Rockwool

Rockwool is an international company headquartered in Denmark.

The company produces stone wool.

The history of Rockwool began in 1909.

Over the 110 years of its existence, it has opened production sites in 28 countries.

Products are supplied to more than 100 countries around the world.

It is very popular in Russia.