Thermal insulation Korund-Classic (20 liters)

Corundum Classic ultra-thin liquid thermal insulation The best universal ultra-thin thermal insulation you have ever worked with. CORUND Classic provides objects with thermal insulation, noise insulation, eliminates the formation of condensation, and is resistant to atmospheric factors. CORUND Classic is highly effective in thermal insulation of internal walls of premises, concrete floors, hot and cold water supply pipelines, steam pipelines, air ducts for air conditioning systems, cooling systems, various containers, tanks, trailers, refrigerators, etc. at operating temperatures from – 60 ° C to + 260 °C. It is used to eliminate condensation on cold water supply pipes and reduce heat loss in accordance with SNiP in heating systems

1 year warranty.

Packaging - plastic hermetically sealed bucket, volume 10 l, 20 l. Ultra-thin thermal insulation Corundum

The undoubted advantages of Corundum thermal insulation are:

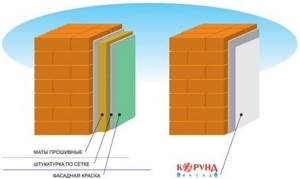

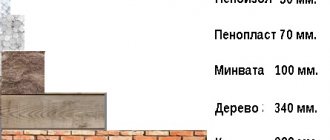

Can be applied to metal, plastic, concrete, brick and other building materials, as well as equipment, pipelines and air ducts. They have ideal adhesion to metal, plastic, propylene, which allows you to isolate the surface to be coated from access to water and air. Not permeable to water and not affected by an aqueous salt solution. Coatings provide surface protection from moisture, precipitation and temperature changes. Effectively reduce heat loss and increase anti-corrosion protection. Protects the surface from the formation of condensation. A coating layer 1 mm thick provides the same insulating properties as 50 mm rolled insulation or brickwork 1-1.5 bricks thick. Can be applied to surfaces of any shape. Do not create additional load on supporting structures. Prevents temperature deformation of metal structures. Reflect up to 85% of radiant energy. Provides constant access to inspect the insulated surface without the need to stop production, downtime associated with repairs, and failures in the operation of production equipment. They are not destroyed by exposure to UV radiation. The fast coating procedure reduces labor costs compared to traditional insulators (easily and quickly applied by brush or airless applicator). Easily repaired and restored. They are insulating building materials that do not support combustion. At a temperature of 260°C they become charred, at 800°C they decompose with the release of carbon monoxide and nitrogen oxide, which helps slow down the spread of flame. Environmentally friendly, non-toxic, do not contain harmful volatile organic compounds. Resistant to alkalis. Hydrogen index (pH) 8.5 – 9.5 Time for complete drying of one layer 24 hours Estimated thermal conductivity at 20°C 0.001 W/m °C Fully certified in Russia.

Advantages and disadvantages of Corundum

The heat insulator is capable of completely filling the micropores of the surface being treated. In this case, the concentration of the polymerized material is 80%. In addition, coating thermal insulation Corundum has the following advantages:

- Excellent heat retention

. One millimeter of heat-saving paint is comparable in effectiveness to 50 millimeters of rolled insulation, for example, mineral wool. - Easy to apply

. Corundum is applied like regular paint using standard tools: brush, roller, spray gun. It does not emit harmful substances and therefore does not require respiratory protection. - Protects surfaces from destruction

. Metal coated with Corundum will not rust, wood will not rot and dry out under the influence of atmospheric conditions, plaster, brick, concrete will not crumble and become cracked. - Does not attract microorganisms, insects, rodents

. Surfaces covered with this insulation will not rot or mold. - Lightness of the insulating layer

. The weight of Corundum insulation is incomparable with traditional roll coating. Such thermal insulation will not place any load on the load-bearing walls and foundation. Therefore, liquid ceramic insulation can be applied even to unstable and fragile structures. - No seams or cold bridges

. Corundum allows you to create a durable, seamless coating through which the cold cannot penetrate into the room. - Environmental friendliness and durability

. Throughout its entire service life, the material does not emit any harmful substances. Therefore, it can be safely used to insulate residential buildings, as well as houses where allergy sufferers live. - Does not affect the geometry of the room

. Unlike bulky traditional thermal insulation, Corundum will not affect the size and shape of the building in any way. - Can serve as an independent finishing layer

. Pigments can be added to thermal paint, which allows it to be used for wall decoration without additional decorative coatings.

Corundum Classic - instructions

Corundum Classic is a liquid thermal insulation coating used to insulate surfaces made of various types of metal, plastic, mineral-based materials (brickwork, concrete, stone), etc. Corundum Classic can be used on surfaces with temperatures ranging from -60°C to +200°C (peak heating up to +260°C is acceptable). Corundum Classic has excellent adhesion to most household and construction surfaces. The surface temperature when applying thermal insulation can be in the range from +7°C to +150°C.

- Preparation of different types of surfaces before using Corundum Classic

- Preparation of thermal insulation coating Corundum Classic

- Coating

- Safety precautions when working with Corundum Classic

Preparation of different types of surfaces before using Corundum Classic

Before treating with Corundum, dust, dirt, old paint, and rust must be removed from the surface.

If the surface is contaminated with oil or grease stains, it must be degreased. There should be no loose rust on old metal when applying Corundum. Otherwise, after application, this rust will peel off along with the thermal insulation. Rust is usually removed with a brush or abrasive materials to a metallic shine. Also, the surface should not be wet or damp, and should not have condensation. If you are going to apply Corundum Classic to ferrous metal that heats up to +150°C, you need to remove dust, degrease it, and apply the first layer of thermal insulation with the Corundum Anticor modification. Also, as an alternative, you can apply primer VL-02 or VL-023 (according to the instructions for the primer).

Non-ferrous metal also needs preliminary preparation. To remove the gloss, the surface must be cleaned mechanically, dust and grease stains must be wiped off, and primed with adhesive primer VL-02 or VL-023 (1-2 layers).

If you plan to apply Corundum Classic on a mineral base (concrete, brick, artificial and natural stone), you need to remove loose areas and open cracks. To reduce Corundum consumption, the surface needs to be repaired (for example, putty joints in brickwork deeper than 5 mm).

You should also clean off greasy stains, remove cement laitance, and clean with a brush, sandblaster or grinding wheel. Next, the surface must be dusted and washed with water. After drying, it can be treated with an acrylic primer for non-absorbent surfaces.

To insulate the facades of buildings made of vapor-permeable materials (brick, concrete, etc.), use Corundum FACADE.

2. Preparation of the thermal insulation coating Corundum Classic

Corundum in the package is almost ready for use. It just needs to be mixed. If you mix Corundum using a drill with an attachment or a mixer, the speed should not exceed 150-200 rpm. At a higher frequency, you can destroy the working component of the material, microscopic granules. This will reduce the effectiveness of the material. When mixing, plunge the blades of the nozzle into the material, begin to mix it slowly, mixing the thick fractions with the thinner ones. Continue stirring the material until it reaches the consistency of cream. The standard time for mixing the material with a mixer is 3-8 minutes, manually - 7-10 minutes.

When stirring, if necessary, you can add water to Corundum, gradually adding it. When painting a surface with a temperature from +7 °C to +80 °C, add no more than 5% of water by volume of the material. If the surface is hotter than +80 °C, reduce the temperature by applying several preliminary layers of Corundum with the addition of 40-50% water. If the material is stored for a long time inside the original container, it may delaminate.

Coating

Corundum Classic is applied by brush, roller or airless spray. This can be a hand-held device of sufficient power, such as a Graco Magnum, or a stationary Graco Mark 5 device (two posts).

To apply the coating to areas of complex shape (valves, taps), use a brush with soft bristles. The temperature of the surface treated with Corundum Classic thermal insulation should be in the range from +7ºС to +150ºС. Do not apply the coating during rain.

To increase the adhesion of the material to the heat-insulated surface, a preliminary primer layer can be applied to it. This layer is applied with Corundum Classic, diluted to milk (40-50% water). Each layer of Corundum Classic 0.4-0.5 mm should be allowed to dry for at least 24 hours. The next layer is applied only after the last one has dried. A layer with a thickness of 0.4-0.5 mm (thickness of optical density, to the state of opacity) is achieved in three passes of a brush or spray. It is not recommended to apply Corundum Classic in a thicker layer in one go. This can cause the formation of a moisture-proof film that interferes with the evaporation of moisture. If you apply Corundum to a hot surface with a temperature from +80ºС to +150ºС, the material boils and quickly polymerizes. In this case, it must be diluted with water in a larger proportion. The hotter the surface, the more the material should be thinned. Corundum diluted in this way is placed in thin layers with quick movements. Allow at least 1 hour for each layer to dry. Thin layers of Corundum are applied until the material stops boiling on the surface. The applied layers are then allowed to dry for 24 hours. After this stage, the thermal insulation is applied according to the standard procedure - with the addition of 3% to 5% water in layers up to 0.5 mm and 24 hours of drying for each layer.

4. Safety precautions when working with Corundum Classic 4.1 Personal protection.

When used as directed and with common sense, the product is safe. It is advisable to work in a room with good ventilation. If ventilation cannot be ensured, we recommend using standard respirators. In case of material contact with eyes, workers must have access to water. Use gloves and protective clothing to protect exposed skin.

4.2 Critical situations.

If Corundum gets on your body, wash it off with soap and water. If Corundum gets into your eyes, rinse them with running water for 10 minutes. If your eyes remain irritated, consult a doctor.

Storage and transportation conditions Corundum Classic

Corundum Classic material is stored in a tightly closed original container at a temperature from +5°C to +30°C, in the shade (without direct sunlight). Transportation of the material must be carried out at temperatures above +5°C.

Scope of application of liquid thermal insulation Corundum

Due to the fact that Corundum thermal insulation has a liquid consistency, it has many advantages over its direct analogues, since it can be applied to a wide variety of surfaces:

- Roof;

- Window slopes;

- Pipes;

- Building facades;

- Various types of containers;

- Internal and external walls;

- Cooling chambers.

In order to prevent any condensation from forming on the surface of the pipeline, and to ensure that hot water reaches you with minimal heat losses, it is recommended to treat the pipes with liquid thermal insulation Corundum. The duration of the operational period of such a coating is equal to 15 years, such thermal insulation can withstand significant temperature changes from -50 to +250 degrees, no analogue can boast of such technical and operational characteristics, and this is subject to the relatively low cost of the material.