Most owners of private houses, and sometimes apartments, prefer autonomous heating systems and hot water supply. Each of them necessarily includes a water heater or boiler. These devices differ in many ways, the main of which is the type of fuel on which they operate.

Home water heater

Despite the differences in constructive and design solutions, they are united by a single operating principle. The hot water boiler heats water, which is used for heating and hot water. Another thing is that in different designs this principle is implemented in different ways. It's hard to say which one is better. Each type of boiler corresponds to specific operating conditions and the number of tasks to be solved.

How does an electric hot water boiler work?

- Indirect heating.

- Direct impact on the coolant.

How is heating of the coolant ensured?

- Indirect heating - this operating principle is used by heating elements and induction models. In the flask, there is a heater whose surface is in contact with the coolant. Under the influence of electricity, the surface of the heating element or induction rod heats up. Heat is transferred to the coolant surrounding the heater surface on all sides. The principle of indirect heating is ineffective. A large amount of thermal energy is spent on heating the heater and is lost during heat transfer. It takes about 10 minutes for the heater to reach operating power after switching on.

- Direct heating is the operating principle that distinguishes electrode electric boilers. The essence of the method is the direct impact of electric current on the coolant. To ensure the required heating intensity, a large volume of salt is added to the heating system fluid. Although you can make the coolant yourself into the heating system, it is recommended to pour a special compound made in a factory. Twice a year, you will need to bleed the gas from the heating system, which is a product of direct exposure to the coolant by electric current.

All boilers using the principle of indirect and direct heating are instantaneous water heating boilers for individual heating systems. For successful and efficient operation, constant coolant circulation is required.

The pressure in the boiler is created in a natural and forced way. In the heating element boiler equipment, a circulation pump is installed, which ensures the necessary movement of the coolant in the heating system. Electrode boilers operate on the principle of natural circulation, but, if necessary, it is possible to install a pump on the return pipeline of the heating circuit.

Providing temperature for hot water supply

- Heating element boilers - some modern models of electric boilers that use a tubular heater have two circuits: for heating the coolant and connecting to the hot water supply. Another heater was added to the boiler design. When the hot water tap is opened, a signal is given to turn on the heating element. Hot water starts flowing after a few seconds.

- Induction and electrode boilers - the device does not provide for the possibility of connecting DHW for domestic needs. If there is a need for hot water, install an indirect heating boiler, connecting it to the heating system.

In terms of their energy efficiency, double-circuit heating elements are significantly inferior to schemes using an indirect heating boiler.

Electric boilers

- Reasonable cost;

- Availability of installation;

- Safety;

- Ease of operation;

- There is no need to allocate a separate room;

- Low noise level;

- Environmentally friendly.

Electric water heating boilers are simple devices. The main elements of this device:

- Heat exchanger, electric heaters are mounted on it;

- Control and regulation unit.

Electric water heating boilers in some cases are sold with a circulation pump, safety valve, expansion tank, and filter included in the kit. These types of boilers, which have low power, are available in two types:

- Single-phase boilers with a power of 220V;

- Three-phase boilers with a power of 380V.

Electric boilers can be either the main source of heating or a backup one.

Features of heating organization

An electric boiler is a convenient equipment option for heating a home. If the house is not used for permanent residence, then it makes sense to use non-freezing liquid rather than water as a coolant

This precaution will prevent the destruction of pipes during an emergency stop of the heating system due to power outages

Due to the thermal insulation of the housing, the circulating coolant will not cool down immediately, so short-term power outages will not affect the operation of the system. But it is impossible to keep the coolant hot for a long time when the power is turned off.

When installing electrical equipment for heating, it is necessary to make a separate supply line with independent fuses. And when installing a boiler, this is not necessary; this equipment is connected to a common line, since its power is low.

So, electric boilers are the best option for areas where there is no gas supply. Such equipment can be used both for heating and for supplying hot water. Thermal equipment is characterized by ease of use, environmental safety and fairly high operating efficiency.

Boilers and other heating elements operating on solid fuel were among the first to appear, and have not lost their relevance to this day. They are successfully used for cottages, baths, and small swimming pools. A wood-burning water heater is also installed in trains and villages where access to gas fuel is difficult. And sometimes the power of the electrical network is not enough to connect an alternative boiler.

For residents of villages and outbacks, a wood-burning heater is a real godsend, allowing them to significantly improve their living conditions. Although the cost of a wood-burning shower head is not too low, the fuel is much cheaper and more accessible.

Types of wood boilers

Depending on the purpose, I distinguish:

- boilers for heating and supplying hot water, with a built-in firebox - known as titanium;

- installations similar to the previous ones, but with a separate column;

- combined - with an electric heating element to maintain temperature;

- spiral-shaped containers for heating water in swimming pools.

Why do you need a hot water boiler?

If the housing does not provide centralized heating and hot water supply, then these functions are assigned to the boiler. As a rule, this situation occurs in suburban buildings. However, heating equipment can be successfully installed in an apartment.

With the right choice of equipment, the system will effectively perform its task, creating warmth and comfort in the room, regardless of the weather outside. Water heating boilers are safe, easy-to-use devices, the heating efficiency of which depends on the specific model and a number of other factors.

Solid fuel boilers

This is a popular type of boiler among home owners. Used for heating in rural areas or in places where firewood, pellets or coal are inexpensive and freely available.

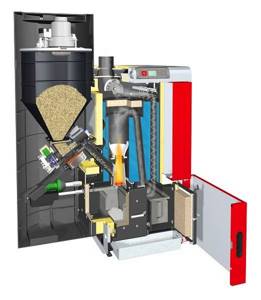

Pellet water heater design

- Type of fuel. Wood is used as fuel - firewood or pellets, as well as coal. There are mixed-type boilers with several fireboxes.

- Method of fuel combustion. Classic, long-burning and pyrolysis are available.

Pellet versions are popular, providing a high level of automation with long-term programming of operating modes. These are the most modern water heaters in the solid fuel family in terms of fuel type.

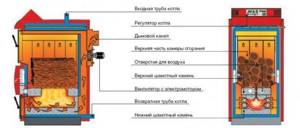

In a classic solid fuel boiler, heat is generated by simply burning wood, like in a stove. Hence all the disadvantages of such units - they will have to be cleaned, monitored for smoke removal, constantly adding firewood and regulating the combustion force and draft with a damper, etc. In principle, we are not talking about any autonomy. Efficiency does not exceed 75%. The advantage lies in reliability, simplicity of design and wiring diagram, independence from electricity and low cost.

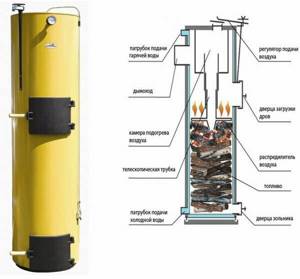

Long-term or top-burning water heaters use a different method of loading fuel - from above. Due to this, complete combustion occurs and efficiency increases.

Construction of a pyrolysis boiler

Solid fuel water heating boilers

Solid fuel water heating boilers are another worthy alternative to gas boilers. The fuel can be wood, coal, coke or wood pellets. You can find boiler models that operate on any of the listed types of fuel.

Many solid fuel boilers are automatically capable of maintaining the desired outlet water temperature. It happens this way. The boiler has a sensor that monitors the water temperature at the outlet. The sensor is connected to the damper. When the temperature starts to go off scale, the damper begins to close. Due to this, the combustion process slows down. When the temperature drops, the damper begins to react and open slightly. It should be noted that such a device does not require a network connection. Let's look at the main types of solid fuel boilers: (See also: Water supply for a bathhouse)

Types of heaters for heating systems

Despite the market diversity, water heating units, depending on what raw material is fuel, are divided into the following types:

- Gas. This is the most common type due to its efficiency and relative cheapness of fuel.

- Solid fuel. These water heating boilers are common in rural areas and areas remote from gas mains.

- Liquid fuel. They are the least popular because they are complex and expensive to operate.

- Electrical. Popular among urban users. They are distinguished by their efficiency, but also by the high cost of fuel - electricity.

- Combined. This is a universal type of heater that helps control fuel costs depending on market conditions.

According to their purpose, water heaters are divided into the following:

- Single-circuit, providing exclusively heating.

- Double-circuit, which additionally provide hot water for personal needs.

According to the method and location of installation, they are divided into wall-mounted and floor-mounted. Some are produced exclusively in a floor-standing version, for example, running on liquid and solid fuel.

Heating boilers Buderus

Each variety has different characteristics that will have to be taken into account when installing autonomous heating.

Types of boilers by heating and installation method

Modern boiler equipment can be classified according to many criteria. One of them is a method of heating the coolant.

There are 3 types of boilers:

- Heating elements. They are equipped with tubular electric heating elements.

- Electrode (ionic, electrolysis). If alternating voltage passes through the coolant, it will begin to heat up. For this purpose, fuel with certain characteristics is used.

- Induction. Their action is determined by the properties of ferromagnets, which heat up under the influence of induction current.

Depending on the manufacturer and specific model, each boiler has unique features, strengths and weaknesses. It is also customary to classify hot water boilers according to the installation method.

Floor-standing

Such units are installed in large premises. Due to their significant weight, they cannot be mounted on a wall. They often require their own foundation. The burners of such boilers are atmospheric and forced. The first ones are simpler, cheaper and quieter. The latter are more expensive, but their efficiency will be higher. Any boiler is equipped with an atmospheric burner, but you will have to purchase a pressurized burner.

Advantages:

- durable heat exchanger;

- if desired, heating systems with a large number of circuits are created;

- possibility of increasing power.

Along with the advantages, such equipment also has disadvantages.

Flaws:

- high price;

- large mass;

- the boiler must be installed in a separate room;

- restrictions on the use of coaxial chimneys.

Thanks to its high power, the unit effectively copes with its main task - heating a large industrial premises.

Wall mounted

These models, considering their power, are ideal for heating rooms from 100 to 350 m2. These are compact devices that are easy to install and at the same time have an attractive design. Exhaust gases are removed in two ways: through a chimney or a special coaxial pipe. The second method is forced due to the built-in fan, therefore it is more effective.

Advantages:

- compactness;

- installed in almost any room;

- availability;

- a coaxial chimney can be installed.

As for the disadvantages, there are only 2 of them: wall-mounted devices are not as powerful and reliable compared to floor-mounted ones.

Wall-mounted appliances can have piezo ignition, for which a special button or automatic electronic mechanism is provided. In a word, in the first case the launch is manual, and in the second it is automatic, the main thing is that there are no problems with the power supply.

How to choose a hot water heating electric boiler

After determining the operating parameters, a suitable model is selected based on manufacturer and cost. Popular boilers are offered by domestic and foreign manufacturers.

The best brands of hot water electric heating boilers

- European boilers - Thermona THERM EL, Kospel EKCO, Warmly Group, Vaillant eloBLOCK VE, Wespe Heizung Complete and Wespe Heizung Master.

- Russian electric boilers - Verpat EVPM, Elvin EVP, Nevsky KEN.

Rules for installing an electric water heating boiler

- The installation is carried out by an electrician who has the appropriate work permit.

- The connection of the electric boiler to the voltage network is carried out through automatic devices and RCDs (with the exception of electrode boilers). Grounding must be connected. It is prohibited to use water supply or heating risers as a grounding loop.

- Safety rules require the installation of a voltage stabilizer and maintenance wiring of the system at least once a year, before the start of the heating season.

The first start-up and commissioning of the boiler is carried out in the presence of a representative of the company supplying electricity. The technical passport contains a note stating that the connection was made without violations, and the name and surname of the electrician who performed the installation is indicated.

The condition for safe and economical operation of an electric boiler is proper connection and operation. Service life varies from 6 to 20 years, depending on the design and internal structure.

Most owners of private houses, and sometimes apartments, prefer autonomous heating systems and hot water supply. Each of them necessarily includes a water heater or boiler. These devices differ in many ways, the main of which is the type of fuel on which they operate.

Home water heater

Despite the differences in constructive and design solutions, they are united by a single operating principle. The hot water boiler heats water, which is used for heating and hot water. Another thing is that in different designs this principle is implemented in different ways. It's hard to say which one is better. Each type of boiler corresponds to specific operating conditions and the number of tasks to be solved.

Gas boilers

Gas boilers are divided into:

Floor-standing models in which the heat exchanger is usually made of steel or cast iron. It is difficult to say which material is the best. Steel boilers are lightweight and resistant to shocks that may occur during transportation. And cast iron models have a much thicker heat exchanger, and this has a positive effect on their service life. Gas fuel is the most common type of fuel nowadays, which is why such boilers are extremely popular. Most modern water heaters have an electronic ignition system, which is very convenient during operation.

The main thing that makes sense to pay attention to when purchasing a gas boiler is the performance indicator. In this matter, you need to take into account the total area that this boiler will heat

Modern heating equipment makes it possible to heat areas up to 350 sq.m. To ensure that combustion products are completely removed, gas heating systems are equipped with natural and forced draft. Wall-mounted water heating boilers are attached to the surface of the wall, and they can also be hidden in a closet or other niche. The advantage of wall-mounted boilers is their compact dimensions. They have a tubular burner as well as a slow-running heat exchanger.

Distinctive features

A long-burning double-circuit boiler operating on solid fuel is a modernized version of classic heating equipment.

It, among other things, also has a heat exchanger built into it, providing the home with a full-fledged hot water supply.

The design of the two-circuit model includes the following elements:

- Housing - can be made of sheet steel or cast iron. The thickness of the metal ranges from 4 to 6 mm.

- Fire chamber . Usually made from the same material as the body of the device.

- Grate type grate . It is located inside the combustion chamber; the material is cast iron. Enriches the fuel with the oxygen necessary to support combustion.

- Ash pan . Accumulates solid waste generated during combustion.

- Chimney - removes combustion products outside the room.

- "Water Shirt" . Most often it is built into the boiler body and filled with water, which receives heat from the walls, after which it enters the heating system.

- Additional heat exchanger coil - distinguishes double-circuit models from single-circuit ones. It is built into the water jacket of heating equipment to provide hot water supply to the house.

The main disadvantage of this design is the low degree of productivity . Therefore, models made of cast iron are more popular because they take longer to cool down.

Steel and cast iron boilers

Boilers with a steel heat exchanger have a long flue gas path. In this regard, they better transfer heat to the heat exchanger. In addition to this, the walls of the smoke duct are easy to clean. To achieve a high level of efficiency, cast iron boilers have a heat exchanger surface with many fins located close to each other. The design of such a boiler does not have a long flue gas path, so cleaning such a boiler is a complex and time-consuming process.

Use of materials is permitted only if there is an indexed link to the page with the material.

Warmth in the house is a prerequisite for comfortable living. In the absence of centralized heat supply systems, boilers are installed to heat water. From an economic point of view, a gas boiler is the most profitable, but central gas supply is not available everywhere. If it is impossible to use gas equipment, an electric boiler will be the best choice.

Heating elements are installed mainly in storage boilers used to heat water for the hot water supply system. But there are also models of boilers with heating elements designed for heating a home. Boilers with heating elements are unreliable. If there is a water supply failure, the automation does not always have time to operate, and the heating element may burn out.

Electrode system

The electrode water heating system is more economical, reliable and safe. Due to direct contact with the heated medium, heat loss is reduced and energy is saved. If there is no liquid inside the housing, the contact between the heating elements disappears and heating stops without the participation of sensors, that is, the boiler cannot burn due to the lack of coolant.

The only but significant drawback, which appears after several years of operation, is the accumulation of scale on the electrodes. This significantly reduces the efficiency of the equipment.

Induction coils

A modern boiler, in which the liquid is heated by electrical induction, is the most effective solution. Since the heating element does not have direct contact with water, scale formation on them is excluded.

Therefore, the induction boiler operates throughout its entire service life without reducing its efficiency. The disadvantages of a boiler with an induction coil include its high cost, so this type of heating equipment is less often used for home improvement.

(no votes yet)