How does a boiler with a pump work?

There is nothing complicated in the design of electric pump boilers. Their main difference from other similar devices is the presence of pumping equipment.

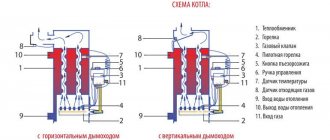

Main boiler blocks:

- Heat exchanger

. Acts as the core of the design of an electric heating boiler. It consists of a container and an internal heating element. - heating element

. Usually we are talking about tubular-type heating elements, although the latest models of forced circulation boilers are sometimes equipped with electrode heaters. - Heating expansion tank

. The coolant is stored inside it before being supplied to the piping system. - Valve

. Makes sure that water does not flow through the pipes in the opposite direction. - Filter

. Helps remove various impurities from water. - The electronic unit

. Performs a control function, regulating the temperature of the boiler, turning the equipment on and off at the right time. - Circulation pump

. An essential element of the entire system that maintains a stable speed of coolant movement in the circuit. This ensures the most efficient heat exchange and heating of the home.

To protect all structural components of an electric boiler with a pump and expansion tank, a casing with thermal insulation protection is used, which prevents excessive heat loss during the operation of the equipment. This allows you to significantly increase the energy efficiency of the heating system, minimizing energy consumption.

Advantages and disadvantages

Electric heating is an energy-saving technology because it can be integrated into green energy schemes - wind and solar power generators. The efficiency of an electric heating circuit depends entirely on the professional selection of equipment and boiler wiring diagrams.

Based on practical experience in using various options for heating boilers in individual heating systems, professionals objectively believe that the most comfortable mode control option is a boiler with electric heating elements and forced circulation of coolant by an electric pump.

Advantages of electric boiler circuits with forced circulation:

- Absolute functionality of the boiler with components of the heating circuit.

- Low specific characteristics of energy consumption for the boiler’s own needs, when carrying out the established tasks. They essentially do not affect the total electricity consumption for thermal energy generation.

- Extremely high efficiency among other heating sources; in many modern devices the efficiency approaches 99%.

- 100% level of automation of thermal processes.

- Environmental safety and environmental protection, since there are no harmful emissions into the atmosphere with flue gases, such as with gas or solid fuel boilers.

- Low specific material consumption, since there is no need to install expensive equipment for smoke removal systems to create draft in the boiler unit and provide primary air supply to the combustion chamber.

To be certain, it should be noted that electric heating has one very significant flaw, which actually prevents its widespread use - the high price of electricity in the thermal energy generation system.

Users who have chosen such a heat source as an autonomous heating system should consider options for reducing the cost of generating thermal energy and purchase electric boilers from trusted manufacturers.

The Protherm Savitr Stout Vaillant Wattek ZOTA double-circuit boiler is very popular at a price of 49,700 rubles, with a power of 9 kW, capable of heating a house with an area of 95 m2.

Modern electric heating schemes offer opportunities to reduce energy costs:

- Effective thermal insulation of a heated object.

- Competent application of combined heat energy generation schemes using secondary energy sources: sun, wind power and water heat pumps.

- Device at the input of a multi-tariff electricity metering facility.

- Connecting a heating fluid storage tank to heat it during the validity period of the cheap night tariff.

How to choose a suitable model with an expansion tank

When choosing an electric heating boiler with a pump for your home, it is recommended to pay attention to the following criteria:

- Power . Affects the performance of heating elements in the heat exchanger (it is indicated in kW). The boiler power is determined by the heating elements. In most cases, models on the modern market have a power from 2-3 to 60-70 kW per heater. Appliances with low power are usually used to heat small private houses and cottages. Boilers with ratings of more than 50 kW are used in the industrial sector.

- Capacity of the thermal accumulator . Thanks to this tank, a significant increase in the efficiency of the boiler is achieved, so it must be installed. The volume of the heat accumulator directly affects the efficiency of coolant distribution in the pipeline. As experts advise, when choosing a tank, you need to focus on the ratio of 20 l/1 kW of boiler power.

- Voltage . In houses with single-phase 220 V networks, boilers up to 12 kW can be used. If it is necessary to install a more powerful device, then in this case you will have to install a three-phase network (380 V).

- Cross-section of switching wires . As the power of heating equipment increases, thicker cabling must be used to supply electricity to the system. Devices with a power of up to 4 kW can be equipped with cables with a cross-section of 4 mm2, and boilers of 12 kW single-phase type are connected with cables of 16 mm2.

In addition to heating elements, electric boilers also include electrode and induction boilers. In the latter case, we are talking about a small dielectric tube and a ferromagnetic rod. The coolant moves inside the tube, heating up due to the passing electric current. The advantage of these models is durability, compactness and efficiency (the “soft start” function allows you to save almost 50% of electricity). The disadvantage of induction devices is the presence of a complex control unit.

As for electrode units, they are also called “direct action” devices (due to the absence of a heating element). Heating of the coolant occurs while an alternating electric current with a frequency of 50 Hz moves through it. Such equipment is safe, as it is equipped with an automatic security system. The disadvantages of electrode boilers include the need for enhanced preparation of the coolant, which must have the required resistance. Regular replacement of the electrodes will also be required due to their gradual dissolution.

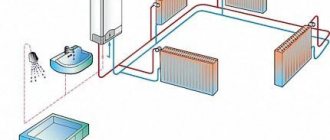

Circulation in double-circuit hot water boilers

The operation of double-circuit electric boilers with a pump is complicated by the need to periodically supply coolant to the heat exchanger that heats water for hot water supply. Here the blower alternately operates in the heating and hot water supply circuits, switching is carried out by a two-way valve with an electric drive at the command of the controller. This happens when the hot water tap in the house is opened; this fact is detected by the flow sensor and transmits a signal to the controller. After switching the flows, the circulation pump pumps the coolant into the flow-through heat exchanger until the tap in the house is closed and the two-way valve directs the flow into the heating supply pipeline. The structure of a double-circuit boiler with a circulation pump is shown in the figure.

Installation diagram

1 – flask with heating elements and automatic air vent; 2 – unit body with mounting holes; 3 – controller; 4 – membrane expansion tank; 5 – pump group with a two-way valve and a flow-through heat exchanger.

The flow-through heater has fairly narrow channels; accordingly, the blower is selected in such a way as to overcome the hydraulic resistance of the heat exchanger, taking into account its increase as scale develops.

For reference: the automation of most electrical installations is programmed to periodically turn on the circulation pump in the summer so that its rotor does not get stuck during idle time.

How to calculate the power of an electric boiler

When choosing a suitable option for an electric boiler with a pump and expansion tank, first of all, we focus on its power. It must be such that all heat losses from the heating system are fully compensated. In addition, the boiler is responsible for an uninterrupted supply of hot water.

Before choosing a suitable heating device model, it is necessary to make a detailed thermal calculation. It takes into account not only the total area of the heated premises, but also the condition of the walls, floors and ceilings, the quality of insulation, and the presence of modern windows and doors. To calculate a boiler for heating a private cottage, it is allowed to use a simplified scheme. Using the instructions below, you can independently determine the necessary device parameters.

To do this you will need the following formula:

W = S x Wsp /10m2, where:

- W – required heating power (kW).

- S – total area of all heated premises (m2).

- Wsp – specific power per 10 m2.

Wsp has different values in different regions. In areas with a harsh climate, this parameter ranges from 1.2-2. In the central zone of Russia, Wud corresponds to 1; in the southern regions values of 0.7 – 0.8 are used.

Installation procedure

Most often, installation activities are carried out by professional installers, because... this requires special permission. However, knowing the sequence of operations will not hurt: at a minimum, this will allow you to monitor the work being carried out, ensuring the correct implementation of each stage.

Installation sequence:

- The most difficult thing when connecting an electric heating installation is to provide it with the necessary power. If the existing wiring is able to support the power of the device, then no modification will be required. Otherwise, you have to lay an additional line.

- After the power supply issue is resolved, the meter, electrical panel and RCD (minimum 25 A) are installed.

- Boilers are wall-mounted and floor-mounted. Typically, all the necessary fasteners are included with the system. After the installation of the electric boiler is completed, it is connected to the meter with a cable of optimal cross-section.

- Temperature sensors are connected via separate wiring. Their task is to automatically regulate the switching on and off of heating elements.

- A separate plumbing cabinet is used to install the heat accumulator.

- Some models do not have a built-in circulation pump: in this case, it must be installed separately. This will require an additional wire to supply power to the pump motor.

To connect all the elements into a single system, you will need pipes (metal or metal-plastic). When performing a test run of the circuit, you need to carefully ensure that there are no coolant leaks anywhere. As can be seen from the description, the installation work is quite complex, so a preliminary study of this process will not be superfluous.

Types of circulation pumps

The correct operation of the circulation pump is ensured by a special element - a rotor, at the ends of which there are special blades, with the help of which the movement of the coolant in the pipes is enhanced.

Most modern models of circulation pumps have one rotor, but in some devices you can find two such elements.

Regardless of the number of rotors, pumps for heating boilers will only work effectively if there is no air in the system.

There are two main types of pumps - wet rotor and dry.

Advantages

The popularity of electric boilers with a heating pump is explained by the following positive characteristics:

- Rich assortment

. Models of various capacities are available for sale, which makes it possible to acquire exactly the brand that best suits the operating conditions. In this way, you can choose a heating device for both a country house and an industrial premises: there are always options with suitable parameters in stock. - Economical

. Due to the high energy efficiency of modern electric heating boilers (their efficiency is close to 99%), their use allows you to save significant finances. An additional economic effect is facilitated by the use of a circulation pump, which is part of the structure itself. Having low energy consumption, it nevertheless significantly increases the rate of coolant passage through all pipes. As a result, rooms warm up many times faster. - Environmental friendliness

. Such a heating system does not emit combustion products during operation. Therefore, there is no need to spend money on organizing a chimney and providing additional air flow. For this reason, electric boilers are widely used in city apartments and office premises. It is important to remember that the absence of smoke does not mean that the ventilation in the house may be poor. - Ease of management

. This is facilitated by maximum optimization of monitoring and control devices. As a result, even an amateur can monitor the operation of heating equipment. Most of the models on the market are equipped with automatic control units: this allows you to resort to adjusting the operation of the system in very rare cases.

Equipment of this type is able not only to heat rooms, but also to cover the need for hot water. To optimize the water supply system, you will need to install an expansion boiler and a tank with a volume of 80 liters or more.

Flaws

Along with many positive characteristics, electric heating boilers with a circulation pump also have certain weaknesses:

- The costs of operating such equipment are directly dependent on electricity prices. This explains the fact that most countries have recognized electric heating systems as not as efficient as gas and solid fuel counterparts. To reduce operating costs, it is recommended to use a heat storage tank. This will significantly reduce heat loss and energy consumption for the preparation of warm water.

- Dependence on proper supply of electrical energy. A double-circuit electric boiler and circulation pump are energy-dependent devices. Therefore, if there are power outages in the region, it is advisable to choose a different type of heating for your home. One option is to install a backup heat source in case of an “emergency” situation. Most often we are talking about a solid fuel stove or fireplace. They are far from full-fledged heaters, but they will certainly be able to provide backup during a short shutdown of the main boiler.

- The need for high-quality electrical wiring. This is a prerequisite for the electric boiler in combination with the circulation pump to operate without any interruptions. It often happens that the wiring in the house does not meet the requirements, and it has to be completely changed. This in any case entails additional costs.

Naturally, people are also concerned about the cost of an electric boiler with a pump. Its size is largely influenced by which model was chosen: the more powerful the device, the more expensive it costs. You should also pay attention to manufacturers, among whom there are several proven domestic companies. In any case, do not delude yourself with cheap samples of dubious quality.

What is the built-in pump for?

Construction of an electric heating boiler with a circulation pump

Electric boilers do not have large or massive elements that are an integral part of the design of other heat sources. Therefore, electrical heating installations are usually made in a wall-mounted design. At the same time, they are equipped with additional elements as much as possible in order to simplify installation and piping of the boiler on site. One of the most important piping elements built into the heater design is the circulation pump. Its presence in an electric boiler is more than appropriate, especially if the latter has a secondary circuit for DHW. Circulation pumps for boilers solve two problems:

- They force the coolant to flow through the pipelines of the heating system at a certain speed.

- In double-circuit electrical installations, they drive coolant through a flow-through heat exchanger to prepare water for domestic hot water supply.

In single-circuit boilers, the pump solves only the problem of forced circulation of water throughout the entire heating system. One nuance arises here: the manufacturer supplies its product with a pump, the parameters of which approximately correspond to the power of the electrical installation - the average value of the hydraulic resistance that the system of a given thermal power should have is taken.

Wilo circulation pump for heating systems

But there are an infinite number of options for heating schemes, some of them have greater hydraulic resistance than a standard heat generator pumping apparatus can overcome. Then an electric boiler with a pump will not be able to supply coolant to all branches of the system.

A simple example: a standard WILO-STAR-RS pumping unit is capable of providing a capacity of 6 m3/h of coolant, developing a pressure of 0.8 Bar or 8 m of water column. If the heat source is located in the basement of a three-story cottage, then a pressure of about 0.6 Bar will be needed just to overcome the lifting height. You also need to deliver the coolant through horizontal branches, the resistance of which is taken in aggregate according to the following ratio: 10 m of horizontal pipe length is considered as 1 m of riser. And as a result of the calculation, it turns out that the electric boiler with a built-in circulation pump will not cope with its task, the circuit will not function.

Advice. If we are talking about heating buildings with a branched system, long branches or large differences in heights, then it is better to perform an enlarged calculation and check its result with the parameters of the pumping device, in consultation with a sales representative of the heat generator manufacturer. This will save you from buying unnecessary equipment later.

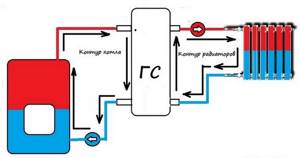

A situation is possible when an electric boiler with a circulation pump has already been purchased and installed, and after that it turns out that the pressure of the standard blower is not enough. In this case, additional costs are inevitable, and the problem can be solved as follows:

- Carry out an enlarged calculation of the hydraulic resistance of the system yourself or with the involvement of a specialist.

- Based on the calculation results, purchase a separate circulation pump.

- Introduce a hydraulic separator (hydraulic arrow) into the circuit, then the heater supercharger will operate in a small circuit.

- Install a separate pump on a large heating circuit, as shown in the diagram:

Heating system with hydraulic separator