How necessary is a thermostat for heating?

Scientific and technological progress allows us to take advantage of new products that improve our lives.

About 30 years ago, special devices began to be used in the heating system, with the help of which it is possible to control the temperature conditions indoors. Heating thermostats - as these devices are called - have become an integral part of any heating system, regardless of the purpose of the room where it is used. The novelty appealed to both specialists and ordinary people. Using thermostats, you can not only regulate the flow and temperature of the coolant in heating radiators, but also, if necessary, completely shut off the supply of the latter. This makes it easier to repair or replace the device, since there is no need to stop the entire heating process and completely drain the coolant. So this is an indispensable device in all respects. Therefore, installing a thermostat is a very worthwhile investment.

Component materials

Together with an uninterruptible and automatic power supply, a pressure control relay is also used, this is a kind of time counter. The main task of the pressure control relay in the heating system is to ensure the continuous operation of the heating structure. When the pressure drops below the programmed norm, the above-mentioned device must start the pumping element and, conversely, when the pressure reaches higher values, it must turn it off.

Relay operating principle

The circuit and principle of operation of the relay, as one of the components for circular pumps, is very simple. At the end of the analysis, the pressure in the system will immediately increase to the highest limit, and with its help the device will temporarily turn off. When the water supply begins, which will be supplied under pressure, the pressure level will decrease. It will decrease until it reaches the minimum limit, then the relay will again start everything necessary.

Water regulation diagram

Thermostat

There are several more elements in the kit, one of them is a fluid regulator, it also regulates the operation of the circular pumping mechanism. The pump thermostat consists of a valve and a thermoelement. Its main task is to control the temperature level in the heating system. At the same time, there are several other different parts, for example, a water recycling device used in systems with autonomous heating.

Thus, automation for the circular pump control ensures uninterrupted operation of the entire structure. To select and install all heating elements, it is better to turn to professionals.

Why do you need a pump in a heating system?

Circulation pumps for heating private houses are designed to create forced movement of coolant in the water circuit. After installing the equipment, the natural circulation of liquid in the system becomes impossible; the pumps will operate in constant mode. For this reason, high demands are placed on circulation equipment regarding:

- Productivity.

- Noise insulation.

- Reliability.

- Long service life.

A circulation pump is needed for “water floors”, as well as two- and one-pipe heating systems. In large buildings it is used for domestic hot water systems.

As practice shows, if you install the station in any system with natural coolant circulation, the heating efficiency and uniform heating along the entire length of the water circuit increases.

The only disadvantage of this solution is the dependence of the pumping equipment on electricity, but the problem, as a rule, is solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private home is justified both when creating a new one and when modifying an existing heating system.

Operating principle of the circulation pump

The operation of circulation pumps increases the energy efficiency of the heating system by 40-50%. The operating principle of the devices, regardless of type and design, is as follows:

- The liquid enters a cavity made in the form of a shell.

- Inside the housing there is an impeller, a flywheel that creates pressure.

- The speed of the coolant increases and, through centrifugal force, the liquid is discharged into a spiral channel connected to the water circuit.

- The coolant enters the water heating circuit at a given speed. Due to the swirling of the water flows, the hydraulic resistance during fluid circulation is reduced.

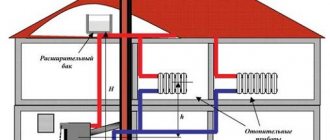

The operating principle of a heating system with a circulation pump differs from circuits with natural circulation in that the fluid movement is forced. The heating efficiency is not affected by slopes, the number of installed radiators, or the diameter of the pipes.

The operation of circulation pumps may differ slightly depending on the type of design, but the principle of operation remains the same. Manufacturers offer more than hundreds of equipment models, with various performance and control parameters. Based on the characteristics of the pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the location of the impeller and moving mechanisms in the housing. Thus, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. “Dry” models have high performance, but have several disadvantages: a high level of noise is created from the operation of the pump, and regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely enclosed in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of a “wet” type water pump in a heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in small domestic premises, has a mechanical regulator with three fixed speeds. Regulating the temperature in the house using a mechanical circulation pump is quite inconvenient. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. The automation independently analyzes the temperature in the room, automatically changing the selected mode. Electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose a suitable model, it will be enough to know about the nuances listed above.

Uninterruptable power source

Providing uninterrupted power supply for the automatic circulation pump is the key to optimal room temperature and stable operation of all devices. But before choosing a room heating scheme, it is necessary to study the positive and negative aspects of existing offers on the market. When choosing a heating concept with natural coolant circulation, it must be taken into account that its main disadvantage is the following:

- Heating in the room may turn off, or the set of devices will not operate at full capacity, unless special mechanisms are installed.

- Fuel consumption can be quite significant if the system operation scheme is incorrectly configured, which entails financial losses.

The way out of this situation is to purchase an uninterruptible power supply. Then, even if there is an unexpected power outage, the circulation pump system will continue to work, since it is equipped with automatic devices. The battery is equipped with an automatic system that ensures continuous operation of all components included in it if the power supply unexpectedly occurs.

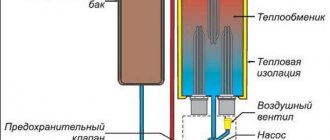

Operating principle of a boiler UPS

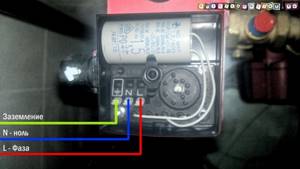

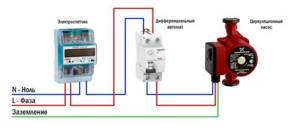

Connection diagram of the circulation pump to the electrical network

The connection diagram for the circulation pump to the electrical network is as follows:

Note. the pump connection diagram must contain either a differential circuit breaker (as in our diagram) or a combination of a protective circuit breaker and an RCD (Residual Current Device)

This is required, first of all, to protect a person from electric shock in the event of a pump malfunction or incorrect connection.

As you can see, there is nothing complicated in the circuit; to operate, a household circulation pump requires a phase and a zero (working zero), and in addition, an indispensable safety element is grounding (protective zero). Therefore, there are three contacts in the pump terminal box, with corresponding markings.

Detailed photo instructions for connecting the circulation pump to the electrical network, according to this diagram - HERE (link will open in a new window).

Most circulation pumps in heating systems are connected according to this standard scheme. The main disadvantage of which is that the pumps have to be turned on and off manually each time, so they are often turned on at the beginning of the heating season and turned off at the end. Disadvantages of this connection method. I think it is obvious that there is excess energy consumption and a decrease in the service life of the pump.

You can automate the operation of the circulation pump in the heating system in order to reduce energy costs and increase the overall service life of the pump by connecting it through a thermostat.

At the same time, the thermostat measures the temperature of the coolant and, if it is low, the circulation pump does not turn on, so as not to waste cold water (or other coolant) through the system, and when the temperature of the coolant at the boiler reaches the required level, the pump starts.

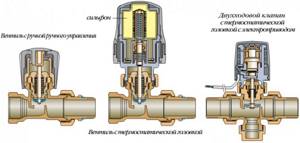

Operating principle

The operating principles of thermostats differ: for example, flow-through thermostats only block access to the coolant into the radiator circuit, while three- and four-way thermostats mix heated liquid with cooled liquid. Each thermostat has its own advantages and disadvantages. The installation of this device should be based on its operational characteristics.

In 1994, when construction companies, in accordance with the new SNiP, were required to equip heating systems with thermoregulating elements, only one enterprise in Kazan was engaged in the production of such devices. Today there are dozens of such manufacturers.

Mechanical models

The valve and thermal head are the main elements, without which it is impossible to imagine almost any thermostat. In this case, the latter performs the function of a sensitive element. These parts do not require external energy in order to function properly.

In turn, the thermal head also has several components. This is a regulator and drive, a liquid element, sometimes elastic or gas parts are found as an alternative.

Internal organization

When choosing a temperature controller, it is necessary to take into account all factors that may affect the operation of the device in the future. Its main parts are as follows:

- adjustable scale;

- ring that fixes the set temperature;

- mechanism of compensatory action;

- union nut;

- stock;

- spool;

- detachable connection;

- sensing element;

- thermostatic element;

- thermostatic valve.

Two-way thermostats

The operating principle of these devices differs significantly from those described above. They are the same valve, only with two pipes - for connecting to the radiator and the coolant supply pipe. In this case, no mixing of coolants occurs. The temperature is reduced by shutting off the hot water supply in the circuit.

But can such devices be classified as thermostats? Most likely it is possible. Let's look at the design of a simple mechanical device.

It resembles a mechanical thermostat, but the liquid filler can be replaced with gas or spring filler. In both cases, the efficiency of responding to temperature changes is sharply reduced. But still this is a reaction without the presence of a person. In this design, the main move is to shut off the main coolant supply circuit and reduce its speed. This is precisely what the work of such a mechanism is based on.

Materials used in the production of circulation pumps

This is a very important aspect that affects not only the quality of work, but also the cost of the unit. It is clear without words that contact of pump parts and assemblies with water brings a lot of trouble. Therefore, for the production of this type, high-strength materials are used that can withstand water with a fairly high temperature.

For example, today analogs are produced where the shaft, that is, the rotor, and bearings are made of ceramics. Such parts have high strength and a long service life. In addition, ceramics are not afraid of water. Plus, such parts work silently.

The average guaranteed service life of circulation pumps is at least ten years. Of course, the manufacturers' requirements here must be strictly followed, otherwise there are no guarantees. What do manufacturers require? Correct selection, correct installation, prepared coolant, preventing some negative indicators in the heating system, for example, air inside.

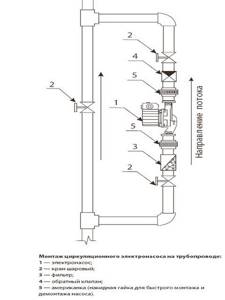

Circulation pump connection

If the pump was not previously included in the heating system. it is required to be “inserted” into the pipeline. Since this operation requires the performer to have some skills and the presence of special equipment, it can be entrusted to professionals, or you can do the work yourself, having previously familiarized yourself with the technology of pipeline installation. The order of work and the list of equipment used will depend on the selected insertion method and pipeline material.

There are 2 ways to insert a circulation pump:

- on the main section of the pipeline;

- on the bypass section (bypass).

Installing the unit on the main site requires less time and money, but has one significant drawback. The pump operates from the mains power supply, so with this installation method, during a power outage in the apartment or house, the heating will not be able to function.

The second method is more complex, but provides the heating system with an increased level of autonomy. In this case, when the system operates in normal mode, the coolant moves through the bypass channel, and the corresponding section of the main line is closed using a specially installed ball valve. During a power outage, the faucet opens and liquid moves through the pipeline naturally.

Installation diagram of the pump on the bypass channel (bypass).

Although this option is common, it has one big drawback - the tap is on the main line. It is better if a ball valve is installed instead of a tap.

Installation of a pump on the supply of a gas floor boiler in a heating system with natural circulation. An article on the topic “How to choose a gas boiler” may be useful to you.

During normal operation, the valve is closed by excess pressure created by the pump above the ball. If the pump is de-energized, the ball rises under the pressure of water moving naturally along the line. This option is relevant if the pump is installed on the “supply” side for one reason or another.

Pump tap-in installation kit includes:

- pipes of the required diameter;

- elements of pipeline fittings;

- union nuts (for polypropylene pipelines) or bends (for steel pipes);

- dirt filter;

- shut-off valves;

- check valve

The diameter of the pipes for tapping must correspond to the diameter of the already installed pipeline, and their total length is determined based on the results of measurements in the area where the pump is intended to be installed. A set of pipeline fittings is selected in the same way. Union nuts (or clamps) are used for quick installation and removal of the pump.

The dirt filter is installed directly before the entrance to the unit. It is necessary to protect the pump from contamination, the source of which may be deposits on the inner surface of the pipelines. The drainage hole of the filter should be directed downward to allow periodic cleaning.

Shut-off valves are placed at the inlet of the pump in front of the filter and at the outlet of it so that, if necessary, the unit can be dismantled without stopping the entire system. When installing a supercharger in a bypass section, an additional valve is installed on the main line parallel to the pump. The check valve is designed to protect the system from water hammer. It is mounted at the outlet of the pump in front of the shut-off valve.

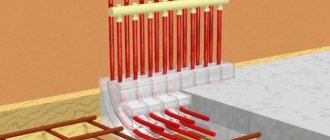

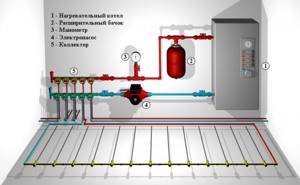

How to independently connect a heated floor to a heating circuit?

Warm floors are an effective heating system for any room. The connection diagram for each model depends on the features of the heating equipment. There are three options: water, film and electric floors. Different operating principles imply differences in installation and activation. The connection procedure begins after a suitable model has been selected and installed with all the technology requirements.

Water heated floor

Connection to an existing heating system is possible if the apartment is on the first or last floor. This requires an upper and lower hot water connection, respectively. Since the carrier rotates in this place, you don’t have to worry about energy leakage for heating neighboring apartments. In private houses this problem does not exist. Before starting work, you need to prepare the equipment and consumables:

- Collector and thermostats.

- Plastic pipes.

- Boiler and circulation pump.

- Ball valves and fittings.

The unit is a comb with outputs ranging from 2 to 20, to which the heating circuit is connected. Ensures distribution of the media and its continuous movement from the boiler and back. It is mounted in a special cabinet, equipped with sensors, drain hoses, and often bleed valves are placed on the manifold to remove air.

During installation, it is important to monitor the location of the pipes, since improperly formed creases will impede pressure and reduce the efficiency of all devices. Often, bleed valves are installed on the manifold for a warm water floor to remove air. Stopcocks can be operated manually or using servomotors. If the connection also includes a circulation pump, all equipment will be a collector station.

2. Mixing unit.

Installation of this device is carried out using two methods. In the first case, two-way and balancing valves are used. A carrier with a constant temperature is supplied to the warm water floor collector, but due to limited throughput, this scheme is suitable for private houses with an area of no more than 200 m2.

The second method is to connect a three-way valve; this ensures the passage of large volumes, but there is a zigzag temperature control. Due to the high inertia of the screed, such jumps are practically unnoticeable.

It is recommended to purchase a complete set of equipment for connecting a water heated floor to a heating system only for a private home, since installation in an apartment will be impractical.

To ensure functionality, you will also need to connect a circulation pump. If the outlet temperature of the media can be adjusted at your discretion, then the collector is installed directly to the tank. This applies to low temperature devices. For other schemes for connecting a water heated floor to a boiler, the following elements are required:

- The control valve maintains the temperature. When the set value is reached, it turns off the supply.

- The balancing valve drives the medium after shutting down in a small circle, preventing it from entering the boiler.

- The pump circulates water through the pipes.

- The thermostat turns off appliances in case of overheating.

- The collection group monitors media consumption.

The effectiveness of distribution between heating circuits depends on the correctly drawn up connection diagram of the collector. At the base and at the entrance points, the pipes are secured using clamps or special polymer plates, which play the role of a profile and a heat insulator at the same time.

The uniform distribution of energy throughout a private house or apartment depends on how the water heating system is installed. Since the water passing through the pipes gradually cools, you need to start from the walls, moving towards the center or exit. The elements are mounted using a snake, leading them along the surface, then making a bend and returning back. The second method is a snail, when the pipes are placed around the perimeter, heading towards the center. At the same time, gaps are left for the reverse stroke.

In some cases, a heated floor is connected using a combined scheme: a snail is placed on one part of the room, and a snake is placed on the other. It is believed that this technology is more effective for uniform heating.

Electrical systems

Not every room has the conditions for installing a water structure, so owners choose network-powered options, for example, Rehau floors. You can use a cable or a film covering consisting of mats. In this case, the main element is not the heating circuit, but the thermostat. The connection diagram is usually displayed on the device body.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

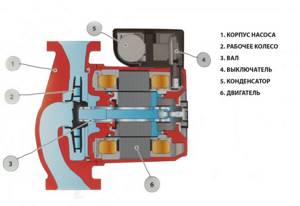

What is a circulation pump and why is it needed?

A circulation pump is a device that changes the speed of movement of a liquid medium without changing pressure. In heating systems it is installed for more efficient heating. In systems with forced circulation it is a mandatory element, in gravity systems it can be installed if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the outside temperature, thus maintaining a stable temperature in the room.

Cross-section of a circulation pump with a wet rotor

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but are very noisy and require regular maintenance. Units with a wet rotor operate almost silently; with normal coolant quality, they can pump water without failure for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than sufficient for heating any private home.

Closed logic

The closed logic of the circulation pump device means that there is a rigid internal structure. The operating algorithm remains constant over time and does not change depending on the state of the environment.

This is quite possible for circulation pumping equipment. There are only a small number of programmable parameters that can be changed.

Varieties

Depending on the design, thermostats come with a built-in or remote sensor. The latter are convenient because they allow you to place the thermoelement and the control knob at a considerable distance from each other.

Classification by number of pipes

Based on the number of connected radiator pipes, they are divided into two-way, three-way and four-way. Two-way thermostats are also called walk-through thermostats. They have two outlets and are attached to only one pipe. A two-way regulator has a mechanical or electrical valve that partially or completely blocks the flow of coolant.

Heating systems equipped with three-way thermostats have great potential. The latter not only block access to hot water, but also supply cold water to the radiator circuit. As a result of mixing flows, the heating temperature of heating devices decreases.

It is important to install the three-way thermostat correctly. The manufacturer usually depicts the installation diagram on the device body

Blue color indicates the place for connecting the supply pipe with cooled coolant, red – with heated coolant, and the outlet location is marked with an arrow. The same applies to four-way models. True, unlike three-way regulators, they are capable of maintaining recirculation of cooled and heated coolants without mixing.

Classification by type of actuation

Depending on the method of actuation, thermostats are divided into two categories - manual and automatic. With the first ones, everything is simple: to reduce the flow of heated water or block its path into the radiator circuit, you need to turn the knob.

The second ones have a more complex design. They consist of a sensor and a thermostatic element built into a plastic housing. The sensor is filled with gas condensate, water or wax, which, when heated to a certain temperature, changes the volume of the medium. After this, the rod of the device begins to move, partially or completely closing the mechanical valve.

You can also install an electronic thermostat. It is equipped with an electrically operated valve. Depending on the principle of operation, electronic devices are:

- automated, which are triggered when the temperature recorded by the sensor changes;

- programmable, triggered in a user-specified period of time;

- radio-controlled, when the temperature of the heating radiator is controlled using a remote control.

What is a circulation pump

This is a small unit that is installed in the heating pipeline system and distils the coolant through all branches of the heating system, that is, it ensures the circulation of hot water. There is a wide variety of circulation pumps for heating systems. but for private houses, units with the so-called “wet rotor” are usually used. What is the design feature of this model?

The thing is that the moving parts of the pump, and this is mainly the rotor and impeller, are cooled and at the same time lubricated by the liquid flowing inside the pump, that is, the coolant. Hence the quiet operation, high reliability, and small dimensions of the unit itself. Let's add durability, efficiency and cost-effectiveness here.

Advantages

Thermostats can reduce thermal energy costs by 10-20%. Those systems that not only have individual thermostats, but are also additionally equipped with regulators at the heating source, save 25-35% of thermal energy.

In addition, a pleasant microclimate is constantly maintained in the room, especially if automation is used to control the coolant.

Additional benefits

Other benefits of using temperature control devices include versatility and high accuracy. The versatility lies in the fact that thermostats are suitable for installation in heating systems of any type.

This equipment is used with gas, electric and solid fuel boilers.

High accuracy of adjustment is manifested in the fact that even a mechanical device stops the supply of heated water to the battery at the correctly calculated moment, not to mention devices with electronic filling.

The latter can be configured in such a way as to maintain a specific, comfortable temperature at certain hours. Often, an electronic thermostat even has a weekly programming function. The advantages also include the following qualities:

- durability - devices are made of corrosion-resistant steel. Particularly interesting is Russian-made equipment, which in terms of hydraulic and strength properties corresponds to domestic realities;

- a wide range of brands and models - today thermostats are manufactured by many companies and supplied from abroad. High competition allows you to reduce the cost of products.

Operating principle of overhead thermostats

There are several types of surface-mounted thermostats. There are thermostats with a bimetallic plate, and there are thermostats with a sleeve. In the first case, a bimetallic plate reacts to heating the coolant, in the second case, a gas enclosed in a sealed flask.

There are also electronic thermostats, which are a board with a display and an overhead resistor that reads the temperature of the water in the heating system. The cost of electronic thermostats is higher than that of overhead thermostats. This article from the construction magazine samastroyka.ru will discuss the procedure for connecting a surface-mounted thermostat with a bimetallic plate.

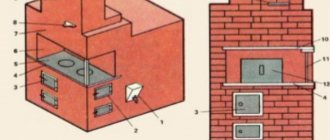

Diagram and principle of operation of circulation pumps for heating

Structurally, the unit is a complex of main components and additional elements.

The supercharger circuit includes:

- Frame. Needed to protect the device from external influences.

- Box with terminals. Electrical components and adjustment devices are connected here.

- Electric motor. Puts the equipment into operation.

- Impeller. The part ensures the transportation of liquid through the pipeline at a given speed.

- Transfer chamber. The compartment is equipped with pressure and supply pipes for connection to the heating network circuits.

The principle of operation of the supercharger is simple:

- through the inlet pipe, water enters the pumping chamber;

- the coolant is picked up by the blades of the impeller, which begin to function when the engine is turned on;

- An increase in pressure sets the coolant in motion, water passes through the outlet pipe and enters the heating system line.

The circuit for the heating pump does not have any difficulties; the device works on the same principle as all blowers. The peculiarity lies in the correct choice of device depending on the type of heating network, design characteristics of the main line, boiler and heating devices.

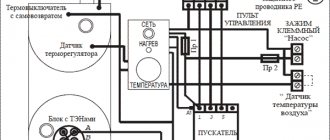

Automatic control unit for circulation pump

The circulation pump is controlled by a thermostat, relay, and uninterruptible power supply. The complex is needed to regulate the heating of the coolant and maintain the operation of the equipment.

Thermostats

The units combine the functions of a thermoelement and a valve; they are needed to adjust the water heating temperature.

The thermostat for the heating circulation pump works like this:

- Reads information from the temperature sensor. Compares indicators with settings. To set the settings mode, there is a side menu with a difference between the pump start temperature and hysteresis. Hysteresis is the time interval of temperature lag when the heater is turned on and off.

- When the equipment is started, hysteresis is automatically added to the water heating indicator when the blower is turned on. When the pump is turned off, the hysteresis is subtracted from the total value.

By default, the hysteresis size is taken to be 1/10 of the coolant heating temperature. Thus, when the water is heated at +50 C, the hysteresis is only 5 degrees. For the automatic control unit to start working, the water must warm up to +55 C. To turn off the unit, it must cool to +45 C. Units with hysteresis are more convenient to use. The equipment maintains a temperature rise of 5 degrees, therefore it is protected from constant switching on/off.

The thermostat should be selected with a firmware hysteresis of at least +/- 1 degree, maximum +/- 10 degrees. Place a thermostat next to the boiler. Provided that it is adjusted taking into account the external temperature in the room, the boiler adjustment should be able to change the media indicator.

Uninterruptible power supply

The heating circulation pump control unit is a volatile equipment and will not work without electricity. A UPS (uninterruptible power supply) or generator will eliminate the possibility of downtime. It is permissible to do without a power supply device, starting the network in gravity mode. But there is a risk of errors in pipeline layout, which will lead to network failure.

The contours of the gravity heating network, according to the laying technique, are inclined towards the return circulation pipe. It is recommended to maintain the slope within 3 cm for each meter of pipeline. This requires accurate calculations of the circuit and increases the network layout area.

The return circulation line is mounted with a slope towards the heater, also taking into account the slope. If the level of reduction is small, there is a risk of coolant stagnation and the formation of an air lock. In addition, the heater should be installed at the lowest point of the circuit, which causes difficulties in the absence of a basement.

A circulation pump will help to avoid all problems; to provide it with power, a UPS or generator is built into the network. The choice depends on the user, but the generator makes a lot of noise during operation, while the uninterruptible power supply operates as quietly as possible.

On/off relay

This is a module for starting equipment into operation and turning off the unit. The heating pump activation relay is an important component responsible for maintaining the functionality of the entire unit.

The task of the unit is simple:

- a decrease in the pressure level in the network is a signal to start the device into operation, the relay turns on the equipment;

- exceeding the established pressure norm is a signal to stop the equipment.

Thus, when the coolant collection stops and the pressure in the network increases, the timer for the heating pump switches off. Resuming the extraction of hot water leads to a decrease in the pressure indicator and puts the device into operation. Whether or not to install a thermostat or UPS is up to the owner.

A high-quality circulation pump with a temperature sensor has a number of advantages:

- reduces fuel consumption;

- ensures maintenance of a comfortable temperature in the premises;

- makes it possible to quickly adjust the operating mode.

Experts recommend choosing devices in accordance with the manufacturers' instructions. Manufacturers of equipment without an automatic control unit indicate in the technical data sheet the parameters of the unit suitable for installation on the devices.

To simplify the regulation of water flow in the battery, it is recommended to equip all batteries in the house with thermostats. When choosing them, you need to take into account the gradations of the settings - the smaller the divisions, the more accurate the mode. It is more practical to take devices with a scale gradation of up to 5 degrees.

Automation for heating and home

Automation for heating system control

The problem of rational use of heat during the cold season is relevant not only for private homes, but also for office, retail and industrial premises.

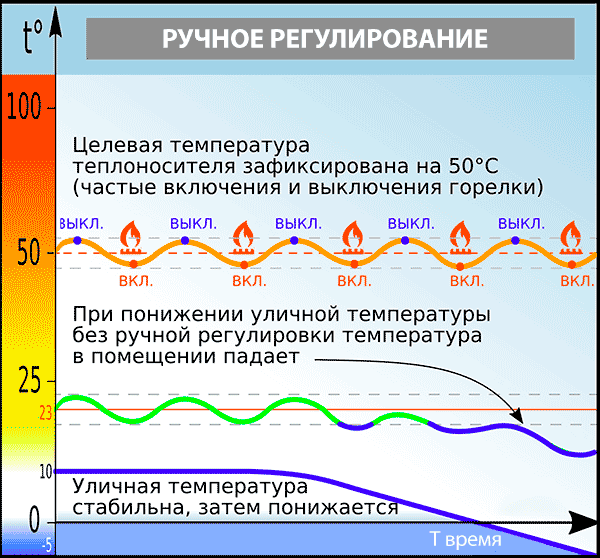

Let's briefly look at the main existing systems, and at the same time get acquainted with the OpenTherm protocol and modulating gas burners. Manual control. Simple and extremely inconvenient. Automation is a thermostat built into the boiler, which is manually adjusted to a certain coolant temperature, for example 50°C. Let’s assume the room temperature is 23°C. When the coolant heats up to the set temperature of 50°C, the thermostat sends a command to turn off the gas burner of the boiler, and if the coolant cools down, then to turn it on. Due to the inertia of the heating system, a wavy orange graph of coolant temperature and a green graph of room temperature are observed.

Tolerable, but, as often happens, a sharp cold snap has begun outside... The boiler thermostat continues to maintain the coolant temperature at the same level of 50°C, which is clearly not enough and, as a result, the temperature in the room inevitably decreases. What to do? There is no way out, we need to correct the situation - go to the boiler room and increase the coolant temperature to higher values. What if the house is large and the boiler room is in the basement? Don't run too fast. The inconvenience of this method of regulation is obvious - a complete lack of comfort. But you don’t need to pay extra for automatic control (it is already installed in the boiler) and, moreover, a stable temperature in the house is maintained while the temperature outside is stable.

Minuses:

- The need for regular manual adjustment of the temperature regime of the boiler;

- A constantly running circulation pump will provide increased energy consumption;

- Frequent switching on and off cycles wear out the boiler automation faster.

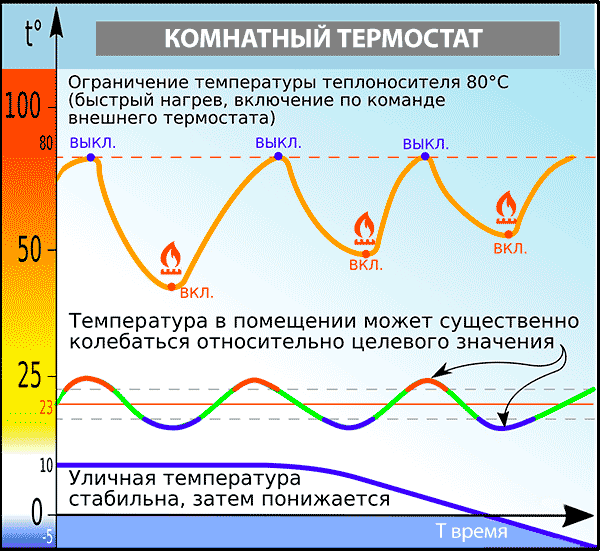

Automatic heating control - room thermostat. Simple, inexpensive and much more convenient.

Operating principle - the device measures the temperature in the living room and, depending on the set temperature value, controls the ignition and shutdown of the gas burner of the boiler. There is a nuance - the inertia of the heating system causes large delays in responding to commands from the room thermostat and the temperature in the living room may, although not by much, differ from the set one, which is clearly visible on the green graph of room temperature in the form of the appearance of red (overheating) and blue ( underheating) of segments.

Usually, for faster heating, a higher temperature of the coolant on the boiler is set (in our case, 80°C). Therefore, the shape of the orange graph becomes crescent-shaped - rapid heating to 80°C, and then turning off the burner and gradually cooling until the thermostat gives a command to turn on the burner. The outside temperature will begin to fall, and the room temperature will also fall, and the thermostat will simply start turning on the burner more often, and the lower limit of the coolant temperature will rise, which compensates for the drop in outside temperature.

Pros:

- The thermostat allows you to stabilize the room temperature without human intervention, although deviations from the set temperature are possible. There is no longer any need to constantly run to the boiler;

- Compared to manual control, the number of cycles of turning the boiler on and off is reduced, which increases the service life of the automatic ignition system;

- Automatic shutdown of the circulation pump when the burner is off leads to significant energy savings.

Minuses:

- Naturally, you will have to fork out for the purchase and installation of a thermostat;

- Insufficient accuracy of maintaining the set temperature.

- Automatic ignition works much less than with manual control, but due to the high threshold value of the coolant temperature, excessive consumption of gas fuel occurs. This shortcoming can be compensated by modern programmable models that allow you to program various daily and weekly operating modes. For example, the target room temperature may decrease at night and increase during the day. Likewise on weekdays and weekends. Flexible settings for the target temperature schedule can significantly reduce heating costs.

- If the boiler power is too high, the boiler often turns on and off (clocking), and if it is low, achieving the set temperature becomes impossible altogether.

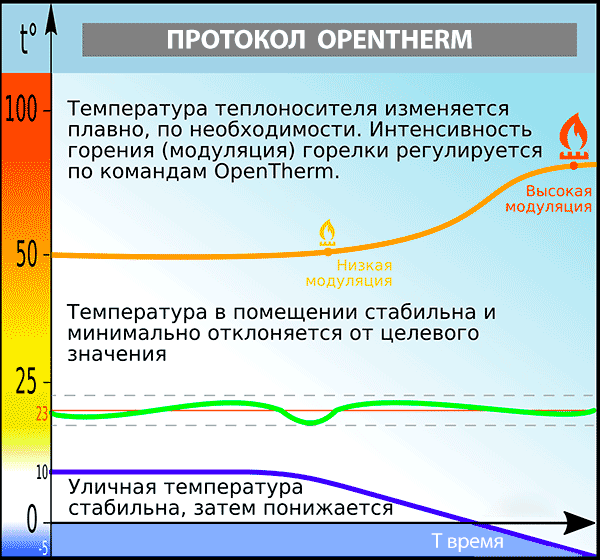

Automatic heating control using the OpenTherm protocol. Maximum comfort and energy efficiency.

The most modern and technologically advanced heating control systems today are devices operating using the OpenTherm protocol. The advent of gas heating boilers capable of controlling burner flame modulation has opened up new opportunities for economical and efficient control of the heating system. In simple words, flame modulation is the regulation of heating power, for example, similar to how you turn the handle of a gas stove, gradually reducing the flame of the burner so that the porridge cooking on it does not escape. In other words, burner flame modulation is the ability of the boiler automation, depending on external conditions, to optimally change the combustion intensity without turning off the burner. The OpenTherm protocol standardly describes all the basic commands for working with modulating burners. This allows you to connect a wide variety of equipment to it: from a thermostat to controllers, to which a large number of temperature sensors can be connected, located both in different areas of the heated facility and on the street. Analyzing the received temperature data outside and inside the room, the controller provides a weather-dependent operating mode of the boiler.

The graph clearly shows that the burner practically does not turn off, but only changes the intensity of its combustion. In this case, the deviation of the target temperature graph is very insignificant and lies within the hysteresis limits of the heating system. Additional advantages are a noticeable increase in the burner’s operating life (there are no ignition, rapid heating and cooling cycles), and significant gas savings are achieved. OpenTherm provides the opportunity to gain full access to the boiler automation settings and adjust them remotely - from any smartphone, tablet or PC. Additionally, access to information about all errors is opened, which provides an important tool for personnel servicing and monitoring the operation of equipment.

Pros:

- Minimal fluctuations in air temperature in the house, regardless of fluctuations in outside temperature;

- Minimum fuel consumption compared to other types of control;

- The number of boiler on and off cycles is minimized;

- Possibility of remote monitoring of the boiler condition and changing its settings.

Cons: higher price compared to other equipment, which pays off due to lower gas consumption.

Remote heating control

Currently, when there is a constant increase in energy prices, owners of country houses, dachas and cottages are increasingly thinking about the question: how to control heating costs by remotely controlling the temperature in their home, thereby reducing their costs for fuel consumed. After all, sometimes in order to achieve a comfortable temperature in the room, for example, when you are going to come to the dacha, it is enough to “heat” a little, and in your absence, reduce the heating power - why throw money away heating an empty house? Using a room thermostat, this is easy to do - just set the device certain temperature parameters, which will be observed automatically. But the problem is that you are not at home and you simply cannot go to the boiler or thermostat and adjust the necessary parameters.

In fact, remote heating control modules act as your personal assistant - call him or contact him using a PC or mobile application, give a command, for example, to heat it hotter in advance, and the whole family will eventually arrive in a warm and cozy home. Or vice versa: if you forgot to turn down the power in the morning when leaving for work - no problem, you can do it right from work, via the Internet. With their help, you can control various parameters of the heating system: change the power and operating mode of the boiler, achieving its greatest efficiency, set the temperature of the coolant, ultimately obtaining a comfortable temperature in the room. Moreover, the devices are capable of independently monitoring temperature sensor readings and adjusting the operation of the boiler depending on preset parameters. Remote heating control monitors the health of not only the boiler, but also the entire heating system! Information is transmitted via mobile communications and the Internet. Although, of course, the device is still not a person and cannot cope with an emergency situation on its own. But he is always capable of promptly notifying the owner about an accident, transmitting a report on changes in boiler operating parameters, or sending a service message. But in winter, such information is simply priceless, because literally a matter of hours counts, and if the necessary measures are not taken in a timely manner, then defrosting of the heating system and subsequent colossal repair costs are practically guaranteed!

Buy equipment for GSM heating control

Articles on the topic of remote heating control:

Remote control of heating of a country house

Smart House. Heating control system SALUS iT600

GSM alarms for home

Wireless GSM home alarm system is a new look at what a modern security device should be. These are high-quality and reliable systems that instantly respond to any suspicious factors and notify the owner of their presence.

Buy GSM alarm system for home

Our specialists will help you select and install automatic heating systems and find an acceptable solution at a price. You will be satisfied by cooperating with us!

Functional purpose of thermostats

In most cases, during heating operation, uneven heat distribution in radiators and pipes is observed. This is due to its cooling while moving along transport routes. For stabilization and timely adjustment, room thermostats for heating are installed.

Controlling the degree of heating of the radiator. By regulating the flow of hot water, the temperature on the surface of the heating device changes;

Optimization of coolant heating costs. An overhead thermostat for heating reduces the cost of heating hot water by reducing the difference in coolant temperature between the supply and return pipes;

Automation of heating operation. Almost all models of temperature control devices operate autonomously

It is important to initially correctly set the initial operating parameters.

How does a thermostat for a heating boiler differ from a similar model for a radiator or circulation pump? First of all, the response speed of the control element and the operating temperature. Therefore, it is recommended to select the optimal model for each heating component. And to do this, you should consider their types and design features.

Any thermostat for heating a home has individual operating parameters - installation features, degree of temperature control, etc. They must correspond to the characteristics of the heating element on which the device will be installed.

Open logic

There are also freely programmable types of devices with open logic. They are also often found in circulation-type pumping products. Such devices can be easily adjusted to any environmental conditions and temperature conditions.

But managing them is quite difficult; special qualifications are required. That is why they are not widely used; in circulation-type devices, closed logic is most often found.

You should not save on purchasing a thermostat for your heating system, because this product significantly increases productivity and efficiency.

Installation of a thermostat

Before installing the thermostat, you need to make sure that it is compatible with the heating system. Each device has its own valve capacity coefficients, denoted Kv and Kvs.

It is recommended to equip single-pipe systems with thermostats with a Kv value greater than 1, and even better - greater than 1.5. For two-pipe regulators, regulators with Kv in the range from 0.5 to 0.9% are more suitable.

Sequence of work

The sequence of installation work is as follows:

- after shutting off the supply riser, water is drained from the heating system;

- horizontal pipe connections are cut off at a short distance from the battery;

- disconnect the cut section of the pipeline along with the valves;

- if the system is single-pipe, a bypass is welded. This is a jumper that will allow coolant to circulate through the circuit when the valves are closed and there is no access to the battery. In two-pipe heating systems, the thermostat is mounted on the upper supply pipe, and the valve is mounted on the lower;

- remove the shanks with nuts from the shut-off valve and thermostat, and then screw them into the radiator plugs;

- The piping is assembled and installed, and then connected to the horizontal supply pipes.

Location nuances

The axis of the thermal head should always be located in a horizontal position so that the temperature measurement accuracy of the device is high.

In a vertical position, the sensor will be exposed to rising and falling heat flows, causing temperature readings to be incorrect.

If the rod axis is mounted vertically, it is better to use a remote electronic sensor with an electric drive or with radio signal transmission.

Thermostats that have a built-in sensor must be positioned so that they are visible, but not within the range of operation of heating devices. Also note that heat is shielded by thick curtains. The optimal height for placing the thermostat is at least 80 cm from the floor surface.

It is allowed to install thermostats on bimetallic, steel and aluminum batteries. If the radiator body is cast from cast iron, it is not recommended to install a thermostat due to the high inertness of this alloy.