In winter, heating costs make up a significant part of utility bills. And even small investments in thermal insulation can save significant money. If it is impossible to insulate the walls from the outside for one reason or another, then all that remains is to organize thermal insulation from the inside. And it is most convenient to do this simultaneously with covering the walls with plasterboard.

The industry offers various materials for wall insulation. One of the most popular materials for interior decoration is mineral wool. Its advantages:

high thermal insulation characteristics;- low weight;

- moderate cost;

- environmental friendliness;

- durability;

- Fire safety.

Insulating walls with mineral wool from the inside plus plasterboard does not worsen the microclimate of the room, since the material allows air to pass through well. And yet, this insulation has several features that are very important to consider when installing under drywall.

We insulate wood with mineral wool: simply, quickly and inexpensively

- Mineral wool is considered the optimal budget functional insulation. She solves several problems at once. Saves money because it is characterized by a high price-quality ratio.

- Simplifies installation, which is accessible even to non-professionals.

- Acts as additional sound insulation.

- Compliance with the technology of insulating wooden walls from the inside with mineral wool requires the use of personal protective equipment (PPE). This will help avoid negative aspects associated with exposure to carcinogenic substances that are hazardous to health: on the skin, respiratory organs, mucous membranes of the eyes, etc.

Necessary tools

For work you will need:

- level (construction level);

- brush;

- roulette;

- marker;

- knife or saw (for cutting insulation);

- PPE: gloves, cap, respirator.

Installation of mineral wool: a wooden wall is taken as an example

- You need to start insulating with a thorough examination of the walls. Clean them from dirt and dust. Remove electrical wiring. Caulk the gaps between boards and logs using jute fiber and a thin chisel: the tool tightly fills the gaps, and in the case of large gaps, use tape tow formed into a roller. Elimination of cracks will be inevitable, because during operation the house dries out, shrinks, etc.

- Protect wood from damage by insects and organic formations.

- Next, insulating wooden walls from the inside with mineral wool involves creating a vapor barrier layer from film. This is necessary in order to protect the walls from moisture penetrating into the room. The rolled material is laid overlapping with the rough side facing the wall surface. The strips are fixed together with a stapler.

- The sheathing for the insulation is made either from wooden blocks or from a metal profile (if you plan to insulate the walls from the inside with mineral wool plus plasterboard).

- To ensure that the corners do not lose their shape when facing, corner posts are additionally designed that resemble the letter “G”. Two beams of the same length, equal to the height of the room, but with different sections (50×50 mm and 50×100 m) are formed using self-tapping screws into a given structure. To do this, a beam of smaller cross-section is joined to the edge of the second beam and secured. The resulting “G” racks are placed in each corner of the room. To avoid deviations from the vertical, constantly check the level.

- Wooden sheathing requires pre-treatment of its guides and posts with an antiseptic, protection from possible rotting and bug damage. Vertical elements with a cross section of 50x50mm are installed at intervals of 0.5 m.

- The installation of insulation can be either tiled or rolled, with preliminary cutting of pieces of the required length. It is equal to the height of the room with an increase of another 10-15 cm. The pieces or strips are located between the bars, close to the film and each other. Fastened with anchors with large diameter caps. The presence of voids between the wall and the wool leads to the deposition of steam on the enclosing surface and the formation of condensation in this place. The moisture from the wet wall then drips onto the floor and can seep into the room.

- The laid insulating material on top is again covered with a hydro- and vapor barrier film, which is then attached to the beam with a stapler or double-sided tape. The protective membrane prevents pieces of mineral wool from entering the air in the living area. In this case, ordinary rolled cellophane can play the role of protection.

You can do the job differently. Make a frame. One side of it will be sheathed with LGK. The opposite is to pack with sheets of mineral wool. They are all pushed one by one into the cavity under the gratings, without making any gaps. Any leakage in the joint is fraught with the formation of “cold bridges”. If the thickness of the insulation “does not fit” into the gap, it is peeled off, removing the excess thickness. The frame filled with insulation is covered with plasterboard sheets.

Which basalt wool is better to choose?

The effectiveness of wall insulation with basalt depends on the correctly selected insulation and compliance with insulation technology. Among the criteria by which it is necessary to choose insulation: the thickness and density of the mats, as well as the manufacturer.

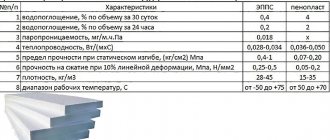

Thickness. The thickness of stone wool for wall insulation depends on the climatic zone in which the house (the apartment is located) is built and on the type of walls: concrete, brick, wood or frame.

For central Russia, an indoor insulating layer of basalt 50 mm thick copes with its function perfectly. For a facade, a thickness of 100 mm is needed, for a frame house - 150-200 mm.

If you wish, you can use an online calculator to more accurately calculate the thickness of the insulation.

Density. The thermal conductivity of the material (the lowest for insulation with a density of 60-80 kg/m3) and the rigidity of the slabs depend on the density indicator. The rigidity indicator is very important when insulating a frame house, where a lot of pressure is applied to the bottom row and when finishing work is carried out directly on the insulation (decorative plaster).

The density of basalt wool for wall insulation should be within:

- 50-75 kg/m3 for frame houses;

- 80-130 kg/m3 for walls with a gap for ventilation;

- 130-160 kg/m3 with the “wet” method of insulation;

- 150-175 kg/m3 for a concrete facade.

It is better to buy basalt fiber wool from reputable manufacturers on the market. At the same time, it is not necessary to strive to purchase mats with the brand “PAROC” or “Rockwool”. They have high quality, but the price is also very high.

Other manufacturers' quality fully complies with European and Russian standards, and the cost is an order of magnitude lower. Therefore, why overpay for a trademark if there are products from TechnoNikol, Isover, URSA, and Beltep (Belarus).

Precautions when working with material

I’ll tell you about precautions when working with mineral wool insulation. Since this material is cheaper than others, it is used very often

Expanded polystyrene is also often used for insulation. Often, mineral insulation for walls is more dangerous.

- Personal protection. First of all, before work, it is necessary to protect the respiratory tract and body as much as possible from the possibility of dust from fibers getting on it. The fibers cause irritation and itching. If dust is inhaled or gets on exposed areas of the body, rinse thoroughly with water. For work you need to use protective overalls, a respirator, a mask, gloves;

- All cutting and grinding work must be carried out in a well-ventilated area;

- Storing and consuming food and various drinks in a room where construction work is being carried out is strictly prohibited;

- Upon completion of work, you must immediately take a shower (preferably cold). Change into clean clothes. If after all the procedures the itching does not disappear completely, do not be upset, this short-term feeling will pass in a few hours.

Insulation of an unheated room

Many novice builders are interested in the issue of installing gypsum board in an unheated room. We warn you right away: most professionals are against such installation. The fact is that even moisture-resistant material cannot withstand strong changes in temperature and humidity. If you decide to install plasterboard structures in such a room, but do not want to install additional thermal insulation, it is enough to attach the sheets to a frame made of metal profiles. The air between the structure and the main wall will provide some thermal insulation.

It is possible to insulate an unheated room, such as a loggia or balcony, only under certain conditions. Firstly, it must be glazed. We are not talking about simple wooden frames, but at least double-glazed windows. They provide reliable protection from moisture and cold. In addition to the walls, you will need to insulate the floor and ceiling, which are covered with high-quality moisture-resistant plasterboard.

GCR can be used in loggias that are connected to a living room with a normal microclimate. Think carefully before you start installing drywall in such rooms, because the structure “eats up” at least 6-7 cm of space. Thermal insulation in the loggia is carried out in the same way as in ordinary rooms, but with some features. First, the wall is covered with waterproofing material.

External insulation with mineral wool

Insulation work with mineral wool is carried out at temperatures from 5 to 25 ° C.

The work is performed according to the following algorithm:

Preparing the walls. It is imperative that the walls become perpendicular to the horizon and, accordingly, parallel to each other. The deviation should not exceed 15 mm per floor. If there are cracks or chips, they must be covered with building mixtures. A wall that is too broken can first be primed and plastered using reinforcing mesh.

- Before sheathing with mineral wool, a metal profile should be secured around the entire perimeter of the house. This is needed to protect against rodents and moisture. In addition, the thermal insulation material will not be deformed. Fixed with dowels at a height of 40–60 cm from the ground.

- The insulation is installed in 2 stages: The adhesive must be suitable for outdoor use. Start installation from the bottom left corner. The mixture is applied to one side of the material: 4 blots in the corners and 1 in the center, or over the entire surface of the sheet. The board is glued to the surface of the house. All elements are applied tightly to one another. If several layers are laid down, the joints must not coincide.

- The material is fixed with dowels. Start work after the glue has completely dried. Usually a day is enough, but the exact hardening time can be seen on the glue package. One slab is fixed with no more than 8 dowels. Fasteners are required in the corners close to the joints and add a few in the center. To install a dowel, use a punch to make a hole 2 cm larger than the length of the dowel. Next the dowel is driven in.

- Mineral wool is reinforced. This step is necessary for finishing the wall for plaster. Hydrophobic adhesive and fiberglass mesh are used. First, glue is applied, then the mesh is applied. The first step is to work on the corners.

- To remove minor differences, rough plastering of the walls is performed. After hardening, several layers of paint are applied.

Common mistakes when insulating the outside walls of a house:

- Temperature mismatch. Many people work in extreme heat or cold weather. This is prohibited; the quality of the material is significantly reduced.

- Poor quality of wall preparation. The first stage is the most important. If the walls are not prepared well enough, after a while many nuances that have not been eliminated will become apparent.

- No starting bar. The element is required; it performs many useful functions. Without it, the insulation will quickly become unusable or move down.

- Incorrect installation of slabs. Be sure to secure them in a checkerboard pattern.

- Incorrect application of glue. The sheet may become deformed if the adhesive is applied incorrectly.

- Incorrect placement of insulation sheets.

If you carry out the work in accordance with the described plan, there should not be any troubles in the future. It is worth taking into account possible errors so that the fastening of the material is reliable and the quality of work is as high as possible.

What is needed for insulation under drywall?

To carry out any work on wall insulation, you always need an additional partition, behind which thermal insulation material will be laid. The most convenient and practical to use is considered to be drywall, which can be divided into standard and moisture-resistant types .

It is also important to consider that mineral wool, despite all its advantages, is a fibrous material and therefore to prevent it from absorbing moisture, you need to worry about high-quality vapor barrier, for which the following materials are suitable:

- often use standard polyethylene film - a practical and at the same time inexpensive material;

- a two-layer film, on one side, which has a smooth surface that does not allow moisture to pass through, and on the other side, a special pile that absorbs water;

- vapor barrier roofing felt;

- membrane vapor barrier, which is much more expensive than previous analogues, but at the same time removes moisture better due to diffuse transmission.

To completely protect your home from the formation of mold, it is better to treat wall surfaces with antiseptic reagents. If the sheathing for plasterboard is wooden, then it is also treated with moisture-repellent preparations. Otherwise, over time the tree may begin to rot.

Pros and cons of using mineral wool for wall insulation

Mineral wool is presented, depending on the source raw material, in three types: glass wool, basalt wool and slag wool.

Each type has its own characteristics, advantages and disadvantages. It is because of them that slag wool is not used for insulating facades: with high hygroscopicity, it quickly becomes damp. At the same time, it not only loses its thermal insulation properties, but also corrodes all materials with which it comes into contact - hydrochloric acid is produced during contact with water.

Glass and basalt wool have both common strengths and weaknesses, as well as individual ones.

General benefits include:

- excellent thermal insulation properties - the thermal conductivity coefficient ranges from 0.035 to 0.052 W/(m K);

- versatility. In addition to the facade, basalt and glass wool is used to insulate the floor, roof, ceiling in the attic, as well as walls from the inside of the room. Mineral wool insulation perfectly copes with its functions in houses made of wood, brick, concrete, aerated concrete, foam block, gas silicate blocks and other materials;

- resistance to high temperatures - glass wool can withstand heating up to 300oC, basalt fiber up to 1000oC;

- perfectly resist mold and mildew - glass and basalt fibers do not provide a basis for the development of microorganisms;

- light weight, which does not create loads on the insulated elements of the building;

- ease of delivery from the retail outlet to the place of insulation;

- simple insulation technology - all thermal insulation work can be done with your own hands;

- environmentally friendly - the material does not cause allergic reactions, during the heating process it practically does not emit harmful substances;

- fire resistance - flammability class NG.

Insulating the outside walls of a house with natural wool also has disadvantages, which include:

- connecting seams through which heat loss begins during operation (mats shrink, losing their shape). However, when using modern technologies for attaching thermal insulation boards to the wall, heat loss can be minimized;

- dust - formed during the installation process requires mandatory protection of the body and respiratory tract.

At the same time, basalt wool has several advantages that fiberglass insulation does not have. This:

- durability - the service life of the material is at least 50 years;

- low hygroscopicity. Experiments show that fibers immersed in water absorb only 0.095% of moisture per day;

- good noise absorption, up to 75 dB, of sound waves traveling through the air. Basalt insulation is powerless against impact and structural noise (spread by house structures);

- resistance against mice and rats - they do not eat cotton wool, do not make passages and nests;

- inertness to chemically active substances used in everyday life;

- high level of elasticity - the mats retain their dimensions throughout their entire service life;

- sufficiently high tensile strength, which makes it possible to insulate the facade using the “wet method” (apply a layer of decorative plaster directly to the insulation).

The disadvantages include the high price.

Glass wool also has individual advantages and weaknesses. The advantages include low cost.

The list of shortcomings is wider:

- high hygroscopicity, which requires insulation to be insulated from moisture. Otherwise, destructive processes begin in the wet fibers, as a result of which the glass wool cakes and settles, forming uninsulated areas;

- short service life - about 10-15 years;

- low resistance to the class of chemicals represented by alkalis - fiberglass is destroyed under their influence;

- attractive to mice and rats - serves as a habitat for them.

Detailed information about mineral wool can be found in the material “Minewool for insulation”.

Main types of mineral wool

There are three such types.

Glass wool

This product is produced by melting broken glass and quartz (sand). When a molten mass is obtained, glass fibers are pulled out of it, the length of which is 15-50 mm, thickness - 5-15 microns.

Considering what this mineral wool consists of, it can be argued that this material:

- chemically absolutely inert;

- cannot become a medium for the development of any forms of biological life (neither microflora, nor rodents, nor insects will grow in glass wool);

- not subject to rotting.

The disadvantage is the causticity and fragility of the elements that make up glass wool. When styling it, you need to work using special protective equipment, otherwise the skin will be completely irritated. Also, glass wool particles should not be allowed to get into the respiratory system or eyes.

So it is not advisable to use glass wool when arranging thermal insulation in residential premises. After all, microparticles will still be released from the laid mats and spread throughout the room. Residents will begin to inhale them along with dust particles and suffer from allergic reactions.

Slag

This mineral wool is also not suitable for thermal insulation of housing. There are many reasons that can be cited, including:

- causticity and fragility of particles;

- high hygroscopicity (ability to accumulate moisture);

- significant shrinkage (as a result, the insulating properties of the insulator layer are lost).

And the designated material cannot be classified as absolutely environmentally friendly. It is produced from blast furnace slag. Their composition is heterogeneous; they can even show increased background radiation. In addition, steam may be highly acidic, and moisture absorption contributes to the formation of an aggressive environment. Metal elements deteriorate first.

Basalt (stone) wool

This insulation is excellent for furnishing residential premises, that is, for internal insulation of houses. This material, when compared with all others, is considered the most elastic and durable. The fibers are less brittle and therefore do not cause irritation to the mucous membranes and skin. At the same time, reducing negative qualities does not in any way reduce the insulating properties. Basalt wool has a thermal conductivity coefficient almost the same as glass wool.

A negative property of stone wool can be considered its ability to absorb moisture. However, its hygroscopicity index remains the lowest when compared with other similar compositions. Complete polymerization of the binder occurs when such a mass is produced. So this mineral wool does not pose a significant danger to human health. You just need to purchase certified products supplied by reputable manufacturers. Laying basalt wool is easy. Such mats (cords):

- hold their shape well;

- easily cut;

- If necessary, they are fixed to the wall with glue.

What you need to know about mineral wool?

Mineral wool for wall insulation can be of three types, it all depends on what source material was used to make the wool.

Based on glass fiber (glass wool)

The raw material for the manufacture of glass wool is glass, but not more than eighty percent. The composition also includes sand, borax, soda and limestone. Fiber thickness is from 5 to 15 microns, length is 15 – 50 mm. Withstands temperature loads from – 60 to +450° C.

Advantages and disadvantages:

Has increased elasticity. The material can be folded in several layers without it deteriorating; Vibration resistance; Excellent moisture resistance. This material is practically waterproof; The purity of the material and the absence of toxic components, hence minimal harm to the human body; Fire resistance. The material is absolutely non-flammable; Not susceptible to mold or mildew

Mineral water does not rot; Absolutely inedible for rodents (rats, mice); Enhanced safety precautions are required when handling the material; Some types contain formaldehyde

Based on slag (slag wool)

The raw material for the production of slag wool is metallurgical slag, which is processed into glassy fibers. It has a fiber thickness from 4 to 12 microns, and a length of 16 mm. Among all types of mineral wool, this type can withstand the lowest temperature - 300° C.

Advantages and disadvantages:

- Has high chemical resistance;

- Simplicity and ease of handling during installation. Cotton wool is produced in rolls;

- Environmentally friendly. The material contains a minimum amount of components harmful to the human body;

- Not resistant to high temperatures. At temperatures above 300° C, the fibers begin to melt and the material loses its performance qualities;

- Hygroscopicity and residual acidity;

- Fiber fragility. The fibers crack and dust from them appears in the air.

Based on stone fiber (stone wool)

The raw material from which this material is produced is rock, namely: gabbro-basalt, metamorphic rocks, marls. The thickness of the fibers almost corresponds to the size of the slag wool fibers.

Stone wool products can withstand very high temperatures, provided the material is not deformed. Wool fibers can withstand temperatures up to 1000° C. Unlike glass and slag wool, stone wool's fibers are not sharp, which makes it easier to handle.

Advantages and disadvantages:

- Has low thermal conductivity. Keeps the house warm;

- Has a very long service life. Shelf life up to forty years;

- The material is not afraid of exposure to mold;

- Has high noise insulation properties;

- Resistant to vibrations;

- Eco-friendly material;

- Has high fire safety;

- Convenient for installation;

- High price;

- There may be heat leakage through the seams. To avoid this, it is necessary to connect the wool slabs together as tightly as possible;

- Does not withstand heavy mechanical loads.

Drywall

Today it is difficult to imagine renovation without the use of drywall.

It is multifunctional and is used for finishing walls, ceilings, creating partitions, and various decorative elements. Some types, due to their water-repellent properties, are used in finishing bathrooms and toilets.

Before using drywall, you need to understand its positive and negative characteristics in order to understand the specifics of handling it.

Advantages of drywall:

- Flexibility and lightness. The use of this material allows you to implement the most daring design solutions. It is easy to make various geometric shapes from it - from banal rectangular to complex semicircles, arches, columns;

- Thermal insulation properties;

- Fire resistance. Drywall doesn't burn. When it is exposed to fire, only the top paper layer suffers.

- Water resistance. Special types of gypsum boards have been developed that are recommended for use in rooms with high humidity.

Disadvantages of drywall:

- The main disadvantage is its fragility. A sheet of drywall can easily be damaged during transportation, installation, and subsequent operation;

- Soundproofing characteristics. Drywall does not have soundproofing properties. Behind a simple gypsum board partition all sounds will be heard.

Drywall

Thermal insulation of brick walls from the inside: although not necessary, it is highly desirable

The brick mansion itself is considered a solid, durable building. But the porous structure of the brick has endowed it with a high thermal conductivity coefficient, especially when wet. Additional insulation of the masonry never hurts.

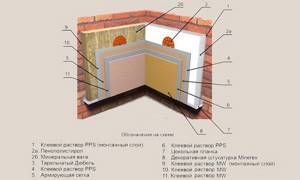

- Insulating a brick wall from the inside with mineral wool will require the manufacture of the same cellular wooden frame or one made from a metal profile. Subsequently, it will be covered with LGK or other decorative coating. Vertical guides are mounted at intervals of 0.6 m: this step is a multiple of the width of the cladding sheet (1.2 m). In this case, 2 cells are closed at once.

- First, waterproofing is laid on top of the sheathing.

- The cell space is sealed with mineral wool slabs. Their total size in the assembled structure should not exceed the height of the sheathing.

- The insulation boards are covered with a vapor barrier film membrane or other material so that the foil side faces the inside of the building. Attached directly to a metal or wooden sheathing structure.

- At the final stage of installation, the front side is masked with finishing.

It is not difficult to carry out internal insulation of walls on your own, but you need to treat it responsibly. Violation of work technology, neglect of calculations and thermal characteristics of materials can lead to freezing of walls. This indicates that more heat passes through the walls of the house than is regulated by building codes. The insulation loses its thermal insulation qualities, it becomes wet, mold forms on the walls, and the microclimate parameters in the house deteriorate.

https://www.youtube.com/watch?v=I7x8yKzAUVg

Features of thermal insulation of internal walls with mineral wool

This material consists of tiny fibers of minerals, such as basalt. In order for the fibers to bind together, phenol-formaldehyde-based resins are used, just as in the manufacture of particle boards. Despite the fact that mineral wool can accumulate water, it is an excellent heat insulator.

It is endowed with such properties thanks to the air that is hidden between the various intertwined fibers. However, if all the air accumulated inside is displaced by water, then a significant part of the thermal insulation qualities of the wall will be lost. For this reason, mineral wool is afraid of even the slightest moisture.

In all places where this heat insulator is used, it is necessary to ensure high-quality ventilation of the room. A ventilation gap must be made behind the insulation layer, and it is advisable to wrap the wool itself with a vapor-permeable membrane. It will minimize the movement of water condensate and particles of the material itself, which is unsafe for the respiratory tract.

In cases where it is necessary to insulate the walls from the inside with mineral wool, additional vapor barrier may not even be used. The wall itself will serve as an obstacle to the entry of steam into the heat insulator, while on the reverse side we have provided air circulation through vertically located channels. Mineral wool is used to protect any structure of a building.

You should also pay attention to the microscopic size of the fibers in the case of insulating internal walls with mineral wool. When they are heated, they release resins that are carcinogenic.

Of course, no one prohibits the use of material for insulation work, but it must be reliably protected from living quarters. It is optimal if toxic fumes are vented outside and not inside the room. It is unacceptable for microfibers to spread throughout the room itself. It is necessary to work with such material using additional protective equipment.

Note! One of the varieties of mineral wool is a material coated with foil on one side. Despite the fact that it is recommended for insulating ceilings, it is also successfully used for thermal insulation of walls.

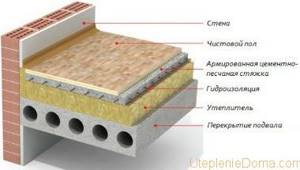

The need for floor insulation

Mineral wool will effectively insulate floors

A little heat escapes from the room through the floors, compared to windows and entrance doors. However, if heat loss occurs through the floor in a living space, then it is impossible to call such a home comfortable.

Cold floors bring much more discomfort than cold walls or ceilings. The fact is that a significant part of the time that a person spends in a room, he is in direct contact with the floors, so the cold coming from the floors is felt much stronger than the cold coming from other structural elements of the room.

This is especially true for rooms located above unheated rooms - basements, cold basement floors, etc.

Insulation of attic floors is necessary for the same reason: the thermal insulation layer in this case does not allow heat to escape through the ceiling of the room below.

Where is the enemy hiding and who is he?

Water, without which life on Earth is impossible, and which is the optimal coolant in the heating system, in this case poses a danger to the insulation and walls.

It is capable of penetrating into the thinnest cracks, and at sub-zero temperatures, freezing, it expands, gradually destroying even monolithic concrete structures. Insulation, when water gets into it, simply loses its thermal insulation qualities. And in conditions of high humidity, all sorts of microorganisms, mold and fungi multiply and grow very well.

The appearance of water in the heat-insulating layer and changes in its humidity occur during periods of the year when the temperature outside the walls (outside) is lower than the temperature in the room. Everyone knows that if you bring a cold object into a warm room, condensation will appear on it - “fog up”, as they say. The same happens at the point of contact between warm and cold surfaces in the heat-insulating layer, where water vapor contained in the air reaches critical saturation (school again, physics again) and falls out in the form of condensation on the cold surface.

The temperature at which this phenomenon occurs is called the “dew point” in physics and construction. This value has a direct relationship with the relative humidity of the air in the room - the higher the humidity, the higher the dew point. For example, with a relative humidity of up to 55% and an air temperature in the room of 21-22 °C, the “dew point” value is +10.5-10.7 °C.

In the heat-insulating layer, the temperature decreases in the direction “from the room to the street”, and in the place where its value is equal to 10.7 °C under given initial conditions, moisture will fall out of the air in the form of condensation. Changes in outside temperature (this means that the indoor temperature is maintained approximately the same year-round) “forces” the dew point to move inside the wall in the direction from the inner wall to the outer wall. And water vapor condenses exactly where it (“dew point”) is located.

An uninsulated building structure warms up due to the heat of the room and radiates it into the outdoor space, that is, we warm up the air at our own expense, and the dew point is in the wall.

In an externally insulated structure, the wall, in contact with the warm air of the room, completely warms up, accumulating heat and shifting the dew point to the zone of the external insulation. Moisture from water vapor located in the wall condenses in it, and this condensate must be “removed” from the heat insulator. This is implemented, for example, in ventilated facades.

Insulating walls from the inside leads to their complete freezing, since warm room air does not have access to them through the heat-insulating barrier.

In this case, the dew point “moves” to the inside of the external walls, and when the temperature rises on the street side, it can shift inside the wall. The result is this: moisture condenses between the wall and the thermal insulation layer, significantly reducing its thermal insulation properties, leading over time to the appearance of damp spots on the walls, fungus and mold. When the wall freezes, this moisture, turning into ice, destroys the adhesive connection of the heat insulator to the wall.

Laying mineral wool on a concrete floor

Method of laying mineral wool under a screed.

Concrete has a porous structure. It absorbs moisture like a sponge, and when wet, it quickly freezes. Therefore, along with insulating the floor with mineral wool in a private house, you need to do high-quality waterproofing. The solution is poured:

- on the ground;

- on concrete floors;

- on a wooden floor.

In all cases, laying mineral wool on the floor is carried out according to the same pattern. Only when pouring concrete on the ground, first you need to create a thin leveling layer of screed. Work method:

- waterproofing is installed (the use of materials with vapor barrier characteristics is allowed);

- mineral wool is placed to insulate the floor;

- the second layer of waterproofing is spread;

- the main screed is poured.

It is completely justified to use mineral wool when insulating a concrete floor along joists. In this case, you can use low-density thermal insulation, and it is also cheaper. After the guide bars are fixed, the work is carried out according to the scheme for insulating the wooden floor. Only in this case will concrete be used as a rough coating.

Installation methods

There are several options for attaching mineral wool to the insulated surface. There are three main ones:

- frame method;

- for direct hangers;

- on mushroom-shaped dowels.

On the frame

To do this, you need to assemble a frame of wooden blocks on the wall, floor or ceiling. Precisely from wood, because wood, in contact with the surface, will not create cold bridges, like a metal profile. Of course, the bars will have to be treated with an antiseptic.

If plasterboard is used for finishing, you will have to take into account the dimensions of this sheet material. Then between the bars it will be necessary to leave a space of 1200 mm (this is the width of the drywall) with the installation of one or two more intermediate elements.

Since the main manufacturers produce mineral wool with a width of 610 mm, the frame for plasterboard will be with the installation of one bar in the middle. And 10 mm will play the role of that very sealing layer that will press the insulation to the frame.

For direct hangers

This option for installing mineral wool is usually used when it is necessary to insulate a ceiling on which a suspended structure made of plasterboard, plastic panels, and so on is mounted. Consider the option with drywall.

To create a suspended structure on the ceiling, it is necessary to install direct suspensions on it, to which profiles will then be mounted. After the suspensions are installed, it is necessary to attach stone wool slabs to them along the entire ceiling. You can also use a roll version, but it is more difficult to work with it under the ceiling.

To do this, you need to make holes in the mineral wool slab through which the ends of the hangers will be squeezed. If a suspended ceiling were installed, then the suspension tendrils would simply need to be bent in different directions, thereby securing the insulation. This cannot be done for a suspended structure under plasterboard, because the frame profiles must be attached to the hangers.

To prevent the mineral wool slabs from falling below the required level, you can stretch a strong thread through the holes in the suspension antennae (and this is a perforated part), or insert a plastic or metal rod (for example, wire) into each element.

On dowels

This is the simplest option for attaching stone wool. Most often it is used to insulate facades. The thing is that often inexperienced craftsmen cannot create the required installation density in this way. Therefore, there may be gaps between the thermal insulation boards that need to be filled with foam.

The installation technology is quite simple. To do this, a heat insulating mat is applied to the wall and two holes are made through it in the insulated surface. Mushroom-shaped dowels made of plastic are then inserted into them. This is how the fastening occurs. In order for the fasteners to be as reliable as possible, these dowels are also installed in the gap between the plates, two on each side.

Insulation of wooden floors along logs

This is the most common method of insulating a wooden floor. It is simple and yet quite effective, eliminating significant heat loss. This method is especially relevant for floors that are located close to the ground (first floors, plinths).

The technology of floor insulation using joists is implemented in this way. The first step is to install wooden logs with a T-shaped cut into the log house or onto the foundation in increments of 0.6-1 m. After this, boards or panels are fixed on which the insulation will be laid. Shields (boards) must be hemmed from below or secured to special cranial bars. Next, insulation is placed on the flooring.

The next stage is the installation of a vapor and waterproofing layer. This layer is only needed when a certain type of insulation is used. For example, protection from moisture and vapor is required when using ecowool or mineral wool. Vapor barrier sheets must be overlapped by 100-150 mm, and its edges in height must be bent up to 100 mm. As a vapor barrier, ordinary polyethylene film and other special materials are used.

The final stage is installing the floorboards on the floor and finishing the floor covering.

Thermal insulation of the floor on the first floors can also be carried out using joists installed on brick columns. That is, the logs are mounted on a brick column on a wooden spacer. Insulation boards (foam plastic, fiberglass, mineral wool, etc.) are installed between them, which are protected by a layer of vapor barrier.

The main advantage of thermal insulation of a wooden floor along joists is the ease of work, which any home craftsman can handle. And at the same time, the effectiveness of this method is quite high. In addition, this method assumes that there is no mechanical load on the insulation, so any heat-insulating material can be used.

The construction of a wooden floor on joists can be viewed in the video below.

https://youtube.com/watch?v=pvlhnnChkUg

Construction of an insulating “pie” from the inside

In construction terminology, the unity of various structural elements is called a pie. If we apply this term to walls that are insulated from inside the building, the list of layers will look like this:

- load-bearing external wall;

- waterproofing layer;

- insulation layer made of mineral wool;

- vapor barrier layer;;

- frame for fastening drywall;

- drywall directly;

- finishing material.

Insulating the walls of a frame house from the outside

In order for the insulation of the house outside to be effective, the layer of mineral wool must be at least 15 centimeters.

To calculate the amount of material that will be needed for work, you need to know the height of the external walls of the building and its perimeter.

To obtain the number of cubic meters of mineral material that will be needed for work, you need to multiply the surface area by the thickness of the layer of wool, for example, if the thickness of the slabs is 20 centimeters, then you need to multiply by 0.2.

To understand how to properly insulate a frame house from the outside, you should know the technology for performing the work.

There are two ways to externally insulate a building with mineral wool:

- the first method, hanging installation, assumes that a frame will be built on the outer surface of the walls of the house, between the uprights of which mineral wool will be inserted;

- the second method is called wet - in this case, the insulation boards are attached to the walls using a special adhesive.

To prepare wall surfaces for hanging mineral wool installation, they are thoroughly cleaned of dust and dirt, and metal elements are removed to avoid corrosion.

If the walls are wooden, then they need to be treated with an antiseptic.

After the preparatory work, a layer of vapor barrier is laid on the surface, and suspended structures are attached at an equal distance on top - wooden beams that will serve as a frame for the mineral wool.

Mineral wool is placed in the grooves between the posts, and the slabs at the joints are secured with glue. Waterproofing is attached on top of the laid insulation; the structure can be covered with decorative materials on top.

To insulate a frame house using the wet method, you need to properly prepare the surface of the walls: prime them or plaster them.

When the walls are prepared, a metal frame is mounted along their bottom, which will serve as a support for the mineral wool slabs.

The mineral wool is laid in the likeness of brickwork, lightly lubricating the joints with adhesive.

Video:

After installation is completed, the insulation layer is left to dry for 24 hours, after which the structure is attached using dowels to the wall of the building.

Fasteners with wide heads are driven through mineral wool slabs into the wall so that their heads do not stick out on top of the insulation.

A reinforcing mesh is attached on top of everything, and after a day you can cover the insulating layer with plaster

Important: the plaster layer should not be thicker than the insulation layer

Mineral wool guarantees high-quality insulation of a frame house, subject to all rules for installing the material.

If the installation work is carried out correctly, then the inside of the building will always be warm and comfortable.

Useful tips and nuances of internal insulation

If possible, it is advisable to carry out insulation from the outside, as this is most effective. In addition, this allows you to neutralize the harmful effects of cold on the walls. Naturally, this does not apply to wooden buildings , where it is necessary to lay a thermal insulation layer both inside and outside the room.

Experts recommend that before installation work, a calculation of the thermal characteristics of the building is carried out, thanks to which it is possible to correctly select the thickness and characteristics of the insulation. Even when individual sections of the walls freeze, they provide thermal insulation around the perimeter of the entire room. If the building has high humidity, then foil insulation is used.

When doing all the work with your own hands in a brick or wooden building, it is important to ensure that the markings are applied correctly. The rolled insulation must be opened in advance so that the mineral wool takes on its original dimensions. If glass wool is used as insulation, then all work on its installation is carried out only with the use of protective equipment . You cannot proceed to the main work until the fungus and mold, as well as other damage to the walls, have been eliminated in the room.

Many experts also recommend laying insulation under the metal profile or using polyurethane foam. Mineral wool must be properly leveled so that it acquires its natural position without dents, deflections or waves. In the case of multi-layer laying of thermal insulation, the seams should not be allowed to coincide.

How to properly insulate a frame house with mineral wool with your own hands

Everyone dreams of having their own country house in the Moscow region, but not many people think that a private house is far from an apartment and requires much more attention, especially if they do not build it themselves, but buy it ready-made. Heating a private house in the cold season is a difficult and expensive task, but you can significantly reduce costs by insulating the walls of a frame house yourself.

Mineral wool is an excellent popular modern insulation material

There are a lot of options on how to make your home warmer, but most often various types of mineral wool are used as insulation. Using mineral wool, you can carry out all the work yourself.

Insulation of a frame structure house is different in that the insulation is located in the center of the wall between the frame sheathing. This is how the frame structure is insulated during the construction of a newly built house. If you want to perform additional insulation of an existing building, then the insulation should be placed outside the walls of the house or inside.

Additional insulation of a frame house is carried out in two ways:

- Work on the external wall with subsequent finishing, for example, siding.

- Internal insulation.

External thermal insulation under siding

This is the most effective option, since the technology involves not only installing an insulating layer, but also updating the facade with materials that are not afraid of negative environmental factors and can easily withstand low temperatures. The siding is fixed on guides, which are used as a wooden beam or a metal frame.

Considering that modern mineral wool is produced in standard sizes in rolls or slabs, the guides for fastening the siding are filled in increments equal to the width of the mineral wool strip. Depending on the type of mineral wool and the walls of the structure, it is secured by shooting it with an industrial stapler or using special glue. Only mineral wool slabs are attached to glue, since they have a relatively dense structure and backing.

Note! In addition to the insulation itself, it is recommended to apply a steam and moisture-proof membrane to the walls of the house. It is mounted directly on the wall, and the insulation is already attached to it

The last stage of external insulation is the installation of siding, the individual strips of which, with the help of locks, are assembled into a single surface, which has many advantages:

- Siding is immune to temperature changes.

- Not afraid of moisture.

- It does not require heavy structures for installation, as it is light in weight.

- Does not fade in the sun.

- It lasts a long time. Manufacturer's warranty for at least 15 years.

Internal thermal insulation

Insulation inside a house is much more difficult compared to outside. Not all materials can be used, as it is necessary to comply with fire safety and environmental standards. Mineral wool is a partially natural and environmentally friendly insulation material that is excellent for interior work.

The installation technology does not differ from the external one, however, the frame is sheathed not with siding, but with plasterboard or OSB panels (approximate strand boards). Thermal insulation of buildings from the inside has its disadvantages, the main of which are:

- Reducing room space.

- If steam and waterproofing are not installed correctly, the walls will begin to become damp, which will lead to the appearance of mold.

- The base of the wall warms up worse, since the heat from inside the house does not reach it, and accordingly a freezing effect appears. Sooner or later this will lead to the destruction of the supporting structure.

- It is possible that a dew point may form inside the insulation layer or directly on the wall due to impaired heat exchange.

How to insulate a frame with mineral wool

As mentioned above, a frame building can be insulated with mineral wool both outside and inside when performing additional insulation of an already built house. When building a house anew, the insulation in a frame structure is located in the middle, between the frame sheathing, and is not attached to the outer or inner surface of the wall.

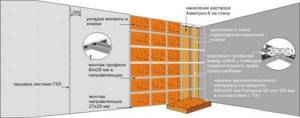

Lathing under mineral wool and drywall - features and installation

Traditionally, you can create a partition sheathing for attaching drywall from two materials:

- wooden slats;

- galvanized profile.

The wooden frame is distinguished by its massive, bulky design. Before installation, wooden slats are treated with an antiseptic to prevent the possibility of rotting.

When installing drywall, it is more advisable to use special galvanized profiles.

They are designed to be attached to each other, in addition, they are provided with mechanisms for attaching to walls - brackets, with which you can adjust the thickness of the partition.

A brief diagram of the installation of lathing for gypsum boards can be presented as follows:

- The thickness of the partition is determined depending on the selected thickness of the insulation;

- a guide profile is attached to the sides of the vertical adjacent walls, along the floor and ceiling;

- the edge from which the plasterboard sheets will be installed is determined;

- Considering the width of the sheets is 120 cm, markings are made every 40 (or 60) centimeters;

- U-shaped brackets are attached along the markings at intervals of 50 cm;

- the supporting posts are inserted into the guide profile in accordance with the markings;

- using a stretched string, level the supporting posts and secure them with brackets;

- Transverse posts are attached to the load-bearing posts to ensure structural rigidity;

Mineral wool lathing

Insulation is laid under the resulting plane.

Thermal insulation of the ceiling of frame houses

One of the key aspects of residential thermal insulation is ceiling insulation. As a rule, this stage is carried out while the roof is not yet assembled, since nothing should interfere with laying mineral wool on top of the ceiling.

The vapor barrier film is attached to the ceiling beams. Then a board, plywood or OSB board, the thickness of which is 2.5 cm, is nailed onto the film. The insulation is fastened to the plywood, according to the same principle as when insulating other structures. Mineral wool must be laid across the entire width of the ceiling, taking into account the overlap of the width of the walls.

If the attic is not used for living, there is no need to install membrane film. For cladding, you can use plywood or a regular board. If it is not possible to insulate the ceiling from above, then internal insulation should be performed by tying insulation boards to the ceiling. Then the ceiling is covered with vapor barrier film and plywood sheets.

Read with this

- Guide to external insulation of house facades

- How to insulate an aerated concrete house from the outside?

- Roll insulation: soft and self-adhesive, plate or rolls, thermal insulation for walls 150 mm, types and properties of thermal insulation materials

- Proper insulation of walls from the inside of a private house with your own hands in several ways

- Do-it-yourself insulation of a sauna from the inside using different materials

- How to insulate walls using expanded clay?

- How and how to insulate a wooden house from the inside

- Do-it-yourself attic floor insulation

- Which is better: basalt or stone wool?

- How to insulate a ceiling in a wooden house: only effective methods

Installation Rules

As mentioned above, hygroscopic mineral wool quickly absorbs moisture. Therefore, when installing from inside the room or outside on the facade, it is necessary to observe measures to protect it. If insulation is carried out from the inside, then waterproofing is applied along the wall, plus a vapor barrier is applied on top of the insulation itself. Membranes are most often used for this.

If facade insulation is being carried out, then it is best to use stone wool under a ventilated facade with the obligatory installation of wind protection. It is better not to install it under plaster mortars. More dense and moisture-resistant materials are suitable for these purposes.

Types of insulation

It is better to insulate the surface under drywall using mineral wool or polystyrene foam. You can also use isolon or penoplex. These insulators differ in installation methods, cost, and strength.

According to research, polystyrene foam, like polystyrene, is harmful to health. It is rarely used in residential premises. Another disadvantage is that some types of foam are eaten by rodents. But it has a low cost and is also available in many densities and sizes.

Example of insulation with plasterboard and mineral wool

Article on the topic - which is better, polystyrene foam or mineral wool?

As for mineral wool, the advantages include low weight (especially important for insulating old buildings), as well as low thermal conductivity. There is only one significant disadvantage of mineral wool - hygroscopicity. Therefore, when thermally insulating partitions and walls, it is necessary to prevent the accumulation of condensation. For this purpose, vapor insulation should be used.

There are several types of mineral wool. They all differ in the production method, composition and technical indicators. Among the types of wool that are on the market, the most popular is fiberglass-based basalt wool. Like other types of insulation, they have both advantages and disadvantages.

The main negative aspects of glass wool:

- The thermal conductivity indicator is greater than that of stone, and therefore heat disappears faster.

- At elevated temperatures it forms a solid glass mass.

- Inconvenient to work with (glass wool fibers can cause itching; requires the use of protective glasses, gloves, a respirator, and wearing a thick suit).

When working with lukewarm fluid, you only need to wear a suit and a respirator.

Despite their external similarity, basalt and glass wool are significantly different. Glass wool is made from very thin glass fibers, and basalt wool is made from volcanic rock. They also differ in the indicator of thermal conductivity, which is lower in basalt, and, therefore, it retains heat better.

Cost of materials for insulation:

- The cheapest way would be to insulate the walls of the house with polystyrene foam, the price of which ranges from 70-90 rubles. for 1 sq. m.

- As for mineral wool, it costs a little more - 90-150 rubles. The price of the material depends on its density, thickness and manufacturer.

- Penoplex, which is extruded foam plastic, but with increased strength and density, costs 1 sq. meter approximately 200 rubles.

Isolon (foamed polyethylene) can also serve as an insulator. Its cost will be 280-300 rubles per 1 square meter.

Required tools and material

Before starting work, you need to prepare tools and materials so as not to be distracted during the process.

So, you will need:

- polystyrene foam (its thickness will depend on the degree of insulation you need);

- adhesive composition (if you work using the frameless method);

- spatula-comb;

- primer emulsion;

- level;

- rule;

- drill;

- a nozzle called a “mixer”;

- dowels for attaching foam plastic (if insulation is done by screwing);

- self-tapping dowels;

- vapor-proof film;

- plaster mesh;

- hanging plates;

- metal profiles to strengthen the frame or insulate the walls if mineral wool is used.