Inductive-conductive electric heaters (sometimes, for simplicity, they are called induction or vortex) appeared on the heating equipment market in the 90s of the last century and since then have significantly displaced the most common heating element and electrode boilers at that time. The balance of power has changed noticeably since then. Induction heaters have gained a share of about 30%, and this share continues to increase. Previously, we already looked at what the fundamental difference between these types of heaters is (here), but now we have to understand in more detail what is the reason for the success of induction heaters, because they are more expensive than their heating element counterparts. And the reason is economics. This is what we will count today.

What is more important: acquisition cost or ownership cost?

Unlike countries with long-standing market traditions, in Russia the practice of calculating the full costs of purchasing and operating equipment over its entire service life is still not widespread. To some extent, this is due to economic uncertainty and short planning horizons at domestic enterprises. Most companies live for today, limiting themselves to plans for the next financial year. Therefore, the main criterion when choosing equipment is often the cost of its acquisition. The rest of the consumer properties of the product take a secondary role: “so what if this heater works 10 times longer? Who knows what will happen to us in a year? Maybe we'll go broke or I won't work here. Why overpay?!” Unfortunately, such “argumentation” often comes up when issues of allocating funds for this or that rather expensive equipment are discussed. As a result, poor or short-sighted decisions are made.

►See Equipment for autonomous heating in our catalog

In countries with developed economies, such questions cannot arise in principle, especially in relation to equipment on which the life of an enterprise depends. To be fair, it should be noted that many of our specialists and managers practice a balanced approach in their work: not only the purchase price is taken into account, but also those costs that will arise during operation over a long period of time (ideally, during the entire service life equipment). The most prudent and far-sighted also calculate the risks associated with ownership and operation - this is a sign of their highest professionalism. Our article can help such specialists.

Regarding efficiency

In terms of performance, boilers are selected on the basis that per 10 sq. m of area for efficient heating there must be at least 1 kW of power consumption, this is provided that the boiler is single-circuit; if it has two circuits, then 25% must still be added to the power consumption.

When choosing a boiler, not only its type is taken into account, but also its performance, the area of the room it must heat, the cost of the equipment, the availability of space for its installation, efficiency, and service life.

But this also depends on the room itself - its area, whether the walls are insulated, what windows and doors are installed.

Based on this, it is decided whether heating the premises with electric boilers will be economically feasible.

For example, heating a large room with them is ineffective, but it can be used as an additional boiler that uses any type of fuel.

This all indicates that the efficiency of using a boiler and its cost-effectiveness is an individual matter.

For some rooms, primarily small ones, this heating method can be very economical; for medium-sized rooms, calculations should already be made.

Payment terms

To ensure that our comparison is objective and impersonal, we will not use specific brands of equipment or specific objects in our analysis. Moreover, since the price range is extremely wide, there is no point in choosing a specific brand of product. We use average figures, which, however, are subject to comparison: prices, power and completeness of conventional products are quite comparable. 50 kW is the power of the induction heater and 50 kW of the heater (and in the latter, we will assume there are only 10 heating elements of 5 kW each).

We will compare at current average prices, without taking into account inflation and regional reference, since if you enter this data, the calculations will become much more complicated: each region has its own tariff setting, and the official inflation rate has little connection with the level of annual growth in electricity tariffs, so we will omit these factors .

We are not particularly interested in the characteristics of the heated object: if heating a room requires 50 kW of energy (or 43,000 kcal), then it does not matter which heater we choose - a heating element or an induction one - to maintain the desired temperature, they must produce the same amount of heat. We can only say that a 50 kW boiler can approximately heat a facility with a total area of about 600 m2 with a ceiling height of 3 m (responsible boiler suppliers will never recommend their equipment without assessing the facility where the equipment will operate and will always offer to make a calculation based on specific characteristics object).

Some types of boilers and their characteristics

Next, we will consider one of each type of electric boilers. It should be noted that many companies produce several types of boilers. One of these is the company Galan (Russia).

We took this company not for advertising purposes, but because this manufacturer really has a lot of models, so it’s easier to find something to use as an example.

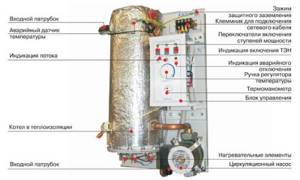

Let's take the average models. Among the heating elements, for example, Galan Geyser Turbo 12 kW.

This boiler has a cylindrical shape and can be used either as a floor-mounted or as a wall-mounted boiler.

The length of this heater is 500 mm, the power is 12 kW, so it is indicated that it is capable of heating a room up to 300 cubic meters, although, as already said, everything depends on the thermal insulation of the room itself.

This model comes with a control unit. It is three-phase, so it operates from a 380 V network.

But the Galan Geyser-9 model can already operate from a 220 and 380 V network.

This model is also very compact, its length is only 360 mm. Its power is 9 kW and can work with a coolant volume of up to 100 liters. The manufacturer indicates that this boiler is capable of heating a room with a volume of up to 340 cubic meters. m.

But this manufacturer does not produce induction boilers. Therefore, we will consider one of the models of the manufacturer SAV PROF series.

Let's look at the parameters of the SAV 5 model.

This boiler has a power of 5 kW. At the same time, it is capable of heating a room with a volume of up to 200 cubic meters. It operates from a 220 V network, and as for its size, it cannot be called small, its height is 640 mm with a width of 455 mm.

Popular among readers: Are infrared heaters worth buying?

Operation of electric boilers: first year

The main costs in the first year of operation will obviously be investments in the purchase and installation of equipment. Induction heaters are more expensive, but their installation and startup is no more difficult than that of a heating element boiler. Operating costs in the first year are also almost the same:

| First year | Induction heater | New heating element |

| Purchase cost | 145 000 | 40 000 |

| Safety stock 1 heating element (2 pcs.) | 0 | 4 000 |

| Heating period2, days. | 200 | 200 |

| Continuous operation time3, hour/day. | 10 | 10 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub/season | 50×200×10×2,8=280 000 | 50×200×10×2,8=280 000 |

| Accident risk4 | 0 | 0 |

| Costs of consumables, rub. | 0 | 0 |

| Labor costs for operation5 | 0 | 0 |

| Total expenses at the end of the period | 145 000+280 000=425 000 | 40 000+4 000+280 000=324 000 |

1It is not necessary to create a stock of replacement elements, but this threatens, in the event of an emergency failure of the heating element, with a reduction in the design power of the equipment, therefore most operators of heating element boilers create a stock of heating elements. And they do it right!

2In Russia there are different climatic zones, and accordingly, the duration of the heating season is different - from 148 days (in Maykop) to 311 (in Anadyr). We use an average figure of 200 days (approximately the latitude of Lipetsk or Tambov).

3If the heater operates continuously during the season, then the equipment is not selected correctly. Typically, equipment is selected in such a way as to work, on average, for 8-10 hours a day

4An accident is considered to be the failure of the heating element, or a decrease in its power by more than 50%. The service life of the heating element is about 5,000 hours. However, there is a possibility that it will last less or longer than expected. We will not consider the “less” option: let’s say that neither the manufacturer of the heating element boiler nor the manufacturer of the induction boiler allowed the defect. And in the first year (2,000 hours of operation) not a single heating element burned out.

5It is absolutely impossible to do without labor costs: an energy specialist, one way or another, must carry out preventive maintenance and monitor the operation of the equipment, however, since there were no equipment failures, we will assume that the operating costs in the first year for the two types of electric boilers are approximately equal and will not take them into account.

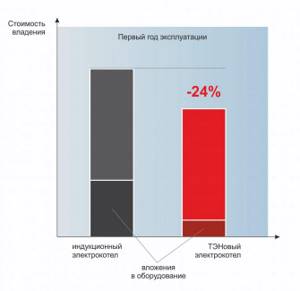

As a result, the first year of operation ended with a convincing superiority of the shadow electric cat. The costs for it, taking into account the purchase of equipment, are almost a quarter lower. Can we celebrate the victory? It's a bit early. The equipment was purchased for more than one season - we’ll see what happens next.

Advantages and disadvantages

Heating devices such as induction boilers, like other similar units, have their pros and cons. It is necessary to familiarize yourself in detail with both their positive and negative sides if you are going to install such equipment in your home. First, let’s look at what is good about induction types of heating boilers.

The main advantage of such units is their reliability. If such products have automation, then they can operate autonomously, and the owners do not have to constantly monitor them. In this case, only the absence of a thermal fluid can lead to a breakdown of the device - then the core body in the system can overheat too much and, as a result, melt.

Induction boilers are distinguished by high efficiency (over 90%). Of course, the specific value mainly depends on the design of the heat exchanger in the unit and other structural features of a particular model. The advantages of such units include the fact that their efficiency does not decrease over the years, so even after a long time you will not notice that your heating system has become less efficient.

Induction heating equipment is not subject to breakdowns - it will not require frequent and expensive repairs. To install such a unit, there is no need to additionally construct ventilation or a chimney, which often costs users a tidy sum.

Such equipment serves for quite a long time. If you use these types of heating boilers correctly, they can last more than 30 years, since there is nothing to burn in them, because the inductor is hermetically sealed in the housing and is reliably insulated from contact with the coolant. In addition, the coils are not twisted tightly and are filled with a special protective compound. For this reason, the possibility of damage to the turns is minimized.

The liquid in such systems is heated to high temperatures. The minimum value is 35 degrees Celsius. Such units are installed quite simply. Household models are a small piece of pipe, which is sealed on both sides. There are 2 fittings on the housing, which are necessary for connecting the coolant supply and return. There is also a cord to connect the automation. Connecting such systems is not particularly difficult - you can cope with this simple work without the involvement of specialists.

Induction heating systems are characterized by high operating efficiency. They are characterized by low inertia, so heating of the coolant begins very quickly (immediately after the system starts). Such boilers turn off just as quickly. In such a device, the waste coolant does not need to be changed too often. It is enough to do this once every 10 years.

These types of heating devices, as a rule, do not leak, since they do not have detachable internal connections. These units are capable of operating at both direct current and low voltage. According to experts, harmful scale does not accumulate on the heating element in such devices. This occurs due to the vibration of the core (because of this, excess particles cannot be deposited on it). In addition, scale will not accumulate due to the temperature of the coolant (not higher than 90 degrees Celsius) and the closed nature of the system, in which a limited number of carriers may be present.

Now it's time to get acquainted with their disadvantages:

- First of all, a number of disadvantages of such devices include their high price. They cost several times more than devices with heating elements. However, the high cost is due to the presence of automation.

- Usually these devices have an impressive weight. For example, a cauldron with a diameter of 12 cm and a height of 45 cm will weigh as much as 23 kg.

- These boilers are suitable exclusively for closed heating systems.

- Such units can create wave interference at a short distance. For this reason, experts advise installing them as far as possible from any household appliances.

- If you are going to install an induction boiler in a large house with 2-3 floors, then you will have to additionally install a high-power circulation pump - this is necessary for the device to operate stably.

- Induction units are energy dependent. If the electricity in your home is turned off, the heating will also stop working. Of course, this problem can be solved - you can purchase diesel generators, but this will be an additional expense.

Operation of electric boilers: second year

It’s not very obvious yet, but changes are starting to happen. Due to the high surface temperature of the heating elements of the heating element boiler, water boils in the boundary layer and scale is inevitably deposited. Its micron thickness is not even visible to the naked eye, but even such scale significantly reduces heat transfer, which is why heat removal decreases. The heating element heats up more, but the water, on the contrary, heats up worse. According to various estimates, the heat transfer efficiency of a heating element boiler may drop by 20% already in the first year of operation. We will try to be extremely objective and calculate this figure as equal to 10%, and only from the second year of operation. In real terms, this would mean that the heater would have to run 10% longer than a brand new heater to produce the required amount of heat energy.

An induction heater does not have such problems: the developed heat exchange area of the heat exchange device and the small temperature difference between the coolant and the heat exchanger (only 10-20°C) do not create conditions for scale deposits. In addition, natural magnetization of water occurs in an induction heater, which also increases its resistance to scale formation. There is no loss of power.

In addition, the heating elements have already worked for 4000 hours and are close to expiring their warranty period. The probability that one of the elements will require replacement during the second season is small - let’s take it equal to 10%. That is, out of ten heating elements, one will have to be replaced. The price of the heating element seems insignificant - about 2000 rubles. However, the electrician will have to work with the installation, and labor costs begin to count.

| Second year | Induction heater | New heating element |

| Heating period, days. | 200 | 200 |

| Continuous operation time, hour/day. | 10 | 11 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub/season | 50×200×10×2,8=280 000 | 50×200×11×2,8=308 000 |

| Risk of accident | 0 | 10 |

| Costs of consumables, rub. | 0 | 2,000 (replacement of 1 heating element) |

| Labor costs for operation* | 0 | 190 |

| Current expenses for the period | 280 000 | 308 000+2 000+190=310 190 |

| Total expenses on a cumulative basis | 425 000+280 000=705 000 | 324 000+310 190=634 190 |

*We will assume the time to replace the heating element to be 1 hour (although in reality this figure may vary greatly). We have prudently created a stock of heating elements, so time is spent only on replacement. With an electrician's salary of 30,000 rubles/month. the cost of replacing one heating element will be only about 190 rubles. If a third-party specialist does the work, it will be about 10 times more expensive.

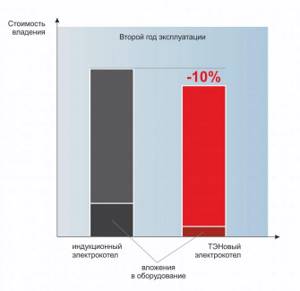

As you can see, at the end of the second year of operation, a heating element boiler turns out to be more profitable than an induction boiler, although not by such a convincing margin: the difference in costs is only about 10%. At the same time, the heating element heater begins to attract unnecessary attention. How much of this attention is required depends on the quality of the boiler itself, the operating conditions, and the quality of the coolant preparation. For now, we are considering a fairly favorable situation for heating elements, so that we are not accused of subjectivity and the desire to denigrate a competitive product.

Electrode type

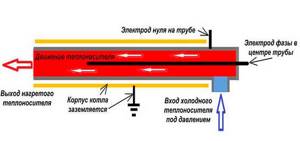

The second type of electric boilers, electrode boilers, operate on a slightly different principle.

They do not have a heating element as such; only special electrodes are located inside such a boiler.

The task of these electrodes is to transmit electrical impulses to the heat carrier – water. And since water has resistance, when an electric current passes through it, it is split at the molecular level into positive and negative particles, which rush to the electrodes of the desired polarity.

The whole process is accompanied by the release of a large amount of energy (heat). That is, the water itself heats up due to its resistance.

The boiler itself has an outwardly simple design - a housing with outlets for connecting it to the heating system, and electrodes are located inside.

Some boiler models are equipped with a control system, but there are also models for which the control and protection unit is purchased separately.

It is worth pointing out that with this type of heating, spontaneous circulation of water does not occur.

When using this type of heating boiler, it is necessary to have a circulation pump in the heat supply system.

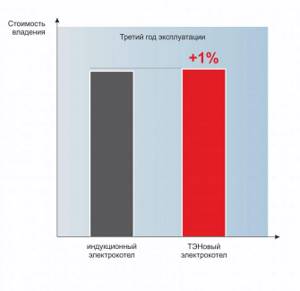

Operation of electric boilers: third year

The changes that began at the end of the first year of operation are beginning to progress. There is more and more scale, although it is still not visible to the naked eye, and the system was flushed with an anti-scale agent in the summer. However, the design of the heating element is such that a drop in power occurs not only due to scale deposits, but also throughout its entire service life. Continuous operation time increased by another 15%. The warranty limit of 5000 operating hours has been exceeded. Of course, all heating elements will not burn out at once, but from this moment the countdown of days to an accident begins. The risk of failure increases significantly – up to 30%.

There are few changes in the induction electric boiler. During the summer, as a preventative measure, his heat exchanger was also washed and its energy characteristics remained unchanged.

| Third year | Induction heater | New heating element |

| Heating period, days. | 200 | 200 |

| Continuous operation time, hour/day. | 10 | 12,65 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub/season | 50×200×10×2,8=280 000 | 50×200×12,65×2,8=354 200 |

| Risk of accident | 0 | 30 |

| Costs of consumables, rub. | 0 | 6,000 (replacement of 3 heating elements) |

| Labor costs for operation* | 0 | 570 |

| Current expenses for the period | 280 000 | 354 200+6 000+570=360 770 |

| Total expenses on a cumulative basis | 705 000+280 000=985 000 | 634 190+360 770=994 960 |

And so, by the end of the third heating season, the scales swung in favor of the induction boiler. Not only has the inductive-conductive unit become more cost-effective, but the shadow unit has also begun to constantly distract attention: there has been a noticeable increase in worries about it.

Cost of heating devices of different types and manufacturers

Heating element varieties have a large difference in cost depending on the brand and power.

| Brand | Price | Power |

| "VAILLANT" (VILLANT) | from 40699 to 51480 rub. | from 6 to 28 kW |

| "ZOTA" (ZOTA) | from 4899 to 376005 rub. | from 3 to 100 kW |

| "PROTHERM" (PROTHERM) Skat series | from 38499 to 47840 rub. | from 6 to 28 kW |

| "EVAN" | from 7800 to 672735 rub. | from 3 to 500 kW |

| "RUSNIT" | from 12100 to 30600 rub. | from 5 to 24 kW |

| "ACV" | from 124,000 to 1,056,850 rubles. | from 8.4 to 263 kW |

Prices for Vaillant electric boilers

Vaillant electric boilers

Induction devices are not represented by such a variety of brands as heating elements.

| Brand | Price | Power |

| Vortex Induction Heater VIN | from 35,000 to 195,000 rub. | from 3 to 80 kW |

| Induction electric boiler SAV | from 29950 to 1400000 rub. | from 2.5 to 500 kW |

Galan offers electrode units for selection.

| Brand | Price | Power |

| Galan "Hearth" | from 3900 to 4050 rub. | from 2 to 6 kW |

| Galan "Geyser" | from 7500 to 7600 rub. | from 9 to 15 kW |

| Galan "Vulcan" | from 7400 to 12100 rub. | from 25 to 50 kW |

All Galan “Ochag” devices are recommended to be operated using mechanical or automatic control devices. If these devices are used in an electric heating boiler, the price of Galan “Ochag” with a mechanical temperature regulator will increase from 7,800 rubles and with an electronic regulator - from 10,000 rubles.

Very small but powerful Galan boiler units are small in size and have low prices, but for their operation it is additionally necessary to purchase automatic control elements, which can be purchased in Moscow. Heating and cooking stoves with oven you will find the answer in the link.

Prices for electric boilers RusNIT

electric boilers RusNIT

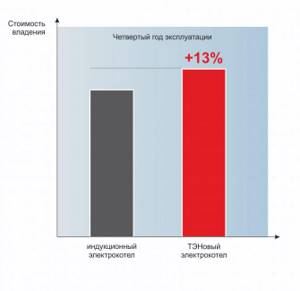

Operation of electric boilers: fourth year

There are no significant changes in the economy of our enterprise. We are already accustomed to the fact that during the season we need to regularly monitor the operation of the heating element boiler. They even installed a GSM control system on it. But we will not take these costs into account: after all, we agreed that we are evaluating a “clean pot” without piping.

Thermal productivity continues to decline, by 20%. It is due to the fact that the old heating elements are working. Their reliability is deceptive: they work, but they don’t provide power. As they say, it’s a pity to throw it away, but it’s more expensive to keep it.

By the end of the 4th year of operation, almost all heating elements that were once new had to be replaced. Still, some of them honestly worked 10 thousand hours – an excellent indicator.

With an induction heater you can only wipe off dust - absolutely nothing else.

| Fourth year | Induction heater | New heating element |

| Heating period, days. | 200 | 200 |

| Continuous operation time, hour/day. | 10 | 15,18 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub/season | 50×200×10×2,8=280 000 | 50×200×15,18×2,8=425 040 |

| Risk of accident | 0 | 50 |

| Costs of consumables, rub. | 0 | 10,000 (replacement of 5 heating elements) |

| Labor costs for operation* | 0 | 950 |

| Current expenses for the period | 280 000 | 425 040+10 000+950=435 990 |

| Total expenses on a cumulative basis | 985 000+280 000=1 265 000 | 994 960+435 990=1 430 950 |

By the end of the fourth year of operation, the induction heater is already an absolutely confident leader in our competition, actually saving the enterprise money, not only monetary, but also time and human.

Only one thing can be said about the tensile boiler: if this continues, the electrician will only deal with it and will have to hire another one to work with the rest of the equipment...

How to choose

The main question is which boiler design to choose?

Two main criteria that lead to the choice of an electric boiler:

- Low cost of equipment and installation;

- Difficulty or impossibility of arranging the supply and storage of another type of fuel.

If you focus only on these two criteria and remember the high cost of electricity, then the best choice would be a simple heating element boiler with a programmer. It is durable and has the fewest operational features. As with any other type of boiler, it is necessary to prepare the coolant, which is easily solved in a private home, and the preparation for heating elements is the simplest. It is enough to use demineralized water.

The programmer will allow you to set the optimal operating mode. Even the difference in the cost of electricity during the day and night is taken into account, as well as the time people spend in the house when maximum heating is required. All this leads to optimization of energy consumption and savings.

Comparing the real costs of installing and servicing a heating element boiler over five years of operation, you may not see the difference at all with gas equipment, and even more so with solid fuel. In addition, comfort increases immeasurably.

An electrode boiler has one undeniable advantage - a high heating rate of the coolant. One additional consequence is added to this: it is excellent for installing natural circulation in a heating system, because it creates a powerful output flow due to a large temperature difference.

However, there are a huge number of requirements for the quality of the coolant, connection method, etc. in addition to the high cost, they complicate the choice of electrode design.

An induction heating boiler for a private home can be called the best option if it is possible to immediately shell out a large sum for the purchase of equipment. Naturally, it makes sense to purchase such expensive equipment only if it is equipped with a normal programmer and the choice of the optimal operating mode.

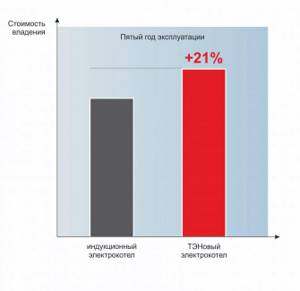

Costs in the fifth year of operation

It seems that we have finally entered operating mode with the heating element boiler: everything has become more rhythmic and ordinary. Yes, you have to pay more for electricity, yes, you have to buy heating elements, yes, recently replaced elements begin to fail (the quality is dropping, perhaps?) and there was an unpleasant incident when a low-quality heating element broke and voltage “went” into the system. It’s good that the heater was grounded at the very beginning, otherwise troubles could not be avoided...

In general, it’s good that we only have a 50-kilowatt heater. What if it was 350? 7 times 50! How many heating elements are there, and how much would all our worries and expenses increase?

The induction heater hums slowly. After all, it is the “brother” of the transformer. It seems to be buzzing a little louder. Although, perhaps, this only seems - there is simply nothing more to complain about.

| Fifth year | Induction heater | New heating element |

| Heating period, days. | 200 | 200 |

| Continuous operation time, hour/day. | 10 | 15,18 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub/season | 50×200×10×2,8=280 000 | 50×200×15,18×2,8=425 040 |

| Risk of accident | 0 | 50 |

| Costs of consumables, rub. | 0 | 10,000 (replacement of 5 heating elements) |

| Labor costs for operation* | 0 | 950 |

| Current expenses for the period | 280 000 | 425 040+10 000+950=435 990 |

| Total expenses on a cumulative basis | 1 265 000+280 000=1 545 000 | 994 960+435 990=1 430 950 |

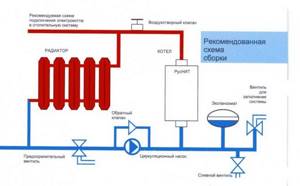

Briefly about installation

Installing any electric boiler is not particularly difficult. The main task is to supply pipelines to the boiler, with the correct location of the water supply and drainage pipelines.

The diameter of the pipes must correspond to the diameter of the inlet and outlet pipes.

Afterwards, the boiler is either fixed to the wall or installed on the floor.

Then the pipelines are connected to the pipes. If the design requires the presence of a circulation pump, then it must be installed on the supply pipe.

It is also necessary to install taps that shut off the water both at the entrance to the boiler and at the exit.

All pipelines must be connected using sealing materials.

Next, coolant is poured into the system to check the quality of the connections. If leaks are detected, the squeegee at the point where it appears must be tightened.

If there is a pump, it will also need to be turned on so that it creates fluid movement.

The last step is to connect the boiler to the electrical network, and when powering the boiler, you need to use a circuit breaker with suitable parameters.

Then a test run of the system is carried out and its operation is checked, as well as configuration and installation of operating parameters.

Payback period for an induction heater

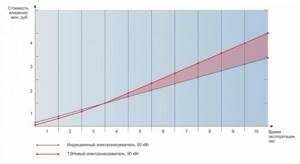

It makes no sense to describe all subsequent years of operation: the algorithm is already clear. Let's just say that from about the middle of the 3rd year of operation, the heating element boiler confidently breaks away from the induction boiler in terms of cost of ownership. And every year these costs will only grow.

I must say that we considered one of the most pessimistic forecasts for an induction heater - we dealt with heating element boilers as diplomatically as possible, because in fact:

- It rarely happens that a heating element lasts longer than 7,000 hours in a water heating system (we counted the operation of some heating elements for more than 10 thousand hours!).

- The power drop of a heating element boiler that has been running for some time can be up to 20% of the nominal value already in the first year of operation. We considered that in the first year there was no decline at all, and only the next year it happened. And that's only 10%.

- We considered that our staff already has the necessary energy specialist who has sufficient qualifications to quickly replace the heating element, and he does not get sick, does not go on vacation and sits, so to speak, with the heating element and a wrench in his hands, ready to rush at the first call for repairs... Does this happen to you? And if the company uses the services of a third-party specialist, the cost of “replacement” will increase at least 10 times.

- We have hardly touched upon the topic of differences in the electrical safety of boilers, but they also have a financial dimension. Electrical safety class 2 for an induction boiler (i.e., there is virtually no risk of electric shock) and electrical safety class 1 for heating elements and the risk of voltage leakage through water into the heating system (of course, there is automatic protection and grounding, but the fact remains that the risks are higher) .

The service life of a heating element boiler, despite the constant replacement of heating elements, is unlikely to exceed 10 years. An induction boiler can operate up to 100,000 hours, because at its core it is a “dry” transformer, the service life of which will end only when the impregnation of the windings of its coils finally ages and crumbles into dust. But this will happen no sooner than in 30 years (more about this in our article Service life - 30 years?!)!

Induction boilers

Induction water heating boilers began to be used for industrial purposes back in the 80s of the last century, and in the mid-90s the first models for domestic use appeared.

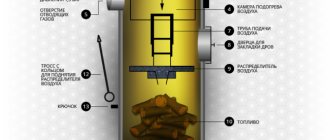

The operation of the boiler is based on the principle of electromagnetic induction. The main element of the system is an inductive coil, which, using a current of 50 Hz, creates an alternating magnetic field. The inductive coil is also a generator, which is due to the placement of the conductor in a magnetic field, thus reducing the level of electricity consumption. Due to magnetization reversal, the system of labyrinths made of ferromagnetic metal is heated, and thermal energy is transferred to the coolant with virtually no losses. Due to the design features and heating method, the use of induction boilers has a number of advantages:

— the absence of a heating element in direct contact with the coolant solves the problem of scale formation, which guarantees a constant efficiency and eliminates the need for periodic replacement of this element; — high efficiency (manufacturers declare up to 99.5%, but one must take into account the seller’s desire to somewhat exaggerate the merits of his product); — stable operation of the equipment practically does not depend on the ambient temperature, which reduces the probability of boiler failure to almost zero; — the boiler design has virtually no flanged or threaded connections, which gives it additional reliability and significantly reduces the likelihood of leakage; — thanks to the heating method used, almost any liquid (water, oil, antifreeze, etc.) can act as a coolant; no special requirements are imposed on it; — durability (at least 30 years) is due to the absence of moving parts; — simplicity and safety of operation.

To the disadvantages

This may include the rather high cost of such boilers, the impossibility of smooth load adjustment (only stepwise) and high weight compared to other types of equipment.

conclusions

In the worst case, when everything is not in favor of an induction electric heater, its purchase will still become more profitable after three years of operation. In practice, this deadline may come much earlier. And the higher the enterprise’s need for electric heating, and the more powerful the installations, the more profitable the purchase of induction electric boilers will be, because we based our calculations on a comparison of 50 kilowatt equipment and it’s not difficult to imagine how big the difference will be for, say, 500 -kilowatt electric boiler.

Comparison with fossil fuel boilers

- From an economic point of view, electric devices for space heating are inferior to fossil fuel boilers, because the price of 1 kWh of electricity is much more expensive than that obtained from fossil fuel.

- The absence of emissions of combustion products into the atmosphere, which means maintaining cleanliness during operation, is an advantage of electric boilers.

- A higher degree of fire safety is also an advantage of electric boilers.

- There is no need for storage facilities for solid fuel reserves.

- If possible, automatic control devices for heating the room, modern gas boilers are not inferior to electric ones.

- The use of double-insulated cable products for connecting electric boilers with a power of 3 kW or more is a necessary condition for their reliable operation.

- Strict attachment to the home's electrical supply system reduces the degree of independence of individual heating.

- Installing a gas boiler involves a lot of troublesome approvals and constant monitoring of the gas service, because it is an object that poses an increased danger to human life.

PS or answer to those who like to calculate NPV

There are specialists (usually with an economic education) who could say: “All this is nonsense! The author cites figures that are far from the real economy - he cites bare numbers, but in reality it is necessary to consider at least NPV (net present value), and then the whole picture may not be so rosy at all!”

Such arguments look ironclad. But only until we take and calculate this terrible NPV. Simply put, we can calculate how much we would earn if we had an amount of 145,000 rubles. and we could have bought an induction electric boiler, but we decided to save money and bought a shadow one for 40,000. And the saved money (105,000 rubles) would have been deposited in the bank at interest, and we would have even made money on it. Every year we would gain about 10% (in fact, most likely even less). By the end of the 5th year, we could withdraw 169,100 rubles from the bank. Those. would have received an additional 60 thousand in profit. There would be no limit to the joy until we returned to the calculations for our heaters. During the same time, we lost 321,940 rubles. - more than 5 times more than they earned. As they say, the miser pays twice. And then he pays extra.

What is such equipment?

Today, manufacturers produce many types of heating equipment that run on different types of fuel. Electric models are considered one of the simplest and most reliable.

They are:

- Tenovye

- Electrode

Let's look at each type. So, the first ones are heating devices, the operating principle of which is familiar to many. Electric heating elements for boilers, immersed in water, heat it to a given temperature. Ionic models differ from them in that in them the water becomes hot due to the movement of ions between the electrodes.