If you already have your own greenhouse, then you know that in March it is still quite possible to do without heating and plant cold-resistant types of greens: radishes, foam, chard. Under the film, right in the beds, they can easily tolerate even temperatures of -6°C. And in mid-March, the soil temperature will calmly rise to a temperature of +10°C, if all the work was done before this in the fall - digging to loosen the soil, laying compost and covering with film. And yet, heating a polycarbonate greenhouse is not a luxury or a necessity only for those who grow for sale - if you want to reap a really good harvest, study this issue in advance. Not only those who dream of growing something in a winter greenhouse, but also those who use it seasonally, will think about additional heating of the greenhouse. The thing is that it is not so easy to melt the frozen ground in spring - this takes a lot of thermal energy. And the sun is a weak helper in this matter. And in the greenhouse itself the temperature should be at least +18°C. Fortunately, polycarbonate is the warmest material for covering greenhouses. It is much easier to heat such structures than glass ones or under film. But you will still have to heat, so let’s look at what is better and more expedient.

Which greenhouse heating to choose?

Today, greenhouse heating is a fairly important element. It is best to organize electric heating in a greenhouse. With its help, you can control heaters in semi-automatic mode.

Electric heaters for greenhouses are quite economical. In this article you will find the most effective schemes for heating a greenhouse with electricity. For electric heating of a greenhouse, you can use several heater options. A simple heating method can be considered by laying a heating cable in the greenhouse. An alternative heating option can be the connection of infrared heaters. The most labor-intensive option can be considered connecting an electric boiler in a greenhouse. Now we can examine each of these systems in detail.

Heating cable in a greenhouse

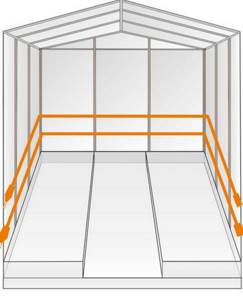

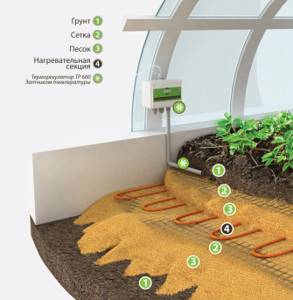

The greenhouse can be heated using a heating cable. If you choose this method, then the greenhouse heating scheme will look like this:

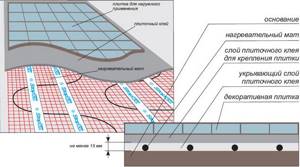

Here is the “pie” that this scheme will consist of:

In this case, your cable will be able to heat the soil to the required level. If you cannot secure the heating cable underground, then you need to lay it along the wall. The electric heating circuit of the greenhouse in this case will look like this:

After you install the heating cable, the system will look like this:

Instead of a heating cable, you can also use ENGL-2 tape. Its installation should be carried out according to a similar scheme.

Brick stoves for greenhouses

Do-it-yourself heating devices for greenhouses often work no worse than purchased devices. Moreover, this is the cheapest option, which makes it possible to comply with all the nuances when placing it in any greenhouse.

Using a brick oven, you can successfully heat a polycarbonate greenhouse even in winter, thanks to its increased heat capacity. Any heating stove is suitable for this, as long as its performance matches the area of the room.

At the same time, for a standard greenhouse of 6x3 meters, you can build a stove with a height of 210 cm and dimensions of 70x50 cm.

To fold it you will need:

- red masonry brick – 215 pcs.;

- fireclay brick – 85 pcs.;

- concrete mortar for the base – 0.30 m³;

- doors for cleaning from soot – 2 pcs.;

- doors for ash removal – 1 pc.;

- combustion door – 1 pc.

Below is the step-by-step laying of a brick oven:

Stage 1. Foundation. First you need to make a reliable foundation according to the size of the future furnace. To do this, first a recess is dug at a distance of 40 cm, then about 10 cm of gravel is poured onto the bottom, formwork is made and the concrete mixture is poured onto the pre-laid rod reinforcement.

Stage 2. After drying the foundation, lay the oven according to the drawings on a clay mortar. At the same time, near the combustion channels, the masonry is made from fireclay fire-resistant bricks, and the rest is made from red stove bricks.

Stage 3. First, 4 rows of red bricks are laid on a clay mortar. Install the ash pan door, securing it in the opening with wire.

Stage 4. Rows 5 to 12 are laid from fireclay bricks on a refractory mixture, while a grate and fire door are installed.

Stage 5. Rows 13 to 15 are also laid with fireclay bricks, then after covering the furnace roof, the masonry continues with red brick. After the 15th row, a door is installed for cleaning soot, and in the 22nd row, a damper for smoke exit is installed.

Stage 6. Rows 23 to 27 extend the smoke holes, and starting from row 28, a narrowed channel is laid out. In the 29th row, a second smoke damper is installed and from the 32nd row they begin to lay out a chimney of the required height from 4 bricks with a bandage.

On a note!

For greenhouse buildings with a small height, the stove is installed with a horizontally located chimney - a hog pipe.

Infrared heaters

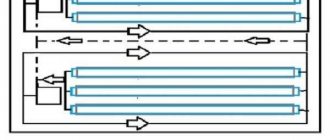

If you have already built it, then it is impossible to heat the greenhouse using a heating cable. In this case, ceiling infrared heaters are suitable for you. They are capable of not only warming up the room, but also doing it in a semi-automatic mode. A typical infrared heating scheme in a greenhouse looks like this:

If necessary, you can place the heating of the greenhouse using infrared heaters on the wall.

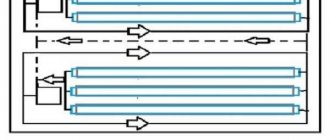

Choosing the optimal boiler

It is necessary to select a boiler model taking into account the size of the installed greenhouse, as well as the crops being grown. If there is gas, then it is better to use gas models. For year-round models, solid fuel boilers are a good option. For small greenhouses with periodic use, installing a solid fuel boiler is not suitable. It is much more profitable to install a low-power electric one. It does not require space or the construction of a chimney, and electricity costs are minimal.

When using radiators, a number of calculations are required. To achieve a good result and maintain a constant microclimate, you should contact a specialist. In this case, the following are taken into account :

- dimensions of the building;

- thermal power ;

- number of radiators.

The sections must be distributed throughout the greenhouse in several rows. It is better to opt for low radiators for good soil heating.

Water heating using radiators Source th.decorexpro.com

Heating a greenhouse with an electric boiler

This method of heating a greenhouse is considered the last. In this case, you need to use water heaters or heated pipe floors.

Of all the schemes for heating a greenhouse with electricity that we provided, this one is the most labor-intensive. Despite these factors, heating a greenhouse with an electric boiler is very popular. If necessary, you can also connect an electrode boiler here.

These were the most effective schemes for heating a greenhouse with electricity. We hope you find these diagrams useful.

Similar articles on the topic

I have been involved in greenhouse activities for a long time. However, installing heating in a greenhouse has always raised a lot of difficult questions. The most important thing is what type of heating is best suited, and how to correctly draw up a heat distribution scheme over the entire area. That’s why I started looking for information on the Internet, since I didn’t have any acquaintances in this matter who could help. Only by going to this resource, I finally found decent and understandable information on all stages of heating installation and its selection. Very satisfied!

Source of the article: https://vse-elektrichestvo.ru/otoplenie/montazh-otopleniya/otoplenie-teplicy.html

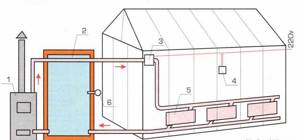

Two-pipe heating

Palace owners claim that for large booths, two-pipe heating is best suited. The stove is installed on a separate platform, which is lined with fireclay. The platform is installed at a distance of 1.5-2 m from the plants to prevent the leaves from burning. It is possible to do steam heating of a greenhouse with your own hands, but during installation you must follow some rules.

- A circuit for a collector-type steam pipeline is removed from the furnace. The main pipe runs along one side of the greenhouse. Exits are made from it in increments of 2 m. They are intended for installation of a heating main, which is placed across the site. Steam will pass through them.

- What kind of decoupling is used for steam heating? How to make circulation for a greenhouse? The pipes are connected from above if the height of the booth is 3 m. The areas where the pipes come into contact with the roof are laid out with asbestos sheets. The pipes run at an angle of 5 mm per 1 linear line. m.

- At the lower junction, it is recommended to install transverse pipes in increments of 4-5 m. They are laid on earthen ramparts that run along the beds. If possible, the highway is hidden underground. The depth should not be less than 50 cm. Otherwise, the plant roots will get burned.

- The pipes do not need to be hidden underground, but laid on the ridges of the beds, but the distance to the seedlings should not be less than 40 cm.

- A condensate pipeline is installed on the opposite side. It also has holes for pipe entry. They must correspond to the markings on the steam line. Otherwise, the line will skew, which puts additional stress on the pipes.

- The condensate is collected in a separate line and passes into a storage tank. From it you can provide a tap for supplying hot water. Do-it-yourself hot water supply can be done in a greenhouse.

- An outlet is made from the tank to drain liquid to the boiler: the slope of the pipe must be observed.

- A water filter and a circulation pump are installed on the circuit. It is designed to pump liquid into the steam generator, which is located in the furnace.

- It is recommended to make a steam outlet near the pump to prevent airing of the system.

Greenhouse heating scheme

Temperature regulators are installed at each steam pipeline connection. They are necessary to prevent elevated levels in the highway. With their help, you can regulate the temperature in individual sections of the greenhouse.

We recommend: Pros and cons of steam heating without a pump

If seedlings are planted in one area, they require more heat than plants that have been growing in a greenhouse for several weeks. It is recommended to provide valves to be able to shut off the steam heating system in the greenhouse and stop heating if necessary.

Galvanized pipes are used. For the steam line, choose a diameter of 115 mm. To drain condensate, use a circuit with a smaller diameter, 70 mm, wall thickness 2.5 mm. A small load falls on it: the steam cools, the pressure decreases.

The lower junction of the highway is similar to a “warm floor” system. You can install automation for it so that the heating is more efficient: it turns off when certain temperature indicators are reached and turns on if the parameters decrease. Automation requires an electrical junction box.

If the greenhouse is stationary, then radiators can be installed in it. In this case, the steam system may have a single-pipe design. For large greenhouses with an area of more than 200 m2, select a boiler with a capacity of 35-40 kW. It is recommended to purchase a diesel fuel unit.

With a single-pipe circuit, it is not necessary to install a circulation pump. A gravity-type system is used. If the area of the greenhouse is more than 300 m2, then it is recommended to install 2 stoves and install its own circuit for each part of the booth.

In large greenhouses, it is recommended to install a two-pipe steam heating system. Boilers can be installed using any fuel. Fireboxes of a certain power are selected. In greenhouses with high ceilings, the pipes are connected at the top.

If the booth is low, then the highway is laid on the ground or underground. It is necessary to set a certain temperature in the pipeline in a timely manner to prevent burns to the vegetative and root parts of the plants.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- What types of steam heating radiators are there?

- How does steam electric heating work?

- Features of steam heating in a bathhouse from a stove

- How to install a steam heating pump?

- Which wood stoves are suitable for steam heating?

- How does a low pressure steam heating system work?

Industrial farm greenhouses from the manufacturer in Belgorod

A boiler for greenhouses is the equipment that will allow you to get a good harvest even in severe frosts. Everyone knows how much vegetables cost in winter, so bringing your own vegetables during this period is a very profitable solution. But every vegetable grower who decides to start heating a greenhouse may face the difficulty of choosing a boiler, because there are several varieties on the market. Which one should you choose for this or that site? Or maybe it would be easier and cheaper to make it yourself from scrap materials?

Boiler options for greenhouses

At the moment, the following boilers for greenhouses are widely used:

- wood;

- combined (wood-coal);

- pellet;

- gas;

- electric.

Conventionally, they are classified into two more subspecies. Solid fuel boilers are the first three types above. Long-burning boilers are included in a separate category, since the principle of their operation is not based on the combustion of materials, but on their smoldering, for which a system of controlled oxygen (air) supply is used. They are the most effective and economical, but are quite expensive.

Making a greenhouse boiler with your own hands

The first step towards self-installation of heating equipment in order to create a heated greenhouse in a personal household should be a detailed drawing of the planned heating installation. The required power is also calculated based on the area and volume of the room, type of boiler, type of fuel, operating time, etc. After a painstaking process of theoretical pre-preparation, one should proceed to the main stages of creating a boiler.

Materials and tools

For a simple solid fuel boiler model you will need:

- A metal barrel with holes or an old gas cylinder, sawn in half.

- Water circuit or coil.

- Hinges, metal handles, matching latches, etc.

- Welding machine.

- Cutting tools.

Construction and connection

The most common model of a homemade boiler looks like this:

- The cylinder (barrel) is placed in a metal oven.

- A chimney pipe is welded to the resulting structure, through which gases will be discharged from the greenhouse premises to the outside.

- The last stage is welding pipes (plastic, metal) together and their further installation.

Video: how to make a solid fuel boiler with your own hands

Which boiler to choose for a greenhouse

When choosing a boiler for heating greenhouses, you need to take into account both the area of the heated room and your financial capabilities. Ideal - long burning, but they cost an average of 100 thousand rubles. But their consumption is 2 styling for 24 hours. In large greenhouses, they completely pay for themselves in just 1-2 seasons (if the firewood or coal is purchased). In small ones, with an area of about 15-20 square meters, the payback will stretch over almost 10 seasons.

For the latter option, simple solid fuel heating boilers or those that run on gas would be ideal. The efficiency of the system will be significantly higher if it is supplemented with a pump for pumping water through pipes. This, by the way, will ensure uniform heating of the heated room.

An electric boiler, as practice shows, is a pointless waste of money. They are inefficient, use too much electricity, and only increase the temperature at the top of the greenhouse. The volume near the ground remains cold, which leads to freezing of plants.

Heating of a film greenhouse can be done in two ways

Water heating

The heat carrier is water heated by a hot water boiler or non-freezing liquids are also used. Boilers are completely different, depending on the fuel they will use (gas, diesel fuel, waste oil, solid fuel). The heated water is supplied through a piping system to the end points of heat distribution using a pump.

Related article:

DIY greenhouse

The most effective devices are water heaters. Hot water is supplied to the heat exchanger of this device, the fan blows off the heat from the heat exchanger and it enters the greenhouse, which is heated accordingly.

Main advantages

- Quick heating of the greenhouse room

- Distribute heat evenly throughout the room

- Absence of cold zones with lower temperatures

- The use of an automation system, including thermostats, together with these devices, allows you to maintain the set temperature

- The thermal power of one such water heater can be more than 100 kW, which is on average about 50 water radiators

- The price of a water heater will be significantly less than the total price of all batteries

Air heating

The main devices of an air heating system are an air heater or air heat generators. Like hot water boilers, heat generators can operate on various types of fuel. The most popular are gas heat generators, due to the low cost of the fuel used and low operating costs.

Related article:

Assembling a greenhouse with your own hands: design with an opening (removable) top

Possible problems with a homemade device

- The most common problems when operating a homemade heating unit are:

- uneven heating of the internal space;

- excessive dry air.

Both factors negatively affect the condition of the plants in the greenhouse, so you should be especially careful when laying air pipes and providing additional air humidification. Undoubtedly, the selection and installation of technically complex, expensive equipment requires a considerable amount of time and effort to study the issue. However, these efforts can be attributed to a prolonged investment in a future rich harvest, which will delight you both morally and materially for more than one season.

Emergency heating boilers

An experienced vegetable grower always has different types of heating boilers at his disposal, since one of them may turn off due to an interruption in gas supply, electricity, or simply break down. So, for emergency situations, electric ones are ideal, where the heating element is heated, and the heat is dissipated by a cooler. But they should be supplemented with an autonomous generator.

The most ordinary wood-burning stove is also an excellent solution for emergency heating of the greenhouse volume. But its construction should be done in advance. Smoke removal can be done in several ways. But we must not forget that vaporous gas is not harmful to plants and reduces thermal conductivity. Thanks to this, the cooling rate of the greenhouse will be significantly reduced.

Every vegetable grower could use a mobile pellet boiler. It is quite easy to transport, but it is useful for burning any solid fuel, including corn cobs. At the same time, heating occurs quickly and evenly. The only drawback is the need to have a chimney, and in strong winds it will blow in from the outside. That is, a large amount of smoke will enter the greenhouse. Plus, pellet boilers are demanding to maintain. They quickly accumulate moisture, which can only be removed mechanically. In any case, this is an excellent option for emergency heating, in which fuel can even be combined (for example, kindling with wood, maintaining temperature with coal or peat).

Standard heating - heating main

So, let's begin. A heating main is the cheapest way to heat such a greenhouse, but it is not available to everyone. This is more of a rarity and luck than an opportunity. Air heating, water heating, and infrared heating are also quite suitable for heating polycarbonate greenhouses. Air heating is not bad if you think carefully about how to humidify the air, because this is one of the main parameters necessary for a normal harvest.

Water is inexpensive and generally justifies the cost - just lay pipes under the beds, hot water will flow through them and warm the soil, or hang radiators. But many people worry whether their metal pipes will rot in the ground? In fact, such fears are unfounded: thanks to the constant temperature, such pipes dry themselves out, and during irrigation, water simply does not reach them.

As for gas heating, you need to be especially careful with it in greenhouse farming. The fact is that under the film and behind the glass there is always at least a little air - some cracks and sometimes entire uncovered areas. But polycarbonate is always attached as tightly as possible, which is what it is famous for, by the way. But the bottom line is the same: if you have even a small gas leak due to a malfunctioning heater, you can get burned. Therefore, take care of additional ventilation anyway, especially since an excess of carbon dioxide is also harmful for plants.

What's good about gas heating is the stability of the supply - when you need it, you turn it on, and you don't depend on power outages. Just for peace of mind, buy heaters with an automatic safety device - as soon as the gas stops flowing into the burner, special sensors will operate. That is why experienced gardeners are sure that, despite all the warnings, it is possible and necessary to heat a greenhouse with gas, but a cannon is far from the best option.

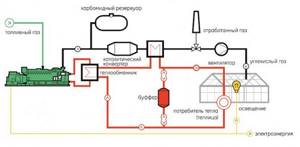

Here is an example of arranging a heating system from a boiler:

It should be noted that heaters with a grid, such as those used in apartments, are much more effective. In them, the gas is burned to CO and CO2 - its complete oxidation, and then there can be no poisoning. For a person in a practically unventilated greenhouse, this is important so that no poisoning occurs. Yes, such devices burn out oxygen, but plants still consume CO2 and thereby restore the balance. Moreover, while maintaining the required humidity in the greenhouse - when gas is burned, water is always released with CO2, and therefore condensation will be visible on the walls already on the first day.

Construction of industrial greenhouses: heating and lighting

Heating an industrial greenhouse always becomes a pressing problem during the cold season. Each owner of a greenhouse complex is looking for his own way out of this situation. Some solve the problem with the help of anthracite coal, some are satisfied with the air heating system, others are introducing small and large Russian and global heating technologies of the new generation.

Heating for industrial greenhouses can be installed with your own hands, or they can be manufactured by a factory that produces finished and component products.

Lighting in large structures is no less important. Especially if the greenhouse “works” in winter. For lighting equipment, new LED lamps and fixtures are installed, starting to turn them on as soon as the seeds germinate. Don't forget about the irrigation system.

Irrigation systems are:

Ventilation also plays an important role. Recently, taking into account 2021, an automatic ventilation system with the installation of curtains has been actively used. You just need to set the sensors correctly, and the circuits will do everything for you.

Why is it necessary to heat a greenhouse?

Numerous crops can be grown throughout the year, regardless of the geographic location of the region. To do this, it is recommended to build a spacious greenhouse that will be heated during the cold season, creating a very favorable microclimate for plants.

Someone may think that it will be enough to build insulated and vapor-tight surfaces (roof, walls). However, at very low temperatures, after some time, warm air will seep out and be replaced by colder air. Thus, without auxiliary means it will be almost impossible to maintain a suitable environment (about 17-20 degrees).

Heating with solid fuel boiler

It is better to install such heating equipment not in the greenhouse itself, but in the vestibule. This option is more preferable for the reason that you won’t have to open the door to the room several times a day, letting cold air in to add another portion of fuel. But at the same time, in this case, heating a polycarbonate greenhouse will be less effective, since the heat also comes from the walls of the boiler itself. It is necessary to correctly calculate the heating of the greenhouse so that the device is powerful enough (about

Plot

0 votes

+

Vote for!

—

Vote against!

It is no secret that the key to full-fledged cultivation of vegetables and other cultivated plants is not only a greenhouse built in accordance with all the rules, but also its year-round operation, ensured by a properly equipped heating system. When developing a greenhouse project, it is important to decide which greenhouse heating system will be most appropriate in each specific case, and also to clearly think through all its functional parameters. This plays an important role in the process of early harvesting, which, in conditions of lack of solar radiation, is possible only thanks to a harmoniously equipped greenhouse heating system.

Content

- Heating a greenhouse: a variety of methods

- Solar heating of greenhouses: a promising technique or a relic of the past?

- Biological heating of a greenhouse in winter: myth or reality?

- Technical heating methods: what to choose?

- Heating a greenhouse with gas

- Heating a greenhouse using electricity

- How to heat a greenhouse using an electric cable?

- Water heating of a greenhouse

- Infrared heating of a greenhouse: how to reduce energy costs?

Heating a greenhouse: a variety of methods

The main problem when equipping greenhouses for the winter period is choosing the most suitable heat source. The variety of modern technologies causes significant difficulties in choosing heating equipment, even if you have completely decided on the most suitable heating method. In modern conditions of development of innovative technologies, experts propose to distinguish three fundamental methods of heating greenhouses:

- Natural, involving the use of solar energy;

- Biological, carried out through the biochemical decomposition of organic materials;

- Technical, which includes many specific technical techniques used to heat greenhouses, which became available after the development of innovative engineering techniques.

The implementation of each of the above methods is aimed at maintaining optimal microclimatic conditions in the greenhouse, namely, the optimal level of night and day temperatures, as well as air humidity.

Solar heating of greenhouses: a promising technique or a relic of the past?

Despite the rapid development of technology, heating based on solar energy remains one of the most reliable and promising methods of heating greenhouses. This heating technique is based on the greenhouse effect formed inside the greenhouse, for the arrangement of which materials based on polyethylene, glass and many other transparent materials available to the consumer were used. From the point of view of specialists, this technique is one of the most cost-effective and environmentally safe, however, the seasonal variability of the amount of solar energy, which is especially relevant in the middle zone and northern regions, significantly limits its use. In this regard, there is a need for limited use of this technique or the conversion of solar energy into other types of thermal energy.

The essence of the technique, which is based on the greenhouse effect, is as follows: passing through the transparent coating of greenhouses, solar energy helps to heat the soil and other elements of the greenhouse, which, in turn, contribute to the gradual warming of the air, which is stored inside the greenhouse due to the density and reliability of its design .

Due to the fact that the amount of solar energy is an unregulated indicator, the goal of the greenhouse owner is to retain warm air inside the structure as efficiently as possible, which is achieved through the correct orientation of the greenhouse relative to the cardinal directions, the functionality of its structural forms, as well as the judicious use of additional heat storage methods.

This method is suitable for heating greenhouses made of polycarbonate and other transparent materials.

Biological heating of a greenhouse in winter: myth or reality?

Another of the most popular and low-cost methods of heating greenhouses is the biological method, which is based on the use of the biochemical activity of individual substances of organic origin. The most commonly used biological materials are horse manure, straw, wood waste and even household waste. During the process of decay, biological materials come into contact with the air, which promotes the activation of biochemical reactions, which are carried out with the release of thermal energy. And what’s interesting is that this energy is released in large quantities, sufficient to heat greenhouses in the winter.

In addition, humus of plant origin is an equally popular biological fuel. To prepare such humus, freshly cut grass is poured into a wooden barrel and a 5% urea solution is added, after which it is covered with a wooden lid and left for 14 days.

Technical heating methods: what to choose?

To avoid unpleasant surprises presented by capricious winter weather, experts advise using additional heating sources that will help protect the crop from the harmful effects of low temperatures.

Technical methods for heating greenhouses are especially relevant in northern latitudes, where severe frosts cause considerable problems for summer residents. You need to know that the lower the air temperature drops, the more difficult it is to achieve the required indicators inside the greenhouse. In this regard, there is a need to arrange an uninterrupted heating system.

Heating a greenhouse with gas

Gas heating of a greenhouse, from the point of view of professionals, is the most acceptable in terms of price-quality ratio. There will be no problems with heating a greenhouse with gas if your site is completely gasified.

In this case, to heat the greenhouse, it uses a system of gas heaters or burners, which are evenly distributed around the perimeter of the heated room. In the case of a small greenhouse area, gas cylinders can be used as a heat source, while for large heated areas, you will have to resort to a centralized connection of the greenhouse to the main gasification system.

Gas heat sources are a source of carbon dioxide necessary for plant life. To ensure uniform distribution of carbon dioxide, fans are installed throughout the greenhouse.

Heating a greenhouse video

Heating a greenhouse using electricity

As a cheaper alternative to gas, which you need to pay close attention to, is electric heating of the greenhouse, which is organized using mobile fan heaters. The design of such devices includes built-in thermostats, which greatly facilitates the operation of such devices and allows you to achieve the required air temperature in the shortest possible time. If you plan to organize year-round operation of the greenhouse, it is advisable to supplement its design with a fairly high base, the most suitable material for which is brick.

Heating a greenhouse using electric fans that blow warm air is not the only way to heat a greenhouse using electrical energy. No less common is cable heating of a greenhouse, which is organized according to the principle of a “warm floor” system. The main advantage of this method is that its implementation does not require taking up a lot of space in the greenhouse, so the entire system is laid underground, which not only saves greenhouse space, but also promotes better heating of the soil and then the air. Heating a greenhouse space with a heat cable, from the point of view of professional summer residents, is much more profitable, since it provides, first of all, warming of the soil, which makes it possible to regulate temperature conditions in accordance with the stage of plant development. In addition, by choosing cable heating for your greenhouse, you can significantly reduce heating costs by installing an automatic temperature control system, the control of which will not cause any difficulties.

Heating the soil in a greenhouse using an electric cable is considered one of the most reliable methods of heating a greenhouse space, which has a lot of undeniable advantages, among which special attention should be paid to:

- A significant increase in the range of cultivated plants (you can even grow subtropical plants that are extremely demanding on temperature conditions);

- Independence from changing temperature conditions of the external environment;

- Accelerating plant growth and prolonging their fruiting;

- Increased productivity;

- And, of course, ease of installation.

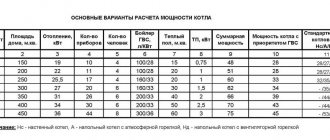

How to heat a greenhouse using an electric cable?

- The process of arranging a heating system begins with laying a heat-insulating layer, which can be filled with materials that do not absorb moisture, for example, polystyrene foam;

- Next, the thermal insulation layer is covered with a layer of waterproofing, for the arrangement of which a polyethylene film is suitable;

- Next, a layer of sand equal to at least 10 cm is laid, on top of which a heating cable is laid, the laying step of which is 15 cm. A 5-centimeter layer of sand is poured on top of the cable;

- To prevent damage to the heat cable, a chain-link mesh is laid on top of the sand layer;

- At the end of the work, a layer of fertile soil equal to 35-40 cm is poured on top of the finished heating system.

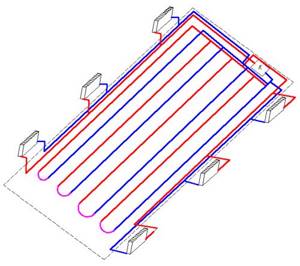

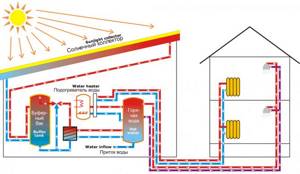

Water heating of a greenhouse

The layout of it is also quite simple. Along the perimeter of the greenhouse, for example, under the beds or shelving, a double row of water pipes is laid, which are subsequently connected to an electric boiler. To connect the boiler, which can be installed both outside and inside the greenhouse, you need to run an electrical cable into the greenhouse. According to experts, it is most profitable to install the boiler outside the greenhouse, which must first be insulated in order to reduce heat losses.

Infrared heating of a greenhouse: how to reduce energy costs?

Heating a room using infrared radiation continues to successfully gain recognition among consumers. The implementation of infrared heating in a greenhouse can significantly reduce energy costs and, at the same time, achieve the most uniform distribution of air inside the heated room.

Infrared heat sources must be installed around the perimeter of the greenhouse, as well as along the external walls, which will significantly reduce the heat losses of the structure. Having given preference to infrared heating, you should know that, in contrast to convection heating, it helps to heat surrounding objects, which subsequently transfer thermal energy to the air.

It is on this principle that the significant energy savings that can be achieved by choosing infrared heating of a greenhouse are based.

Having considered the most common methods of heating greenhouses, we consider it necessary to note that the main goal pursued by the organization of a greenhouse heating system is to create the optimal temperature and humidity of the environment, the most favorable for increasing productivity in cold seasons. We believe that in order to competently and most rationally solve this problem, an integrated approach is required, which involves selecting the most durable greenhouse heating system, functioning in two main directions, namely:

- Warming up the air;

- Warming up the soil.

If we consider the problem in this context, then the most optimal system is cable heating of the greenhouse, which will simultaneously provide both soil heating and air heating, which will be the key to the successful functioning of the heating system and a significant increase in productivity.

Heating a greenhouse using solar panels

The greenhouse can also be heated with devices that absorb solar rays.

To create such a heating system:

- first they dig a hole about 15 centimeters deep;

- then a layer of polystyrene or any other heat-insulating material is laid on the ground;

- a plastic film is placed on top to provide waterproofing;

- Wet sand and soil are poured onto the film on top.

This system is very simple and does not require financial costs, but at the same time it is quite suitable for maintaining the temperature in the greenhouse that is optimal for plant growth. In this case, there must be special devices on the roof that will absorb solar energy and thereby help heat the greenhouse. It is worth considering that in winter such a system will be ineffective - on cloudy days the greenhouse will not be able to warm up (pro

How to heat a greenhouse with a candle. Why is heating used in greenhouses?

If you heat shelters for growing crops, this will help to significantly extend the period of harvesting, and will also allow you to harvest the earliest possible harvest. Well-established heating will allow you to grow plants all year round and get several harvests.

In this case, it is best to use a permanent greenhouse and install heating in it. In this case, it is necessary to organize automatic control or constantly monitor the process.

Such systems can help in growing heat-loving exotic crops in regions with harsh climates.

It will be important to install a heater in a cold greenhouse in climates with short summers or changeable springs with recurrent frosts.

Important! When choosing a heater for a winter greenhouse, you should take into account the parameters of the greenhouse and climatic conditions, the power and efficiency of the device, and the budget. We should also not forget that the cost of vegetables grown in shelters should not be higher than the cost of heating.

When and how to use

It makes sense to use heaters at such times:

- In the spring. It is used for earlier planting of seedlings or sowing seeds for seedlings, while taking into account the characteristics of the crops being grown. For example, the minimum soil temperature for tomato seeds to germinate is +10°C, but at +16°C they will sprout faster. For normal development of seedlings, the air temperature at night should not be below +15°C, and temperatures below +12°C are generally undesirable. Such heat-loving crops are planted when the soil warms up to +10...+12°C. And radishes and greens sprout already at +3...+5°C. In sheltered areas, the soil temperature is usually only a few degrees warmer than in open beds.

If you use heaters, then all sowing or planting work can be done earlier. As the weather warms up, heating can only be left on overnight. But you shouldn’t get carried away with it so that the temperature difference necessary for the crops remains. - In summer. Sometimes even in summer, in some regions temperatures drop to critical levels. But usually there is no need for heating at this time in protected ground.

- In autumn. When temperatures begin to decline and the nights become colder, heating at night becomes important.

- In winter. It is very important during the cold period to constantly maintain the required conditions for growing crops. The use of heaters makes sense in capital or well-sealed rooms with well-established lighting and the use of automation. Not every device can handle this.