06 Mar 2013, 07:20

What happened, the gas water heater stopped turning on, the gas simply won’t ignite. Water flows, there is pressure in the system, the gas is open - it doesn’t light up and that’s it. The column is completely automatic, you can do it as the master explained - you don’t need anything, it works by itself, lights up and turns off.

06 Mar 2013, 07:22

In 90% of cases, the problem turns out to be dead batteries. If your speaker is fully automatic, then it must have batteries. The manufacturer usually puts Duracell. Since they are more powerful than regular ones and with them the column lights up without problems.

If the user replaces them with cheap alternatives, hoping to win some money, these batteries do not draw the required power and the column does not light up. Especially when it comes to salt batteries.

Causes of breakdowns and their elimination

Despite the simplicity of the design and ease of operation, the flow-through heater is not immune to breakdowns. If the Vector brand geyser does not turn on, do not panic. There may be several reasons for the problem and most of them can be eliminated yourself.

Problem #1 - lack of traction in the column

The lack of draft indicates that combustion products cannot be promptly removed from the room. This poses a danger to users, so the sensor turns off the gas water heater.

Sometimes the burner lights up but goes out immediately. This can happen when there is not enough air to burn the gas - the flame goes out due to lack of oxygen to support combustion.

In any case, you first need to check the draft by holding a burning match to a special hole on the speaker body. If the flame is directed inward, then the chimney is working normally, combustion products will be promptly removed, but the cause of the malfunction lies elsewhere. If the flame remains motionless, directed upward or towards the user, then it is worth carefully inspecting the chimney and cleaning it.

Along with combustion products, soot enters the air. It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction disappears. The problem can be solved by thoroughly cleaning the chimney

Problem #2 - difficulties with water pressure

Another reason why a Vector brand household gas water heater does not light up may be low cold water pressure or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption and evaluate its pressure. If there is insufficient water pressure in the system, the solution may be to install a pump or replace old, clogged pipes.

If there are no problems with the water supply, you should proceed to inspect the column. The solution to the problem can be adjusting the water supply to the column. To do this, you must fully open the corresponding tap.

Another reason for insufficient water pressure in the column is a clogged filter. To inspect it, it is necessary to turn off the water and gas supply to the valves, unscrew the nuts, and rinse the mesh. If you cannot clean it, the filter will have to be replaced.

It will take a few minutes to inspect the filter. However, in some cases, washing alone is not enough; a complete replacement of the part is required.

Problem #3 - insufficient gas pressure

Sometimes the gas pressure is not enough to ignite the flow column and allow it to operate normally. However, you cannot solve such a problem on your own. You need to contact your gas service.

Problem #4 - no ignition when turned on

The presence of an electric ignition system ensures comfortable operation of the gas water heater and eliminates the use of a wick that is constantly burning. However, it is this element that can cause the device to malfunction.

When the tap is opened, automatic ignition should be triggered. This action is accompanied by a characteristic crash. If the ignition does not work or the spark is too weak to ignite the gas, the column will not be able to connect. Replacing the batteries will help solve this problem.

For uninterrupted operation of the instantaneous water heater, batteries are required. When the batteries are discharged, the electric ignition does not work and the speaker does not turn on.

Problem #5 - clogged pipes

Water and gas pass through the Vector gas water heater during operation. Using filters allows you to clean them from unnecessary impurities. However, the presence of blockages may cause the device simply not to turn on.

However, the filter is not always able to bring water to an ideal state. Soluble salts enter the heater along with the liquid and settle on the walls of the heat exchanger. As a result, the patency of thin tubes is impaired.

Specialists remove scale using specialized reagents. A home technician can deal with it using a solution of citric acid or vinegar. To clean the heat exchanger, you need to remove it and place it in a warm solution with vinegar added. You can also use special purchased products - “chemicals” designed for cleaning heat exchangers.

It is better to entrust the removal of heat exchanger blockage to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, can be easily damaged

We discussed cleaning and repairing the heat exchanger in detail in the next article.

Other malfunctions of flow-through heaters

In addition to the problems listed above, speaker owners have to deal with the following problems:

- weak sparking, sometimes single discharges slip through, the gas does not flare up;

- ignition is accompanied by a strong bang;

- after closing the DHW valve, the burner continues to operate until the electromagnet cuts off the fuel supply due to strong heating (at the command of the sensor);

- spontaneous ignition after connecting to a power source;

- insufficient heating;

- Water is leaking from the water heater.

Advice regarding weak discharges on electrodes. If the batteries and contacts are in order, try cleaning the ends of the electrodes and adjusting the gap between the needles and the plane of the burner (the value is indicated in the technical data sheet of the product). If there is no result, call a specialist - most likely the reason is in the pulse block.

Problems with sparking cause popping noises - gas has time to accumulate in the combustion chamber before a sufficiently powerful discharge is formed. If the spark remains weak, the fuel-air mixture ignites when it reaches a high concentration, which is accompanied by a micro-explosion. There have been cases where the pops damaged the heat exchanger, disrupted seals and normal contact in the electrical circuits of the sensors.

Continuing heating after turning off the water is a rather dangerous malfunction. If it coincides with a failure of the overheating sensor, a vapor phase will form in the heat exchanger that can rupture copper tubes and honeycombs. The reason is the jamming of the “frog” rod that opens the gas valve. How to repair:

- Remove the water module according to the instructions above.

- Disassemble the “frog” and remove the plastic plate.

- Unscrew the nut (or screw) in the left half of the membrane chamber and remove the pusher.

- Change the seals, thoroughly clean all parts from deposits, including the spring monostat (located on the right side of the “frog” behind the membrane).

Recommendation. Before assembly, check how freely the rod moves inside the new seals. For details on disassembling and repairing the speaker, watch the video:

Spontaneous start of heating without turning on the water is a consequence of sticking of the pusher. When the burner of the device does not turn off and the thermostat trips, the user temporarily turns off the power source. Since the rod remains pressed, after the power supply is restored, the column turns on itself, without opening the DHW tap. The “treatment” method is described above.

The reason for low heating is total contamination of the main elements of the unit - the heat exchanger and burner. The column needs to be completely disassembled and serviced; it is better to entrust such work to a specialist. In case of burnout and leakage, the heat exchange unit must be removed and properly soldered, which is not always possible to do at home.

The wick does not light

If the column lights up, but very poorly, then there may be several reasons. Let's look at each of them:

- If the piezoelectric element does not work, then problems with the igniter may occur in the Astra and Zerten models. The wick should always be lit, and it is triggered when the tap is opened or when the corresponding button is pressed. If the element does not work, the wick does not burn, then the column jets may be clogged. To do this, disassemble the device, remove the metal protection or casing and clear the clogged nozzle. It is better to do this with thin wire. Usually, after cleaning the nozzle, the column works normally. This is one of the reasons why the Astra gas water heater and other similar devices do not light up.

- Another case is automatic speakers that take a long time to light up. The automatic ignition system of the column runs on batteries. When the tap opens, the device is triggered and a powerful spark is formed, which ignites the column burner. If there is no spark, then you should try replacing the batteries, or better yet install batteries.

- The generator of the hydrodynamic system may also fail. The generator rotates when water passes through it. When the unit rotates, it generates a current, from which a spark is then formed. If this is precisely the reason why the gas water heater does not light up, then it is better to entrust the repair to professionals.

Repairing leaks

Best 4 Burner Gas Hobs for 2021

Let's see what to do with the column if it leaks. At home, you can also fix this problem, because the problem is often hidden in the water unit. Whatever the nature of the breakdown, take several steps step by step:

Remove the casing and inspect the water assembly

Most often, the problem may be hidden here; Turn off the water, remove and disassemble the gearbox; Pay attention to the diaphragm, stem seal and gasket. The membrane may become leaky, the gasket may break due to age, and the seal may simply become unusable.

Both elements must be replaced.

If the water unit is in order, the cause of the leak may be a burnout of the heat exchanger. If a hole has formed as a result of a burnout, the repair will not give positive results, because the integrity of the metal has already been compromised over its entire area. Microcracks noticed at an early stage, through which perspiration appears, can still be repaired. Then the column can work for several more years, but in both cases it is recommended to replace the heat exchanger with a new one.

Electronics failures

The presence in modern models of a large presence of electronic components, on the one hand, ensures high safety of the device and ease of use, on the other hand, it complicates troubleshooting and subsequent repairs.

The causes of electronic malfunctions are mainly related to the influence of external factors - voltage drops in the network, lightning discharges entering the main gas pipes and water entering the circuit boards from leaks inside the device. In addition, failure of individual electronic components due to failures in the electronics itself cannot be ruled out.

The reason that the vector geyser does not light up may be a malfunction of the electronics, and the following situations may arise:

- No spark when igniting;

- Extinguished digital display;

- The device does not start the first time;

- During operation, an alarm signal is constantly displayed;

- Protection systems are constantly triggered;

- The device turns on and then turns off again;

- Diagnosis of a breakdown usually begins with checking the batteries; old or dead batteries need to be replaced with new ones. If there are traces of electrolyte leaking onto the terminals, it must be cleaned.

If this operation does not resolve the device problems, you must call a technician to check the electronic unit. Most often, in such models, the electronics unit cannot be repaired; it is simply replaced with a new one. When replacing a unit, the technician must inspect all components of the device, and when connecting a new unit, in addition, test the system and configure its parameters

Particular attention is paid to the presence of leaks at the junction points and the integrity of the heat exchanger

Water unit malfunction

Most often, geyser repairs are made due to a faulty water block. Its work is that, under the influence of liquid pressure, the membrane located inside it, arching, transmits movement to the rod, and it then moves the pusher of the gas unit. As a result, the spring valve opens and the electrical power supply to the control module is turned on. Therefore, if the water unit is faulty, the device will not start.

A broken water block can be determined by external signs.

- If you opened the water supply, and the rod pressing the switch plate remained motionless (shown in the figure with a blue arrow), this means that the membrane located inside the main component of the water unit - the “frog” - is damaged.

- Stem jamming may be due to sticking.

- There may be a leak in the place where the gas and water units are connected, or liquid leakage from under the control valve (shown by red arrows).

If you notice even one sign, the unit will need to be removed and repaired. The water unit can only be removed together with the gas module, since they are a single structure. You can do this in the following way:

- after you have made sure that the gas valve on the pipe is in the closed state, you can disconnect the supply hose (a);

- similarly, when the water supply is turned off, the nut on the water block pipe (b) is unscrewed;

- then, using a wrench, you need to unscrew the nut that connects the water block to the heat exchanger (c);

- disconnect the terminal block (d) on the conductors connecting the solenoid valve to the control module;

- wires (d) going to the switch are disconnected in the same way;

- using a screwdriver, you need to unscrew the 2 screws (e) attaching the pipe to the water-gas unit, through which fuel is supplied to the burner manifold;

- After unscrewing the fasteners, the entire assembly can be easily removed from the device.

Next, you will need to disassemble the gas-water module itself.

After removing the device, you need to separate the water unit. To do this, unscrew the 2 screws (indicated by arrows). It is not necessary to unscrew them completely. They use a clamp to secure the “frog” in the gas unit. The attachment of the “frog” to the latter may differ in different models, as, for example, in the Neva 3208 gas water heater.

This is what the gas module looks like with the water module disconnected.

Next, you will need to disassemble the “frog” itself by unscrewing 6 screws. They can stick and twist tightly or even be “licked off” with a screwdriver if you apply a lot of force. To prevent this from happening, you can first drop a special liquid WD-40 on them, after which they will easily unscrew and none of them will break.

After successfully unscrewing the screws, the module opens into two halves and you will see a rubber membrane.

The membrane must be carefully inspected, and if it is found that it has been stretched too much or there are tears on it, it must be replaced with a new one.

To get to the plate with the spring, you need to remove the membrane. If it is intact, you must do this carefully so as not to damage the ring with which it fits onto the pipe (indicated by the red arrow in the figure above). After removing the membrane you will see a plate with a spring.

To avoid having to disassemble the unit once again, inspect the oil seal

To do this, carefully remove the plate with the rod.

Take out the spring and you will see a plug with a cut for a screwdriver. There is an o-ring underneath

The plug must be unscrewed from time to time to lubricate and replace the rubber seal.

Having previously purchased a repair kit for the “frog”, replace the failed oil seal and membrane. When you install the oil seal back, do not forget to lubricate it with silicone grease, and also lubricate its location.

Assembling the water block of the geyser occurs in the reverse order. The plug must be tightened so that the rod passes through it without much effort. When you have completely assembled the “frog”, the repair of the water block can be considered complete.

Repairing a Neva 3208 gas water heater due to a faulty “frog” is similar and intuitive, although the internal appearance of the unit is slightly different. The Neva 4511 gas water heater can be disassembled in the same way, and repairing it yourself is quite feasible.

When a Chinese gas water heater is repaired, you are always surprised by the size of the water unit. It is quite small in size, and to disassemble the “frog” you only need to unscrew 4 screws.

If the gas heater goes out during operation

No traction.

If the window in the room is tightly closed, there is no flow of fresh air, the column overheats and the automatic system is activated, which turns it off. If after that you open the window, after 10 minutes you turn on the column, and it works, then the reason has been found.

The draft also decreases when the ventilation duct is clogged. To check the draft, you need to open the window and cover the channel with a sheet of paper: if the sheet holds, then the draft is normal. You can also check it by lighting a match near the exhaust duct: if the flame becomes horizontal, then the draft is good, if not, then you need to clean the duct.

Malfunctions of the water unit.

The burner in the gas water heater may also go out if the water pressure is insufficient. This may be due to a clogged strainer. To clean it, you need to turn off the water supply and clean the mesh.

We eliminate leaks in connections.

A tap must be installed on the pipe that supplies water to the radiator of the geyser, and the tap must also be installed on the pipe through which the gas is supplied. All water connections are made using union nuts, and sealing is done using rubber gaskets.

Due to temperature changes and over time, the elasticity of the gaskets decreases - this leads to water leaking from the joints. It is necessary to periodically replace the gaskets. If one gasket is not enough and water flows from the connection, then two gaskets must be installed.

Cleaning the igniter.

After some time, the igniter becomes clogged with soot, the wick flame decreases, and the gas leaving the burner does not immediately ignite. An explosion may occur if gas accumulates. To prevent this, it is necessary to urgently clean the igniter.

The air supply holes need to be cleaned. To do this, remove the nozzle and clean the nozzle using a thin wire. Some speakers have automatic electric ignition, but it has disadvantages: it works unstably when the water pressure is low, and the batteries need to be changed periodically.

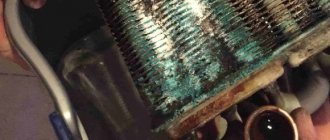

The water heater is leaking

If you see similar stains on your column, then be sure that it is leaking and needs repair.

This malfunction can occur mainly in geysers that have been operating for a long time. The two main reasons for the leak are:

The radiator is leaking.

Tubes (bends) or gaskets in connections are cracked. Replacing the radiator or taps is quite expensive. Therefore, there is a reason to repair the geyser on your own. For repairs you need:

- screwdrivers (cross and regular);

- open-end wrenches (set);

- solder with rosin;

- vacuum cleaner;

- solvent;

- "skin".

Sealing holes

Due to harsh operating conditions, the radiator or taps may burn out and holes may appear on them. If you have determined where the leak is, you can repair the small hole with a regular soldering iron.

Preparing a gas water heater for repair

- Drain all liquid from the system - open only the hot water tap, unscrew the nut on the cold water inlet pipe, and most of the water will flow out;

- Remove the radiator completely;

- Inspect the entire tube. - if you see “green”, clean and inspect these places for cracks.

Soldering a heat exchanger does not always give good results; a lot depends on your skill. If the soldering is bad, the heat exchanger will quickly leak again.

When you have found leaks, you need to do the following:

- clean the holes found with sandpaper and immediately wipe with a cloth with solvent (this will remove any remaining grease, carbon deposits and dirt);

- using rosin with solder, tin this place with a 100-watt hoop (if you don’t have rosin, use aspirin);

- Fill the crack or hole with solder, and after it cools, add more tin (the layer should be 1-2 mm).

Attention! In some cases, with holes of about 5 cm, craftsmen apply a “temporary” overlay made of a copper or aluminum plate, securing it with thick wire or metal tape

But as a rule, such a “temporary” solution remains for a long time. We recommend replacing the radiator completely and forgetting about its leaks

Faulty gaskets and tubes

Replacing flexible hoses of this type does not require special skills; anyone can do it with a wrench.

Very often, leaks form at the points where the taps are connected to the heater externally or to the internal components of the column. All connections are made “American” with gaskets inside.

Due to constant heating/cooling, rubberized liners either melt or lose their properties and harden. Cracks appear in them, through which water flows. If you notice a gas column leak in such connections, replace the gaskets. Using a wrench (usually 24), unscrew the nut and replace it.

It also happens that the flanges on the tubes crack over time - in this case, you need to replace the entire tubes.

Prevention methods

To avoid having to tinker with the unit too often or constantly call the repair service, you should adhere to the following rules:

- Set the temperature at the optimal level so that there is no need to dilute the water, then scale will not appear so quickly. To avoid having to adjust the column every season, it is preferable to choose a model that remembers the settings for winter and summer modes.

- To remove salts from water with high hardness, you can install an electromagnetic system that will purify the liquid.

- Regular cleaning of the chimney and parts of the water heating system is necessary.

- Modern speakers that have a built-in electronic controller are better connected to the network through a stabilizer and not turned off at night.

- If the hose is longer than 3 meters, the pressure during gas supply will greatly decrease.

- When the column is operating, it is better to open the window; this simple method will allow you to get a lot of air for the normal functioning of the unit.

- The chimney and parts of the column that quickly become dusty should be periodically checked for dirt, cobwebs and the like and removed with brushes and a vacuum cleaner.

Signs that unscheduled maintenance and technical inspection from a specialist are required:

- the pressure in the water supply is normal, but the heat exchanger still works for a small amount of time;

- the unit constantly turns off or does not function at all, although the supply of gas and water is carried out in optimal mode;

- often the thermal protection is triggered for no reason, causing the working system to shut down;

- The heating of the water decreases, although there are no noticeable operational disturbances.

To check the column from the inside, you need to remove the upper housing. This is done using a Phillips screwdriver, which is used to unscrew the screw located on the handle of the gas lock valve.

The handle itself is removed by pulling it towards you. Then, using a flat-head screwdriver, remove the screws that secure the case, after which it can be removed.

The main tasks in routine maintenance are to check the general performance, inspect the column inside and outside to identify places that need to be cleaned from dust and dirt, and assess the condition of the heat exchanger as accurately as possible.

Periodic preventive maintenance and checks can increase the life of the device due to the timely detection of problems in the functioning of the column.

The work itself should usually be carried out once a year, but if the column is already old and often malfunctions, then if it is impossible to replace it, checks should be carried out more often.

It is better to entrust the annual inspection to professionals from specialized gas services, as they will be able to accurately determine the condition of the unit.

High-quality maintenance usually includes a complete disassembly of all equipment, searching for defects and areas of damage that can cause interruptions in the operation of the column.

Each main part is also cleaned (wet and dry cleaning), all components of the gas water heater are adjusted or returned to their original position, reconnected and tested for readiness for operation.

- https://sovet-ingenera.com/gaz/equip/ne-srabatyvaet-gazovyy-klapan-na-gazovoy-kolonke.html

- https://mmdog.ru/automation-and-controls/the-valve-on-the-gas-does-not-work-the-solenoid-valve-of-the-gas-column-does-not-work/

- https://lifehacker.ru/gazovaya-kolonka/

- https://cosmo-frost.ru/gazovye-kolonki-i-kotly/neispravnosti-gazovye-kolonki-i-kotly/pochemu-ne-zazhigaetsya-gazovaya-kolonka-neispravnosti-remont-svoimi-rukami/

- https://ks5.ru/otoplenie/kotly/gazovye/ne-zazhigaetsya.html

Characteristic

The internal part of a gas water heater is considered the same type. If you look at the device from other companies, there are no significant differences. The difference lies in certain options, for example, the presence of a second temperature sensor, or a display.

There is a special heat exchanger in the inside of the device. It is a tube with a ribbed texture made of copper. It is along it that the flow of water moves.

During a breakdown, many are interested in what to choose: do-it-yourself repair or call a specialist. Both options should be considered.

To eliminate the unpleasant odor (this may indicate a gas leak), you need to repair the device. Most often they call the experts.

You can contact Gorgaz employees. But there is a high risk that they will not come due to workload. Sometimes the reason for refusal is that the repair work should be carried out by the company that installed the relevant equipment.

Today there are many companies that do not have supporting documents. Therefore, if you see the incompetence of the master, refuse his services. The downside is that often these companies will charge you double the actual value.

The second option is to repair the geyser yourself. Not all problems can be resolved on your own. But, if you know how to work with tools, then repair work will not seem difficult to you.

Lights up but goes out

Let's consider several moments when the column fades out some time after ignition and what ways there are to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

Checking the traction force

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats and the overheating sensor is triggered.

You can eliminate it by opening a window or vent, creating a draft in the room. A gas heater burns a very large amount of oxygen during operation, so it requires a constant supply of fresh air to operate.

The second reason for the column to fade out may be the insufficient time of holding the ignition button. It should be held for at least 20 seconds; if held for less time, the column will go out.

A malfunction of the combustion products exhaust sensor is the next point. To check the sensor, you need to ring it by connecting two terminals. Normally, the resistance should show infinity. If the reading is different, the sensor will have to be replaced.

Strong cold water pressure and low hot water pressure - this situation also often causes the water heater to fade. This happens when you use hot water and open a cold tap. To eliminate this problem, you need to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is incorrect operation of the device and can lead to damage to the heater.

High water pressure can lead to attenuation. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. In this case, the strong pressure of the flow bends the membrane of the water unit, the membrane moves the rod in the gas supply. It is necessary to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has activated, protecting the device from overheating.

Column temperature sensor Vector

The heater works for some time after ignition, then goes out again. If you try to turn on the device right away, there will be no result. After some time, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only replacing it will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is working, you need to clean the contacts and the automation unit.

The design of the igniter itself (device for generating an electric spark). The electrode is mounted in such a way that the spark hits the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Taking into account the fact that a small reverse draft is almost always formed inside the system, a weak level of gas goes down under the pressure of this draft, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark does not fall on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always lights up, ignition is fast, stable and soft.

The formation of holes between the gas exhaust pipe, the connecting pipes of the gas exhaust device and the chimney, between individual sections of the gas exhaust pipe. Determined visually, to eliminate it, it is necessary to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

Repair of gas hobs

If you have any questions about using a gas hob, please contact us. We will always come to the rescue, we will help eliminate such troubles as: turning off the burners, jamming the tap, we will adjust the ignition process, we will adjust the gas combustion, we will change the frying table, glass, we will clean the garland of buttons, we will clean the grease from the mechanisms. All this breaks, and we fix it all in due time. Call. Repair of gas hobs is carried out with the installation of original spare parts. We are ready to cooperate with all clients, regardless of the brand of hob manufacturer, whether domestic or imported, its cost and service life.

Read more…

How to repair boiler fault codes?

Boiler overheating error

Gas boiler malfunction in the form of overheating can occur due to lack of circulation. In this case, you need to check the pump and filter. The overheating thermostat may also be broken.

Low system pressure

If the pressure does not rise when the boiler warms up, then the tightness of the system may simply be broken and you need to tighten the connections, and then add a little pressure. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through an automatic air vent and add a little water.

There is no draft of the gas boiler

If the boiler has an open combustion chamber, just check to see if it is clogged with anything. If the combustion chamber is closed, then condensate drips from the outer pipe, entering the inner one and freezing in the winter, turning into an icicle, blocking the access of air to the boiler. To eliminate this problem, you need to pour hot water over the resulting icicle. Another foreign object may also get into the chimney.

The boiler does not light a flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler lights up, but the flame goes out immediately

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to some electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel displays incorrect errors

Sometimes electronic board errors may occur. This happens due to poor electricity and poor quality power supply. This causes some parasitic charges to appear on the boards, which is why such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. During this time, the capacitors will discharge and these unnecessary charges will disappear. After this, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

Removing scale from the heat exchanger

Scale is a very common problem with any water heating equipment. It is formed as a result of the interaction of salts contained in water with high temperatures. Accordingly, its main concentration falls on those elements that are simultaneously in contact with both heat and liquid. In this case, it is a heat exchanger.

Scale has a rather negative effect on equipment. At a minimum, it clogs the tubes, reducing their capacity. Because of this, the water circulates worse, and even heats up poorly in the process.

You can determine whether there is a problem even before you disassemble the column and look inside the heat exchanger. Symptoms may include:

- hot water from the mixer runs much worse than cold water,

- the gas in the water heater goes out almost immediately after ignition,

- the column does not turn on,

- The water began to heat up worse than before.

Fortunately, you can deal with scale yourself, and it will not require any major costs. All you need is some time, a large basin, a hose, citric acid and warm water. Just in case, also stock up on a rag—some liquid may spill onto the floor during the process.

- Prepare a cleaning solution. To do this, 100 grams of citric acid must be diluted in 1 liter of warm water. If there is a lot of scale, then it is better to use more radical means. Household chemical stores sell various chemical compounds designed specifically to remove such deposits. Of course, this will cost more than citric acid, but this product also works more effectively. If both options are not suitable for you for some reason, you can try a not too concentrated solution of vinegar - you should use the table variety for it, not the essence. In extreme cases, a soda like Coca-Cola or Sprite can pass for a cleaning agent. They contain orthophosphoric acid, which plays the role of a solvent. But use this method at your own peril and risk, since, to put it mildly, it is not recommended.

- Place the heat exchanger in a large basin. Pour the prepared solution into the tubes until they are completely filled. To make it more convenient, use a rubber enema bulb or something similar.

- If you used vinegar or lemon solution for cleaning, then the heat exchanger should lie in a flooded state for 15 minutes. If you used store-bought chemicals, the soaking time is indicated on the package.

- After the soaking has taken effect, it is necessary to drain the solution and rinse the heat exchanger. For this you will need a hose. Lower one end of it into the nearest sink, and attach the other to the heat exchanger, which must be connected to the cold water supply pipe. Then open the shut-off valve on it. A stream of water will wash away all the solution, draining through the hose into the sink. Do the flushing for a longer period of time so that all the aggressive composition leaves the walls of the heat exchanger. Otherwise, exposure to substances will continue, which may lead to damage to the metal.

After washing, perform a visual inspection of the heat exchanger tubes. If the walls are clean, great, you can assemble the column to its original state. If there is some scale left in the tubes, then repeat the procedure from the very beginning.

Adjusting the gas heater flame

Another way to adjust the water heater is to change the gas supply to the burner. This is done by adjusting the flame. On the body of automatic and semi-automatic hot water boilers there is a gas adjustment knob that reduces and increases the supply of blue fuel. The power of the speaker depends on this lever.

As the flame increases, heating becomes more intense and gas consumption increases. Experts recommend changing the gas supply speed to fine-tune the burner flame. After selecting the burning intensity, for additional adjustments use the knob for changing the water pressure. Another way to change the combustion temperature is to change the winter-summer mode.

To reduce gas costs in semi-automatic models, you can adjust the igniter. The wick adjustment is carried out using a special bolt on the pilot burner. Changes should be made carefully. Reducing the pilot flame too much will cause the water heater to stop working. A strong increase in flame intensity will lead to significant excess gas consumption.

The column belongs to complex gas equipment. Fine adjustments and maintenance must be performed by a licensed technician. You can independently change the intensity of water flow and gas pressure by adjusting the operating mode of the water heater to suit you.

Device structure

In order to be able to diagnose device malfunctions without the help of a geyser technician, you need to have a general understanding of their structure, because this is what determines how the repair work will be carried out. There is no need to delve into the intricacies of assembling many different models, because... most of them are similar. Therefore, we can limit ourselves to only familiarizing ourselves with the general principles of operation of such devices.

By historical standards, hot water supply appeared in homes not so long ago. Water was heated using various methods, but the easiest way to do this was using a solid fuel heater. Usually it was heated with coal, less often wood or fuel oil was used. In order to have enough hot water to take a bath, you had to spend quite a lot of time heating it up - from 2 hours or more. Of course, this is not entirely convenient, and geysers were created to solve the problem.

You can see the design of a gas water heater in this video:

This device is designed to increase the temperature of water using gas from the city mains. To speed up the heating process, heat exchangers were built into the equipment - it is in them that moisture is distributed through a system of thin tubes located above the gas burner. Due to this feature, the column is able to heat water quite quickly and does not require filling a large tank.

Geyser - equipment that allows you to heat water using gas

This is the main principle of operation of all gas appliances; the rest of the technical filling is designed to ignite, maintain the flame, regulate the heating temperature, and also ensure safety during operation. Ignition of the main component - the burner - can occur:

- From the igniter. It is lit manually using a match, a special lighter, or turned on with a button (automatic or mechanical). The first options are considered outdated, so such speakers are unlikely to be found on sale.

- Without igniter (piezo ignition).

- Using electronics. This method works the same way as igniting cars.

The security system blocks the flow of gas to the burner if water gets inside

Most modern speakers are equipped with a mechanical security system. Even devices with electronic filling have this type of protection, located between the membrane in the device for receiving water and the valve of the gas pipe. The system works on the following principle: the valve stops interfering with the flow of natural fuel into the device only if the water pressure presses on the membrane with the required force. Everything can be explained even simpler: gas is not supplied to the burner if water does not enter the column.

Troubleshooting that prevents the gas heater from igniting

There is a turbocharged gas water heater with electric ignition. When the hot water is turned on, the heater clicks, but does not light up. An electric discharge is heard and the fan turns on.

The first step is to carry out an inspection; to do this, remove the column cover. It is fastened with four bolts: two from below, two from above. We also remove the knobs for adjusting the flame, temperature, and winter-summer mode. Upon inspection, everything seems intact, the wires are not burned anywhere, water is not leaking anywhere.

The principle of operation is that when a water flow appears, the gas valve is activated, an electric discharge is created, the gas is ignited, and at the same time the fan is turned on to draw waste combustion products outside. If the water pressure is insufficient or the hood does not work, the gas goes out and the column turns off.

So, open the tap and see what happens. Water rustled through the heat exchanger tubes, the electrodes gave a discharge, the fan turned on, but the gas did not ignite. Let's check if the relay (microswitch) is working, which is activated when there is sufficient water pressure and opens the gas supply valve. To do this, turn the tap again, the relay tongue should move away.

It works, which means the pressure is sufficient for the gas water heater to operate. Now let's check the operation of the gas valve. To do this, use a screwdriver to move the same tongue away without opening the water. If there is a spark at the electrodes and the fan starts working, then the gas valve is working.

The fault was found quite quickly; the ignition electrode did not produce a spark. There are only two of them: extreme ones. The one in the center is the control one; if there is no flame, it turns off the gas supply.

The water coming out of the tap is very hot

In the warm season, when the water in the water supply is warm and its pressure is low, a problem arises, seemingly associated with a malfunction of the gas water heater. When you set the gas supply knob to the minimum water heating position, the water from the column still comes out very hot. This is not a malfunction, it’s just that this model of geyser is not designed for this mode of operation. The operating instructions usually indicate the minimum water pressure at which the gas water heater ensures normal operation.

Solving the problem is very simple: it is enough to limit the gas supply by slightly turning off the gas supply valve installed on the gas pipe in front of the entrance to the gas water heater.

Not enough charge

When you open the water, you observe a normal flow, when you turn it on, there is a characteristic click, a spark is formed and everything is generally visually good. But there is one noticeable point: the burner itself in the gas water heater does not ignite. If you look through the window, there is no flame. This is the reason why there is no hot water. The owner does not have hot water, which causes a lot of inconvenience. This reason must be eliminated as soon as possible.

The reason for the malfunction and lack of hot water lies in a completely simple phenomenon. When the batteries stop working, the speaker stops functioning. It does not heat up and therefore the hot water supply stops.

The battery charge in the final stages is only enough to produce a spark. Therefore, visually you observe a spark, and there is also a noticeable click. But the battery energy is not enough to ignite the burner itself.

Replacing the batteries yourself is not difficult. To do this, you need to open the box with the batteries and take them out. Next, you should replace it with new, high-quality, powerful batteries.

More about batteries

Polarity in batteries matters. If you insert batteries without taking into account their polarity, the column will not light up. Batteries can sometimes get stuck in the pack, so keep an eye on them.

Replacement with new functioning batteries is carried out if two main criteria are met:

- The polarity of the batteries must be taken into account;

- The box intended for batteries must be closed until it clicks.

The batteries used in geysers must be standard D (in other words, barrel batteries). Salt options are not suitable because they have the ability to quickly fail. In most cases, alkaline batteries are used for geysers. They are otherwise called alkaline batteries.

There are often cases when a person purchases batteries, but they do not light the column. Here, too, several questions arise as to why even new batteries cannot cope with their functions. At this stage, the owner may also become confused and look for a completely different reason. In order not to find yourself in such an unpleasant situation, you need to wisely choose batteries for the operation of the gas water heater. There are a few tips to keep in mind...

Tips for choosing batteries

It is not advisable to choose too cheap ones. In this case, it is recommended to choose more expensive batteries (normal ones cost about 200 rubles). If you buy cheap ones, they most likely will not work properly, which means that in the future you will need to overpay

Therefore, initially purchase good quality expensive batteries; Pay attention to the expiration date of the batteries; As for brands, Duracell and Energizer brands are preferred. The battery must be alkaline or lithium.

It will be more informative to use a specific multimeter tester that accurately determines the charge. Anyone can use such a tester; it won’t be difficult. This method is convenient and practical to use, and you can purchase a battery tester at any store.

Characteristic

The internal part of a gas water heater is considered the same type. If you look at the device from other companies, there are no significant differences. The difference lies in certain options, for example, the presence of a second temperature sensor, or a display.

There is a special heat exchanger in the inside of the device. It is a tube with a ribbed texture made of copper. It is along it that the flow of water moves.

During a breakdown, many are interested in what to choose: do-it-yourself repair or call a specialist. Both options should be considered.

To eliminate the unpleasant odor (this may indicate a gas leak), you need to repair the device. Most often they call the experts.

You can contact Gorgaz employees. But there is a high risk that they will not come due to workload. Sometimes the reason for refusal is that the repair work should be carried out by the company that installed the relevant equipment.

Today there are many companies that do not have supporting documents. Therefore, if you see the incompetence of the master, refuse his services. The downside is that often these companies will charge you double the actual value.

The second option is to repair the geyser yourself. Not all problems can be resolved on your own. But, if you know how to work with tools, then repair work will not seem difficult to you.