When planning the assembly of an autonomous heating system, you need to take into account a number of features of its operation. It is important to properly establish coolant circulation through the pipes. As a rule, this problem is solved by installing a circulation pump for heating systems. Read below about the features of how to choose the right circulation pump for heating systems, as well as how to install it.

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Pump speed modes may vary depending on the model and configuration. On average, the minimum is 30-35 l/min , the maximum is 80-90 l/min .

Why do you need to check the settings?

To ensure maximum performance of the device, before using it . This is done, as a rule, according to two parameters.

Noise insulation. There are several reasons why a heater may make a lot of noise:

- incorrect installation;

- air in pipes;

- voltage fluctuations;

- device malfunction.

To avoid these problems, it is better to entrust the installation to a specialist who will carry out comprehensive diagnostics and ensure the correct installation and functionality of the device.

Uniform heating. The main reason for uneven heating of radiators is insufficient power. Low speed contributes to the rapid cooling of the water, as a result of which the heat simply does not reach the end of the system.

Airiness or an incorrectly selected thermostat mode also leads to a similar problem . May affect the performance of the device and improper installation . This is especially true for aluminum and bimetallic batteries, which must be installed as level as possible.

How to properly install a Wilo pump in a heating system

Which pump is better to choose - Wilo or DAB

Judging by reviews and statistical reports, individual heating systems with forced circulation of coolant, with Wilo and Grundfos pumps, are considered the most reliable. They are somewhat inferior to DAB products.

The Wilo pump can operate continuously for at least 7-9 years. The models offered by the manufacturer are designed for domestic and industrial heating systems. Models with two electric motors are optimal for simultaneous heating with underfloor heating and radiators.

The cost of products from the Danish concern DAB and the German concern Wilo is approximately the same, but in terms of technical parameters, Wilo modules are significantly ahead of their competitors.

Forced movement of water in water supply and heating systems is provided using pumps. Reliable and efficient operation of the pump, when heating rooms, supplying cold and hot water, will provide all domestic needs, and in some cases, industrial needs.

Normal operation of the Wilo pump is possible only if the operating rules are followed, timely maintenance (preventive maintenance), high-quality diagnostics and repairs.

How electronically controlled circulation pumps should work

Models with electronic heating type have two types of speed control: manual and automatic. Manual regulation involves setting the power of the device at the desired level. In this case, pressure drops are not corrected.

Photo 1. Control circuit for the DAB EVOSTA circulation pump with electronic control. Selecting the operating mode is done with one button.

In the case of automatic control, the reduction or increase in speed is carried out by the system itself and directly depends on the temperature in the pipeline. The autopilot itself determines the optimal level of performance and, if necessary, reduces energy consumption without reducing productivity.

Important! Automatic reduction of pump speed is only possible after hydraulic balancing of the system.

Operating the circulation pump

It is necessary to follow some rules when operating the pump, including the following:

- The pump should not operate if there is no water in the heating system.

- The pump must not be allowed to operate at zero flow.

- A certain range of permissible flow rates must be observed during pump operation. The pump may fail if the water supply is too low or too high.

- If the pump is idle for quite a long period of time, then to prevent it you will need to turn it on at least once a month for 10-15 minutes. If this is not done, some pump components may oxidize.

- For normal operation of the pump, the temperature of the coolant in the heating system should not be higher than +65 degrees. This is necessary in order to prevent the precipitation of hard salts.

- First, you need to make sure that there are no vibrations or noise from the heating pump.

- Check how the circulation pump works, based on its pressure-flow characteristics.

- Check to see if the electric pump motor is overheating.

- Check visually if there is a ground connection on the pump housing.

- Check if there are any leaks in the places where the pump is attached to the pipeline. If there is a slight leak, you will need to replace the gaskets or tighten the connecting components.

- Check how well the electrical wires in the terminal block are connected to each other.

Maintenance of circulation pumps

Pump malfunctions and ways to eliminate them

The design of a circulation pump with a “wet” type rotor is based on a modular principle. Modules can be configured in different configurations. It all depends on the power and size of the pump.

Any repair work can only be carried out if the power is completely turned off and the area has been drained.

Malfunctions of the heating circulation pump:

- The pump turns on, sounds are heard, but the shaft does not rotate. Why is the heating pump noisy and why do other “symptoms” appear? The reason may be oxidation of the shaft after a long period of inactivity of the device. If the pump is blocked, the device must not be left on. It is necessary to drain the water and all the screws that connect the pump housing with the electric motor must be unscrewed. Next, we remove the engine itself, and its impeller is turned manually. If the pump is of low power, the shaft can be unlocked by turning it with a screwdriver. For this purpose, there is a special notch at the end of the shaft.

- A foreign object has blocked the wheel. How to disassemble a heating circulation pump? We dismantle the pump motor using the above method. To prevent blocking from happening again, a mesh type filter must be installed in front of the pump.

Which circulation pump should I use for heating?

A “wet” pump rotor is suitable for small private houses, and a “dry” pump rotor is suitable for large premises and multi-storey buildings. What is their difference? The first type is the most economical and silent, but is inferior in power, which limits the area of use, making it ideal for a residential building.

Advantages of circulation pumps with a “wet” type rotor:

— ease of installation;

- small size and weight.

Advantages of pumps with a dry rotor:

- high efficiency, which provides uniform heating of large areas.

For heating private houses in the heating system, in 50% of cases pumps marked 25*4 or 25*40 are used. The first number (25) indicates the diameter of the pump connection. The second number (4 or 40) indicates the pressure of the circulation pump.

note

Advantages of using heating circulation pumps

- Allows heat to be distributed evenly in all rooms.

- Fast system warm-up.

- Saving electricity and gas, which is achieved by reducing the cost of starting heating and rapid cooling of the coolant. The system is designed in such a way that the required amount of liquid is first heated, while spending a relatively small amount of energy. The benefits are huge compared to the cost of electricity to run the equipment.

- Durability of use if a properly selected pump is installed specifically for a given room.

- A universal approach for all heating systems.

In what case is it necessary to install a heating circulation pump if you have a system with natural water circulation.

— Naturally, the question arises if the water in the boiler is already boiling, but the room still does not heat up to the required temperature.

— If the slope of the heating pipes does not meet the slope standards: 5 mm per 1 linear meter. Instead of tearing down walls and installing pipes with the required slope, you can use a circulation pump; it will be more profitable, more reliable, and without headaches.

- heating pipes are in one direction and one pipe passes through the system.

- great savings benefits.

The heating system pump has these wonderful properties.

Design and types of circulation pumps

Most pumps have the following design:

- Body with attached volute

- The circuit pipes are screwed to the cochlea

- The housing contains an electric motor with a control board and terminals for connecting power supply wires.

- The rotating part of the engine - a rotor with a nozzle (impeller) - moves water, sucking it in on one side and pumping it into the circuit pipes on the other side

As a result of the work, a certain vacuum is obtained at the pump inlet and the required pressure (compression) is obtained at the outlet. All circulation pumps, depending on their design features, are classified into two types:

- “dry” type (with a dry rotor);

- “wet” type (with a wet rotor).

“Dry” type pumps are characterized by the fact that their rotor does not itself come into contact with the working fluid of the heating circuit during operation. It is reliably isolated from it by a sliding seal - a ring. Such pumps have a fairly high efficiency - up to 75-85%, but operate with a certain noise level. These pumps are larger in size than their “wet” counterparts and require special piping of the circuit. In addition, they usually require periodic maintenance .

As a rule, these pumps are used in individual boiler houses that provide heat to several buildings or an industrial enterprise. In “wet” type pumps, the rotating rotor itself is in contact with the pumped coolant fluid , and the stationary part of the pump motor, the stator, is isolated from it. Interaction with the liquid ensures the necessary lubrication of the rotor parts and quiet operation of the entire pump as a whole.

Typically pumps have a built-in step speed controller. Wet-type circulation pumps can operate for years, and sometimes decades, without requiring any maintenance. But they have low efficiency - only 50-65%. Pumps of this type are most widespread in private household heating systems precisely because of their small size and quiet operation. These aspects are among a number of others when choosing a circulation pump for the heating circuit of your home. But there are other aspects to choosing a pump. We will consider them.

Advantages and features of using circulation pumps

Features of modern circulation pumps (CP) are efficiency, durability, small dimensions and noiselessness. When installed correctly, circulation pumps are virtually silent. You can only tell if the pump is working by a slight vibration when you touch it with your hand.

How to choose the right circulation pump? It is important to select the correct pump in accordance with the hydraulic parameters of a particular heating system. It is better to entrust this to specialists. First of all, you need to know how much heat you will need to heat your house. This is a rather complex calculation, which includes many parameters and is done by specialists. Everything is important: what kind of windows are installed in the building, how the walls, floors and ceilings are insulated, whether thermostatic valves are provided in the system, etc. and so on. The result of these calculations is the determination of the required volumetric coolant supply in the system (m3/h), according to which the pump is selected. When reconstructing an existing system, it is preferable to use an adjustable pump. Such central heating units independently adapt to changes in flow rate in the system, are practically silent and very economical. You will not be able to independently make calculations for a complex and multi-level heating system! But, if you still decide to try, the calculation formula is given in SNiP 2.04.05-91*.

How to choose the right circulation pump?

A well-functioning pump in the heating system of a separate house or cottage must meet the following requirements.

- Work performance (its productivity). Calculated under the condition of minimum pump load.

- Pump pressure, its pressure.

- Working conditions - volume of the heated room , type of liquid, temperature (ambient and coolant), pipe diameters.

- External aspects of pump operation—size, noise level during operation, difficulty of maintenance.

Everything is clear with the last point. The smaller the pump and the quieter it operates, the better. From this point of view, “wet” type circulation pumps are undoubtedly more suitable for installation in a heating system . Let's look at other points.

Calculation of pump performance

The first three requirements for a pump are closely related and one depends on the other. Productivity implies the amount of liquid distilled , its consumption at a minimum pump load. To put it simply, the higher it is, the better.

There is a well-known formula for calculating it: Q = N / (t 2 - t 1)

- Q - flow rate (productivity),

- N is the power of the heating source (heating boiler),

- t1 is the temperature of the liquid in the return pipes of the heating circuit,

- t2 is the temperature in the supply part of the circuit, i.e. after the heating boiler.

When calculating, the t1 value is taken within the range of +60 ÷ +70С°, and the t2 value - +90 ÷ +95С°. This formula allows you to approximately select the parameters of the desired pump. It is generally accepted that for 10 meters of the length of the circulation ring of the circuit, approximately 0.6 meters of pump pressure is needed.

There are already calculated thermal standards. It is considered: for warming up 10 sq. meters of room requires 1 kW of heating boiler power. If we take the thermal power of one radiator section as 200 W, then per 10 sq. meters will require 5 sections. As a rule, a small supply is taken in the form of 1-2 sections . The pump must be able to supply water to all radiators in the building

Pump pressure

Pump pressure refers to the level to which the pump can raise water in the heating system. It is measured in meters of water column or atmospheres. Usually this value is indicated in the documentation for the pump and on the pump itself (special label).

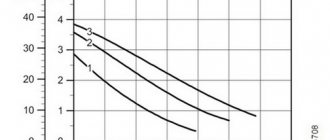

Consider the GRUNDFOS UPS 25−40 pump.

The manufacturer is quite well known. The number 40 indicates the height of the coolant rise - 4 meters. Which corresponds to 0.4 atm. pressure. It is by this value that you need to select a pump primarily for your system. What does the number 25 mean? It indicates the diameter of the connected pipes - 25 mm (1 inch). Typically, pipes with a diameter of 25 mm and 32 mm (1.25 inches) are used to connect the pump. Therefore, you should look at the full name of the pump - it must match the diameter of the pipes (adapters) in your heating system. Typically, the pump also indicates the power consumption in different modes, the number of revolutions and the direction of movement of the rotor and coolant.

Pump selection

First of all, you should choose a pump that will effectively cope with the task. The key parameters are productivity, measured in cubic meters that the pump pumps within an hour, as well as the pressure it creates.

In equivalent, the pressure is converted into meters of water column, determining to what height the pump is capable of raising water through the pipes.

The target parameters of the heating system for which the pump is selected are:

- The coolant flow rate through the pipes is in the range from 0.8 to 1.5 m/s;

- The pressure must be greater than the hydrodynamic resistance of the circuit, taking into account all possible heating operating modes.

The coolant speed is calculated based on the total volume of coolant in the heating circuit and the pump performance. Reverse calculation makes it possible to determine the required performance for equipment selection.

To select equipment based on pressure, it is important to determine the maximum resistance value to the coolant current in the circuit. In this case, it is important to take into account not only the presence of fittings, pipelines, boiler and its piping, but also control thermostats, the number of circuits, and the presence of bypasses

In this case, it is important to take into account not only the presence of fittings, pipelines, boiler and its piping, but also control thermostats, the number of circuits, and the presence of bypasses. Most pumps for heating a private house with a wet rotor have three modes for performance and pressure

Ideally, optimal operation in normal mode should be carried out at second speed. The greatest productivity will be used only at the time of the first start of heating for quick access to operating mode

Most pumps for heating a private house with a wet rotor have three modes for performance and pressure. Ideally, optimal operation in normal mode should be carried out at second speed. The greatest productivity will be used only at the time of the first start of heating for quick access to operating mode.

The lowest performance will allow you to start heating in a gentle mode, for example, during periods of relatively mild frosts at the beginning and end of the heating season, when there is no point in pumping the coolant too actively.

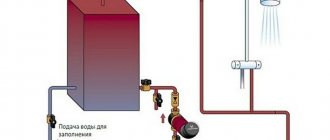

It is important to determine the number of circulation pumps in the heating system. If it comes to a single-circuit connection diagram, in which only radiators are included in a one-story house, then one pump is enough

However, if two or more circuits are connected in parallel for different floors of the building or to connect a heated floor system, wiring to separate wings of the building, it is more reliable to turn on its own pump for each of them.

Is the brand of pump so important?

There are many types of pumps from different companies on sale. Almost all of them have the same characteristics. They differ mainly in the degree of reliability and service life.

The most common brands are Grundfos, Wilo, Wester, Wita, ELSOTHERM, Speroni. There are also a lot of different fakes from China or clearly Chinese products. The first two brands on the list are the most reliable. They are distinguished by excellent reliability and noiselessness. You can verify their operation by ear only in close proximity (5-10 cm) or by placing your hand on them. They work for years without requiring any attention. But they have one small drawback - their high price. Their price is approximately 2 times higher than lesser-known brands.

The remaining brands are considered average in terms of price/quality ratio. They work quite well, problems with them are very rare. Their prices are in the average range.

Owners always agree on Chinese products: sooner or later these products begin to make noise, the rotor becomes loose, or the pumps simply burn out. They can work for a couple of months, or they can last a couple of years. The price for them, of course, is small .

Which one should you choose? Let’s say right away - never buy Chinese pumps. If you don’t mind overpaying for a brand, take Grundfos or Wilo. If you don’t want to overpay for the brand, buy a pump from the middle price category.

How to choose a Wilo pump for a heating system

How to recognize the original Wilo pump

Vilo brand pumping equipment is one of the most popular solutions on the domestic market. It is not surprising that according to statistics, every two out of three units of equipment sold are low-quality surrogates.

In fact, it is quite simple to distinguish a fake:

- Packaging – the original model is packaged in a square shape made of high-quality cardboard, brightly colored.

- The American ones included in the kit are made of galvanized steel and have a golden hue (the fake is black, the material is ordinary steel).

- The sticker on the motor housing is straight and has a certification mark. The screwdriver socket is white, not yellow.

- Turnkey racks are provided on the bends to facilitate installation. The housing has an arrow indicating the direction of movement of the coolant.

Using these four signs, you can independently distinguish an original Wilo pump from a fake. Another sign worth paying attention to is low cost. Compared to the original, the analogue costs 2 times less.

How to calculate which Wilo pump you need

- Operating instructions - unlike models from other manufacturers, the documentation indicates not only the capacity and pressure of the pump, but also the approximate heating area.

- Online calculators - just enter existing parameters into the cells and find out the most suitable equipment model.

Alternatively, when selecting a pump, you can seek help from consultants from a company that sells circulation equipment.

Grundfos pump - is it capable of passing coolant without electricity?

The house has both an electric boiler and a solid fuel boiler. The electric one will work to maintain the desired temperature in the absence of the owners in the house, and the solid fuel one will work as the main one during their presence. The system has a built-in pump connected to both boilers.

The question is this. If for some reason there is no electricity in the house, but the solid fuel boiler is working, will the coolant be able to pass through the pump freely?

Igor Iofchu wrote: will the coolant be able to pass through the pump without hindrance?

Yes. Any hydraulic centrifugal pump with a locked rotor creates insignificant hydraulic resistance.

Vladimir_Vas wrote: Yes. Any hydraulic centrifugal pump with a locked rotor creates insignificant hydraulic resistance.

That is, there is no need to make a special arc to bypass the pump? I'm afraid that the solid fuel boiler might boil if something happens.

Igor Iofchu wrote: I’m afraid that the solid fuel boiler might boil if something happens.

Maybe. But not because of the resistance of the de-energized pump. You take any circulation pump from the shelf and just blow into the pipe - the questions will disappear on their own.

Vladimir_Vas wrote: Maybe. But not because of the resistance of the de-energized pump. You take any circulation pump from the shelf and just blow into the pipe - the questions will disappear on their own.

OK. Thanks a lot. They calmed me down.

Igor Iofchu wrote: If for some reason there is no electricity in the house, but the solid fuel boiler is working, will the coolant be able to pass through the pump unhindered?

With a normal EC, it will be able to pass, but not entirely unhindered.

Igor Iofchu wrote: So there is no need to make a special arc to bypass the pump?

With EC, the pump is switched to bypass and the return valve, with a ball of positive buoyancy, the valve or, especially, the shut-off valve on the main line should not be installed at all, since the check valve may stick, the shut-off valve may not be switched at the right time and the hydraulic resistance will be greater than just pump located on the main line.

With an EC with a pump, so that without electricity there is the minimum possible hydraulic resistance, the bypass with the pump must be connected to the main line at the minimum possible angle, without a check valve and, even more so, without a shut-off valve on the main line between the pump connection points.

Igor Iofchu wrote: I’m afraid that the solid fuel boiler might boil if something happens.

To do this, you need an EC and RB on the boiler return, but in any case, measures must be taken to forcibly reduce the critical temperature of the coolant.

Typical circulation pump malfunctions

Compliance with all operating rules of the device does not guarantee uninterrupted operation of the unit. Breakdowns may occur that do not depend on human actions: the filter is clogged, voltage surges, etc.

If the engine does not turn on, but the pump does not make humming or other strange sounds, it is worth checking the fuse. It reacts sharply to surges in the electrical network and if the engine is threatened, it melts, thereby breaking the electrical circuit. In this case, the fuse will have to be replaced, after which the device will return to normal operation.

If the failure was not in the fuse, you should check the power cord, the circuit breaker in the distribution box and the electrical wiring. There may be a section of wire or switch that needs replacing.

After checking the wiring, you should move on to the electric motor winding. Its serviceability is checked by measuring the resistance. The multimeter should read 10-15 ohms. Some units are equipped with a starting winding, the resistance of which is 35-40 Ohms.

If the multimeter displays “infinity,” it means the winding has failed. And when the readings are closer to zero, an interturn short circuit has occurred. In this case, turning on the device is accompanied by the operation of fuses in the panel.

Modern devices have a low noise level, so often the owner of such a unit cannot understand whether it works or not?

To diagnose the device, use a circulation pump shaft rotation tester indicator, which will show whether the device is working without an electrical outlet. To do this, you need to bring your indicator to the motor shaft and the scale will show whether the shaft is rotating or not working at all.

When the circulation pump hums, but the shaft with the impeller does not rotate, you should immediately turn off the unit, because the motor winding may burn out.

There are several reasons for this malfunction:

- The shaft does not work due to downtime in the summer. For the same reason, the impeller sticks to the housing. In this case, you need to disassemble the device and manually turn the shaft. Manufacturers took this point into account, so the shaft has a notch for a screwdriver.

- The impeller does not rotate due to a foreign object in the chamber. After removing it, system operation will resume.

If the device makes unusual noise during operation, this may be air accumulated in the system. To remove it, it is recommended to install an automatic air vent on the heating circuit. But if it is not there, then the air is bled off manually

Why does the circulation unit heat up?

The temperature of the device must match the temperature of the coolant pipes. If it rises higher, it means that errors were made during installation, or improper operation was taking place.

The circulation unit may overheat for the following reasons:

- initially incorrect installation. It is not difficult to determine the problem: the pump heats up at the initial stage immediately after installation.

- blockage in the system. During long-term operation, deposits and rust accumulate in the pipes, which leads to a decrease in water passage. The device is overloaded to ensure normal coolant circulation. In this case, the engine overheats, but unscheduled maintenance can cope with the breakdown.

- foreign body. When communications are slagged, pieces of rust or plaque break off from pipes and radiators, which, when they get into the device, jam the electric motor. If the device is not disassembled and cleaned in time, the electric motor coils may fail and the device will simply stop turning on.

- Lack of lubrication for bearings. If there is insufficient amount of lubricant, the bearings are poorly lubricated and quickly wear out, which leads to a reduction in the service life of the unit as a whole. If the engine jams as a result, the pump is dismantled and handed over to a service center.

- low voltage in the network. At voltages below 220 V, the electric motor overheats and quickly fails. In the first minutes of overheating, it is worth checking the voltage in the network with a voltmeter, because the problem may not be in the pump.

The device works, but does not pump coolant

One of the problems that happens with heating units is the operation of the pump without pumping water.

There are four reasons for this condition:

- air ingress or water leakage, which can be eliminated by repairing holes and cracks in the pipes;

- incorrect adjustment of the heating system. The malfunction can be solved by checking the correct position of the taps (primarily before the pump);

- no water. To repair such a malfunction is to supply water to the device.

- Valve blocked or stuck. To resolve, repair or replace the valve.

How to disassemble the circulation pump?

To repair the circulation pump, it is necessary to dismantle and disassemble it.

Dismantle the device according to the following scheme:

- The unit is disconnected from power. In order to disconnect the cable from the terminal box, you need to remove the housing from the device's power supply.

- Shut off the liquid supply with the side valves and drain the remainder in the system.

- The device is unscrewed with a hex screwdriver, but suddenly the bolts become stuck, they are moistened with a special WD liquid and after 20-30 minutes they try to unscrew it again.

After dismantling, the unit cover is removed. Below it is a rotor with a wheel and blades. Basically, the rotor is secured with clamps or bolts. After removing it, access to the inside of the device opens. After carefully inspecting the pump, problems are detected and corrected.