A large number of types of insulation in the retail chain makes it difficult to choose. Because of this, in practice there are often cases when mistakes are made and the wrong thermal insulation materials are purchased: by thickness, method of fastening, absence or presence of vapor barrier properties, when it was necessary to buy the opposite, etc. When going shopping, the consumer should know almost everything about the product being purchased: properties, strengths and weaknesses, areas of application, installation methods.

Filling some gaps in the knowledge of home craftsmen, the editors of the StroyGuru.Com portal consider on their pages a group of insulation materials that have a thin layer of metal on their surface. Note that among experts there is no consensus on the name of insulation with foil. Some classify it as a group of combined materials, since the insulation consists of 2 layers, others classify it as foil.

At first glance, it seems that the second version of the name is more accurate. However, one small problem arises here: it is not clear what the insulation with “foil” is called when lavsan is used instead of aluminum. These are completely different types of insulation with different characteristics, advantages and disadvantages. In order not to confuse our readers, the article discusses insulation only with aluminum foil.

General features of foil insulation

The principle of operation of the classical type of insulation is based on the presence of a huge number of air chambers in their fibrous, fluffy, porous or foamed and other structure. And air, as we know, is the worst conductor of heat of all materials. Therefore, the more air inside the thermal insulation material, the better it copes with its task.

The ability of foil materials to create a barrier to heat leakage is based on completely different physical laws and principles. Their essence is the ability of infrared waves, close in spectrum length to daylight, to be reflected from a mirror surface similar to a sunbeam. This feature of thermal radiation was noticed at the beginning of the twentieth century by the Scottish scientist James Dewar. The result of the discovery was the well-known thermos. The heat in such a simple design is retained for a long time.

The builders tried to transfer the operating principle of the thermos to insulation: they glued thin, polished aluminum foil to one side of the material. The first experiments showed that heat savings when using aluminum as a reflector reach record levels - 97-99%.

Attention: on sale you can find insulation coated with aluminum. Such a metallized layer is not able to reflect heat back into the room. This is the same as trying to let in sun “bunnies” with a matte mirror.

In modern production conditions, it has become possible to apply foil to any sheet heat-insulating material, obtaining a durable, multi-layer structure, the delamination of which requires considerable force. As a result, insulation materials acquired new qualities, and the scope of application expanded significantly.

The most popular type of insulation with foil for interior finishing is aluform

Bestizol or Alufom is a bubble base consisting of aluminum foil (outer layer) and polyethylene (inner layer) on one side. The foil acts as a reflector of solar and heat rays. The polyethylene layer has a cellular structure and neutralizes sound waves and shocks. The advantage of this material is low thermal conductivity.

Bestizol can be used in both cold and hot weather. Due to its small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- air duct coverings;

- insulation of pipelines and other outlet communications.

Basic performance characteristics of foil insulation

The appearance of a foil layer on the insulation significantly changes the quality characteristics of the thermal insulation material. He:

- better tolerates sudden changes in temperature;

- is not afraid of moisture from the foil side;

- receives a high vapor permeability threshold - 0.001 mg/m*K;

- begins to return heat into the room by reflection - 95-97%;

- increases resistance to open fire;

- improves sound insulation properties, bringing the level of noise absorption to 68%, even for materials with conditional noise protection properties;

- increases the service life of all types of insulation by almost 2 times (some experts talk about a durability of 95 years).

Scope of application

Foil thermal insulation is used almost everywhere. It is used:

- for lining hot and cold water supply pipes;

- thermal insulation of ventilation air ducts, wells, wells;

- as a reflective screen near heating devices: batteries and air heaters;

- when installing a “warm floor”;

- insulation of various structural elements of the building: roof ceiling, walls outside and inside the building, attic, floor.

Thermal insulation with foil works great in the steam room of baths, in the country, in the garage, in utility buildings, for example, when heating an incubator, etc.

What insulation and why is it better to choose?

The appearance of foil on insulation led to the differentiation of its areas of application. Materials now have a narrow specialization.

Foil polyethylene foam

Foil-rolled polyethylene foam insulation in the class of reflective insulation has the widest range of applications. It is used for insulation:

- • floor. It is used as an additional thermal insulation layer in individual construction and the main one in apartments of multi-storey buildings. At the same time, it can simultaneously perform the functions of waterproofing materials. Insulation with a thickness of 2-3 mm is used as a substrate for parquet, laminate or linoleum floors;

- walls and ceilings. The material is especially in demand in conditions of limited space (balcony, loggia), since the small thickness of thermal insulation minimally “steals” the usable area;

For reference: More details about the problem of thick insulation for walls indoors can be found on the StroyGuru website in the work “Insulation for walls from inside a house or apartment.”

- roofs. Used alone or in combination with other types of insulation;

- baths At the same time, it performs two functions: heat and vapor barrier, protecting walls and ceilings from heat loss and waterlogging. But there are exceptions: they cannot be used in steam rooms and saunas, as they become deformed due to high temperatures.

Another area of application available only to this type of insulation is heat-reflecting screens behind heating devices: radiators, air heaters, infrared films located on the walls and ceiling. This measure allows you to save thermal resources, and in significant quantities.

Foiled polystyrene foam

The main task of foil foam is to direct the downward heat flows of all types of “warm floors” back into the room. It is not used for other purposes, although the instructions do not prohibit it. The reason is the prices. With almost the same effect, you can insulate the walls with polystyrene foam without foil, which will cost about two to three times less.

The use of foil polyethylene foam is not limited to construction. It can be found in agriculture (insulation of calf barns, incubators), automotive (insulation and sound insulation of passenger car interiors) and footwear (warm insoles) industries.

Foil glass wool (mineral wool)

Like foam plastic, foiled glass wool has a narrow specialization - it is the main type of insulation for baths (primarily steam rooms) and saunas, although nothing prevents you from insulating a roof or attic with wool and foil.

The high heat resistance (+300oC) of glass wool with a foil side has made it possible to increase the scope of its application. It is widely used for thermal insulation of boilers, boilers, and pipelines. At the same time, collapsible cylinders or half-cylinders of different sizes, both in length and diameter, are produced specifically for pipes.

Foil basalt wool

The excellent thermal insulation properties of basalt wool do not require a layer of foil when insulating residential premises. This type of insulation can only be afforded by consumers with unlimited financial capabilities. Therefore, foiled stone wool is used mainly for insulating buildings with a high level of fire danger (withstands up to +700oC), for example, gas stations. In this case, the external walls (facade) are insulated.

Types of material

Let's look at what types of insulation are called:

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to film with foil. Scope of application in various equipment, lining of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, it is fire resistant.

- Mineral wool with foil coating can have the form of a plate or cylinder. It also has a high degree of fire resistance.

- Expanded polystyrene, coated with foil on both sides. It also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the materials described above, is made on the basis of foil material, however, thanks to its unique technology, it can withstand temperature fluctuations from -200 +600 degrees, and is resistant to aggressive chemical environments.

How to put insulation on pipes

As a rule, such material has the form of a pipe “cocoon” made of mineral wool (withstands high temperatures) or polystyrene foam (moisture resistant). And how to insulate them, the question disappears in itself, since they have the appearance of a “cocoon”, which is put on top and fixed. There are main ones for chimneys of various diameters and temperature conditions.

However, if you decide to purchase sheet insulation, you may be faced with the question of how to glue it to metal? Aluminum tape will come to your aid, which is wound onto the insulation over the pipe. And, as in the options described above, you need to wear it with the shiny side facing you.

Is it possible to insulate the walls from the outside?

To insulate the walls from the outside, perforated foil insulation is used. This is a material that, among other things, has soundproofing qualities, can protect your home from moisture and wind, and also does not prevent moisture from leaving the room. This option is ideal for those who do not have the opportunity to perform such work indoors. However, such activities can only be carried out in the warm season and in dry weather.

To do this you will have to do the following:

- If you had any covering on the wall, you need to get rid of it. Then treat the surface with an antiseptic solution. It is better to do this in hot weather so that everything dries well; treat the lower part of the building especially carefully. Within two days the surface will dry completely.

- Next, build a frame from timber, secure it with self-tapping screws. Lay Penafol, then leave an air tunnel, glue the joints, then install the outer frame.

In conclusion, we suggest watching a video about the installation of Penofol thermal insulation:

Pros and cons of foil insulation

Like any building material, foil insulation has its pros and cons.

Among the advantages :

- service life increased by 25-75%;

- improvement of heat and sound insulation properties;

- reduction of heat losses, leading to savings on heating costs;

- reducing the load on autonomous heating systems, which prolongs their durability;

- eliminating drafts;

- a change in insulation technology that makes it possible to abandon vapor barrier work;

- moisture resistance, which eliminates the prohibitions on use in wet areas;

- preserves usable space in an apartment or house by using thinner insulation, up to 5 mm thick, to insulate the walls from the inside;

- ease of installation;

- low specific gravity, which does not create additional loads on the building elements.

Many experts and professional builders cite the affordable price as a plus. According to the editors of the portal, the cost of foil insulation cannot be mentioned at all among the strengths and weaknesses of insulation with foil due to the very wide range of prices. In some cases this is a plus, in others it is a significant minus.

Among the disadvantages, several points should be noted:

- there is no possibility of pouring a screed over the foil for glass wool and basalt wool;

- The small thickness of the insulation with thin walls does not provide complete thermal insulation. It is necessary to pair other heat insulators with the foil material;

- for gluing connecting seams you need a special, metallized adhesive tape (scotch tape), which increases repair costs;

- Foil insulation can only be laid on vertical or inclined surfaces using glue (other types of fastening violate the integrity of the foil layer). Self-adhesive rolls can be found in polyethylene foam. In all other cases, you need to buy special glue, which again increases the cost of the repair work.

Life time

Foil insulation is a new product on the construction market, so it is not yet possible to accurately determine its service life. Manufacturers claim that the material will not lose its qualities, will not deform and will not decompose for 95 years. Tests carried out with some types of insulation indicate that they can “last” even 150 years and remain of the same quality.

Foil insulation for walls has a very high service life

The service life of insulation with foil may depend on the adhesive composition used during installation. For example, if the glue can no longer perform its functions, then it is replaced, but the insulating material is left the same.

Popular brands and prices

Each foil insulation has its own leaders in the sales market. Here are the top three manufacturers of polyethylene foam, expanded polystyrene, glass wool and basalt wool (based on sales volumes) and the prices for these products.

Foil polyethylene foam. Many companies produce polyethylene foam insulation with a foil side. The leaders among them are:

- “Izolon” - can be bought from 78 rub./m2 with a thickness of 2 mm and from 110 rub./m2 with a thickness of 3 mm;

- “Penofol” - the price varies from 65 rub./m2 for insulation with a thickness of 3 mm to 456 rub./m2 with a thickness of 20 mm;

- "Ekofol" - sold at prices from 37 (2 mm) to 70 (10 mm) rubles/m2.

Please note: prices are average. Listed for St. Petersburg. In other regions, they may differ slightly in one direction or the other.

In addition to the above companies, Isoflex, Jermaflex and Folgoizol receive positive reviews.

Foiled polystyrene foam. Buyers are well aware of such brands of foil foam as Penoplex, Knauf, Technonikol and others. Prices depend on the thickness of the base. Therefore, for comparison, we will give in m3, although such a comparison does not make it possible to understand the huge variability of the price range: from 2.0 to 9.0 thousand rubles. for 1 cubic meter

Foil glass wool. Most often, foiled mineral wool is purchased - the price of insulation with a thickness of 50 mm is in the range of 130-140 rubles / m2. The brands “Rockwool”, “Knauf”, “PAROC” also find their buyers. However, prices here are much higher and have a wide range, and therefore it is inappropriate to list them.

Foil basalt wool. Among foiled stone wool, the leaders are “Rockwool” and “PAROC”. Prices are high and start at 4,000 rubles/m3 and end at around 14,000 rubles/m3.

How to lay it correctly

The presence of foil on the insulation dictates a slightly different installation technology. Therefore, we will consider some features of performing thermal insulation work with unusual insulation.

Which side should the insulation be placed on the structure to be insulated?

The answer is short: foil insulation indoors can only be placed with the foil facing out. When installed on the contrary, there is no reflection of heat waves back into the room. On the façade also, outwards. The metallized layer in this case is primarily a wind and vapor barrier, and only secondly helps the base of the insulation to retain cold air.

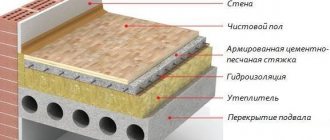

Floor insulation

Floor insulation is carried out using two technologies:

- "floating screed";

- “floating floor” - used mainly when installing “warm floors”.

"Floating screed"

Before laying the insulation on the concrete base of the floor, the following preparatory work is carried out:

- the concrete floor is freed from the old screed;

- repair work is being carried out to restore the surface of the concrete slab;

- the base of the floor is primed;

- waterproofing work is being carried out, etc. Detailed instructions for preparing the floor for pouring screed are given in the article “Preparing the floor for pouring screed”.

When using insulation without a self-adhesive side, the concrete base and insulation are lubricated with glue for the selected type of base. The edges of the slabs are also treated with adhesive. If the glue is contact (for Penofol), a pause is made for about 30-40 seconds, during which polymerization of the open surface of the glue occurs. After the specified time, the mats are fixed.

For better adhesion, the surface is carefully smoothed with smooth movements with little effort. Thin (2-3 mm) “Penofol” is placed on the walls to a height of 5-7 cm, and overlapped in the middle of the room. Thick slabs (5-10 mm) are mounted tightly to each other, without gaps. The joints are taped with aluminum tape (insulating aluminum tape). A fiberglass reinforcing mesh is attached to the laid insulation layer, after which the screed is poured.

Under "warm floor"

When installing a “warm floor” with heating elements placed inside a cement screed, the work is performed in the same sequence as when insulating a floor under a “floating screed”.

Under the infrared film, 3 mm thick insulation is attached to the base of the floor. A heating element is placed on it, and logs or sheets of plywood or OSB are attached on top of it. For this option, experts recommend buying ALP type insulation.

If possible, you should ground the foil through a Euro socket - if the infrared heater film breaks down, the aluminum foil will be energized. Cases of electric shock have not been written about on the forums, but such a possibility exists. Therefore, it is better to play it safe.

And we also note that many experts advise first reinforcing the insulation, and then attaching a reinforcing mesh over the heating elements. This is exactly the case when “you can’t spoil porridge with butter.”

Wall insulation

Foil insulation for walls can be based on fiberglass or polyethylene foam. It is attached to the surface using glue (in this case, only vertical slats are stuffed for fastening sheets of gypsum plasterboard, plywood or OSB) or placed in the cells of the sheathing.

The connecting seams are taped with metallized tape (adhesive tape). The gaps between the slats and the insulation are foamed with polyurethane foam, but it is better to avoid them. Vapor barrier work is not carried out - foil serves as a barrier to vapor molecules. From above, everything is covered with a protective screen made of plasterboard, plywood or OSB.

Ceiling insulation

Thermal insulation of the ceiling is carried out mainly by Isolon, 2-5 mm thick, type B (foil on 2 sides) or C (self-adhesive).

In the first case, the lathing is placed directly on the ceiling, in the second - on top of the heat-insulating layer. In both cases, the insulation is fixed with glue. In addition, you can use special self-tapping dowels with a large plastic head. When installing a stretch ceiling, no other types of work are performed. If the ceiling is to be painted or wallpapered, then plasterboard is attached to the sheathing.

Bath insulation

Rolled glass wool of medium thickness is ideal for insulating the ceiling and walls of a bathhouse. Insulation work starts from the ceiling and ends on the walls. Quite often they play it safe and attach parchment paper to the ceiling - it serves as an additional barrier to the penetration of steam into the insulation.

The insulation scheme includes:

- lathing device;

- laying insulation in the cells of the frame;

- gluing the joints with special tape (metalized);

- A counter-lattice is attached on top of the frame. The goal is to create a ventilation gap and a base for attaching the finishing trim.

Roof insulation

For thermal insulation of the attic space, foil mats made of mineral fiber are best suited. The order of work is as follows (enlarged):

- on the roof, all detected cracks are sealed with tow and foam;

- a counter-lattice is placed on the boards;

- a class B vapor barrier film (with the smooth side facing the room) or glassine is attached to the created frame with glue or a construction stapler;

- At the bottom of the rafter system, strips are placed behind which the thermal insulation will be laid;

- foiled mineral wool mats or expanded polystyrene slabs are laid;

- connecting joints are glued with metallized tape.

Insulation from outside

To insulate the facade you will need:

- foil mineral wool of medium thickness;

- reinforcing fiberglass mesh;

- wooden planks for lathing;

- glue;

- dowels with self-tapping screws.

According to the instructions, technological operations are performed in the following sequence:

- wooden slats are attached vertically to the wall using dowels in increments equal to the width of the insulation. Experts advise reducing this distance by a few mm so that the insulation fits tightly between the studs;

- sheets are glued to the wall;

- a reinforcing mesh is attached on top of the thermal insulation layer;

- The finishing work on the facade is carried out using the grid: siding is installed or decorative plaster is applied.

Let's sum it up

So, we found out that there are several types of foil insulation:

- polystyrene foam in sheets for flooring;

- mineral wool in sheets and rolls;

- penofol;

- shells for insulating pipes made of foam plastic and mineral wool.

All types of insulation, except shells, with a reflective layer are intended for internal insulation. The foil should be placed in the middle of the room. Such materials are suitable for external insulation, since the concept of reflecting IR radiation is reduced to nothing. Therefore, there is no point in paying for something that will not bring results.

Foam and mineral wool slabs must be glued using a special plaster-adhesive mixture from trusted manufacturers. The latter include the same Knauf or Ceresit. Laying on the walls is carried out from the bottom up, the sheets are additionally secured with dowels. And the most important thing is the presence of a ventilated gap in front of the reflective surface. If it is not there, then instead of reflecting heat you will get even more heat leakage and, in addition, mold on the finish.

The latest thermal insulation materials help to significantly reduce the cost of heating rooms. Covering walls with foil insulation is an economical solution for homeowners who are ready to install thermal insulation on their own.