One of the most important elements of gas equipment is gas injectors , whose task is to ensure the timely supply of atomized gas into the combustion chamber. Although there is equipment where regular gasoline injectors are used to inject gas in a liquefied state, it is small and is intended for ultra-modern engines. Much more often now systems are used in which gas injectors are installed in tandem with gasoline ones.

Gas nozzle for heating a private house

A gas nozzle is a godsend for heating a private home. This device has a number of advantages: simple design of the spray device, safety in operation and high efficiency, and therefore its use becomes economically feasible. A gas nozzle for a heating furnace is a device with the help of which a gas-air combustible mixture is created in order to ensure complete combustion of fuel in the combustion chamber. Fuel injectors have a wide range of applications in thermal power engineering. They are installed not only in household stoves, but also in heating boilers of low, medium and high power, operating on gaseous and liquid fuels.

What types of gas ovens are there?

Stove GEFEST 1200С7 K8 on Yandex Market

GEFEST 900 stove on Yandex Market

Stove GEFEST 5100-02 0010 on Yandex Market

Gorenje GI 62 CLB stove on Yandex Market

Electrolux EKG 95010 CW stove on Yandex Market

Gas stoves are used to heat households and country houses, but such devices have gained the greatest popularity in the construction of bathhouses. Most often, for this case, they buy factory-made units that have a metal body. In this case, you need to choose the right model in terms of power and purpose, taking into account the operating conditions. Brick ovens are also being built.

Based on the method of generating heat, furnaces can be divided into two types:

- Having a combustion chamber. The gas enters the heating chamber and, when burned, heats its walls.

- Furnace with heat exchanger. In the designs of these heating units, gas enters a curved, heat-resistant steel tube, which acts as a heat exchanger.

In the second case, the furnaces are additionally equipped with a system of forced air supply and exhaust of combustion products.

Gas furnaces are distinguished by heat capacity. This indicator depends on the ability of the unit to accumulate heat.

According to this parameter, furnaces are divided into the following categories:

- Constant burning stoves. They have thinner walls that cool quickly enough. However, there is a significant plus - they warm up the room just as quickly, releasing heat outside. In order to maintain a constant comfortable temperature in the room, the stove must be in the “on” mode. This is a typical country house option. You can come and immediately warm up.

- Intermittent furnace. This is a massive heat-intensive structure that is capable of giving off heat even after the gas is turned off. In order to retain heat, the channels and combustion chamber are lined with clay bricks. It is very convenient to install such stoves in baths. They will warm up the stones in a short time and begin to give off heat for a long time. For heating households, this option is also more acceptable.

Stove gas burners, which are installed in the stove of a household or a country house, are similar to each other. They have a combustion chamber (heat exchanger), a housing, a smoke exhaust system, channels for heated air and an automatic unit.

However, there is one obligatory part that has its own characteristics in each case - a gas burner for the stove. It is she who is responsible for the efficiency of the heating unit, power characteristics, economical fuel consumption, safe operation and other important parameters.

Single-stage atmospheric gas burners for a home stove are not difficult to use, they are easy to install in a heating unit. They don't need electrical power. This burner is placed on the front side, where the combustion door is located.

If a gas burner is considered from the point of view of the method of controlling thermal power, then all models can be divided into the following categories:

- Single stage. In this case, gas supply (switching off) occurs automatically, based on a rheostat signal.

- Two-stage. The burner has the design ability to switch to an economical mode. This process is regulated automatically.

- Burners with floating adjustment. The burner power can be changed smoothly, from 10 to 100 percent.

Burners are divided according to the method of air supply:

- Atmospheric. In this option, no electricity is needed; air flows to the burner under the natural action of draft. The efficiency is not very high, no more than 90 percent. This is a simple design: a pipe with holes into which fuel is supplied. It works in open combustion chambers. They can be quickly converted, if necessary, to use liquid fuel; the service life of such burners is very long. However, such burners impose increased safety requirements.

- Supercharged. They are also called blower or fan burners. This is a rather complex design. Air is supplied to the burner by a fan; in this case, the combustion chamber is closed. Efficiency exceeds 95 percent. Stoves with such burners do not require bulky chimneys. At the same time, the furnace operates stably even at low gas pressure. However, they produce a lot of noise and are volatile.

- Diffuse-kinetic. The air is partially pumped into the combustion chamber, the rest is supplied directly to the flame.

Gas nozzles for furnaces: types and selection

Many users confuse two devices - a burner and a nozzle; in fact, they are not the same thing. The nozzle is included in the burner design, that is, they work in pairs. It is responsible for the process of mixing fuel with air in the required ratio. If little air is supplied, then such a mixture will smoke, and if there is a lot, then the combustion process will not be able to occur.

There are 2 types of nozzles, depending on the air supply technology:

Advantages of gas injectors

Liquid and gaseous fuel nozzles are an essential element of a burner device; they have many advantages:

Important points when choosing a nozzle

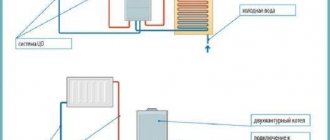

A gas fuel stove is a modification of solid fuel heating devices. Usually the stove is switched to gaseous fuel when it and the smoke exhaust system are in satisfactory condition. If heating equipment is being installed in a house for the first time, it is recommended that the nozzle be installed not in a stove, but in a special heating boiler.

Therefore, before choosing a nozzle for a furnace, it is necessary to carefully study all the technological nuances of such an installation:

Replacing injectors

A specialist from the gas service will be able to change the jets efficiently and professionally. He has the necessary knowledge and qualifications to correctly adjust the gas supply when switching to another fuel. Especially considering that to use bottled gas it is necessary to additionally connect a reducer. But if you rely on the data contained in the correspondence table, then a home master can confidently cope with such work.

Below in the table you can find the required diameter of the gas nozzle depending on the fuel used.

| Burner type | Gas type and pressure | |||

| NG G20 (20 mBar) | LPG G30 (50 mBar) | NG G25 (20 mBar) | LPG G30 (30 mBar) | |

| Small | 0.75mm | 0.43 mm | 0.70mm | 0.50 mm |

| Average | 0.92mm | 0.55 mm | 0.92mm | 0.65mm |

| Big | 1.15 mm | 0.60mm | 1.15 mm | 0.75mm |

| Oven burner | 1.20 mm | 0.65mm | 1.15 mm | 0.75mm |

| Grill burner | 0.95 mm | 0.60mm | 0.95 mm | 0.65mm |

On the burners

For those who decide to change the jets with their own hands, below is an algorithm of actions that must be followed:

- to gain access to the burner, you need to remove the top cover of the gas stove, which is secured with screws;

- then you should remove the tips with nozzles from the traverse with the burners, for which you first need to find the latch (outwardly resembling a clothespin), effortlessly squeeze its ends and carefully remove it;

- Next, the tip should be released from the socket and removed from the gas pipeline tube;

- an O-ring will remain in the tip, which needs to be removed from there and put back on the tube;

- the next step is to carefully unscrew the jets using a socket wrench counterclockwise (if the nozzle is stuck and does not budge, it is recommended to use a vice);

- and finally, new nozzles need to be screwed into each tip, and then reinstalled.

Due to the low pressure in the network, sealing the threaded connection is not required. How to lubricate the o-ring. How smoothly the burner will burn depends on how carefully and correctly the reassembly of the structure is carried out.

In modern gas stoves, the process of converting to use other fuels is even simpler. To get to the burners, you only need to remove the grates with the burners. After this, you can easily remove the tips and replace the jets with new ones.

In the oven

To change the jets in a gas oven, you need to follow these steps:

- open the oven door and the lower oven compartment completely;

- pull towards you and pull out the floor of the oven compartment;

- unscrew the fastenings of the gas burner and move it to the side;

- a nozzle is hidden in a special housing on the left (if the stove has not been in use for long, the nozzle will easily unscrew from this position, and if the nozzle has become stuck, then you need to continue disassembling so as not to strip the thread);

- remove the left side wall by unscrewing the three fastening screws;

- Using a 17mm wrench, unscrew the nut and move the pipeline to the side;

- unscrew the last two screws that secure the nozzle body to the wall;

- treat the stuck thread with kerosene or WD-40 and use a vice for convenience when unscrewing the jet (if necessary);

- install a new injector.

Then you need to carefully install the oven in the reverse order.

How does a gas stove nozzle work?

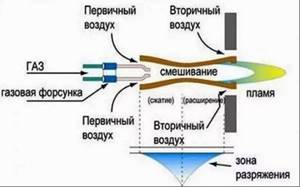

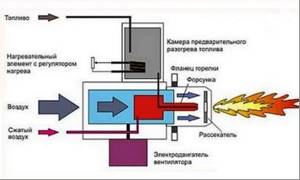

Nozzles are used to form a combustible mixture of gaseous fuel and air. Next, the enriched mixture under pressure enters through special holes, thereby ensuring complete combustion of the fuel in the form of a fiery torch. The atmospheric nozzle functions like a regular ejector. Gas, passing through nozzles of a special configuration, creates a vacuum zone into which air is drawn and thus a constant thrust mode is created.

READ Mercedes wis asra how to install

Nozzle control and regulation

Adjusting the operation of such a device depends on its design. Recently, low-temperature sprayers have gained particular popularity among consumers. They are most applicable for installation in furnaces, since they create a mode sufficient for the normal operation of brick structures.

The principle of nozzle regulation can be organized as follows:

Photos in the text to illustrate what was said

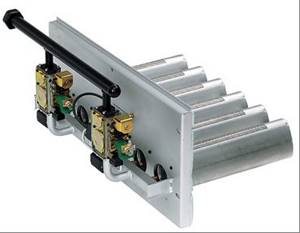

Atmospheric gas burner for furnace

Atmospheric nozzle with flame dividers

Gas burner with nozzle and power adjustment

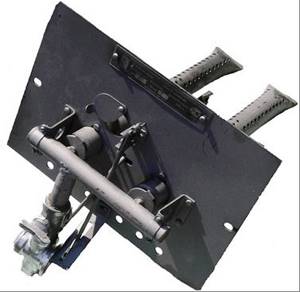

Blast gas burners with nozzle

Turbocharged air injectors

Principle of operation

There are 2 types of such devices on the gas burner market:

- atmospheric;

- supercharged.

Atmospheric nozzles draw air from the room where the stove is located. In addition, the operation does not require the use of complex automation. Thanks to this, the product has a simpler and more uncomplicated design. The main drawback is the requirement for good air circulation. Therefore, atmospheric burners should be installed in well-ventilated areas. However, some models have special sensors that monitor the oxygen level and, if its content is low, turn off the gas supply.

Supercharged products are equipped with complex automation , due to which they have a more complex design. Such products operate on the principle of forced air injection. Fans are responsible for this, regulating the pressure and volume of supplied oxygen. The main requirement for use is that air must be taken from the street.

What is the reason for the ban on gas workers using a stove with a gas nozzle?

A ban by representatives of gas services regarding the use of stoves with gas nozzles may be due to the poor technical condition of the heating device. Or using a homemade nozzle.

This is due to the fact that there have been numerous accidents in furnaces with homemade gas sprayers. In this case, the actions of city gas representatives comply with directive materials on the safe operation of gas equipment.

If the owner uses a factory-made nozzle for reconstruction with all the necessary documentation. And the reconstruction itself to convert the furnace to gas fuel was agreed upon with Gorgaz, then in this case there should be no ban on the operation of such equipment.

Source

Installation of a gas burner in a heating furnace

We remind you that it is prohibited to install gas equipment yourself. However, it won’t hurt to familiarize yourself with the nuances of installing a gas burner in a stove.

So, installation of a gas burner is permissible in furnaces in which the length, shape, nature and temperature of the flame can be adapted to the nature of the material of the combustion chamber. The flame should not touch the walls, but should be freely located in the combustion space. If it is a brick wall, then the firebox should be made of refractory bricks.

Before installation, check the walls of the stove for cracks, voids, and unsealed seams through which combustion products can enter the room. The room into which the firebox door opens must have an opening window, a ventilation duct and a gap in the door for air to enter from below.

Gas burners of any type are characterized by the creation of high temperatures - more than 1000 °C in the combustion chamber. When installing a gas burner in the oven, you must ensure that the flame does not touch the walls.

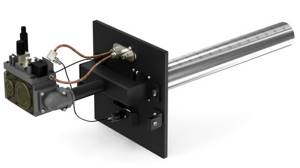

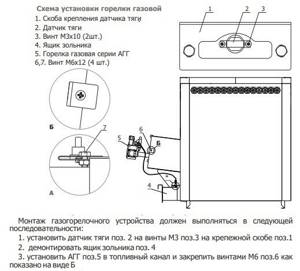

The installation process itself is not complicated and is carried out in the following sequence:

- Remove the firebox door.

- A burner is placed in the combustion chamber.

- The shield is secured in the door frame.

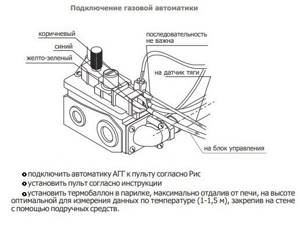

- Connect the automation according to the manufacturer's instructions.

At the end of installation, connect the burner to a hose, the other end of which is connected to a gas source.

Installing a burner using the example of an AGG gas burner device: the stage of installing a gas burner block in a furnace with dismantling the ash pan

The system is launched by a master from the gas service, he checks the operation of the nozzles, the automatic control and safety systems, configures and tests the response of the sensors.

Installation of a gas burner in an industrial furnace using the example of an AGG gas burner device. Connecting automation, placing the remote control and thermal cylinder

Another step is to check the tightness of all connections and the presence of traction. After successful startup of the system, the gas installer must issue a completed control certificate for the installation of the burner.

When starting the heating, you should first select the minimum thermal power, heating the stove continuously and little by little or, if there is no power adjustment, cyclically, turning the burner on and off. This is especially important for a brick kiln - strong continuous heating of a cooled brick can lead to cracking.

Gas nozzles for furnaces: types and selection

Many users confuse two devices - a burner and a nozzle; in fact, they are not the same thing. The nozzle is included in the burner design, that is, they work in pairs. It is responsible for the process of mixing fuel with air in the required ratio. If little air is supplied, then such a mixture will smoke, and if there is a lot, then the combustion process will not be able to occur.

There are 2 types of nozzles, depending on the air supply technology:

Advantages of gas injectors

Liquid and gaseous fuel nozzles are an essential element of a burner device; they have many advantages:

Important points when choosing a nozzle

A gas fuel stove is a modification of solid fuel heating devices. Usually the stove is switched to gaseous fuel when it and the smoke exhaust system are in satisfactory condition. If heating equipment is being installed in a house for the first time, it is recommended that the nozzle be installed not in a stove, but in a special heating boiler.

Therefore, before choosing a nozzle for a furnace, it is necessary to carefully study all the technological nuances of such an installation:

How to choose a burner?

In order to choose the right burner for a gas boiler, it is necessary to carefully study the technical parameters of the device, as well as the principle by which air is mixed with gas, and the method of supplying natural gas.

The main characteristics of such products are:

- Thermal power.

- Characteristics of the gas that will be used in the product.

- The relative length of the flame leaving the burner.

- Design gas pressure in the furnace.

- Operating adjustment: ratio of theoretical thermal power to minimum.

- Limit adjustment: the ratio of the highest thermal power to the lowest.

- Chemical composition of the fuel.

- The noise level produced by the product.

When choosing a device, you need to keep the following factors in mind:

- Simplicity of design. In this case, the cross-sections of the paths for the passage of gas must be the same and create minimal resistance to the gas.

- Room size. For small rooms, an atmospheric device will be sufficient, but for larger rooms the power of such devices may not be enough.

- Manufacturer of the product. Domestic and foreign (mostly products made in Germany are on the market) units have approximately the same cost, but some similar devices are designed for installation in specific types of stoves. For example, the domestic product AGG-15 is suitable for use only in stoves with a long channel for the fuel mixture.

Photo 2. Gas nozzle AGG-26, suitable for furnaces with a long channel.

- Type of heating device.

Important! You need to know where the fuel will come from to the heating device: from individual cylinders or from the main pipe. This is also taken into account when installing the stove.

Installation Requirements

There are special requirements for the installation of gas equipment in a bathhouse or home. The permit is issued by the gas supply organization. To obtain documents for installation, you must provide:

READ How to install a gas meter in Penza

We invite you to familiarize yourself with Connecting timber or logs - various methods and types of corner fastenings

These requirements are mandatory; if not met, you will not be able to obtain the necessary permits to use gas burners for sauna stoves.

How does a gas stove nozzle work?

Nozzles are used to form a combustible mixture of gaseous fuel and air. Next, the enriched mixture under pressure enters through special holes, thereby ensuring complete combustion of the fuel in the form of a fiery torch. The atmospheric nozzle functions like a regular ejector. Gas, passing through nozzles of a special configuration, creates a vacuum zone into which air is drawn and thus a constant thrust mode is created.

Nozzle control and regulation

Adjusting the operation of such a device depends on its design. Recently, low-temperature sprayers have gained particular popularity among consumers. They are most applicable for installation in furnaces, since they create a mode sufficient for the normal operation of brick structures.

The principle of nozzle regulation can be organized as follows:

Safety rules for operating gas burners

During operation, a gas burner accumulates a lot of soot on its surface. To ensure that the unit does not break down and operates efficiently, soot is regularly removed. Sometimes, if there is a significant accumulation of soot, it may ignite. Gas boilers with closed combustion chambers must be regularly inspected and serviced by specialists. If you have experience, you can clean the structure yourself. When installing the unit, the standardized distances must be observed. Atmospheric type devices are equipped with a high-quality chimney, and fan type devices are equipped with a coaxial type smoke removal system.

What burners are used in wall-mounted and floor-standing boilers?

For wall-mounted gas boilers, the most suitable option is automatic or ventilation type burners. Gas burners of a floor-standing boiler are most often atmospheric, which are included in the standard heating system kit.

Special low-temperature burners are especially popular these days. They have a wide variety of applications - they are excellent for use in direct combustion processes, are characterized by simplicity and increased reliability.

Depending on the type of flame adjustment, there may be:

- Single-stage gas burners are designed to operate in only one mode. They are equipped with automatic switching for frequent switching on or off when the device reaches a certain temperature, which significantly reduces their service life and also adversely affects the performance of the boiler itself;

- Two-stage burners for a gas boiler are devices capable of operating in two different modes or with different power of the fire torch. Switching, as a rule, occurs automatically as a result of a special sensor issuing a command aimed at regulating the temperature regime of the boiler. Using this type of burner, you can save fuel by using the device for a fairly long operating period;

- Modulating gas burners are considered the most economical and also functional. They work on the principle of fairly smooth adjustment of the burning fiery torch. They are divided into the following types: with electronic, pneumatic and mechanical flame control systems.

What is the reason for the ban on gas workers using a stove with a gas nozzle?

A ban by representatives of gas services regarding the use of stoves with gas nozzles may be due to the poor technical condition of the heating device. Or using a homemade nozzle.

This is due to the fact that there have been numerous accidents in furnaces with homemade gas sprayers. In this case, the actions of city gas representatives comply with directive materials on the safe operation of gas equipment.

If the owner uses a factory-made nozzle for reconstruction with all the necessary documentation. And the reconstruction itself to convert the furnace to gas fuel was agreed upon with Gorgaz, then in this case there should be no ban on the operation of such equipment.

The manufacturing process of an atmospheric gas burner

An atmospheric burner is easier to build, since it is structurally much simpler than its fan counterpart. The most typical example known to most Russians is the burner block in old-style geysers. There are no energy-dependent elements in its design that force gas and air to mix in the required proportions.

Air is drawn into the chamber with the atmospheric burner module spontaneously as needed. Blue fuel processing products are discharged naturally through a standard chimney due to the presence of draft. All the work consists of constructing a manifold with gas nozzles through which gas will flow at the required speed.

If you want to build a gas burner with your own hands, it is better to take a factory-made product as a basis, or rather, the drawing available in its technical passport with the dimensions and designation of structural elements

To make a burner with your own hands to equip a gas heating boiler, you will need:

- Valve series VK-74. Typically used on oxygen cylinders, designed for a maximum pressure of 20 mPa. The package should include a 3/4″ union nut, with which you can tightly connect to the gas supply pipe or hose. The valve will serve as a support base for fixing the nozzle.

- Nozzle cap. The device will hold the gas supply dispenser and form a narrowly directed jet. A hole is drilled at the top of the cap into which the nozzle is to be placed. The base screws onto the valve.

- Nozzle. It is better to buy it ready-made with the expectation of supplying main gas or a liquefied gas mixture. The injectors have different outlet diameters. Instead of nozzles for boilers, you can use a jet from a gas burner.

- Homemade injector. It is constructed from a steel tube with a wall thickness of up to 2 mm. You will need a piece of pipe approximately 10 cm long.

- Piezo element. It is installed at will, although you can do without it. Homemade products can be set on fire with matches.

All of the above elements are assembled mainly by welding. Therefore, skills and minimal knowledge in welding will be very useful for an enterprising “do-it-yourselfer”. However, where it is possible to use threads, it should remain a priority.

The gas supply channel must be impeccable and sealed, because safety depends on its condition. A distance of 10 cm must be maintained between the gas inlet into the device and the nozzle, which is necessary for mixing fuel with air.

The home craftsman just has to figure out how to secure a homemade gas burner in the combustion chamber of a used water heater or in the firebox of a former wood-burning boiler. Please note that you need to leave room for air flow. Air must be regularly supplied to the chamber, for which round or longitudinal holes must be cut in the door.

Do not forget that the above option can hardly be called a safe gas supply device. The design does not have automatic equipment that interrupts the operation of the boiler in case of blowing out or unstable flame. Owners will not have the opportunity to adjust the pressure and gas flow, so there can be no talk of either convenience or savings.

Before you start using a product made at home with your own hands, you need to go through the following procedures:

- The burner must undergo a quality check at the local Rostechnadzor office in accordance with the regulations established in the Federal Law on the Safety of Buildings and Structures dated December 30, 2009.

- After this check, it is necessary to obtain a certificate from Rostekhnadzor regarding the suitability of the burner for operation.

In order to start making the nozzle, you need the following materials:

- A valve that will serve to regulate the fuel supply of the device. To supply gas to the burner, you must use the valve installed on the gas source.

- Steel pipe. It is desirable that it have a thickness of up to 2 mm and a length of up to 100 mm.

- Steel cap for making a fuel dispenser. You can also use a jet from a blowtorch.

- Steel handle. It can be made from a regular fitting.

- Rubber for handle lining.

- Wire. It will be used for welding.

You will also need the following tools:

- Welding machine.

- Grinder for cutting parts.

For homemade production, an atmospheric nozzle is preferable due to the simplicity of its design. The procedure is as follows:

- First, screw the cap onto the valve. For example, if a standard VK-74 valve is used, then the cap has a conical thread.

- Then, by cutting the existing steel pipe with a grinder to the required size, the nozzle of the future nozzle is made - its basis.

- Next, the nozzle is welded to the cap using wire. In this case, the cap and nozzle should not touch.

- A piezoelectric element is installed, which is needed to activate the device.

After this, the product is ready for installation.

Attention! To install a system for supplying fuel to the stove from a central heating system, you need special equipment and experience working with gas systems.

Furnace installation

When installing a finished unit in a furnace, take into account what materials it is made of:

- If we are talking about a brick stove, then the obvious disadvantage will be the high cost and complexity of such a structure, which can only be assembled by a specialist. In this case, the nozzle is mounted inside the furnace.

- In turn, installing the unit in a metal furnace is much simpler and can be done without the involvement of specialists. In this case, the nozzle is mounted directly into the stove so that the flame enters the boiler in sufficient quantities to form a fuel mixture.

The gas nozzle - the heart of the stove - must be of high quality and correctly installed. If this unit malfunctions, fuel-related problems may occur, which can lead to irreversible consequences.

Making gas burners yourself: to do or not

Doing something with your own hands is a pleasure, and often brings significant savings. But in the case of gas burners, it’s better not to take risks: you can’t be sure that you did everything right, and the cost of a mistake is too high. At the same time, the cost of an atmospheric burner is only about $20. It's not worth it. The only thing you can do is change the parameters of the distribution pipes. This part can be redone without much risk.

One more thing: you will never get permission to use a homemade burner. You can, of course, install equipment without permission, but the fines are too high.

Which one is better to choose?

Any buyer thinking about converting their wood stove to gas fuel must carefully weigh the many parameters and factors that will ultimately influence the choice of a specific solution. Atmospheric burners are cheaper - they can be purchased for as little as $100 and do not rely on electricity - but you will likely need some modifications to the fuel chamber.

However, in any case - if you are just planning to build your own bathhouse and are thinking about purchasing a heater stove - it is better to buy a ready-made gas stove with a built-in burner. The design of such a stove and the configuration of its fuel chamber will be adapted to the type of burner you have chosen, and it will be equipped with all the necessary automation and safety systems. And believe me, after you try a gas oven, you will not regret your choice.

Service details

Maintenance of a gas burner Maintenance of gas burners of any homemade version only involves cleaning it.

This process must be annual. Doing it yourself is not recommended. After all, you will have to disassemble and reassemble the boiler. As a rule, people turn to service centers for service. Accumulated contaminants are eliminated by air blowing. The air here is compressed. READ Php ssh2 how to install ubuntu

The pressure to the burners must be adjusted carefully. For example, for some current versions of burners, parameters of 8-10 atm can be detrimental.

The need for cleaning the burner can be reduced significantly if a filter is installed on the gas supply pipe. This work is performed by a gas service employee, who should be contacted with a special request.

Opening the valve

Valve on a gas burner The power of such a device can be controlled by closing or opening the valve.

The highest temperature is concentrated in the green-blue part of the fire. To adjust the nozzle, you need to place a torch in the middle of it. To do this, the wire holders are slightly bent. To create a working version of the burner, a tip is welded to its nozzle. Its angle of curvature is 45⸰.

The basis for manufacturing may be a steel valve (also from a cylinder). A plug with a hole for the nozzle is threaded onto its exiting section. It is taken from a blowtorch. The diameter of its nozzle is 0.8 mm. The required diameter of the burner nozzle is 3 cm. The length of the nozzle can be varied with nozzles. This is how the torch parameters are controlled. The valve becomes the regulator here.

Source