- home

- Services

- Residential insulation

- Roof insulation with foam plastic - the pros and cons of the material

—

—

—

The stage of erecting the walls of the house has come to an end, and then the equally important stage of installing the roof structure begins. And the question immediately arises: “How to install not only a strong and durable roof, but also ensure its maximum thermal insulation?”

Polystyrene foam is often used to reduce the thermal conductivity of both roofs and walls

This question has good reasons - according to statistics, up to 30% of the heat is lost through the roof of the house, so you need to approach the choice of high-quality thermal insulation with all responsibility.

Today, thermal insulation methods such as roof insulation with foam plastic, laying mineral mats and slabs, and high-tech spraying of polyurethane foam coating are used.

Is it possible to insulate an attic from the inside with polystyrene foam?

The decision to insulate the attic from the inside using foam boards is made by many consumers. The main reason for this is considered to be the budget cost of the material and ease of installation.

Often, experts do not recommend using polystyrene foam as insulation inside the premises, focusing on the following nuances:

- Special attic design. Wood is used to construct the roof, which requires good ventilation. In turn, foam plastic has the ability to not allow air masses to pass through, which is why it will be necessary to additionally equip the room with a ventilation system.

- Fragility of thermal insulation functions. Over time, the joints between the slabs can expand, which will lead to a deterioration in thermal insulation parameters. It must be taken into account that the attic is susceptible to intense weather conditions (heating in summer, cooling and accumulation of ice and snow in winter). This affects the condition of the joints between the slabs, which will dry out.

- Questionable fire safety. The insulation burns weakly due to the use of special flame retardants in its composition. However, when exposed to an open fire source, it will burn, simultaneously releasing toxic substances. Considering the fact that lighting is often provided from inside the attic, electrical wiring will be laid near the insulation, which can cause a fire.

Polystyrene foam is considered a good thermal insulation material, which is easy to use and has excellent performance characteristics. However, when deciding on its use for insulation, you need to think carefully and consult with a specialist.

Where to use polystyrene foam?

So why, despite all the negative qualities, is polystyrene foam popular? How to use the best qualities of the material to make your home comfortable and reduce the negative to a minimum?

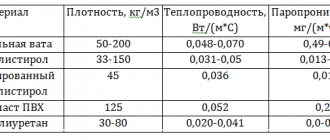

Let's consider foam insulation. A little bit of thermal engineering in the tape: for the insulation system to work, it is necessary that the vapor permeability of the materials increases from the inside out, and the thermal conductivity of the materials, on the contrary, decreases.

That is, the material on the street side should have greater vapor permeability than the internal material and a lower coefficient of heat transfer resistance.

Comparing the heat transfer resistance of building materials and polystyrene foam, we see that this indicator satisfies the requirement, but when comparing vapor permeability, it turns out that in the case of wood, the indicator of polystyrene foam is lower than that of wood, which means that the dew point will be on the wooden structure, which will lead to to condensation settling on it, getting wet and rotting.

When insulating a wooden house with polystyrene foam from the inside, the requirement is also not met, since the heat transfer resistance coefficient of wood is greater than that of insulation.

Polystyrene foam is not suitable for insulating wooden houses, but it will do an excellent job of retaining heat with walls made of brick or light cellular concrete. When choosing an insulation system, it is better to choose a wet (plaster) system if the house is located near crop areas where voles are a common occurrence.

Taking into account everything said above and strictly following the manufacturers’ instructions when performing work, the use of polystyrene foam for insulation is justified and will last longer than the guaranteed 50 years.

Pros and cons of attic insulation with foam plastic

Among the most noticeable advantages of using polystyrene foam as insulation are:

- low level of thermal conductivity;

- lack of water absorption, high level of hydrophobicity (when the material is immersed in water for 24 hours, it will absorb no more than 1% of the liquid from its volume);

- strength - not subject to compression and stretching;

- ease of installation;

- no problems with rotting, resistance to harmful microorganisms;

- resistance to any weather conditions;

- light weight, due to which the material does not create additional load on the rafter system and attic roof;

- the absence of hazardous chemical compounds, which makes it harmless to humans and the environment.

In addition to the advantages, do not forget about the disadvantages:

- a rather rigid structure, which causes the material to become brittle;

- low resistance to mechanical loads;

- lack of protection against the effects of aggressive chemical compounds. When treated with nitro paints or varnishes, the structure of the insulation is destroyed;

- polystyrene foam does not allow air to pass through, which is why you will need to think about installing ventilation;

- needs additional protection, as it does not create obstacles for rodents and birds.

Despite the controversy regarding the use of foam plastic for roof insulation from the inside, this material continues to be in great demand. Low cost and good operational capabilities made it the most budget option for roofing.

Important! When burning, the material can release toxic substances, therefore it is necessary to take into account all fire safety rules during installation.

What to choose?

Often, to enhance the thermal insulation properties, both materials are used, mineral wool and polystyrene foam.

When comparing these two materials, I do not want to highlight any clear advantages of one over the other. I just want to note that mineral wool is more suitable for thermal insulation of pitched roofs - it is the most acceptable material for this type of insulation. But in our market there are not many manufacturers with mineral wool that can be used on flat roofs.

I repeat - use proven basalt-based materials to protect yourself from heat loss, installation errors, subsidence of insulation... and even when using the right insulation, do not forget about the correct roofing cake.

And if we talk about foam plastic slabs, then I consider this material an ideal material for thermal insulation of floors, foundations and blind areas. Where its biggest plus is low water absorption is very necessary.

+7(495) 241-00-59

Installation and repair of roofing and facade coverings from economy to VIP class

Calculate online

my experience is your saved money and nerves.

I advise everyone who contacts me, even if you later leave to join another brigade. Ask questions, don’t be shy, I answer everyone - it’s free

+7(495) 241-00-59 I am available for calls 7/24 - I will be happy to help you, please contact me!

If you have any questions about roof insulation, you can ask me personally in the form below.

What is better to insulate the attic - polystyrene foam or mineral wool?

Polystyrene foam and mineral wool continue to be the most popular insulation materials for interior roof construction. If it is difficult to make a final decision on the use of one material or another, it is necessary to analyze the technical characteristics of both insulation materials according to several parameters:

- Fire safety. According to this criterion, the undisputed leader will be mineral wool, which does not emit dangerous carcinogens when burned. Regarding the ability to burn, the indicator for both insulation materials is the same. Without proximity to the source of fire, they quickly extinguish.

- Thermal resistance indicator. In this parameter, foam plastic is the leader, demonstrating better results in comparison with mineral wool.

- Price. The price of both insulation does not differ much. However, mineral wool is considered a more expensive insulation material.

- Material weight. Polystyrene foam is the lightest of insulation materials, which has become its positive characteristic. However, the mass of mineral wool is also small, which allows it to be used for arranging the roof from the inside.

It is extremely difficult to speak unequivocally about which insulation is better. Therefore, each consumer must make his own choice, focusing on his preferences and budget. You can insulate the attic with polystyrene foam or other insulation, but you must follow the installation rules and technology.

What is foam plastic

Let’s clarify right away: polystyrene foam and expanded polystyrene are made from the same raw materials, but they are different materials. Polystyrene foam is a fragile, flammable material that decomposes in light and cannot withstand mechanical loads and is intended for packaging. For insulation, polystyrene foam is used - a denser material with completely different characteristics, but in common parlance both materials are called the same, which often leads to confusion.

The production process of foamed organic substance styrene is a technical development of the American concern BASF in 1951. The insulation, called “styrofoam,” consisted of 98% air filling a cellular foam base. The material was characterized by low thermal conductivity, low water absorption and vapor permeability.

As a result of improvements in technology, extruded polystyrene foam appeared - self-extinguishing foam. Their main difference is in the structure of the cells: expanded polystyrene has an open structure, while extruded material has a closed structure, which reduces water absorption and increases fire resistance.

The quality and technical characteristics of foam plastics in Russia are declared by GOST 15588-2014 “Heat-insulating polystyrene foam boards. Technical conditions". To insulate walls in a system with an external plaster layer, in accordance with this document, it is necessary to use polystyrene foam marked F - facade.

The letter G in the marking of the plates indicates the content of graphite, which gives lower thermal conductivity and colors the material in the mass in a silver-black color.

This is what people say who have recently insulated their home with polystyrene foam. Indeed, the material has a lot of positive qualities:

- Low weight.

- Low thermal conductivity.

- Excellent noise absorption performance.

- Self-extinguishing property.

- Ease of use.

- Low cost.

Yes, indeed, foam plastic is second only to polyurethane foam in thermal conductivity, the volumetric weight of the slabs is from 10 to 50 kg per 1 m3, while for the best mineral wool materials it starts from 30–35 kg/m3, it perfectly dampens noise and is attenuated in 1 second, and any homeowner can work with it.

How to choose polystyrene foam for insulating an attic roof

Not every polystyrene foam can be used as insulation for an attic space from the inside. Different brands differ in technical capabilities and operational parameters.

When arranging the roof, preference should be given to more durable categories. These include the brands PSB-S15 (density - 11-15 kg/cubic m), PSB-S25 (16-26 kg/cubic m) and PSB-S35 (25-35 kg/cubic m).

Depending on the density, the thermal conductivity of the material is determined. For PSB-S15 it is 0.037 W/mk, PSB-S25 – 0.035 W/mk, PSB-S35 – 0.033 W/mk.

Important! When arranging flat and attic roofs, it is recommended to use the PSB-S35 brand, for attic and pitched roofs - PSB-S15.

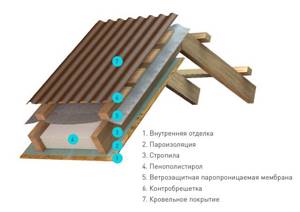

Roofing pie composition

The roof, insulated from the inside according to technology, is a kind of “roofing cake” consisting of several layers:

- Roofing and rafter system. Often the rafters are made of wooden beams, less often of plastic (in new buildings). Tile, slate and other materials are used as roofing.

- Waterproofing. They use special membrane films that have the ability to freely pass steam, but not allow moisture to pass through. The most budget-friendly waterproofing option for an attic roof is roofing felt, which has the necessary properties.

- Insulation. Foam plays this role. Its use can significantly reduce the cost of arranging and insulating the roof.

- Vapor barrier. It is necessary to protect the insulation from the penetration of steam, which forms condensation.

- Decorative finishing. This is the final stage of insulating the attic from the inside. As a finishing material, you can use anything, from drywall and OSB boards to wood or plastic panels.

Disadvantages of polystyrene foam

- This material also has a number of disadvantages:

- It crumbles well. Very often, in private homes, rodents appear in the attics, which can cause many problems for the owners. Materials such as polystyrene, unfortunately, are very attractive to mice.

- An event such as thermal insulation of a roof with foam plastic takes quite a lot of time if insulation occurs after the sheathing process. In this case, each slab must be cut and adjusted to size, which creates additional labor costs both for installation and for cleaning the room after it.

- With prolonged high humidity and lack of sufficient air exchange, a kind of black mold deposit forms on the foam. In order to prevent this, it is necessary to provide a gap of at least 2 centimeters during installation.

- The environmental friendliness of polystyrene foam is also questionable. Some believe that polystyrene foam can release toxic fumes into the environment. But this opinion does not have sufficiently strong grounds, so it is quite controversial.

- Also, roof insulation with foam plastic does not sufficiently comply with fire safety standards. At extremely high temperatures that occur during a fire, polystyrene foam can ignite. In other cases, the material melts.

Polystyrene foam cannot be called an environmentally friendly material

Work such as insulating the roof with foam plastic from the inside is carried out on a special frame or sheathing using self-tapping screws. The slabs are fitted end-to-end as closely as possible, and the seams between them are carefully foamed with polyurethane foam or sealed with sealant. This is done in order to prevent the occurrence of so-called “cold bridges”. Despite the moisture resistance of the material, it is necessary to lay waterproofing between the foam and the roof and leave a gap for air circulation.

Next, a finishing ceiling made of plasterboard or chipboard is mounted on top of the foam. Installation of thermal insulation of a flat roof with foam plastic is carried out by laying sheets of the latter on a flat, clean surface of a bitumen-polymer membrane. The foam is covered with geotextile on top and then covered with gravel about 5 centimeters thick.

“Green roofs” are created using the same principle. A reinforced coating is placed on the insulation layer, on top of which a profile membrane, geotextile and a layer of soil are alternately laid, into which ground cover plants with a superficial root system are planted.

How to insulate an attic with foam plastic with your own hands

Insulation can be quite a challenge: the problem lies in the shape of the roof. If the roof is flat, there will be no problems. It is enough to cut a sheet of suitable size and attach it to the sheathing. If the roof has a complex geometric configuration, you may find it necessary to tinker with cutting out the necessary fragments.

Do-it-yourself insulation of the attic from the inside with polystyrene foam involves a certain procedure:

- Preparatory work. The attic must be cleared of unnecessary things. Additionally, you need to check the wear of the roof truss system. If there is any damage to the rafters, they need to be removed, as this will affect performance.

- Waterproofing. Polystyrene foam as insulation for an attic roof will be effective if it does not come into contact with moisture. That is why a waterproofing film should be stretched over the entire inner surface of the roof, which will prevent contact with water. The film must be reinforced with special fasteners with an overlap of 5-10 cm.

- Installation. Before fixing the insulation from the inside, it is necessary to cut out the blanks. This must be done as carefully as possible so that there are no cracks or gaps between the sheets. Primary fastening from the inside of the attic is carried out with an adhesive composition.

- Additional foam fixation. After the initial fastening is completed, it is necessary to secure the structure with boards or wooden slats to create a system of cells. In places of contact with the rafters, it is recommended to treat the joints with polyurethane foam in order to maximally seal the roof from the inside.

- Formation of a vapor barrier layer. Many people overlook this point, although when insulating the attic from the inside with foam sheets, there must be a vapor barrier. To do this, after installation it is necessary to fix and fix a special film with a vapor barrier effect.

Important! When choosing a vapor barrier, it is necessary to take into account its technical features. The film should be as compatible as possible with the foam.

Methods for installing foam insulation

Installation methods differ depending on the type of roof, that is, the method depends specifically on the type of roof that is being thermally insulated. The methods of insulating a flat and attic roof differ significantly from each other.

Before starting work, it is necessary to perform a quantitative calculation of the required building materials. To clarify the number of required slabs, you need to calculate the roof area. At the same time, keep in mind that you will need a certain amount of foam for cutting. This is necessary so that in case of incorrect cutting you do not have to buy additional polystyrene foam boards. And if the material remains, it can be used in the future for routine repairs of the roofing.

When transporting the slabs, make sure that they are not subject to physical stress or atmospheric influences. And when storing, you need to find a place where the likelihood of damage will be minimal.

Polystyrene foam is one of the most effective materials for insulating not only the roof and the facade of the house. Read about insulating the facade of a house with polystyrene foam and the rules for its implementation in our article.

And also read this article about how windows are insulated using Swedish technology.

Tips and tricks

When installing foam plastic sheets to insulate the attic from the inside, the following recommendations must be taken into account:

- It is necessary to avoid the appearance of gaps between the slabs from inside the room. They will be the reason for the appearance of moisture in the insulation, which will affect its functionality. In addition, in winter the gaps will become “cold bridges”, which will also negatively affect the microclimate in the attic.

- Under no circumstances should you use polyethylene film or materials containing polyethylene as waterproofing from the inside of the attic. Such insulation quickly loses its properties, as a result of which the performance characteristics will sharply deteriorate.

- When insulating an attic from the inside, it is necessary to take into account the installation technology and the rules of thermal insulation.

- Before you begin installation, you need to make a correct calculation of the thickness of the insulating material. An incorrectly chosen width of the slabs can cause a leak in the insulation.