When is it necessary to install a circulation pump in a heating system?

The presence of a circulation pump in the heating system reduces the heating time of radiators to several minutes. It forcibly accelerates the coolant through the heating system, ensuring uniform circulation of hot liquid. The need to install it arises in cases where the natural circulation of the coolant cannot cope with heating the house.

Pumps are installed immediately when installing a heating system or during its modernization. Sometimes, errors in the design of heating systems are discovered only during operation.

The reason for poor heating of housing construction can be fouling of the internal walls of the system pipes with rust, scale or dirt.

This increases the hydraulic resistance in the heating system and deteriorates the circulation of the coolant in general in it or in certain areas. Installing a pump can help solve the problem of heating a home in such cases without completely replacing the heating system. The smooth operation of pumps depends on their correct installation.

Rules and nuances of equipment operation

A circulation pump is not bought for a year or even two. Therefore, every owner of a country house must ensure that the equipment is in good working order for many years. Reliability and correct operation of the device can only be achieved through correct and timely maintenance.

The list of basic rules for operating a heating pump must include the following aspects:

- it is prohibited to turn on the device with zero supply;

- make sure that the equipment is grounded;

- make sure that the electric motor does not heat up above the permissible norm;

- check the connection in the terminal box for the presence/absence of damage, and all cables must be completely dry;

- make sure that there is no extraneous noise or vibration when the device starts;

- the equipment must operate at the coolant flow level recommended by the manufacturer;

- It is forbidden to run the circulation pump without water.

If the equipment is idle for a long time, it is recommended to turn it on for 10-30 minutes every month. This simple rule will help avoid oxidation and, as a result, shaft blocking.

If any malfunctions or problems occur in the operation of the pump, you should call a specialist as soon as possible. This will help get rid of many problems and unplanned financial expenses.

Particular attention must be paid to the temperature of the coolant. It should not exceed 60-65 degrees Celsius. If you neglect this rule, sediment will appear in the pipes and inside the pump, which will negatively affect the operation of the entire heating system.

What are the benefits of installing circulation pumps in heating systems?

Modern pumps allow you to regulate the intensity of coolant supply in the system automatically. Maintaining a constant temperature in it protects system parts from premature wear, and the uniform movement of coolant through pipes and radiators increases the service life of the thermal unit and expansion tank.

Other advantages of installing circulation pumps in the heating system include:

- eliminating the possibility of air locks forming in the system;

- increasing the efficiency of the thermal boiler and reducing fuel consumption for heating the house;

- the possibility of installing heated towel rails and using small diameter pipes in the heating system.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

The main disadvantage of circulation pumps is their dependence on electricity. Interruptions in its supply can damage the devices.

Common breakdowns

The most common problem that causes equipment that provides forced pumping of coolant to fail is its prolonged downtime.

Most often, the heating system is actively used in winter, and is turned off during the warm season. But since the water in it is not clean, sediment forms in the pipes over time. Due to the accumulation of hardness salts between the impeller and the pump, the unit stops working and may fail.

The above problem can be solved quite easily. To do this, you need to try to start the equipment yourself by unscrewing the nut and manually turning the pump shaft. Often this action is more than enough.

If the device still does not start, then the only solution is to dismantle the rotor and then thoroughly clean the pump of accumulated salt deposits.

Types, features

Centrifugal-type devices operate on the principle of fluid intake by an impeller and ejection in a given direction. They work with equal efficiency for suction and discharge. All circulation pumps used in heating systems are divided into two main groups: wet and dry rotor. Each type of device has its own design features.

Glandless Rotor Pumps

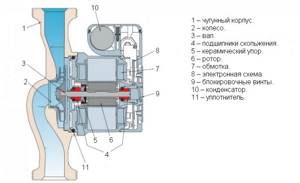

Equipment of this type is considered the most suitable for domestic heating systems due to the low noise level they create during operation. In their structure they are similar to drainage units. Externally, pumps with a wet rotor can be distinguished from dry designs by the absence of fins on the motor housing and the impeller at its end.

Their impeller is mounted directly on the motor shaft. Seals are placed on it to prevent leakage. The housing has a sealed design. For its manufacture use: brass, cast iron, bronze or stainless steel. The pump rotor is most often made of ceramic material. A special feature of the design is its direct contact with water.

Centrifugal force is created inside the pump. The rotating impeller reduces the pressure inside the device body. This causes an influx of fluid. It increases the pressure. The resulting temperature difference creates conditions for pushing the carrier into the system.

Among the advantages of pumps of this type:

- independent removal of air locks from the system;

- less wear on pump parts;

- self-cooling.

Dry rotor pumps

The device does not have direct contact with liquid. Pumps of this type have the highest efficiency. The structure is cooled using an air system. The main disadvantage of this type of equipment is the increased noise level during operation. Dry rotor circulation pumps are designed to work with large volumes of water. They are preferred when installed in the heating system of industrial facilities.

Specifications

What data must be specified for the product:

- Pressure H. (meters of water column). This is the difference between the inlet and outlet pressures. Indicates the height to which the liquid can be driven.

- Flow Q. Measured in cubic meters of liquid per hour of operation. This is the actual volume of water that can be pumped per unit of time.

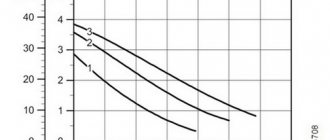

- Pressure-flow characteristic. This is a graph that shows the relationship between flow and pressure.

- Hydraulic characteristics. Also a graph that shows the dynamics of pressure loss depending on the amount of incoming liquid. Almost always a pattern emerges - to increase the flow by 2 times, the pressure increases by 4.

- Cavitation reserve. Indicates the minimum inlet pressure at which the absence of processes leading to water hammer and, consequently, irreversible mechanical impact on pump parts is guaranteed.

- Useful power. The number of watts that will be spent on useful work with the liquid.

- Actual power. Given without taking into account losses, sellers often try to pass off this value as useful.

- Nominal diameter. Inner diameter of pipes. Must match the diameter of the home circuit pipes.

- Efficiency

- Nominal pressure. The highest barrel indicator at which the manufacturer still guarantees normal operation. Indicated for 20 degrees.

- Energy efficiency class. Shows the level of electricity consumption during operation. Now all household appliances have this indicator, so the closer to A, the better.

The best circulation pumps for heating systems

Grundfos UPS 25-40 180

Country of origin: Serbia. The model is one of the most popular and in demand. Installation method: horizontal and vertical. The unit has protection against overheating. Operating the pump for pumping heavily contaminated liquids is strictly prohibited. The operating temperature limit is from 2°C to 110°C. The unit operation setting is mechanical.

Characteristics:

- productivity – 2900 l/h;

- power consumption – 45 W;

- head – 3.8 m.

Advantages:

- high performance;

- affordable price;

- reliability;

- good pressure.

Flaws:

- more expensive than similar domestically produced devices;

- the model is often counterfeited.

"Whirlwind" TsN-25-4

Country of origin: Russia. The model is designed for pumping hot and cold liquids. Operating temperature range from -10°C to 110°C. The body of the product is made of cast iron. The optimal operating mode of the pump is selected using a special switch.

Characteristics:

- productivity – 50 l/min.;

- power consumption – 72 W;

- head – 4 m.

Advantages:

- low noise level;

- ease of installation and operation;

- long service life;

- affordable price;

- efficiency;

- compactness.

Main disadvantage

- discrepancy between the characteristics declared by the manufacturer and the actual ones.

Oasis CN 25/4

Country of origin: China. The model with a wet rotor is intended for installation in heating systems designed to heat rooms up to 100 sq.m. Installation method: horizontal. The body is made of cast iron, the rotor is ceramic. The model can be used to supply hot water and in underfloor heating systems.

Characteristics:

- productivity – 170 l/min;

- power consumption – 245 W;

- head – 8 m.

Advantages:

- efficiency;

- compactness;

- light weight;

- long service life;

- ease of installation and maintenance.

Flaws:

- not identified.

Grundfos UPS 25-60 180

Country of origin: Denmark. Model with wet rotor. Designed for installation in horizontal and vertical positions. There are requirements for the purity of the liquid. Can be used for heating and hot water supply systems. The product has a bronze body. The pump has 3 operating speeds, with which the pressure in the system is regulated.

Characteristics:

- productivity – 4.35 cubic meters/hour;

- power consumption – 60 W;

- head – 6 m.

Advantages:

- several rotor speeds;

- compactness;

- reliability;

- ease of installation and operation.

Flaws:

- not identified.

Grundfos ALPHA2 25-60 180

Country of origin: Denmark. The low-noise pump model has a high quality design. Designed for installation in heating systems of low-rise buildings. The model has two settings: manual and automatic. The device installation method is vertical.

Characteristics:

- productivity – 3 cubic meters/hour;

- power consumption – 45 W;

- head – 6 m.

Advantages:

- low noise level during operation;

- ease of installation and operation;

- reliability;

- long service life.

Main disadvantage:

- high price.

Valtec VRS 25/4 130

Country of origin: Russia. Model with wet rotor and three-stage speed switch. The body of the product is made of cast iron. Installation method: vertical and horizontal. The maximum operating temperature limit is 110°C. The rotor is cooled by the pumped liquid.

Characteristics:

- productivity – 3000 l/hour;

- power consumption – 72 W;

- head – 4.2 m.

Advantages:

- reliability of the design;

- affordable price;

- ease of installation and operation.

Main disadvantage:

- short standard power cord.

JEMIX WRF-50/12

Country of origin: Russia. Model with wet rotor. The pump has an aluminum single-speed motor. The product is intended for installation in heating systems of small cottages. The method of connection to the pipeline is flange. The pump is installed directly into the pipeline.

Characteristics:

- productivity – 9600 l/hour;

- power consumption – 550 W;

- head – 12 m.

Advantages:

- high pressure;

- reliability;

- high efficiency.

Flaws:

- the need to weld counter flanges to the pipeline;

- high price.

WWQ CN 25/60-180

Country of origin: Russia. Three-speed model with a wet ceramic rotor. The pump is designed for installation in the heating system of low-rise buildings.

Characteristics:

- productivity – 58 l./min.;

- power consumption – 90 W;

- head – 6 m.

Advantages:

- overheat protection;

- ease of maintenance and operation.

Main disadvantage:

- short network cable.

What to consider when choosing

The determining factor in choosing a circulation pump for a heating system is its performance. To pressurize large-diameter pipes, it is necessary to install units with high power. When installing pumps in a separate room, the temperature conditions of the equipment must be taken into account.

Other factors influencing the choice of circulation pumps for heating include:

- principle of operation;

- method of connection to the system;

- number of circuits.

When purchasing a pump, you should pay attention to the manufacturers' recommendations on room heating standards. These values differ depending on the country in which the unit is installed.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

The functionality of the devices is important. It is preferable to install pumps with automatic adjustment of operating modes in heating systems.