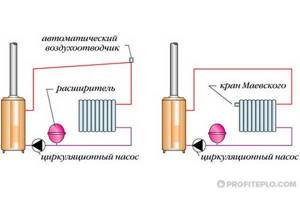

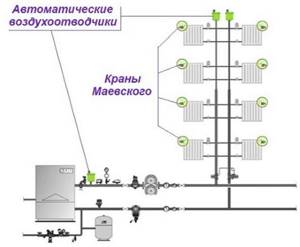

To remove air pockets from heating systems, manually controlled devices are traditionally used - drain valves, Mayevsky taps. Also widely used is an automatic air vent, which vents gases accumulated in a pipeline with a coolant liquid, without human intervention.

Automatic air vents for heating systems

Design and operating principle

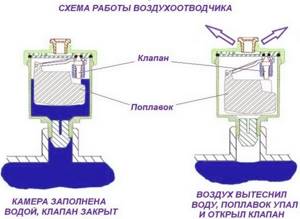

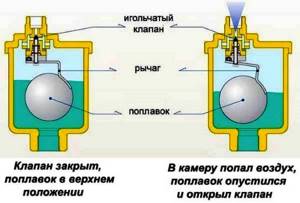

The automatic air valve for heating systems has a simple and reliable design. The hollow metal body is equipped with a connecting pipe, which is located at the bottom or side, depending on the version of the product. In the inner chamber of the device there is a float made of polymer resin. The float is connected by a lever rod to a needle valve that closes the hole in the upper part of the air vent cover.

When removing the plug using a manual valve, you need to control the process in order to shut off the device in time - the air will be completely released when a trickle of coolant flows through the vent. Installing an automatic air vent eliminates the hassle of servicing the heating system.

The operating principle of the device is based on the use of gravity - a hollow float is lighter than water, but heavier than air. In the normal state, the air extractor is filled with coolant, due to which the float is in the upper position, pressing the needle valve. Over time, the coolant is displaced from the internal chamber of the device by accumulating gas.

As a result, the float falls down under the influence of gravity, opening the valve slightly. The accumulated air under the pressure of the liquid in the heating system comes out through the hole in the drain body, and the chamber is again filled with coolant, which raises the float, automatically closing the valve.

Float ventilators serve to remove air pockets and also help speed up the draining of coolant from the system during maintenance or repair work. Due to a decrease in the coolant level in the circuit, the valves automatically open, and the air entering through them causes the liquid to drain faster.

Reasons for airing the system

Air in the heating circuit negatively affects the function and durability of the system. Oxygen reacts with steel and causes corrosion. Air locks interfere with the normal movement of the coolant, blocking the heating of the upper part of the radiators or entire heating devices. The presence of air bubbles in the coolant leads to premature wear of the moving parts of circulation pumps.

Air-filled heating system

There are several reasons for the formation of air jams

:

- Using water from a water supply system as a coolant that has not undergone special treatment to remove dissolved air. When heated, gases leave the liquid medium and accumulate at the upper points of the pipeline and batteries.

- Excessively fast filling of the system with coolant or its supply is not from the lowest point. In such a situation, the liquid does not have time to displace air from all corners of the installed system.

- Loss of system tightness due to installation errors or damage to elements.

- The use of polymer pipes that do not have a barrier coating, which prevents the penetration of oxygen molecules into the coolant.

- Errors when developing a project or arranging a system (incorrectly chosen angle of inclination of pipes, etc.).

- Air entering the system during repairs that require dismantling circuit elements.

Note! If an air lock regularly forms in one of the sections of the pipeline and it is necessary to increase the pressure in the system in order to move it to the air vent, it is recommended to install an additional automatic air bleeder in the problem area.

Technical parameters and functionality of air valves

In order for the water supply and heating system to function properly, experts recommend installing an air valve. This device allows you to protect the water supply from the accumulation of free air, and therefore protects it from damage. The presence of air bubbles, pockets, and vacuum contribute to the appearance of damage. Depending on the type of air vent, its functionality will change, but the technical parameters remain the same:

- Material. The main raw material for production is brass coated with nickel. Sometimes manufacturers use bronze, but the products are rare and have a high cost.

- Installation features. The air vent must be installed at the highest point of the heating or water supply system.

- The maximum pressure for heating pipes is 10 bar.

- The temperature of the working environment is from 100 to 120 degrees.

- The outlet can be located on the top or side.

- The diameter of the connection pipes is ½, ¾, 1 inch or 3/8.

- Models can be angular or straight.

- The float inside the structure is made of polypropylene or Teflon.

- The service life of parts reaches 30 years.

Variety of models for sewerage

*

Air valves are small-sized devices that can be independently installed into the system. They perform the function of removing air from the pipes, preventing the accumulation of air pockets.

Types of automatic air vents

Depending on the manufacturing option, the automatic float air vent can be straight, angular or radiator. Models differ in appearance and installation location, but the principle of air bleed is the same.

Devices with straight connection

A straight air vent is the most popular version of the device, since it is suitable for installation on the upper ends of vertical risers, on underfloor heating manifolds, as part of a safety group, on circulation pumps. Using a tee, it can be cut into a problem section of the pipeline if a small slope angle provokes the occurrence of air pockets.

Design of a direct automatic air vent with a pipe

Radiator and corner models

The corner air vent is designed for installation in hard-to-reach places. For example, due to the pipe located on the side of the housing, the device can be connected to the threaded end of a horizontal pipeline of a dead-end branch of the heating system. If necessary, corner automatic air vents in the heating system can be used instead of straight ones.

Instead of a Mayevsky manual tap, standard corner automatic drain valves can be installed on radiators to remove frequently occurring air pockets from radiators. However, a more rational approach is to use special radiator automatic air vents. This model also has an angular design, but differs from the standard one in its threaded design - it is suitable for connecting the device directly to the radiator, without using an adapter.

Technical specifications

Air vents for heating systems operating in automatic mode have different connecting diameters. Russian heating systems use devices with 1/2” and 3/4” threaded connections. The most common thread is 1/2”, which is also known as DN15 (connecting size is 15 mm).

The following characteristics are also taken into account when choosing:

:

- operating pressure (standard 10 atm, there are models with an indicator of 16 atm);

- operating temperature of the environment (standard up to 110-120°C);

- type of threaded connection - external or internal thread.

Main types of air vents

*

Automatic air valves allow you to remove accumulated gases in pipes, preventing them from malfunctioning. There are 3 types of air vents on sale - lever, membrane and cylindrical.

Lever

The lever mechanism located inside the structure is more sensitive to contamination of the working environment. The device is considered productive and is used on pipelines and heating systems that use water.

A traditional lever air vent consists of:

- brass body;

- a hollow plastic float moving inside;

- a rocker arm, which is pivotally connected to the float;

- an elastomeric spool located at the end of the rocker arm;

- spring loaded;

- fixed clip;

- lever mechanism.

Side connection model

*

As the water level decreases, the float begins to descend and pulls the lever along with it. This, in turn, opens an oval outlet. Thanks to this process, excess air comes out. Such devices are considered common and are suitable for water supply or heating systems.

Membrane

Membrane-type aerators are made from polyvinyl chloride. The most common use case is at the entrance to the system, where it is necessary to get rid of excess air and air pockets, as well as to prevent pressure drops. Some craftsmen suggest using a bypass valve, which maintains the medium pressure at the required level. This happens due to a bypass through a branch pipeline. The resulting air will not be able to re-enter the system due to the membrane closing the hole.

Cylindrical

The air vent of a cylindrical design has an oblong shape. Such models are often produced automatically; they have a cylinder-shaped float. Models have a side or direct connection; their structure includes a body with a cover, a float, a jet and a spool. There is a shut-off valve located at the bottom, through which the product is connected to the plumbing or heating system. The design must have a sealing ring to protect it from leaks.

Where are air vents installed?

Given how the automatic air vent works, the device is designed to be installed

:

- At the highest points of heating circuits (top of vertical risers, etc.), where air bubbles from the coolant tend to enter.

- At the ends of dead-end pipeline branches.

- As part of the safety group for boiler piping (primarily solid fuel) in a closed-type heating system. The automatic air vent is mounted on the manifold along with a pressure gauge and an emergency valve. The device helps to bleed air when the water jacket of a boiler unit is filled with coolant or quickly drain water from it when emptying a heat generator cut off from the heating circuit.

- On the circulation pump in order to improve its operation, if the design of the unit provides for the installation of a device for releasing air. Pumping airy coolant impairs the operation of the pump, an air lock causes it to stop, and the impeller and bearings wear out faster. The air vent also removes steam from the overheated coolant.

- On the pipeline of a working system if an area is detected where air constantly accumulates (this happens, in particular, if the angle of inclination of the pipes is not observed).

- For heating devices.

Air vents for heating. Selection and installation

There is always air in the heating system, which must be released by air vents. Where does the air come from? – gets in with the liquid when pouring, oxygen can also penetrate through plastic parts.

- Air is dissolved in the coolant and is released in the form of bubbles when pressure changes. Then the air accumulates at the highest points of the system, causing airing - air jams, and as a result, the cessation of circulation, or its reduction, as well as noise, water hammer...

To prevent significant influence of air on the operation of the system, requirements must be met.

- The system must be made in accordance with standards and regulations, with rational angles of inclination of all pipelines, without U-shaped transitions. If elevated areas cannot be avoided, then air exhaust means must be installed in them.

- An automatic air vent must be installed in the system, or several, in certain places, and manual air vents must be used - Mayevsky taps.

How the Mayevsky crane works, how it is installed

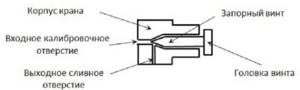

In the design of a manual air vent (Maevsky tap), one can distinguish a needle screw that locks a thin hole in the body. The air is vented to the side hole, which is convenient, since it can be turned in the desired direction and a container can be placed to collect the liquid.

The body has a standard diameter with a ½-inch or ¾-inch thread, so it screws into any standard fitting of the system, into radiator plugs.

- It is better to choose a Mayevsky faucet with a handle, so as not to use a screwdriver or wrench to unscrew it. But if there are small children, then the handles should be removed to prevent the child from being injured by hot liquid.

The Mayevsky tap must be installed in the upper corners of all radiators without exception, as well as at high points of the system, in U-shaped transitions. But for better results, in elevated areas, you need to additionally install an air sump where air can accumulate. Simply installing a tee and screwing an air vent into the upper outlet is not always effective.

Automatic air vents

Let's look at a typical design of an automatic air vent. The body contains a float, which is connected by a lever to a needle valve. There is an air vent in the top cover, which is closed by this valve.

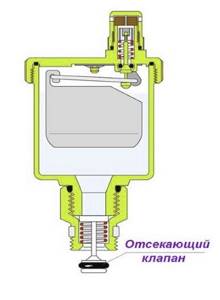

The entire device is positioned strictly vertically; at the bottom there is a fitting with a spring-loaded valve. Therefore, the housing can be removed for disassembly and cleaning from a filled system under pressure at any time - when the housing is unscrewed, the valve will close the hole.

Air from the coolant in the form of bubbles will rush upward and gradually accumulate in the upper part of the automatic air vent, displacing the liquid down. The float will drop, the needle valve will open, the air will be released, the liquid level will rise, and the valve will close.

Maintenance of automatic air vents, why they leak

The automatic air vent operates continuously. In the needle valve, where water and air are alternately present, significant salt deposits occur when the water dries out. Salts damage the seal in the valve seat. As a result, after the air, the coolant leaks out, the valve leaks, and water is released drop by drop from the air outlet hole.

- How to eliminate a leak in an automatic air vent is to remove the top cover, which in all designs can be easily unscrewed, and perhaps carefully use an adjustable wrench. Then disassemble and clean all parts of the needle valve. Mechanical cleaning with a wooden stick (a soft tool!), or soaking in concentrated citric acid or using other chemicals to remove sediment usually helps.

Placement of air vents in the system

It is recommended to install an automatic air vent:

- as part of a safety group at the highest point of supply at the outlet of a solid fuel boiler;

- at the upper points of storage and distribution fittings - buffer tanks, hydraulic switches, collectors, including heated floors;

- at the highest points of risers;

- on air vent separators;

It is always included in the automated boiler, so an additional one is not required near the boiler.

Manual air vents should be installed in each radiator, in U-shaped outlets and elevations of the system. Can replace automatic ones in vertical risers.

What to do if there is air in the system

If the system still becomes airy, then first of all you need to pay attention to the correct assembly and installation, drain the system and redo it by eliminating characteristic places for collecting air or installing manual and automatic air vents.

- The use of separators significantly helps to combat dissolved air in the coolant. If the volumetric system does not have devices performing air-separating functions (vertical hydraulic arrow, heat accumulator), then it is recommended to additionally equip it with a separator.

- If in a system with an automated boiler, the standard air vent cannot cope with complete air removal - there is constant noise in the boiler, which changes depending on the passage of air, then it is recommended to additionally install a separator with an automatic air vent on the return line.

The usual measure to combat the resulting air lock is to bleed air and coolant through taps, plugs, manual air vents with coolant supplied to the system from the water supply, pump...

What type of radiators require air vents?

Automatic radiator models are primarily intended for aluminum heating devices in which gas formation occurs due to contact of the coolant with the metal. It is also recommended to equip partially bimetallic radiators with an air vent valve. Fully bimetallic batteries have a steel core, which allows the installation of a manual valve.

Types of radiators for heating systems

Steel panel heating devices are equipped with a standard Mayevsky manual tap; a drain valve is mounted on cast iron radiators and tubular steel radiators.

Note! Do not smoke or light a fire near an aluminum battery equipped with an automatic valve for releasing gases. The device releases explosive hydrogen generated during a chemical reaction.

Types of air vents

Today on the air conditioning equipment market you can buy 3 modifications of devices: automatic, manual and for a radiator.

Automatic devices are the most versatile and have undeniable advantages during operation, since they do not require human intervention. Of course, the buyer will have to take into account that such designs have a high price.

Manual

The simplest and most inexpensive design. They usually have a brass body with threads. Some modifications are equipped with a specialized plastic insert.

There is a tiny outlet channel in the middle, which makes it possible to use the air vent with maximum convenience. Manual air vents work like this:

- During the operation of heating networks, the vent screw is closed and completely covers the outlet hole.

- When it becomes necessary to release air, the screw is slightly unscrewed, and under the pressure of the network, the air is released into the environment.

- Initially, only air flows out of the battery, and after a while - a mixture with water.

- The valve is closed after clean water flows out of it.

Automatic

An automatic air vent, for example, from the Danfoss brand, is installed in thermal systems and operates without human presence.

The body of the parts is made of brass, it contains a barrel, and is equipped with a threaded connection for connection to the heating network section. The body contains a plastic float, the movement of which is influenced by the liquid medium.

The operating principle of the automatic air vent is as follows:

- When the heating system is in an operational position, the working chamber is filled with water, which pushes the float upward under the pressure of the medium; in this position the valve is closed.

- When there is air in the housing cavity, the float gradually descends.

- When the fall level is sufficient, the valve opens and the accumulated air masses are released into the atmosphere. Installing an automatic air vent with a check valve prevents the backflow of network water.

- Instead of air, water enters the chamber, the float moves up and closes the discharge hole.

Radiator

The automatic corner air vent is designed for installation in hard-to-reach areas. For example, if the pipe is located on the side, it can be connected to the threaded end of a horizontal dead-end section of the heating line. Instead of the simplest Mayevsky tap, standard corner automatic drain valves can be installed on heating appliances on radiators, which often become airy.

The most optimal solution is the use of automatic air vents for Valtec radiators. This modification has an angular design, but differs from a standard vent with a threaded connection in that it can be directly installed to the radiator, without using an adapter.

Installation principles

The automatic air release device is installed vertically - for both straight and corner models, the cap covering the outlet is directed upward. A ball valve or shut-off valve must be installed in the pipeline before the drain valve.

Attention! An exception is the air vent in the boiler safety group - there should be no shut-off valves between this unit and the boiler pipe.

A shut-off check valve allows you to clean the air vent or replace a faulty device without draining all the coolant from the circuit. The automatic air vent with a check valve is easy to use.

When installing an automatic Mayevsky crane, use a wrench rather than an adjustable wrench to control the tightening force of the fasteners. In this case, you should not hold the device by the body, so as not to break it. Hold the air vent by the hexagon under the cylindrical chamber.

Results

The home heating system requires the installation of valves that remove gases from the pipeline and radiators. Automatic devices eliminate the need to regularly check the uniform heating of pipes and radiators and manually eliminate air pockets.

The air in the heating system is one of its main enemies. Therefore, automatic air vents must be provided in the heating system. Since not all heating systems operate on the same principle, the process of air circulation in the circuit also differs. Before you bleed air from the heating system, you should figure out how to do this, or you don’t need to do anything and it will come out on its own, for example, like in an open system.

Design features

The operating principle is based on the application of gravity to the float. If the float is in the raised position, the valve will be closed. If the tap is opened, the float will drop. Inside, the structure contains a rocker arm that is connected to a spring-loaded spool. When air enters the system, the float begins to compress downward, the spool opens, providing an opening for the release of accumulated gases. In principle, the operation of the air valve can be observed as the body fills with water as air escapes, and the spool closes automatically.

This device is installed in the water supply system.

There is a protective cap on the fitting - it serves as a fuse against heat loss in the event of possible malfunctions. The cap also protects against dust and dirt, preventing them from penetrating into the system when bleeding air. For example, an automatic air valve controls the release of air itself. It can operate at temperatures from -10 to +110 degrees, so it is installed both in the water supply and heating systems.

How does air enter the circuit?

There are two types of contours:

Peculiar automatic air vents in an open-type heating system allow coolant to pass through them, which circulates by gravity. The direction of circulation is determined by the design of the circuit. It always maintains a slope from the highest point, on the supply flow, to the lowest, on the return. There should be no air pockets. Air enters the heating system together with the coolant, which is in contact with it in the expansion tank. Then it is drawn into the flow in the form of small particles, since it is impossible to bleed air from the heating system from a coolant with a temperature of 20 degrees. The hotter the water, the more intense the process of separation of bubbles from the coolant occurs. The liquid pushes the bubbles upward. Accordingly, they reach a peak point where they find a way out.

Since expelling air from heating is one of the key tasks for safe and efficient heating of premises, equipment specially designed for this purpose is installed in the circuit.

Closed systems are sealed and circulation in them occurs thanks to a pump. In such circuits the flow rate is higher. They are designed in such a way that air pockets are formed in them. In this case, the installation of special equipment is required, since it is necessary to bleed air from the heating system while maintaining its tightness. It's called an automatic heating system air bleeder. Since the system is not in contact with the environment and is sealed, oxygen can only enter it with the coolant.

In addition to the transit of oxygen by the coolant into the circuit, airing can occur:

- due to mechanical damage;

- due to repair work;

- in case of leakage;

- after verification work.

Since it is not possible to prevent oxygen from entering the system, it is necessary to ensure that it finds a way out. For this purpose, several types of equipment are used to perform the task. They can work autonomously or in manual mode.

Applications for air valves

The devices are usually used in sewerage, heating, and water supply systems. The main task of the valves is to prevent air from getting inside the pipes, and if it does end up there, to remove it, ensuring normal functioning of the system without interruptions or breakdowns.

This shut-off valve is used in the following situations:

- If the plumbing is located far from the common riser.

- If the sewerage system is not provided with normal ventilation.

- If the system has a predisposition to burst pressure release.

An air valve will protect the pipeline from damage, because it will help stabilize the air pressure. A variety of models will allow you to modernize the system. The use of a kinetic air valve ensures that no vacuum is formed. It is used to let air in and out of the system before it is filled with fluid. Using electrically driven air valves will help you not have to control the process of changing the air flow, since the device will do everything on its own.

Types of equipment and principle of its operation

- open type expansion tank.

How to remove air from a closed heating system with a simple tank? It can perform the function of an air vent only in open circuits. Since it is not possible to ventilate a closed circuit heating system using a tank. Only sealed tanks are installed in them. The open tank is at the peak of the circuit, where oxygen bubbles tend to flow. The problem is that the water is enriched with it in the same tank, so there is a high level of air in the coolant, which is there until the liquid is heated;

Types of air valves

Air bubbles contained in the coolant tend to accumulate in certain places in the heating network and inside radiators. The resulting bubble continues to be fed with new portions of oxygen and develops into an air plug, blocking the movement of heated water in this area. As a result, nearby batteries or radiator sections cool down.

To bleed air from the heating system, 2 types of valves are used:

- Mayevsky manual crane;

- automatic air vent of float type.

Historical reference. During Soviet times, such air separators were not used. In private houses, open-type circuits were used, where the air escaped through an expansion tank. Centralized heating networks of apartment buildings were equipped with air collectors and drain valves installed at the highest points, and sometimes in radiators.

How does a drain valve work?

The design of the Mayevsky valve shown in the drawing is not difficult to understand. At the end of the brass body with an external threaded connection ½” (DN 15) or ¾” (DN 20), a hole Ø2 mm is made, the cross-section of which covers a screw with a conical tip. There is a small diameter hole made in the side of the body, designed to release air.

What can lead to traffic jams in the circuit?

The importance of air vents cannot be overstated. Traffic jams in the circuit can lead to different processes:

- circulation disturbance;

- pressure surges;

- reduction in the efficiency of heating equipment;

- corrosion of metal.

Autonomous air vent

Installing an air vent in the heating system prevents the formation of plugs and pockets. When bumping into them, the coolant stops. Sometimes plugs cut off entire sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air collected in the batteries, the circuit continued to work, only half of the radiator became cold. This significantly reduces the heating efficiency and slightly increases the cost of its operation.

For open systems, one of the most serious threats is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, so there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to remove air from the heating system, oxygen reacts intensively with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to replace it.

The direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

Occurs if the valve for bleeding air from the heating system and all sensors are in good working order and working correctly. Due to the increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its quantity in the circuit. After cooling, there will not be enough fluid in the system, and the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on. And from this moment in winter, the countdown begins when the pipes defrost. Depends on how insulated the house is. Sometimes this happens in just three hours. In this case, unpleasant news awaits you at home from work;

This occurs if there is a malfunction of the valve for bleeding air from the heating system, or the temperature-controlling equipment. An unlikely situation, although possible. The results of this are very disastrous. At best, repair or replacement of the boiler; at worst, injury;

- rupture of the circuit and release of the hot water fountain.

A very likely situation is that the joints may not be tightened enough. As the pressure increases, they cannot withstand and crack. At the same time, hot coolant flows from the pipe like a fountain. Not only does the circuit need to be repaired, but the neighbors also need to repair the ceiling, since you flooded it thoroughly. This is the kind of chain that can be caused by simply airing the system.

A plug in the circuit can lead to serious consequences, such as system defrosting or an accident.

How to remove a plug from a circuit

Before removing air from the system, it must be detected. Options:

- before you bleed the air from the heating system yourself, would it be better to call a technician and get it over with?;

- try to find it yourself by knocking on the pipes. The sound in the area where the traffic jam is located will be different;

- check the uniform heating of the radiators. The top should be warm, there may be a slight difference from the bottom. The main thing is that the temperature at the top is higher. If this is not the case, then there is a problem in the batteries.

Why do you need an automatic air vent?

The purpose of this device speaks for itself: to remove air from the heating system, and in automatic mode, without our participation.

The appearance of the air vent is as follows:

This is with a bronze body. And this is with a stainless steel case:

In the second photo, in addition to the air vent, there is also a shut-off valve; these two devices are often placed together.

Why is there a shut-off valve for an automatic air vent?

For convenience: first screw in such a valve, and then install an air vent into it; the valve has a plastic flag, which, when screwed in, the air vent presses on, thereby opening access to the heating system. If for some reason you need to disconnect the air vent, you do this, after which the valve will cover the remaining “hole”, preventing the coolant from leaking out. We repaired this air vent or bought a new one, screwed it in again - the valve opened...

How to repair an automatic air vent?

What problems can occur with automatic air vents?

“Thanks to” the low-quality coolant, hardness salts may form on the valve needle, which is why the valve will not tightly cover the outlet hole - the air vent will begin to leak. The fix is simple: unscrew the housing cover, clean the needle and other mechanism, and put everything back together. The problem will be solved until the next formation of hardness salts on the valve parts.

Another possible malfunction is the destruction of the sealing ring under the housing cover. In this case, the coolant also begins to leak, but from under the lid. The fix is also simple: either replace the ring, or wind fum tape onto the threads on the body.

Types of automatic air vents

Automatic air vents are available in the following types:

– the straight lines that we met in the very first pictures, I’ll show them again:

– corner ones, which are often installed on radiators instead of the Mayevsky tap:

– radiator plugs, having the same thread as the radiator plugs:

As you know, Mayevsky valves are designed to bleed air from the system through the radiator. This bleeding is performed manually as an air plug forms in the radiator, which is easy to determine by touching the radiator with your hand... Installing a radiator air vent frees you from such work, since the air will be removed automatically.

However, no matter what the air vent looks like, they work on the same principle.

Mayevsky crane

Of course, Mayevsky’s faucet does not belong to the category of automatic air vents, so it seems to be off topic of the article. But there’s not much to write about it, and since it’s still an air vent, a few words about it here.

Mayevsky taps are installed on radiators:

To bleed air, you just need to slightly open the screw on the tap with a screwdriver:

The blue arrow shows where the air will come out from.

If initially (when installing heating) we plan to install a Mayevsky tap, then we need to install the radiator so that the part where the tap is “looks” upward (1...2 cm higher).