Variety of devices

Grease traps are presented in specialized stores in a fairly large assortment, with different capacities and configurations.

First of all, devices are divided into types according to the material from which the case is made. They can be plastic, fiberglass or metal.

Polyethylene and polypropylene are used in the manufacture of industrial and household models. Such products are characterized by low maintenance, light weight, low cost and a fairly long service life.

Fiberglass is characterized by high strength and resistance to aggressive environments. This allows grease traps to be buried in the ground or installed outside the building.

Metal grease traps are made of stainless steel, so they can withstand cleaning with a stiff brush without damaging the surface. They have an aesthetically attractive appearance, but are quite expensive. Sometimes there are models made of galvanized or painted steel, but they are susceptible to rust. In contrast, products made of aluminum and stainless steel are characterized by a fairly long service life.

The second characteristic by which all grease traps can be divided is the design feature of the products.

There are several main types:

- Grease trap under the sink

. Suitable for installation in a private house, apartment or small catering establishment, it requires manual operation. - Industrial model

. Installed in a catering unit designed to serve a large number of people, or in food industry enterprises. In most cases, industrial equipment has a fill sensor. - Automatic equipment

. The presence of an electric mechanism for automatic fat collection makes maintenance simpler and easier. In addition, the possibility of clogging the inlet and outlet pipes is almost completely eliminated. - Models with the possibility of being located below the sewer level

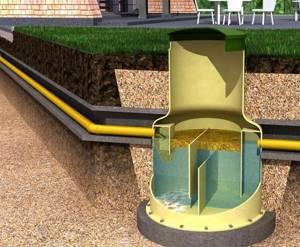

. A distinctive feature of such grease traps is the presence of a built-in electric pump. With its help, purified water rises to the sewer system, which is located at a higher level. This allows equipment to be installed in basements or buried in the ground. - The well model

has the shape of a cylinder and belongs to large industrial devices. They are placed in a special external well and served through a hatch.

For household use, it is recommended to purchase a regular grease trap under the sink, which is suitable for independent maintenance once every 2-3 weeks. The design and arrangement of such products are not particularly difficult.

Selecting a grease trap

Choosing a suitable fat trap is always an individual matter. When choosing, you need to take into account a number of parameters, starting from the purpose of the device and its operating conditions to the set of additional functions. However, one thing is for sure - if the equipment is suitable for a specific situation, then its effectiveness will be quite high.

Installation methods

Depending on the installation features, all fat traps are divided into two categories:

- Outdoor, intended for installation outside the building;

- Home ones, which are installed exclusively indoors.

There are also combined solutions suitable for installation in any conditions - but such devices are practically not found on sale. However, the range of standard models is so wide that choosing the best option for specific operating conditions is not difficult.

Regardless of the type, grease separators are installed directly in the sewer system, but the specific installation point may vary. For example, household equipment can be mounted either directly under the plumbing or in the basement. Sometimes grease traps are installed in a separate room. Of course, when installing in a building, you need to take into account the size of the equipment and how convenient it will be to maintain.

With external separators the situation is more complicated. For the manufacture of such devices, more durable materials are used, since the equipment must withstand greater load and exposure to external factors. Outdoor grease traps must be installed underground. This process is quite complicated - you first need to prepare the site, concrete the area, and only after that can the separator be installed. For such work, it would be best to involve specialists.

Grease trap structure and operating principle

Domestic kitchen sink drains contain large amounts of grease, which can settle on the inside walls of the drain pipes. Over time, the build-up increases and causes pipe clogging and an unpleasant odor from the process of decomposition of organic compounds. In some cases, old fatty deposits cannot be cleaned mechanically, and the only solution in such a situation is to dismantle the sewer. When installing a grease trap in a private home, the problem of clogging with fat deposits loses its relevance.

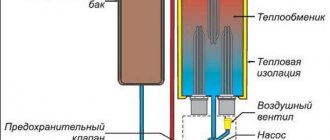

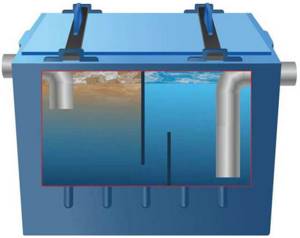

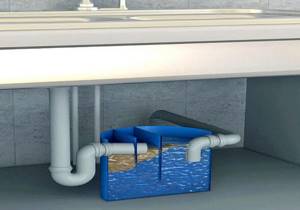

Considering the equipment, we can highlight the following design elements:

- The body is rectangular in shape, having an inlet and outlet on opposite sides.

- Partitions that slow down the movement of water and prevent greasy and solid particles from entering the pipes of the sewer system.

- The lid has a rubberized gasket for tighter closure and prevents unpleasant odors from entering the room.

- Short inlet pipe elbow.

- The exhaust pipe is in the form of a tee with open holes on all sides. The long part of the pipe is lowered to the bottom of the housing, the short part ends under the lid.

- Ventilation hole.

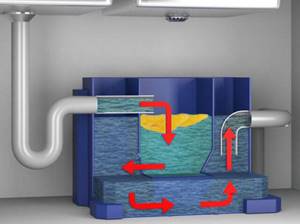

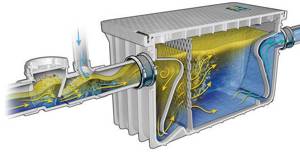

The design determines the operating principle of the grease trap under the sink. From the sink, water enters the receiving chamber, and the inlet can be located on the top or side wall of the grease trap. Next there may be one or two partitions that separate the receiving chamber from the main body. Everyone knows from school that water and fat have different densities, so fat rises upward, where it gradually accumulates.

An additional chamber is formed behind the partitions, in the lower part of which there is an outlet for discharging purified water into the sewer.

To prevent accumulated fats from entering the outlet, they require regular removal. To do this, the upper part of the internal space is cleaned at certain intervals.

Classification of grease traps

There are two main types of fat traps:

- Household;

- Industrial.

The first category of devices is suitable for use in private homes, apartment networks and small catering establishments. In addition, a household grease trap is required for installation in any restaurant, since a large amount of grease deposits are formed during the dishwashing process. Cleaning of such devices is carried out manually. Standard household products are used in networks where the total liquid flow does not exceed 1.5 cubic meters/hour.

Industrial equipment is intended for installation in large enterprises with a wastewater volume of 2 cubic meters per hour or more. There is a need to install a grease trap if the enterprise works with substances, the processing of which releases fat, oils or other impurities that are not intended to enter the sewer in their pure form.

Rules for calculating equipment performance

To choose the right equipment, you need to understand why you need a grease trap under the sink, and perform several calculations using a simple formula:

P = n*Ps.

Here the letter “P” denotes the performance of the device, “n” is the number of connected sinks, Ps is the speed at which water enters the grease trap (measured in liters per second). The last value can be determined independently, using any container with a known volume. Fill the container with water and set the filling time.

Then calculate how much water flows out of the tap in 1 second using the following formula:

Ps = V/T,

where V is the number of full liters in the container, T is the time to fill the container in seconds.

Having determined the required equipment performance, you can calculate the recommended volume. To do this, use the formula:

V = 60*P*t.

Here the symbol t denotes the rate of fat floating. Most often, this value is determined by the manufacturer; for household equipment, the value is 6.4 minutes.

If only one sink is connected to the grease trap, then its productivity should be 0.5-1 m3/hour. The equipment on the market is characterized by a productivity of 0.145 l/s and has a volume of 50 liters.

What does the market offer?

Today on the market of plumbing fixtures in the Russian Federation there are quite a lot of products from companies that produce grease separators for kitchen sinks. Among them are the leaders:

- Products

It can be found in four layout modifications: “standard”, “pro”, “auto-assembled”, “steel”. In each of these configurations, you can select a grease trap that matches the tasks assigned to it. The choice may be influenced by the following parameters: productivity - 0.5-1.5 m3/h, peak water discharge - 25-175 l, number of connected sinks - 1-3, material of the working container - polypropylene or steel. However, ease of maintenance is also important, which is provided by removable plates or canisters for fat, as well as garbage trays in certain modifications. The most compact device has dimensions of 420*320*370 mm (L*W*H). - Evostok OIL separators are also presented in models - from the smallest, designed for installation under sinks in standard apartments, to large-sized ones, capable of cleaning the drains of large cottages, canteens, restaurants, etc. They are distinguished by the simplicity of their internal structure, assembled in a polypropylene case using a two-chamber design. Dimensions of the smallest model – 420*320*370 mm.

- The Termit brand offers only four standard sizes of its separators, covering the most popular segment, installed under grease trap sinks. The containers of the devices are made of high-density polyethylene in a three-chamber design. An additional option in their configuration may be a tray for garbage and large waste. This is a removable plastic container that can be easily removed and washed when filled. The smallest installation is 450x350x395 mm.

- Triton-PM cleaners are reliable units of the Russian brand. Available in two-chamber cast polymer housings. Their models occupy the entire functional range in terms of operating capacity and peak discharge for use in everyday life, as well as in mini-industry (cafes, canteens, restaurants). Although the dimensions of the smallest standard product are 420*320*370 mm, the manufacturer is ready to manufacture a separation plumbing installation to suit the customer’s individual requests.

As a contrasting example, consider the Hydrig automatic grease removal equipment. These are quite complex and expensive stainless steel products intended for use primarily in catering facilities.

Grease trap "Hydrig"

In them, the technological separation process occurs due to electrical heating of wastewater, followed by separation and collection of fat mechanically. The equipment is energy-dependent, but provides the highest degree of purification compared to the above-described gravitational installations. The dimensions of the main unit of the smallest model are 590*500*335 mm.

Operating rules

When using a grease trap for a home sink, you must follow several specific rules that will allow you to achieve maximum efficiency in the operation of the equipment, prevent flooding and the appearance of an unpleasant odor in the kitchen.

In particular we are talking about the following:

- Mineral and synthetic oils should not be present in water waste.

- It is not recommended to connect the equipment to the toilet.

- It is forbidden to install a pump in front of the grease trap to avoid the formation of an emulsion that does not settle well.

- The inlet pipe should be located at a minimum distance from the sink and at a slope of at least 2 degrees.

- Purified water must immediately go into the sewer system.

- It is recommended to connect the equipment in the ventilation system shaft (if there is a corresponding hole in the wall or ceiling).

Grease trap installation

Grease traps

, as a rule, are installed directly at the point of discharge of wastewater containing fats. Maximum efficiency of the trap system is possible by installing devices for each wastewater source.

During the construction process and subsequent installation work, impacts on the body of these installations should be avoided.

The placement of grease removal equipment for the entire facility as a whole has an individual approach, and as a result does not have standard instructions.

The installation process includes the following stages:

1.

Preparation for installation

2.

Installation of the loading plate

3.

Installation of the housing

4.

Backfilling

5.

Installation of the safety plate

Preparation for installation

Initially, preparatory work is carried out in the pit. They are performed according to the following algorithm:

- when developing a pit using machinery, work should be suspended until the project mark in order to maintain the integrity of the soil;

- then activities up to the final mark are carried out manually, it is important to maintain absolute accuracy;

- Along with the creation of a pit, regular water reduction is carried out.

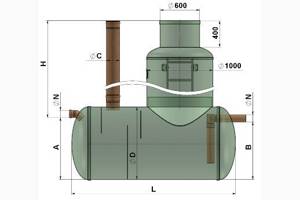

Loading plate installation

Clean the bottom from foreign elements.

A ready-made concrete base is mounted or installed at the bottom of the created pit. The dimensions of the slab must match the dimensions of the grease trap

. But its mass is recommended at the rate of twice the difference between the device’s own mass and the mass of groundwater displaced by the device. The thickness of the slab is set based on the depth of the pit.

When pouring a concrete base, reinforcing structural elements should be used: a 20 ? mesh mesh is optimal. 20 mm, ? 5 mm.

Installation of the case

Clean the surface of the concrete base from foreign elements. A layer of sifted sand up to 30 cm high is poured onto the slab, followed by careful compaction. At the next stage , you need to make sure that there are no unnecessary objects between the body of the device and the sand layer

.

Installation of equipment on a sand compacted layer is carried out horizontally. During the work, it is important to distribute the entire load of the device’s mass evenly across the slings used.

.

The housing should be lowered in strict accordance with the design position

. Upon completion of installation, the housing is inspected to identify possible damage and defects.

To secure the body to the concrete slab, anchor bolts are used, which are attached to holding nylon belts or metal strips. In the case of using belts, it is recommended to provide in advance for the installation of appropriate locks in the concrete during the process of pouring the base.

.

backfilling

After a certain period of time, when the concrete slab acquires grade strength, the pit is completely filled up to the mark where the drainage inlet and outlet pipes are located.

Backfilling is carried out in the form of a layer cake, each layer of which is half a meter thick. In this case, you cannot use frozen soil or sand containing large mechanical fractions

.

To create each layer, it is compacted evenly around the entire perimeter. This is extremely important to avoid possible deformation of the device body. When performing work in winter, it is recommended to cover the backfill soil with thermal insulation or store it in a heated room so that it does not freeze.

The use of mechanical vibrating presses weighing over 100 kg in the compaction procedure is prohibited!

The soil is compacted only at a distance of 30 cm from the device body; approaching is unacceptable!

Installation of a safety plate

When installing a grease trap dangerously close to a parking lot or directly on the roadway, as well as when installing the device to a depth of more than one and a half meters, it is imperative to use a protective reinforced concrete slab above the buried device

. Its dimensions must exceed the dimensions of the pit so that the edges of the slab rest on the soil - up to half a meter on each side of the device.

If you ignore these recommendations, in order to avoid mechanical damage to the grease trap, you should limit the collision of vehicles with the place where the device is buried

. In this case, the limitation should apply not only to the installation point itself, but also to two meters from each side of the installed grease trap, in order to avoid subsidence of the ground and compression of the body.

| It is recommended to entrust installation of the device only to highly qualified specialists. Our company is always ready to provide services such as septic tank installation and a grease trap. |

Advantages of grease traps

A grease trap for domestic use has a small volume, but the dimensions of the equipment itself require quite a lot of space. Most often, the device occupies the entire cabinet under the sink, so its installation must be justified.

Those who have doubts about the use of such equipment should study the principle of operation of a grease trap under the sink and become familiar with its advantages:

- The design of the grease trap is quite simple, so the possibility of making it yourself from an old plastic container is not ruled out.

- Easy installation. Connecting to a siphon involves connecting two tubes without using any tools.

- Easy maintenance. The cleaning process involves removing grease from the top of the device every few weeks. The entire procedure takes no more than 5 minutes.

- No blockages in sewer pipes. A grease trap for your home allows you to operate the system without additional cleaning.

- Possibility of placing the container in the cabinet under the sink.

- In some cases, a grease fill sensor can be installed.

The main purpose of a grease trap is to separate particles from the main liquid that can cause blockages in the sewer pipe.

How to clean a grease trap?

Household appliances installed inside the house are cleaned manually. For this purpose, the separators are equipped with a special blade. This process is quite simple, does not take much time, but is somewhat unpleasant. The algorithm of actions is as follows:

- Open the top cover.

- We collect the accumulated fat with a spatula. It should be noted that waste fats when unloading grease traps are subject to mandatory disposal, but these standards do not yet apply to household devices.

- We check the pipes and, if necessary, remove large particles that have accumulated from them.

- Remove accumulated sediment from the bottom. Can be cleaned using any detergent.

- Flushing the system with hot water will remove particles of fat and oil from the pipes that can lead to clogging.

- Close the lid and continue further operation of the separator.

To pump out accumulated fat from a street separator, you will need to use special equipment.

Cleaning must be carried out regularly, otherwise there is a high probability of system clogging.

Choice for home use

Before you go to the store to purchase equipment, you need to study the place where you plan to install it. The parameters of this section will allow you to reduce the number of options when deciding how to choose a grease trap for a sink directly in a store or on the Internet (read: “How to choose a grease trap for sewerage - types, differences, installation rules”).

In particular, we are talking about the following:

- The size of the internal space under the sink. When analyzing these values, it is necessary to take into account the additional distance to the top panel of the cabinet for free removal of the cover; space is required on both sides of the equipment to connect the inlet and outlet pipes.

- The diameter of the sewer pipe to which the equipment will be directly connected. The grease trap holes should have the same diameter to avoid purchasing additional adapters.

- Number of connected sinks. Need to know to determine equipment performance.

- Characteristics of waste water.

- If large quantities of solid particles are present in the drain, it is recommended to purchase a model with several partitions.

- Sewer riser or drain pipe in close proximity to the equipment installation site. This prevents the water seal on the siphon from breaking.

- Possibility of unhindered maintenance of the device, its individual elements and cleaning of the space after completed activities.

- The material from which the body is made. Most often, this question is relevant for equipment located in plain sight. In this case, it is better to purchase a grease trap for a private home, the body of which is made of stainless steel. If you plan to place the equipment in a cabinet under the sink, then you can get by with a plastic product.

- The volume of the sink bowl is especially important when it becomes necessary to immediately drain a large amount of water from the sink. In the manufacturer's instructions supplied with the device, this value is indicated as one of the characteristics.

Having studied all the selection criteria, you can safely go to the store for suitable equipment.

Grease trap for sink advantages

Such equipment for capturing fats and oils has many advantages:

- The unpleasant odor that invariably forms during the decomposition of fats is destroyed.

- The trap is sealed as tightly as possible, which prevents the penetration of foreign liquids and other debris into it.

- The device is not difficult to install and further operate.

- Long validity period.

- Affordable cost compared to other types of filter devices.

- The strength of the structure and the materials from which it is made.

- It does not consume electricity and can work at any time without adding active chemical components.

- Prevents sewer pipes from corrosion.

- The device can be equipped with a sensor that monitors fat levels.

Today, all food service establishments are required to install grease traps in their restaurant drains to improve the quality of their wastewater. This is strictly monitored by the sanitary and epidemiological station, the water utility and the relevant municipal body responsible for environmental protection.

Self-installation of equipment in the cabinet under the sink

All work on installing a grease trap under a sink can be done independently; for this you do not need to have special knowledge or special tools. Connecting elements for connection are purchased directly with the equipment. Additional fittings and pipes are required only to connect the unit to the sewer system and siphon.

In most cases, the store presents assembled structures, including grease traps for the sink, which requires the presence of connecting tubes or rubber adapters that are inserted and tested for leaks.

Directly installing equipment under the sink to purify water from grease impurities involves performing the following actions:

- Before installing a grease trap under the sink, you need to prepare a place for it.

- Next, the equipment is assembled if the main unit and additional connecting elements were purchased separately. In particular, the fluid supply elbow and the outlet tee must be connected to the corresponding holes, having previously treated the joint with silicone grease.

- If the design requires adapters, then they must also be screwed to the main body.

- Next, the equipment is installed in its main place.

- Coat the outer part of the pipes and siphon, which are directly adjacent to the grease trap, with a sealing compound.

- After connecting all the elements, the structure is left for some time so that the sealant completely hardens.

- If there is an air duct, connect it to the sewer riser.

- Open the tap and supply water to the equipment. Check the functionality of the structure and the tightness of all connections. If there are no leaks, the work of installing a grease trap under the sink can be considered complete.

When choosing a place to install equipment, it is important to understand that when exposed to high temperatures, its operating efficiency is significantly reduced. For this reason, you need to choose a place away from the oven. In addition, do not allow the temperature to be too low, which will cause the liquid to freeze and cause the tank to rupture.

Installation in a building

It is much easier to install a household separator, which is largely due to the absence of the need for earthworks. One of the most important conditions for the correct installation of a grease trap is the correct choice of location. It should be easily accessible, firm and level. In addition, the equipment must be located near the plumbing and in such a way that the gravitational principle of the grease trap can ensure the operation of the device.

The installation technology is as follows:

- The outlet pipe is connected to the sewer and sealed with a gasket included with the equipment;

- The inlet pipe is connected to plumbing or a general pipeline;

- The grease trap is filled with water and checked for leaks;

- If the device operates correctly, then the cover can be installed on it, thereby completing the installation process.

Service

This is not to say that the procedure for removing fat from the upper part of the equipment body is a pleasant undertaking. However, cleaning sewer pipes is an even more unpleasant task. Depending on the volume of the tank, the nature of the family’s diet and the temperature of the water used, the frequency of cleaning work is determined. In most cases, it takes several weeks to several months between cleanings.

It is very important to check the operation of the equipment the first time after installing a grease trap under the sink. The layer of fat should not be allowed to reach the level of the inlet and clog it. For this reason, you should regularly open the main body cover and check the level of fat deposits.

Cleaning the grease trap is performed after the fat layer reaches a line located 4-5 cm above the outlet pipe. The procedure involves removing the fatty viscous mass with gloves or some other device.

At the end of cleaning activities, be sure to rinse the equipment with a stream of hot water for several minutes. It is worth noting that after determining the approximate period of safe use of the structure, monitoring can be carried out less frequently.

Review of popular manufacturers of grease traps for sinks

Nowadays there are no difficulties with purchasing a fat trap. The device is produced not only by foreign, but also by Russian manufacturers. Of course, you can always add something new to the design of the device, but in most cases the design is almost identical. Therefore, we intend to focus specifically on the reputation and fame of the manufacturer.

A popular Russian company, under whose name industrial equipment is usually produced.

"Fifth Element"

An enterprise that produces very inexpensive grease traps made of PP, which are intended not only for industrial, but also for domestic use.

Flotenk

Another Russian company engaged in the production of household/industrial equipment for sewage systems. In production, fiberglass is used, the service life of which can reach 50 years.

Evo Stock

A company from Russia specializing in polypropylene grease separators for household/industrial use. Reinforced plastic can also be used in production.

A Finnish company that produces high-quality polyethylene grease traps under the EuroREK Omega brand.

Installation

Installing a grease trap is a simple process, especially if you think through everything in advance and create the conditions necessary for operating the device.

Where to install

Household grease separation devices can be installed in a building or on the street (in a country house - in front of an external sewage septic tank. In a cafe, restaurant or dining room, separators can be installed in a separate room, in a dishwasher, in a basement or on the street. Industrial - in workshops and on the OS.

To install the separator outdoors, you need to arrange a place - dig a hole, level and concrete the area for the grease separator. This device requires careful preparation. To install a street separator, they usually turn to specialists.

To install a grease separator under the sink, you must first accurately measure the location of the furniture and sewerage units so that the device fits optimally. It is necessary to ensure a gap between the separator and the walls of the furniture of at least 3-4 cm, and also provide free access to the grease separator for its maintenance.

How to install

To install a grease trap, you must select and prepare the location correctly. The installation site should be as level as possible. It must be remembered that the device is filled with water during operation, so instead of a lightweight PVC case, you need to rely on a heavy unit weighing no less than 40 kg. This is only a static load. To it you need to add a dynamic load, because water, portionwise entering the separator body, invariably generates vibrations. A light shelf or one with weak fastenings will not support this shaking monster.

It is necessary to provide enough space so that the separator and its pipes fit in one compartment (cabinet), and are not connected to each other through the walls of furniture. After all, displacement of a heavy separator (for one reason or another) will cause breakage of pipes, the freedom of which is limited by the hole in the walls of the furniture. Therefore, see the picture for the correct installation option if there is not enough space under the sink.

The assembly process is described in the instructions. Installing a grease trap is not difficult. The main thing is to make sure that everything is in order inside the device (you can make sure when purchasing). Next is required:

- Place the housing in the desired location,

- connect it to the sink drain using a corrugated pipe,

- connect the housing output to the sewerage system.

The main thing is to make sure that all rubber gaskets are installed during installation, and not to confuse where the grease trap has the inlet and where the outlet is. Before installation, you can lubricate the gaskets with silicone, and after installation, coat the joints on the outside with silicone or another sealant.

Shop type grease traps

Large shop-type grease traps are usually installed in basements or technical rooms. With their help, wastewater is purified from the entire enterprise or from some workshops in which food products are processed. The productivity of such devices is much higher - from 2m3 per hour (0.5 l/s). Cleaning one grease trap is faster and easier than several, which is why enterprises prefer to install shop-type grease traps. The principle of their operation is also based on the gravitational method. The housing is usually made of polyethylene or polypropylene, providing the equipment with corrosion resistance and durability (service life up to 30 years). Grease traps are available in rectangular and cylindrical shapes. If it is not possible to place the grease trap on the surface, installation is carried out on a concreted area or in a pit. The efficiency of workshop-type equipment is quite high - at least half of all fat contained in the incoming water is eliminated. Maintenance of the devices consists of mechanically removing fat accumulations from the grease collectors with which shop-type grease traps are equipped. If the volume of industrial wastewater is large, grease traps are cleaned and grease waste is disposed of using a sewage disposal machine.

Care and cleaning rules

Whatever the operating principle of a sewer grease trap, sooner or later it will have to be cleaned. If you don't do this, you will encounter the following problems:

- strong unpleasant odor;

- pipe obstruction and blockage;

- accumulation of large amounts of waste and proliferation of bacteria.

Leaving an uncleaned container with fat is dangerous to health, especially if this is allowed in public catering. The standard cleaning method is to scoop out waste by hand. Mechanical removal of sewage is also possible. If you try to do everything on your own, you will realize that the procedure takes a lot of time. An untrained person is not familiar with the correct chemicals, methods of disinfection, and disposal of the resulting sludge. There is a high probability that important parts of the installation will be damaged, and the kitchen will have to be washed.

It is better to delegate this task to specialists. Our workers remove all types of contaminants, fight bacteria and unpleasant odors. It is inexpensive and the process takes minimal time. You can order regular service - the team will come to you on schedule. Visits are possible at a convenient time - if you work in the catering industry, this will not interrupt the cooking process.

To order a grease trap cleaning service or learn more about it, leave a request on the website or call us at the numbers provided.

Step-by-step instructions for installing a grease trap

- Preparing the required space.

- If the parts are supplied separately, install the outlet and inlet tubes (preliminary lubrication with silicone is required).

- Screwing the necessary adapters.

- Inserting the device body into the designated area.

- Treatment of all connection points with the siphon and sewer connected to the device with a sealing compound.

- Connecting all pipes and curing the sealant.

- Connection of the air duct to the sewer riser, if any.

- Check the tightness of the grease trap body and pipe connections using open water.

- The absence of leaks indicates that the device is ready for operation.

Benefits of treatment

Let us outline our distinctive advantages:

- When ordering installation of a grease trap in St. Petersburg and Leningrad Region from our company, you can have no doubt about the quality of the work. The service is carried out by a team of experienced workers who are familiar with all the nuances of performing such tasks, so the likelihood of errors during installation is minimized. It is not recommended to trust the installation of a grease trap to workers with questionable qualifications. With us there is no need to worry about system failures.

- Another advantage of using our company to install a grease trap is the speed of the work. We always adhere to the established deadlines when installing a grease trap, so nothing will disrupt the customer’s plans.

- The company’s pricing policy is formed taking into account the interests of the client - when ordering any of the services from us, you will not have to overpay. Installation of a grease trap at manufacturer's prices. Thanks to calculations and estimates, you will immediately see the entire cost and will be able to plan your expenses wisely.

- The use of modern equipment and advanced technologies when installing a grease trap determines the functionality of the device and the duration of its operational period.