Production features and general description

Thermal insulation Corundum is a composition based on ceramic microspheres and an acrylic binder. The last ingredient is produced using catalysts and fixatives.

The size of the microspheres varies from 0.01 to 0.5 mm. The composition of the product is also supplemented with all kinds of additives to enhance its performance properties. This composition gives the material flexibility, lightness and elasticity. In addition, Corundum is characterized by good adhesion to a wide variety of surfaces.

The consistency of this brand of heat insulator resembles ordinary paint. In fact, it is a white suspension, which, after hardening, forms a very reliable and elastic polymer coating.

In comparison with ordinary heat-insulating materials, Corundum provides not only protection against heat loss, but also against corrosion .

Initially, such coatings with heat-protective properties were created at the request of NASA for finishing spacecraft. Over time, experts adapted these mixtures for “earthly” needs. Corundum is the commercial name of a product that was developed by Russian specialists. This heat insulator has special certificates that indicate its high quality.

Almost like paint

If we talk about the appearance of the material being described, it most closely resembles the usual white paint. By the way, the material dries almost the same way as paint. In particular, a special coating is formed on the treated surface, which not only guarantees excellent thermal insulation, but also has anti-corrosion characteristics.

The technical characteristics of Corundum thermal insulation allow it to be used on a variety of surfaces, including pipelines, the temperature of which can range from minus seventy to plus two hundred and sixty degrees Celsius.

When is Corundum used?

The described thermal insulation can be used equally successfully on surfaces of any type.

As the instructions for using Corundum thermal insulation say, the material is suitable for processing:

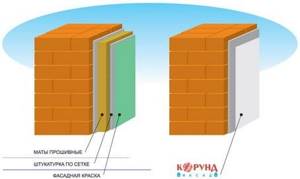

- brick walls outside and inside the building, interior brick walls;

- external pipelines, regardless of their purpose (water supply, time, gas and oil transportation, other purposes), protecting them from rust;

- walls and roofs of objects for various purposes - industrial, warehouse, farm, etc.;

- objects and equipment where it is extremely important to maintain low temperatures (for example, refrigeration units, cabinets, air conditioners, etc.);

- insulation of walls and roofs of metal buildings (for example, garages, sheds, etc.);

- structures and structures in which high humidity is periodically or constantly observed.

Treatment of walls of a multi-storey building

And this is not a complete list of objects where the described thermal insulation can be used. In principle, it can be applied everywhere and in any conditions.

What results can be achieved?

Liquid thermal insulation allows you to achieve truly fantastic results.

In particular, it guarantees:

- significant reduction in heat losses;

- ensuring a comfortable microclimate in the room;

- saving energy resources;

- anti-corrosion protection;

- truly seamless coating, which cannot be guaranteed by other insulation materials of any class;

- protection against freezing of walls;

- saving space inside the building, because other insulation materials in any case “eat up” several centimeters of usable space;

- protection against fungi and mold;

- magnificent appearance of buildings, pipelines, etc.

Treatment of external walls of the house

The described liquid thermal insulation is recommended for use in residential premises, since it is non-toxic and does not emit negative fumes.

Well, the most important thing that can be noted about the material when used on external surfaces is that, unlike other insulation materials, it cannot be stolen, and it will not be damaged by rodents or insects, which so love to live in cotton wool, roll insulation materials.

This means:

- constant aesthetics of treated surfaces;

- durability and reliability.

Functional Features

The quality of thermal protection of thermal paint directly depends on the applied layer and the number of stains. However, it is also not recommended to apply an excessively thick layer; the best option is 2-4 paintings, no more than 6 mm thick. The number of layers depends on the type of heat-insulating liquid material, as well as on the type of surface to be applied. The service life is 12-40 years, and the temperature characteristics are -70°C, +260°C.

Main advantages

The main advantage of liquid insulation for work inside buildings is thermal insulation without reducing space

It is important to note the material’s resistance to temperature changes, which occurs in winter during the heating season: it’s minus outside and plus inside, condensation collects, which forms a favorable environment for the development of fungus. Additional benefits:

- environmental friendliness - the paint does not emit harmful toxic compounds at high temperatures and does not react with other building materials;

- saving on heat bills due to thermal insulation;

- strengthening treated surfaces.

Types of material

Today, the domestic market can offer several types of ultra-thin corundum material.

Classic version

This advanced multi-component material is universal and suitable for the protective treatment of the following surfaces:

- Roofs.

- Window slopes.

- Various pipelines.

- Containers and tanks.

- And much more.

Thermal insulation "anti-corrosion"

This liquid thermal insulation is intended for treating metal surfaces to insulate them and protect them from rust. The uniqueness of this type of corundum facade is the fact that it can be applied directly to old rust. You just need to brush the metal and brush off any loose rust.

Technical characteristics of liquid ceramic thermal insulation Corundum

Thermal insulation material Corundum has technical characteristics that allow it to be used on structures of various configurations and purposes. With a minimum thickness, this product can provide a good level of insulation. Let's consider the main characteristics of Corundum thermal insulation:

- Thermal conductivity

. In numerical value, this indicator is equal to 0.0012 W/(m*C). This is significantly lower than many traditional thermal insulators such as polystyrene foam or mineral wool. - Moisture resistance

. The material does not allow moisture to pass through and is not destroyed under its influence. Even saline solutions have no effect on Corundum. - Vapor permeability

. Thermal paint does not create an airtight film on surfaces. It allows air exchange to occur, maintaining an optimal microclimate in the room. - Fire resistance

. The material does not support combustion. When the temperature reaches 800 degrees, Corundum begins to decompose, releasing carbon and nitrogen monoxide. And at a temperature of +260 degrees, the thermal insulation becomes charred. According to fire safety standards, the material belongs to classes G1 (non-flammable) and B1 (non-flammable). - Adhesion

. In terms of tear-off force, this indicator may vary depending on the type of surface on which Corundum is applied. So, for concrete this coefficient is 1.28 MPa, for steel - 1.2 MPa, for brick - 2.0 MPa. - Operating temperature range

. Corundum has a fairly large range and ranges from -60 to +260 degrees. - Ultraviolet resistance

. The material does not deteriorate under the influence of sunlight. Therefore, you can use it even without a protective coating. - Biological stability

. Mold, fungi, and rot do not form on surfaces treated with Corundum. Also, the material is not used as food by insects or rodents. - Environmental friendliness

. Liquid ceramic thermal insulation does not emit any toxic compounds into the atmosphere even when heated. You can also work with it without using special personal protective equipment. - Lifetime

. This is a durable coating that does not lose its quality for at least 10 years. It does not crack and does not collapse.

Ceramic insulation technology

It is necessary to apply ultra-thin thermal insulation Corundum to a previously prepared surface, regardless of the modification of the composition. The basic rules that should be followed before starting paint insulation include the following:

- If ceramic insulation is intended for wall treatment, the working surface should be cleaned of dust and dirt, and existing gaps and chips should be expanded and filled with cement mortar.

- Before painting thermal insulation on concrete slabs, they should be cleaned of “cement laitance”.

- It is also necessary to treat the wall with an abrasive wheel, sandblasting machine or a stiff metal brush.

- If you plan to treat a metal surface, it must be dust-free and degreased (substances recommended by the manufacturer - Solv-Ur, Solvent). To paint objects made of non-ferrous metal, it is necessary to remove the gloss and apply primer VL-02 or VL-023.

- It is also worth considering that it is necessary to dilute ceramic thermal paint immediately before applying it to the wall.

It is also worth considering that in some modifications of the composition it is necessary to add water before starting work, so you need to carefully study the manufacturer’s instructions. The volume of liquid depends on the purpose of thermal insulation; in any case, the required proportions are indicated on the packaging of the composition.

The technique of applying ultra-thin thermal insulation Corundum is carried out in three ways:

- using air spray devices;

- airless spray method;

- manually - using a roller or brush.

The manufacturer recommends applying the composition in three layers, and the consumption should be 1 m/m2. When working on thermal insulation, this composition does not require additional ventilation in the room, nor the use of special personal protective equipment.

To guarantee the effectiveness of the result, it is important to strictly follow the manufacturer’s instructions and fully adhere to the recommendations indicated on the packaging

Date: September 25, 2021

Advantages and disadvantages of Corundum

The heat insulator is capable of completely filling the micropores of the surface being treated. In this case, the concentration of the polymerized material is 80%. In addition, coating thermal insulation Corundum has the following advantages:

- Excellent heat retention

. One millimeter of heat-saving paint is comparable in effectiveness to 50 millimeters of rolled insulation, for example, mineral wool. - Easy to apply

. Corundum is applied like regular paint using standard tools: brush, roller, spray gun. It does not emit harmful substances and therefore does not require respiratory protection. - Protects surfaces from destruction

. Metal coated with Corundum will not rust, wood will not rot and dry out under the influence of atmospheric conditions, plaster, brick, concrete will not crumble and become cracked. - Does not attract microorganisms, insects, rodents

. Surfaces covered with this insulation will not rot or mold. - Lightness of the insulating layer

. The weight of Corundum insulation is incomparable with traditional roll coating. Such thermal insulation will not place any load on the load-bearing walls and foundation. Therefore, liquid ceramic insulation can be applied even to unstable and fragile structures. - No seams or cold bridges

. Corundum allows you to create a durable, seamless coating through which the cold cannot penetrate into the room. - Environmental friendliness and durability

. Throughout its entire service life, the material does not emit any harmful substances. Therefore, it can be safely used to insulate residential buildings, as well as houses where allergy sufferers live. - Does not affect the geometry of the room

. Unlike bulky traditional thermal insulation, Corundum will not affect the size and shape of the building in any way. - Can serve as an independent finishing layer

. Pigments can be added to thermal paint, which allows it to be used for wall decoration without additional decorative coatings.

For information

Liquid thermal insulation Corundum is a mixture based on an acrylic binder and ceramic microspheres, which have thin walls and contain rarefied air inside. Acrylic-type binders are created using substances from the group of catalysts and fixatives.

Microspheres have sizes up to 0.5 mm. In addition, it contains various additives, so if Corundum is chosen, the facade will be processed very efficiently, since such additives enhance certain qualities of the product. The composition is completely balanced, so the material is elastic, light and stretchable. In addition, the Corundum coating has good adhesion.

The consistency of the substance resembles simple paint. This is a whitish suspension. The material not only has thermal insulation properties, but is also able to protect metal parts from corrosion.

In addition, Corundum is a thermal insulation that has many other advantages:

- Keeps warm well. It has been established that 1 mm of such paint is comparable in its ability to conserve heat with 5 cm of roll-type insulation (for example, mineral wool). The reviews are very good.

- It is easy to apply the substance to surfaces. The paint must be applied using conventional tools. You can use a spray gun, roller, or brush. The product does not emit harmful compounds, so respiratory protection is not required.

- If Corundum is chosen, the facade will be protected from various damages due to the influence of aggressive environmental factors. For example, metal will not rust. Wood does not dry out or rot. The brick, concrete layer and plaster do not crumble and cracks do not appear on them.

- If Corundum is applied, the facade will not be destroyed due to the influence of rodents, insects, bacteria and other pests. The surface does not rot. Mold does not form either.

- The insulating layer is lightweight. If Corundum is chosen, the facade will not have additional load, as if other insulation materials were used, for which it is necessary to install additional special retaining structures. Due to the light weight of the layer, Corundum can be applied even to fragile surfaces.

- There are no seams. Thanks to this, there will be no cold spots. The thermal insulation layer will be seamless, so the cold will definitely not be able to penetrate into the room.

- Durability. It is enough to apply the product only once, and you will not need to replace such a layer for a long time.

- The use of the material is also associated with its environmental friendliness. Over a long period of operation, such a layer does not emit harmful components. The product can even be used in homes where people who are prone to allergies live.

- Neither the area of the room nor its geometry is affected, which is taken into account when using bulky structures. Corundum will not affect the dimensions and shape of the building.

- Can be used as a finishing material. Special components from the group of pigments are added to this paint, so it is also used as a decorative coating.

But it must be taken into account that such a heat-insulating layer also has its drawbacks. First of all, this concerns the high cost. The material appeared on the construction products market not so long ago, so the price is still quite high. However, this drawback is offset by the fact that thermal paint retains heat well and the layer will last quite a long time. You also need to take into account that the material, as reviews indicate, hardens very quickly, so you will have to apply it quickly.

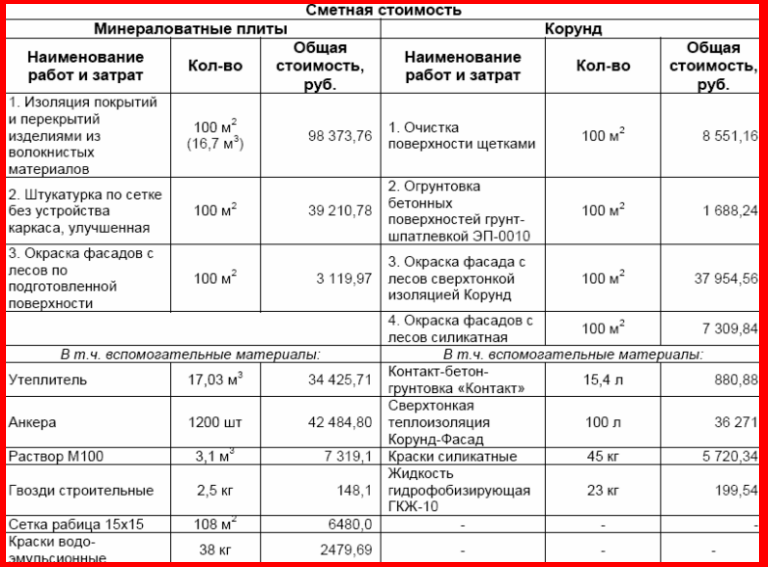

An example of an estimate for using corundum thermal insulation

Criteria for choosing Corundum insulation

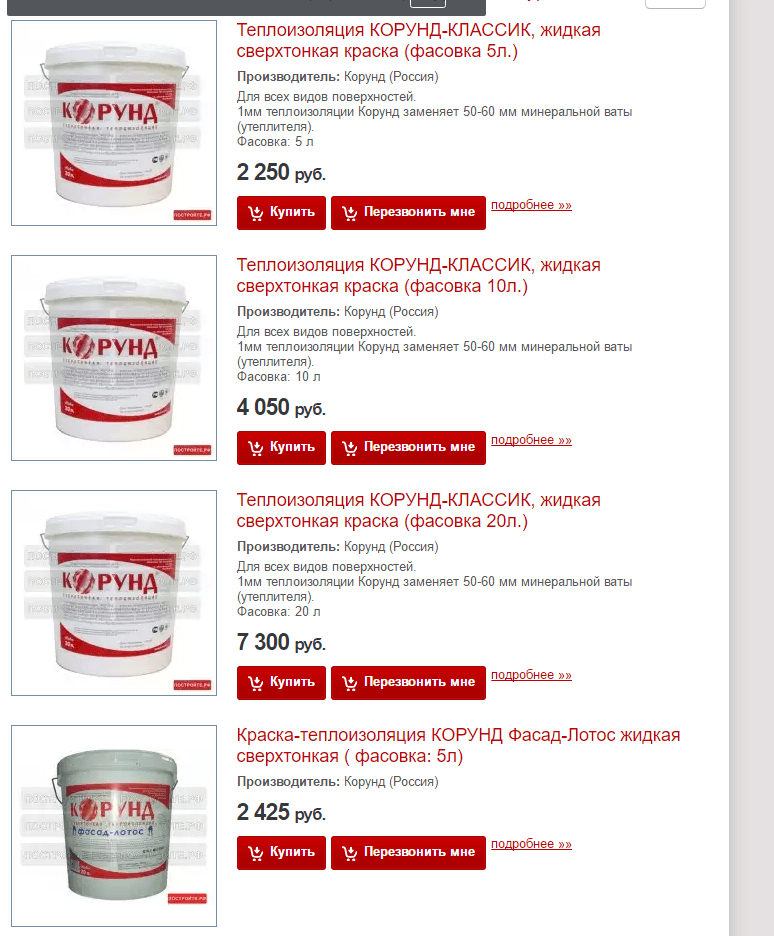

The optimal state of Corundum insulation is a white paste-like suspension. Standard packaging is plastic buckets of various sizes. The packaging must indicate the manufacturer's information. The price of Corundum thermal insulation may vary depending on the type of material and place of sale. On average in Russia the cost of liquid ceramic insulation is as follows:

- Corundum Classic - 375 rubles per 1 liter;

- Corundum Anticor - 435 rubles per liter;

- Corundum Winter - 540 rubles per liter;

- Corundum Facade - 400 rubles per 1 liter.

Application instructions

Before you start applying Corundum paint, you need to choose the right material. You should not buy products from unverified sellers. The manufacturer is the Russian company Fullerene. In addition, there is a network of distributors. Be sure to pay attention to the condition of the paint. It should take the form of a suspension of paste-like consistency with a whitish tint. Traditional packaging is a plastic bucket. It can be of different volumes. The label must contain information about the manufacturer.

As for the cost of Corund paint, it differs depending on the type of material and the place where sales are made. For example, in Russia the cost of the Classic modification for 100 ml is approximately 34 rubles. Anticor coating can be purchased for 450 rubles per 1 liter. Corundum costs from 400 rubles per 1 liter, and Corundum Winter – from 550 rubles.

To apply thermal paint, you need to stock up on the appropriate painting tools. This can be a spray gun, roller or brush. It is best to apply paint using the first option, since it not only reduces the consumption of the substance, but also makes the coating better.

The thickness of one layer of paint should be approximately 0.4 mm. The next layers should be applied only after the previous layer has dried. If you use a brush or roller, the average product consumption is approximately 500 ml per 1 m².

Here is the algorithm of actions:

- Pour the liquid into a large container and stir well until it has a uniform consistency. To do this, you can use a special drill with a suitable tip. Experts advise setting the machine to medium speed so that the structure of the ceramic microspheres does not deteriorate during mixing.

- Clean the surface to which paint will then be applied. Pre-treat with degreasing compounds. To do this, you can use a special solvent. If the surface is metal, then the rust should be removed.

- Allow the surface to dry completely before applying paint. The first layer should be minimal in thickness, since it is a primer.

- When using a roller or spray gun, you need to carefully handle joints and other places where there is no access. You'll have to use a brush.

- It is recommended to do no more than 3 layers of paint for optimal results.

- It will take about a day to dry completely. If you paint warm pipes, the paint will dry even faster.

Thermal paint Corundum will look beautiful, so it can be used not only as thermal insulation, but also as a finishing coating.

About durability and “performance”

That is, applying thermal insulation to any surface does not present any problems. When the structure is ready, you can safely cover the walls with Corundum. Moreover, they can even be of incredibly complex configurations.

Agree, if the walls have several kinks, and quite frequently located (well, this is the idea of an architect or interior designer), then it will be difficult to lay solid insulating material on them, but liquid insulating material will be no problem.

If we talk in more detail about the performance characteristics of the material, its service life is at least ten years.

In this case, it does not matter at all what kind of material it is applied to:

- concrete;

- metal;

- reinforced concrete;

- tree;

- plastic, etc.

Scope of application of liquid thermal insulation Corundum

Due to the fact that Corundum thermal insulation has a liquid consistency, it has many advantages over its direct analogues, since it can be applied to a wide variety of surfaces:

- Roof;

- Window slopes;

- Pipes;

- Building facades;

- Various types of containers;

- Internal and external walls;

- Cooling chambers.

In order to prevent any condensation from forming on the surface of the pipeline, and to ensure that hot water reaches you with minimal heat losses, it is recommended to treat the pipes with liquid thermal insulation Corundum. The duration of the operational period of such a coating is equal to 15 years, such thermal insulation can withstand significant temperature changes from -50 to +250 degrees, no analogue can boast of such technical and operational characteristics, and this is subject to the relatively low cost of the material.

How good is Corundum as a heat insulator?

As practice shows, condensation on the surface and excess humidity really disappear. In addition, there is a very real chance to completely eliminate mold and rotting of walls, for example. However, if you do it in a good way, and not “for show,” then one layer will not be enough - it is better to apply at least three.

With this approach, the temperature in the room should rise by one and a half degrees. It turns out that some more significant, noticeable improvements can only appear when many layers are applied, but this is no longer practical from a purely financial perspective. At significant expense, it is already easier to make a facade from mineral wool.

This concludes the review of the insulation (or rather thermal insulator) “Corundum” and now, probably, it is easier to draw objective conclusions and make a decision to purchase it.

Advantages of liquid thermal insulation Corundum

The main advantages of liquid thermal insulation Corundum include the following positive aspects:

- The application process can be carried out independently; for this, a regular brush or spray can be used;

- Just one millimeter of liquid thermal insulation Corundum will provide the same properties as 600 mm of rolled thermal insulation material;

- It is considered a waterproof material and is not negatively affected by saline solution and ultraviolet radiation;

- Provides visual access to inspect the isolated surface;

- It is a fire-resistant material that does not support the combustion process. When exposed to 260 degrees, the material is charred, but if the temperature rises to 800 degrees, the decomposition process begins with the release of nitrogen oxide and carbon, and these substances stop the combustion process.

Insulation paint – paint and insulate

Insulation paint is multifunctional. It retains heat well, prevents water from penetrating into structures, and protects against the formation of mold. Corundum thermal insulation extends the service life of pipes, tanks, refrigeration equipment, and air conditioners. Retaining heat is the main purpose of thermal paint, so it is indispensable for thermal insulation of pipes. The materials currently used are short-lived and harmful to humans. Pipes coated with corundum thermal insulation withstand the effects of precipitation and sunlight.

According to sad statistics, a huge number of fires occur due to the fault or direct participation of heat-insulating materials. Often the walls are lined with flammable thermal insulation, and in the event of a fire, the fire with lightning speed, with the help of this insulation, spreads throughout the entire building, spreading to the roof and neighboring entrances. To prevent this from happening, use heat paint. This is an inexpensive material that is safe in all respects and does not support combustion.

Main modifications of modern liquid thermal insulation

Modern thermal insulation coating Corundum is presented in several modifications. Each of them has its own characteristics in application.

Let's look at each type in more detail.

- Classic

This type of thermal insulation is successfully used when processing:

- facades;

- roofs;

- concrete floors and screeds;

- interior partitions;

- pipelines supplying cold and hot water.

Eliminates the possibility of condensation and also prevents heat loss. Therefore, it is also successfully used when processing refrigerators and trailer tanks.

Coating the tank with Corundum

- Anticorrosive

A unique product that can be applied even to rusty surfaces. Neutralizes corrosion and prevents its development. The material is applicable to structures of any type.

Treated rusty metal tank

- Winter

This type of thermal insulation is designed for application to surfaces at sub-zero temperatures (but not lower than minus ten degrees Celsius). Excellent for buildings and other objects constructed or insulated in extreme conditions, because other types of Corundum can only be applied at air temperatures no lower than plus five on the Celsius scale.

The material contains the following components:

- acrylic polymers;

- flame retardant additives;

- pigmenting additives;

- foam glass microgranules and other additives.

- Facade

This type of thermal insulation is specially created for application to concrete coatings and surfaces for insulating facades. It is characterized by increased heat-reflecting properties, which is appreciated by many professionals in the field of construction and construction of any type of structure.

The material can be applied even in a thick layer, which can significantly save time on insulating the building. When used outside a building, after Corundum has dried, any decorative facing materials can be applied to it, which will in no way affect the thermal insulation properties of the coating.

Facade of a multi-storey building

As can be concluded from the presented photos, the described material really has excellent aesthetic properties. But, as already described above, its performance characteristics are at the same level.

In addition, the price of thermal insulation is relatively low, especially when you consider all the actual positive properties of the material!

Therefore, if you want the room to be warm and the water in the pipes not to freeze or cool, use modern thermal insulation! In the video presented in this article you will find additional information on this topic.

Properties of corundum

This material is essentially ordinary facade paint, which is applied in a thin layer. But at the same time it acts as a good layer of insulation. The applications of this thinnest heat insulator are very diverse:

- Insulation of buildings for any purpose made of all types of building materials (concrete, wood, metal and even plastic walls).

- Insulation of equipment subject to vibration.

- Insulation of various pipelines, which operate in a wide temperature range: from -70 to +250 °C.

- The coating also has waterproofing properties and prevents corrosion of the treated surfaces.

It is thanks to such unique characteristics that corundum facades quickly found their niche among other building materials and began to be in high demand.